Device and method for producing high-propylene cracking gas and low-olefin gasoline

A technology of propylene content and cracked gas, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrocarbon oil treatment products, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

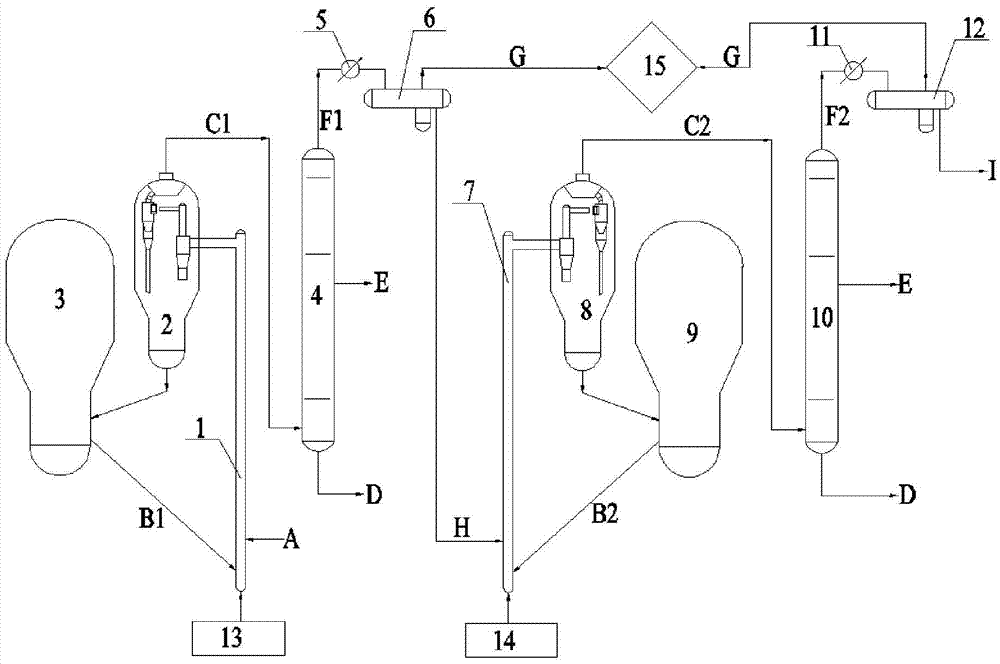

[0080] as attached figure 1 As shown, the embodiment of the present invention provides a device for producing cracked gas G with high propylene content and gasoline with low olefin content, which device includes: a first riser 1, a first settler 2, a first catalytic cracking regenerator 3, First fractionation tower 4, first cooler 5, first gas-liquid separator 6, second riser 7, second settler 8, second catalytic cracking regenerator 9, second fractionation tower 10, second cooler 11. The second gas-liquid separator 12 , the first catalyst pre-lifter 13 , the second catalyst pre-lifter 14 , and the third fractionation device 15 .

[0081] Wherein, the upper outlet of the first riser 1, the middle inlet and the lower catalyst outlet of the first settler 2, the first catalytic cracking regenerator 3, and the catalyst inlet at the bottom of the first riser 1 are connected in sequence, forming the first catalyst regeneration reuse unit. The upper outlet of the second riser 7, the ...

Embodiment 2

[0085] In this embodiment, the device provided in Example 1 is used to produce cracked gas with high propylene content and gasoline with low olefin content, and the specific steps are as follows:

[0086] The heavy oil raw material A preheated to 200°C enters the first riser 1, and under the conditions of a reaction temperature of 530°C and an absolute reaction pressure of 0.24MPa, it is mixed with the first catalyst B1 rectified by the pre-lift medium: super The stabilized molecular sieve catalyst was contacted for 0.8s to generate a catalytic reaction. Among them, the mass ratio of ultra-stable molecular sieve catalyst to heavy oil raw material A is 8:1. The oil and gas products obtained after the catalytic reaction enter the first settler 2 together with the coke-generated ultra-stable molecular sieve catalyst for sedimentation treatment, and the separated coke-generated ultra-stable molecular sieve catalyst enters the first catalytic cracking regenerator 3 at 700°C Carry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com