Vanadium-based catalyst, its preparation method and application

A technology of catalysts and main catalysts, which is applied in the field of vanadium-based catalysts and its preparation, and can solve problems such as harm to the human body, environmental pollution, and restrictions on the application of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The invention discloses a method for preparing the vanadium-based catalyst described in the above technical solution, comprising the following steps:

[0049] (A) mixing the compound of vanadium or the complex of vanadium and the electron donor in an organic solvent to obtain the main catalyst;

[0050] The compound of vanadium is V(acac) 3 、VO(OR) 3 、VO(acac) 3 、VO(OR) 2 Cl, VO(OR)Cl 2 , VCl 4 or VOCl 3 ;

[0051] The ligands of the vanadium complexes are fatty alcohols, amines, phosphates, β-diketones, octahydroxyquinoline or oximes;

[0052] (B) main catalyst and cocatalyst are mixed, obtain vanadium series catalyst;

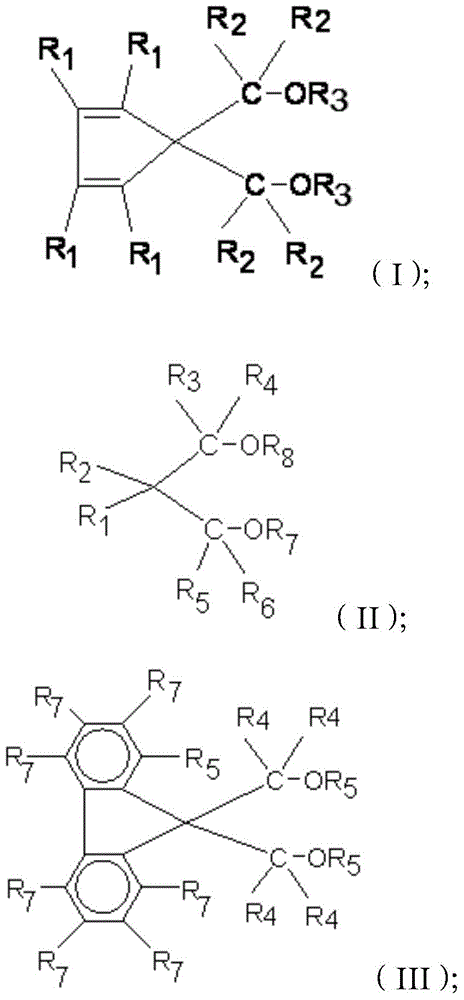

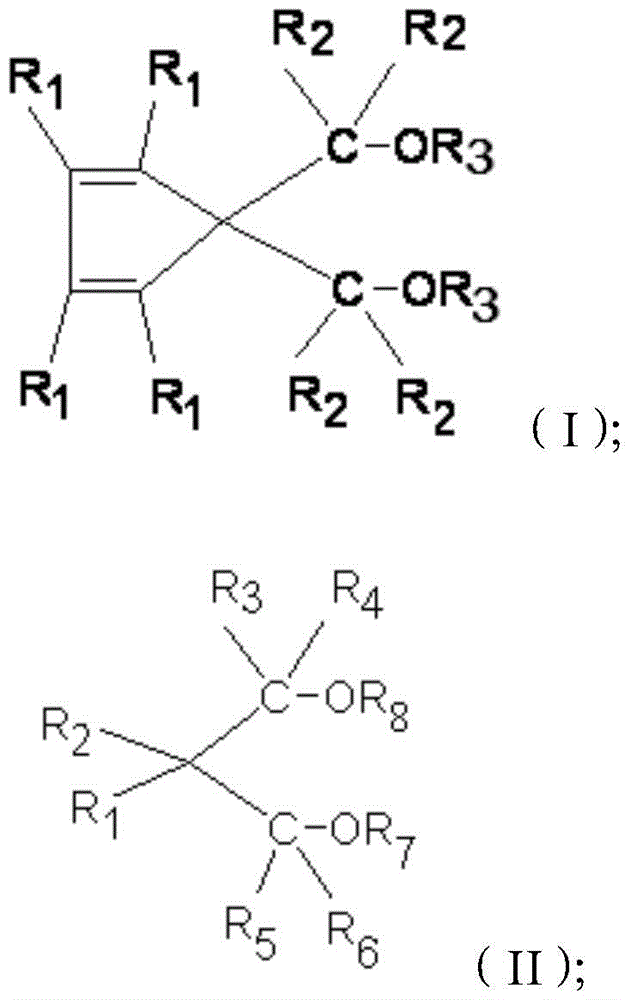

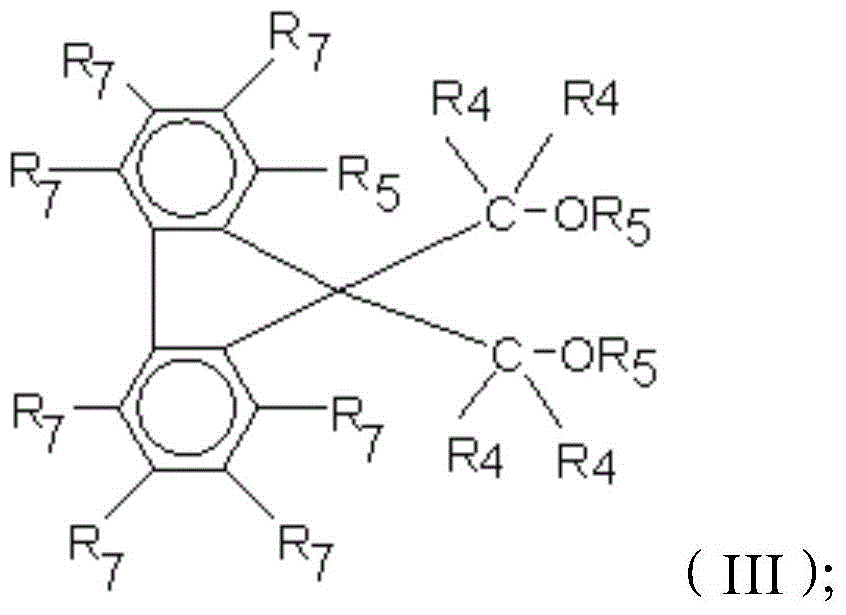

[0053] The electron donor is a monocyclic aromatic hydrocarbon compound, an acrylate compound, a methacrylate compound, a compound of the formula (I), a compound of the formula (II) or a compound of the formula (III);

[0054]

[0055] Among them, R 1 , R 2 , R 3 , R 4 , R 5 and R 6 independently selected from hydrogen, C1-C18 alkyl, ...

Embodiment 1

[0063] Taking benzene as an example, modifying VOCl 3 The method of the catalyst is as follows: In an ampoule bottle replaced with nitrogen, configure 10ml of hexane solution containing 1mmol of benzene, and extract 1mmol of VOCl 3 The solution was poured into the above-mentioned ampoule, and shaken evenly, ready for polymerization.

Embodiment 2

[0065] Weigh 0.4g of ether 2 (1,1-bis(methoxymethyl)-1,3-cyclopentadiene) in the glove box and put it into an ampoule bottle replaced with nitrogen, inject 1ml of toluene through a syringe, and then Then inject 10ml of hexane solution, seal the ampoule with a latex tube, and finally extract 1mmol of VOCl 3 The solution was poured into the above-mentioned ampule bottle, and the ampule bottle was placed in an ultrasonic oscillator in a 70°C water bath, kept for 30 minutes, and oscillated evenly for polymerization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com