Preparation method of rare earth modified hierarchical porous ZSM-5 molecular sieve for yield increase of propylene

A technology of ZSM-5 and rare earth modification, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve the problems affecting the catalytic cracking efficiency of catalytic cracking main catalysts, the quality of propylene products, and poor propylene selectivity, etc. problem, to achieve the effect of improving the conversion efficiency of raw material catalytic cracking, low production cost and good propylene selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

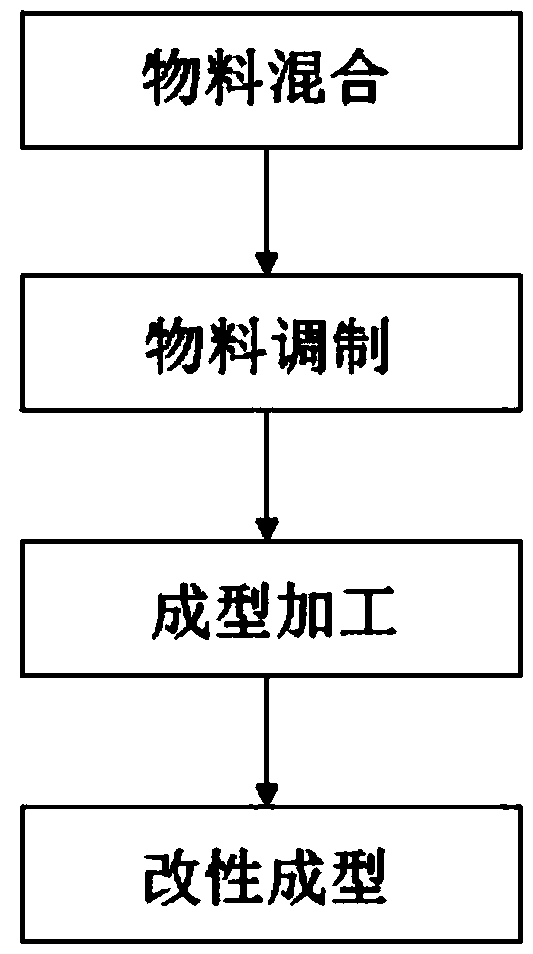

[0023] Such as figure 1 Shown, a kind of preparation method of the rare-earth modified multi-stage channel ZSM-5 molecular sieve that is used for propylene increasing production comprises the following steps:

[0024] The first step is to mix the materials. First, aluminum ash, quartz sand, sodium carbonate, borax, and non-ionic polyacrylamide are added to deionized water at a temperature of 20°C to mix and stir evenly to obtain a liquid base material. The base material is kept in a stirring state and stored for later use;

[0025] The second step is material preparation. Firstly, under the same condition of stirring the liquid base material, within 10 minutes, add calcium hydroxide, zeolite powder, silica sol and sodium methyl silicate to the liquid base material at a uniform speed. , and then under the condition of keeping the stirring state unchanged, the temperature of the mixture was raised to 50°C at a constant speed of 5°C / min, and the mixture was continuously heated a...

Embodiment 2

[0035] Such as figure 1 Shown, a kind of preparation method of the rare-earth modified multi-stage channel ZSM-5 molecular sieve that is used for propylene increasing production comprises the following steps:

[0036] The first step is to mix the materials. First, aluminum ash, quartz sand, sodium carbonate, borax, and non-ionic polyacrylamide are added to deionized water at a temperature of 30°C to mix and stir evenly to obtain a liquid base material. The base material is kept in a stirring state and stored for later use;

[0037] The second step is material preparation. Firstly, under the condition that the stirring state of the liquid base material remains unchanged, within 15 minutes, calcium hydroxide, zeolite powder, silica sol and sodium methyl silicate are added to the liquid base material at a uniform speed. , and then under the condition of keeping the stirring state unchanged, the temperature of the mixture was raised to 80°C at a constant speed of 10°C / min, and th...

Embodiment 3

[0048] like figure 1 Shown, a kind of preparation method of the rare-earth modified multi-stage channel ZSM-5 molecular sieve that is used for propylene increasing production comprises the following steps:

[0049] The first step is to mix the materials. First, aluminum ash, quartz sand, sodium carbonate, borax, and non-ionic polyacrylamide are added to deionized water at a temperature of 25°C to mix and stir evenly to obtain a liquid base material. The base material is kept in a stirring state and stored for later use;

[0050] The second step is material preparation. Firstly, under the condition that the stirring state of the liquid base material remains unchanged, within 12 minutes, calcium hydroxide, zeolite powder, silica sol and sodium methyl silicate are added to the liquid base material at a uniform speed. , and then under the condition of keeping the stirring state unchanged, the temperature of the mixture was raised to 60°C at a constant speed of 8°C / min, and the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com