Preparation method of polypropylene

A polypropylene and propylene technology, applied in the field of olefin polymerization, can solve the problems of limited rubber phase content, easy breakage of catalyst particles, attenuation of catalyst activity, etc., so as to reduce the problem of block and wall sticking, reduce local overheating, and improve catalyst performance. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

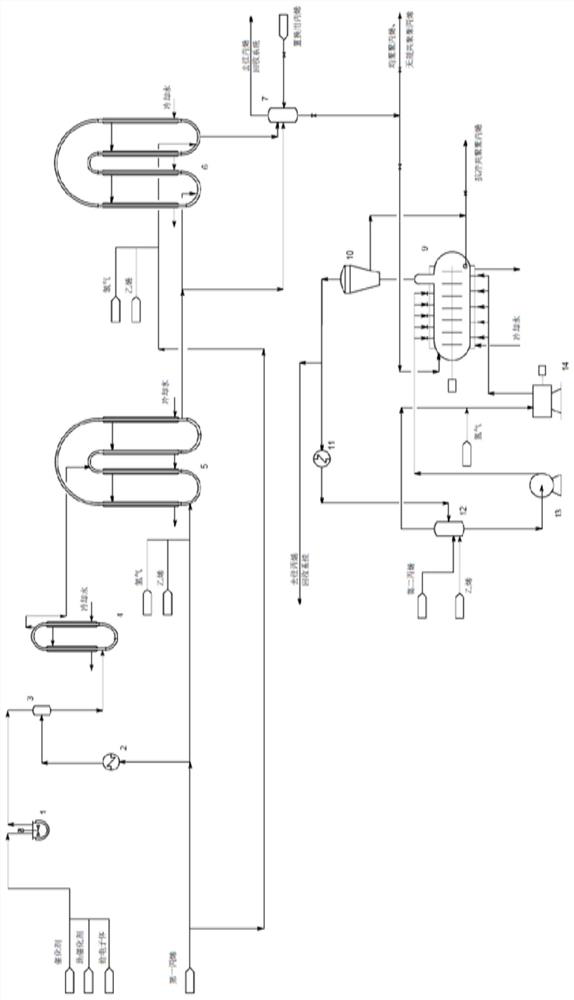

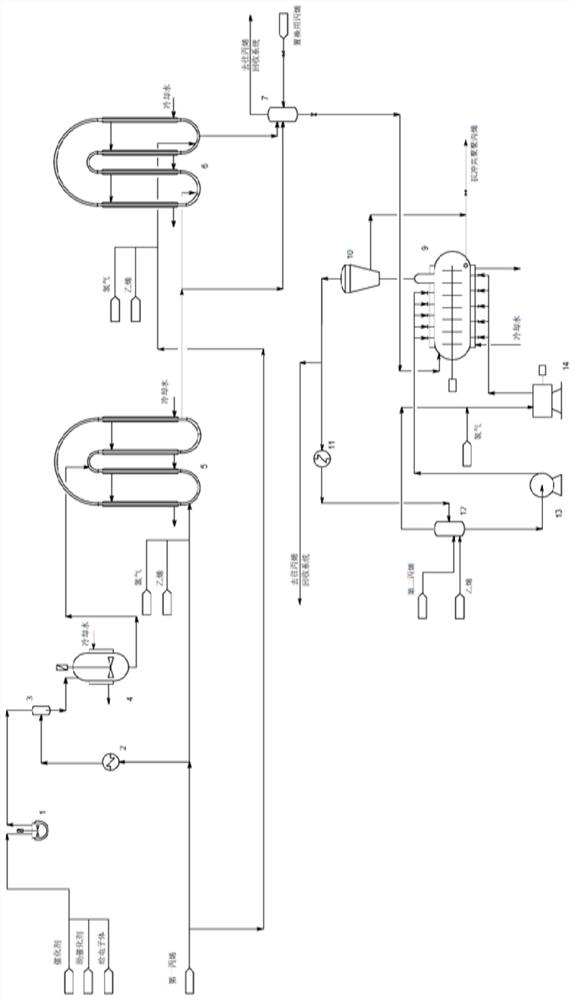

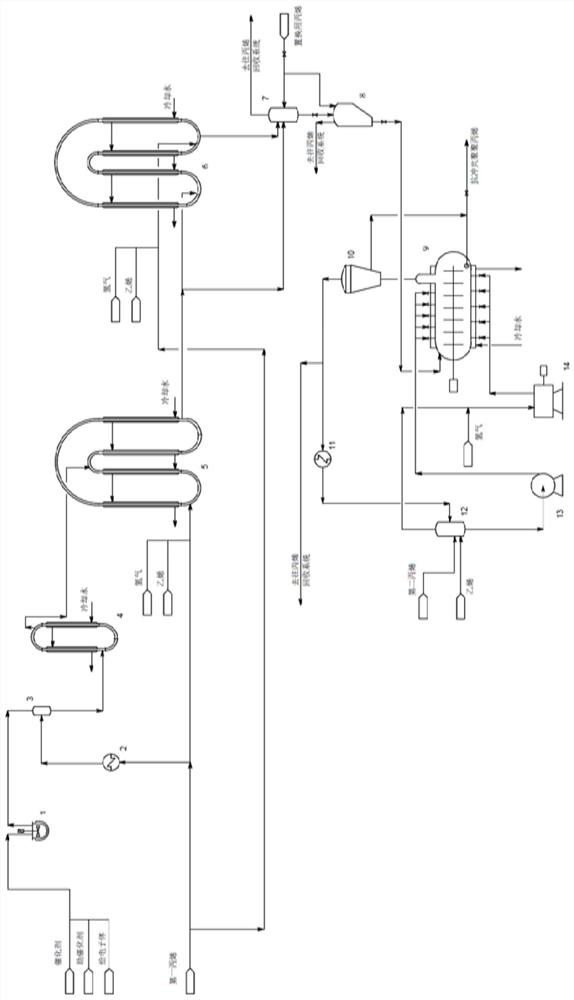

[0054] The propylene multi-stage polymerization method of the preparation method of the impact copolymer polypropylene disclosed by the present invention, the specific process is as follows figure 1 , figure 2 with image 3 Shown:

[0055] The polypropylene catalyst composed of catalyst, co-catalyst and electron donor is stirred and mixed evenly in the catalyst pre-mixing tank 1, and then sent to the catalyst and propylene mixer 3 and the first liquid phase cooled by the first propylene heat exchanger 2 The propylene is mixed in-line, and then passed together into the prepolymerization reactor 4 to carry out the low temperature prepolymerization reaction of propylene. The temperature of the prepolymerization reaction is 10-40°C, the pressure is 3.0-5.0Mpa, and the average residence time of the reaction materials is 5-20 minutes. The type of prepolymerization reactor 4 can be loop reactor (as figure 1 with image 3 shown) or vertical stirred tank (such as figure 2 Shown...

Embodiment 1

[0062] The specific process is as figure 1 Shown:

[0063] The main catalyst ZN-M1, the cocatalyst triethylaluminum and the electron donor cyclohexylmethyldimethoxysilane are stirred and mixed evenly in the catalyst premixing tank 1, and then sent to the catalyst and propylene mixer 3 and passed through the first propylene The propylene in the first liquid phase after cooling in the heat exchanger 2 is mixed online, and then passed together into the prepolymerization reactor 4 for low temperature prepolymerization of propylene. The type of the prepolymerization reactor is a loop reactor, and jacketed cooling water is used to remove the heat of polymerization reaction. The reaction temperature is 19°C, the pressure is 3.8Mpa, and the average residence time of the reaction materials is 13 minutes.

[0064] The low-molecular-weight polypropylene prepolymer-containing slurry obtained through low-temperature prepolymerization is all sent into the first loop reactor 5 for liquid-ph...

Embodiment 2

[0068] The specific process is as figure 1 Shown:

[0069] Main catalyst CS-2, cocatalyst triethylaluminum and electron donor cyclohexylmethyldimethoxysilane are stirred and mixed evenly in the catalyst premixing tank 1, and then sent to the catalyst and propylene mixer 3 and passed through the first propylene The propylene in the first liquid phase after cooling in the heat exchanger 2 is mixed online, and then passed together into the prepolymerization reactor 4 for low temperature prepolymerization of propylene. The type of the prepolymerization reactor is a loop reactor, and jacketed cooling water is used to remove the heat of polymerization reaction. The reaction temperature is 18° C., the pressure is 3.4 Mpag, and the average residence time of the reaction materials is 16 minutes.

[0070] The low-molecular-weight polypropylene prepolymer-containing slurry obtained through low-temperature prepolymerization is all sent into the first loop reactor 5 for liquid-phase bulk ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com