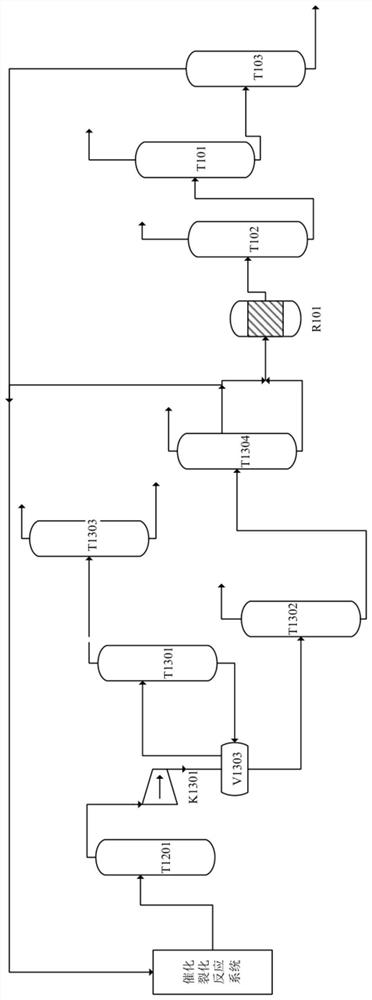

A kind of method combining catalytic cracking and gasoline hydrogenation

A catalytic cracking and gasoline hydrogenation technology, applied in the field of oil refining and chemical industry, can solve the problems of affecting oil adjustment and high olefin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

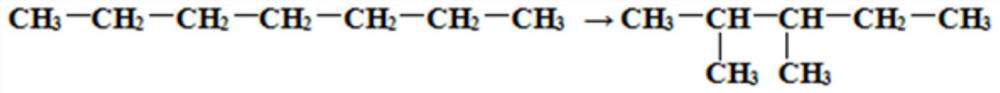

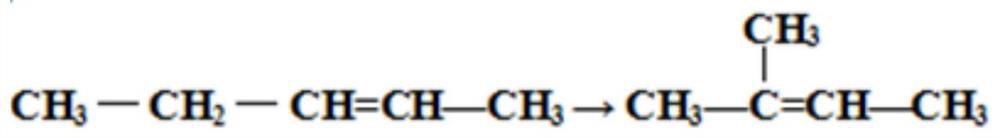

Method used

Image

Examples

Embodiment 1

[0072] Adopt the combined process of catalytic cracking and gasoline hydrogenation described in the above technical scheme;

[0073] Wherein, take the unimplemented light naphtha and the reused material as the feed component as the control group;

[0074] Data accumulation is carried out on the operation of the device before the implementation of the present invention, and the catalytic cracking raw materials are controlled to be relatively stable. Data accumulation is performed again on the device situation after the implementation of the present invention is stable, and the differences before and after the implementation of the present invention are compared. The specific situation is shown in Table 1.1 below:

[0075] Table 1.1 Comparison of device operation data

[0076]

[0077]

[0078] The C3+C4 of the light naphtha produced by T1304 is less than 1%, and the dry point is controlled to be less than 70°C; the present invention performs PONA analysis on the light nap...

Embodiment 2

[0089] During the period when the raw materials of the catalytic cracking unit are stable, data accumulation is carried out on the operation of the device in the implementation stage of the present invention, and then the relevant materials of the present invention are cut out. After the operation is stable, data accumulation is carried out again, and the differences before and after the implementation of the present invention are compared. The specific conditions are shown in Table 2.1. Show:

[0090] Table 2.1 Comparison of device operation data

[0091]

[0092]

[0093] The C3+C4 of the light naphtha produced by T1304 is less than 1wt%, and the dry point is controlled to be less than 70°C; the present invention performs PONA analysis on the light naphtha, that is, hydrocarbon composition analysis, and the results are shown in Table 2.2:

[0094] Table 2.2 PONA analysis results of light naphtha

[0095]

[0096] The initial boiling point of the recycled material o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com