Propylene catalyst prepared from methanol as well as preparation method and application thereof

A technology of catalyst and methanol, which is applied in the field of methanol to produce propylene catalyst and its preparation and application, can solve the problem of many reaction by-products, and achieve the effect of high propylene content and good catalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

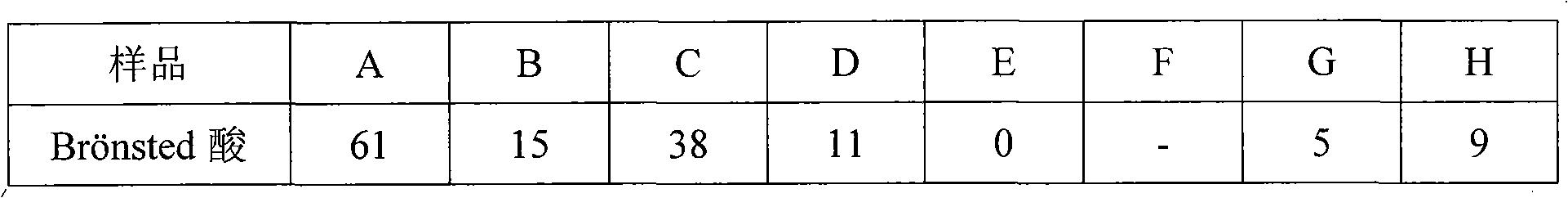

[0028] SiAl to SiO 2 / Al 2 o 3 The 48 ZSM-5 molecular sieve raw powder was calcined in air atmosphere, the calcining temperature was 540°C, and the calcining time was 6 hours. The obtained ZSM-5 was exchanged with 1 mol / L hydrochloric acid solution, the liquid-solid weight ratio was 10, and the temperature was 70°C, then washed, dried at 105°C, and then calcined at 520°C for 6 hours. According to the weight percentage of 50% H-type molecular sieve and 50% alumina, it is kneaded and shaped, then dried at 105°C for 6 hours, and then calcined in an air atmosphere. The calcining temperature is 520°C and the calcining time is 6 hours. Use an equal volume of calcium nitrate solution to impregnate, then dry at 105°C for 6 hours, and then roast in an air atmosphere. The roasting temperature is 520°C, and the roasting time is 6 hours to obtain a Ca / HZSM-5 catalyst sample C. Its weight composition is Molecular sieve:alumina:Ca=250:250:2, the surface acid measurement results are liste...

Embodiment 2

[0030] SiAl to SiO 2 / Al 2 o 3 The 48 ZSM-5 molecular sieve raw powder was calcined under air atmosphere, the calcining temperature was 750°C, and the calcining time was 1 hour. The obtained ZSM-5 was exchanged with 6 mol / L phosphoric acid solution, the liquid-solid weight ratio was 2, and the temperature was 20°C, then washed, dried at 100°C, and then calcined at 750°C for 1 hour. According to the weight percentage of 35% H-type molecular sieve and 65% alumina, kneading and molding, drying at 100°C for 24 hours, and then calcining in air atmosphere, the calcining temperature is 750°C, and the calcining time is 1 hour. Impregnated with an equal volume of calcium phosphate solution, dried at 100°C for 24 hours, and then calcined in an air atmosphere at a temperature of 750°C for 1 hour to obtain a Ca / HZSM-5 catalyst sample D, whose weight ratio composition Molecular sieve:alumina:Ca=154:286:9, surface acid measurement results are listed in Table 1. Under the same reaction c...

Embodiment 3

[0032] SiAl to SiO 2 / Al 2 o 3 The 48 ZSM-5 molecular sieve raw powder was calcined in an air atmosphere, the calcining temperature was 480° C., and the calcining time was 10 hours. The obtained ZSM-5 was exchanged with 4 mol / L hydrochloric acid solution, the liquid-solid weight ratio was 5, and the temperature was 50°C, then washed, dried at 110°C, and then calcined at 480°C for 10 hours. According to the weight percentage of 90% H-type molecular sieve and 10% alumina, it is kneaded and shaped, then dried at 110°C for 10 hours, and then calcined in an air atmosphere at a calcining temperature of 480°C and a calcining time of 10 hours. Use equal volume of calcium nitrate solution to impregnate, then dry at 110°C for 10 hours, then roast in air atmosphere, the roasting temperature is 480°C, and the roasting time is 10 hours to obtain Ca / HZSM-5 catalyst sample E, its weight composition is Molecular sieve:alumina:Ca=450:50:35, the surface acid measurement results are listed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com