Method for synthesising halogenated aromatic amine through hydrogenation in solvent-free condition

A halogenated arylamine, solvent-free technology, applied in the field of hydrogenation to synthesize halogenated arylamines, can solve the problems of few research reports, decreased catalytic activity, etc., and achieve the effects of reducing separation and purification, simple method, and improving reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 8

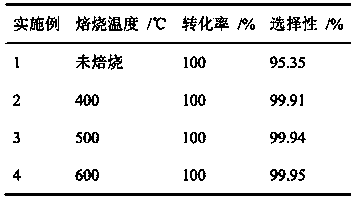

[0032] Examples 1 to 8 investigated the performance of the carbon-supported large particle size noble metal catalysts in the solvent-free liquid phase hydrogenation synthesis of halogenated arylamines after treatment at different calcination temperatures. The particle size is 800 mesh and the specific surface area is 1200m 2 / g of activated carbon, it was formulated into a slurry at a temperature of 80°C, and the H 2 PdCl 4solution, fully stirred evenly; after soaking for 2 hours, add NaOH solution to adjust the pH value to 7.5, and lower the temperature to room temperature, filter, and wash the filter cake with deionized water until neutral; then configure the filter cake into a slurry at 70°C , drop an excess of hydrazine hydrate solution, stir, filter, wash the filter cake with deionized water until neutral, and dry it in vacuum at 100°C to obtain a carbon-supported palladium catalyst; , 600, 700, 800, 900, and 1000°C for 5 hours to obtain different carbon-supported large...

Embodiment 17 20

[0044] Examples 17 to 26 investigated the performance of different carbon-supported large particle size noble metal catalysts in the solvent-free liquid-phase hydrogenation synthesis of halogenated arylamines. The particle size is 1000 mesh and the specific surface area is 1000m 2 / g of activated carbon used to prepare the catalyst, which was prepared into a slurry at a temperature of 90°C, and slowly added H 2 PdCl 4 or H 2 PtCl 6 solution, fully stirred evenly; after soaking for 5 hours, add ammonia water to adjust the pH value to 8.5, and lower the temperature to room temperature, filter, and wash the filter cake with deionized water until neutral; then configure the filter cake into a slurry at 60°C, Add excess formic acid solution dropwise, stir, filter, wash the filter cake with deionized water until neutral, and dry it in vacuum at 110°C to obtain a carbon-supported noble metal catalyst; particle size noble metal catalysts.

[0045] Add 200g of 3-chloro-4-methylnit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com