Catalytic conversion method for petroleum hydrocarbon

A catalytic conversion method and technology for petroleum hydrocarbons, applied in the field of catalytic conversion of petroleum hydrocarbons, can solve the problems of insufficient utilization of the latent content of aromatics in gasoline and achieve the effects of increasing the content of ethylene and propylene, improving economic benefits, and reducing the yield of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

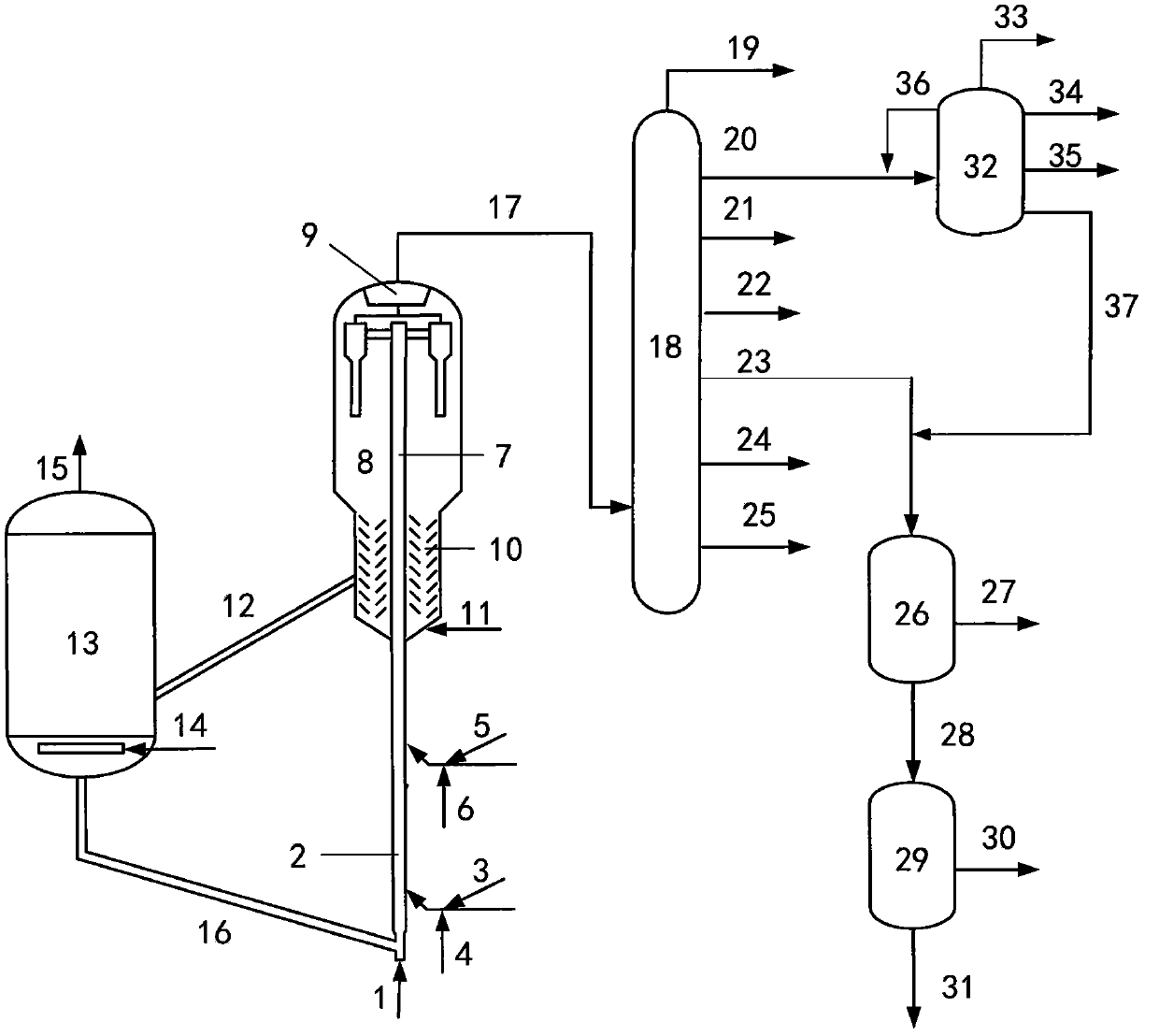

[0053] This embodiment is tested according to the flow process of accompanying drawing, raw material oil A is directly used as the raw material of catalytic cracking, is tested on the medium-sized device by riser reactor, and raw material oil enters riser bottom, at reaction temperature 640 ℃, weight hourly space velocity 180h -1 , the weight ratio of catalytic cracking catalyst to raw oil is 60, and the weight ratio of water vapor to raw oil is 0.20. The cracking reaction is carried out. The reaction product oil gas and the unborn catalyst are separated in the settler, and the product is cut according to the distillation range in the separation system. , so as to obtain dry gas rich in ethylene, ethane, propane, butane, propylene, C4 olefins and aromatics-rich gasoline and other products, wherein ethane, propane and butane enter the steam cracking, C4 olefins return to the reactor and then Cracking, aromatic-rich gasoline enters the selective hydrogenation unit, under hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com