Process and device for processing and preparing hydrocarbon by utilizing liquefied gas

A liquefied gas and process technology, which is applied in the fields of hydrocarbon cracking to produce hydrocarbons, production of liquid hydrocarbon mixtures, and organic chemistry, etc., can solve the problems of uncoordinated device operation, low price, and low propylene content in the gas separation feed gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A process for producing hydrocarbons by utilizing liquefied gas, including the following steps:

[0070] (1) Cracking reaction process:

[0071] The C4 raw material in the cracking raw material tank is transported to the device area by the raw material pump, and exchanges heat with the pyrolysis reaction product through the first heat exchanger and the second heat exchanger. After the heat exchange, the C4 raw material enters the heating furnace to further raise the temperature To 500°C, the heated gas enters from the top of the cracking reactor to carry out the cracking reaction;

[0072] From the bottom of the cracking reactor, the cracking reaction product passes through the second heat exchanger, the first heat exchanger, the hot water heat exchanger, and the cracking product cooler (reaction condenser) for heat exchange and cooling until the temperature drops to 40 After ℃, it enters the gas-liquid separation tank for separation (the cracking reaction product cond...

Embodiment 2

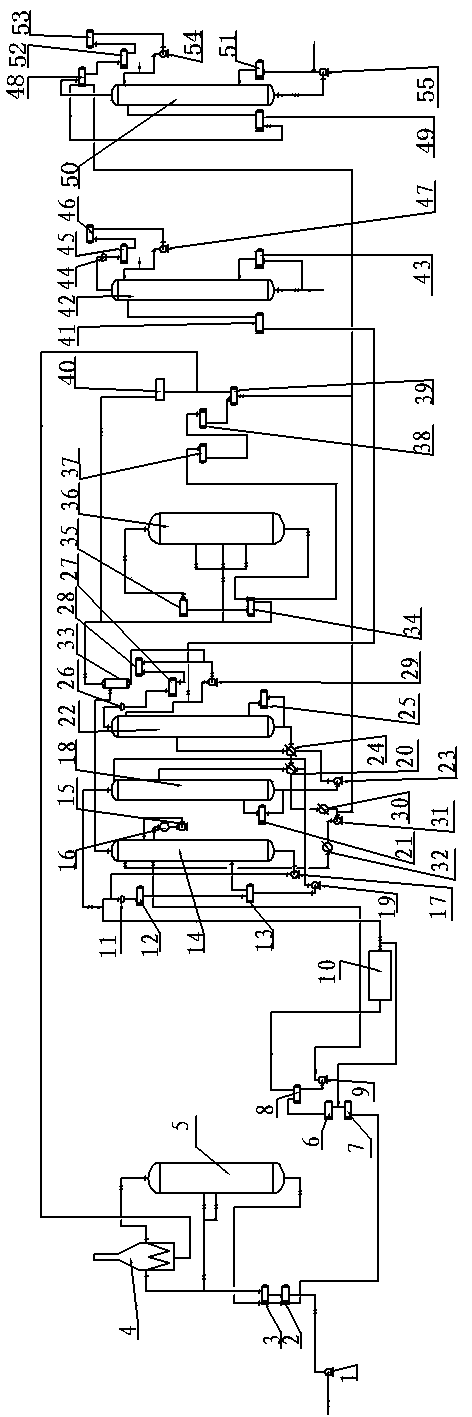

[0096] Such as figure 1 As shown, a device for realizing the process of utilizing liquefied gas to process hydrocarbons as described in Example 1 includes a cracking reaction system, an absorption stabilization system, an aromatization reaction system, a gas separation raw material gas concentration system, and an aromatics purification system.

[0097] The cracking reaction system includes: raw material pump 1, first heat exchanger 2, second heat exchanger 3, heating furnace 4, cracking reactor 5, reaction product cooler 6, hot water heat exchanger 7, gas Liquid separation tank 8, reaction liquid pump 9, rich gas compressor 10, air compressor outlet air cooler 11, air compressor outlet cooler 12, air compressor outlet liquid separation tank 13;

[0098] The outlet of raw material pump 1 is connected to the bottom nozzle of the shell side of the first heat exchanger 2, the top nozzle of the shell side of the first heat exchanger 2 is connected to the bottom nozzle of the shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com