Self-supporting boron-doped diamond electrochemical sensor and preparation method

A diamond and boron doping technology, applied in the fields of electrochemical variables of materials, scientific instruments, gaseous chemical plating, etc., can solve the problems of inability to meet the requirements of accurate and long-term application, to overcome the short working life performance, reproducible Better reproducibility, lower detection limits, and higher reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

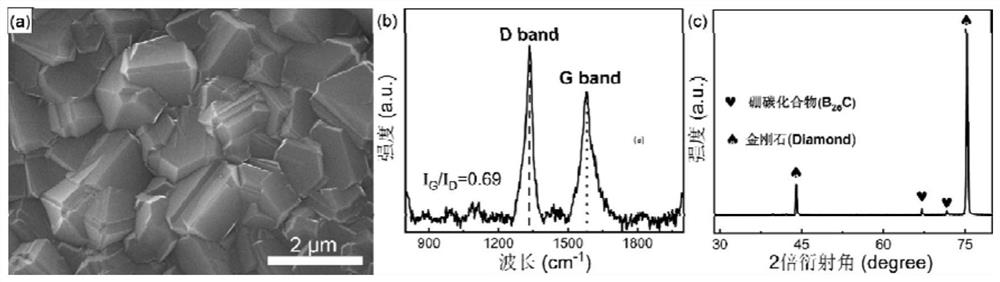

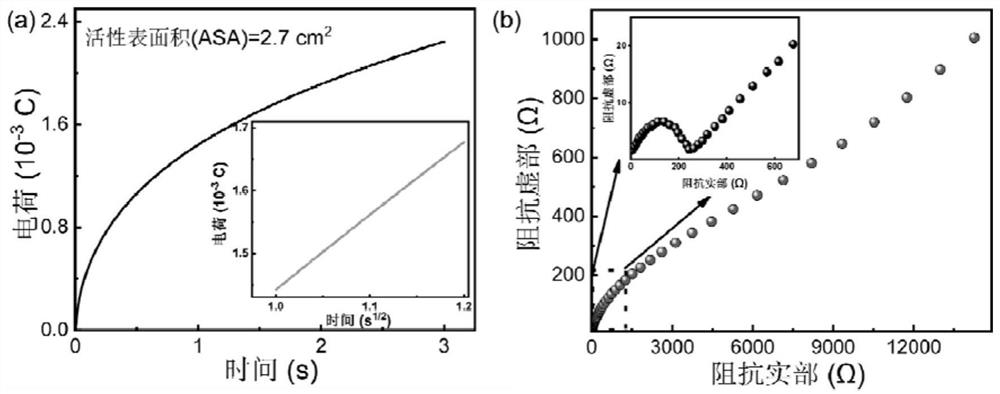

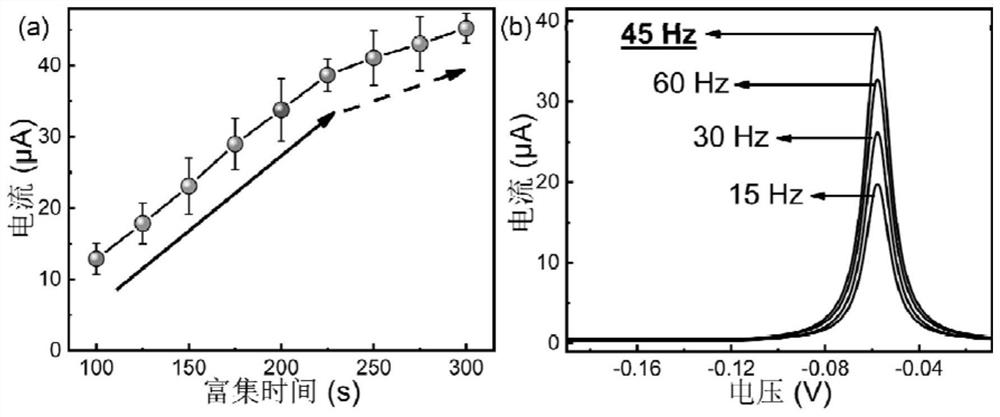

[0045] The present embodiment provides a kind of preparation method of FBDD electrochemical sensor, comprises the following steps:

[0046] (1) Pretreatment: Polish the surface of the metal molybdenum disc to remove the oxide layer, and use W0.5 diamond polishing agent to polish it into a mirror surface, place it in acetone for ultrasonic cleaning for 10 minutes, transfer to ethanol for ultrasonic cleaning for 5 minutes, and dry it for later use;

[0047] (2) Substrate seed crystal: 1 g of nano-diamond powder (50 nm in particle size) was uniformly densely spread on the surface of a metal molybdenum disc with a diameter of 10 cm, mechanically ground for 5 min, and then the surface was blown clean with nitrogen gas for later use.

[0048] (3) CVD coating: put the base material after the above seed crystal into the reaction chamber, reduce the vacuum degree in the furnace to 10 -4 Below Pa, start to feed the reaction gas for coating. The heat source is provided by tungsten wire,...

Embodiment 2

[0061] The present embodiment provides a kind of preparation method of FBDD electrochemical sensor, comprises the following steps:

[0062](1) Pretreatment: Polish the surface of the metal molybdenum disc to remove the oxide layer, and use W0.5 diamond polishing agent to polish it into a mirror surface, place it in acetone for ultrasonic cleaning for 10 minutes, transfer to ethanol for ultrasonic cleaning for 5 minutes, and dry it for later use;

[0063] (2) Substrate seed crystal: 1 g of nano-diamond powder (60 nm in particle size) was evenly and densely spread on the surface of a metal molybdenum disc with a diameter of 10 cm, mechanically ground for 5 min, and then the surface was blown clean with nitrogen gas for later use.

[0064] (3) CVD coating: put the base material after the above seed crystal into the reaction chamber, reduce the vacuum degree in the furnace to 10 -4 Below Pa, start to feed the reaction gas for coating. The heat source is provided by tungsten wire,...

Embodiment 3

[0069] The present embodiment provides a kind of preparation method of FBDD electrochemical sensor, comprises the following steps:

[0070] (1) Pretreatment: Polish the surface of the metal molybdenum disc to remove the oxide layer, and use W0.5 diamond polishing agent to polish it into a mirror surface, place it in acetone for ultrasonic cleaning for 10 minutes, transfer to ethanol for ultrasonic cleaning for 5 minutes, and dry it for later use;

[0071] (2) Substrate seed crystal: 1g of nano-diamond powder (particle size: 40nm) was evenly and densely spread on the surface of metal molybdenum disk with a diameter of 10cm, mechanically ground for 5min, and then the surface was blown clean with nitrogen gas for later use.

[0072] (3) CVD coating: put the base material after the above seed crystal into the reaction chamber, reduce the vacuum degree in the furnace to 10 -4 Below Pa, start to feed the reaction gas for coating. The heat source is provided by tungsten wire, (CH 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| detection limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com