Patents

Literature

84results about How to "Guaranteed insertion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

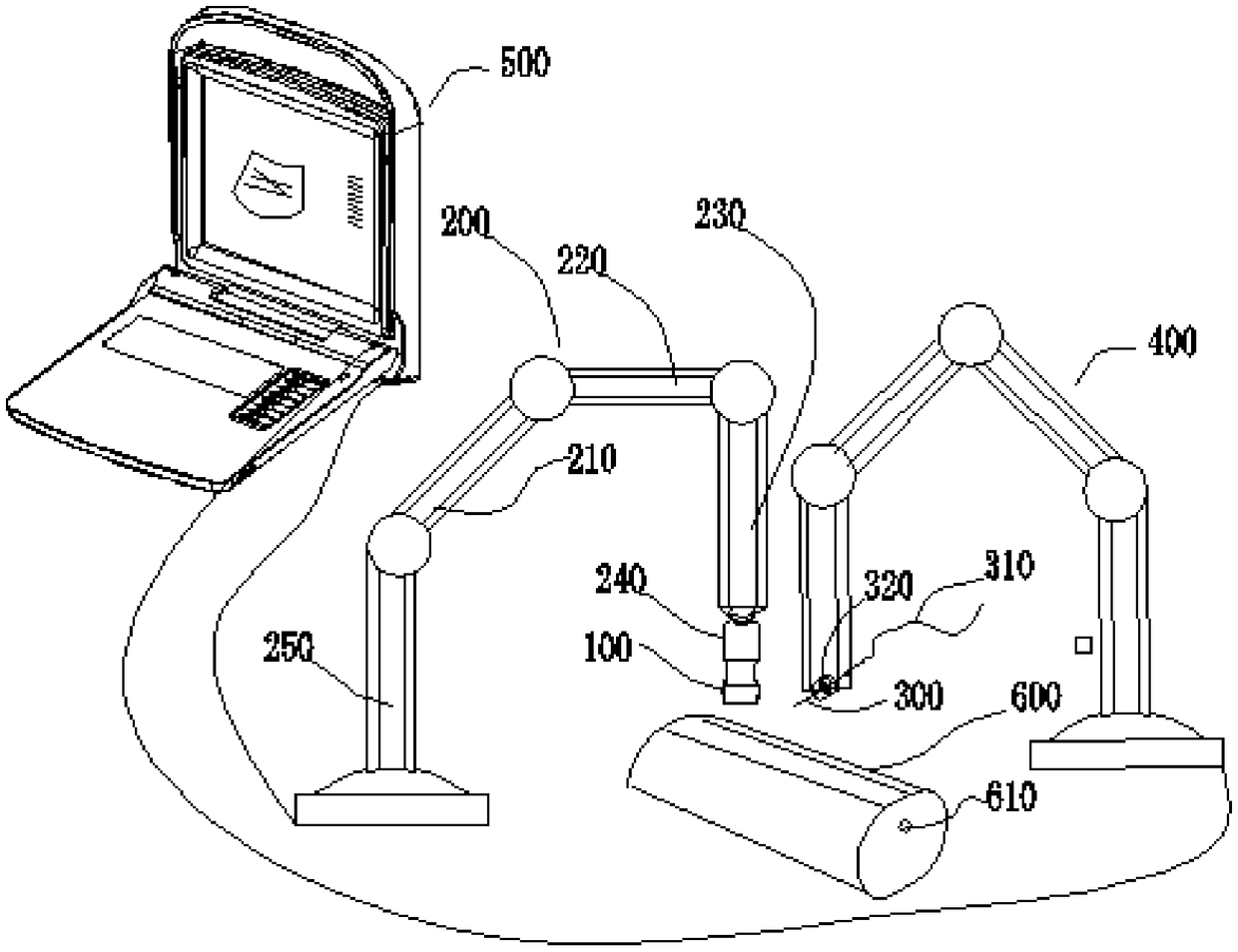

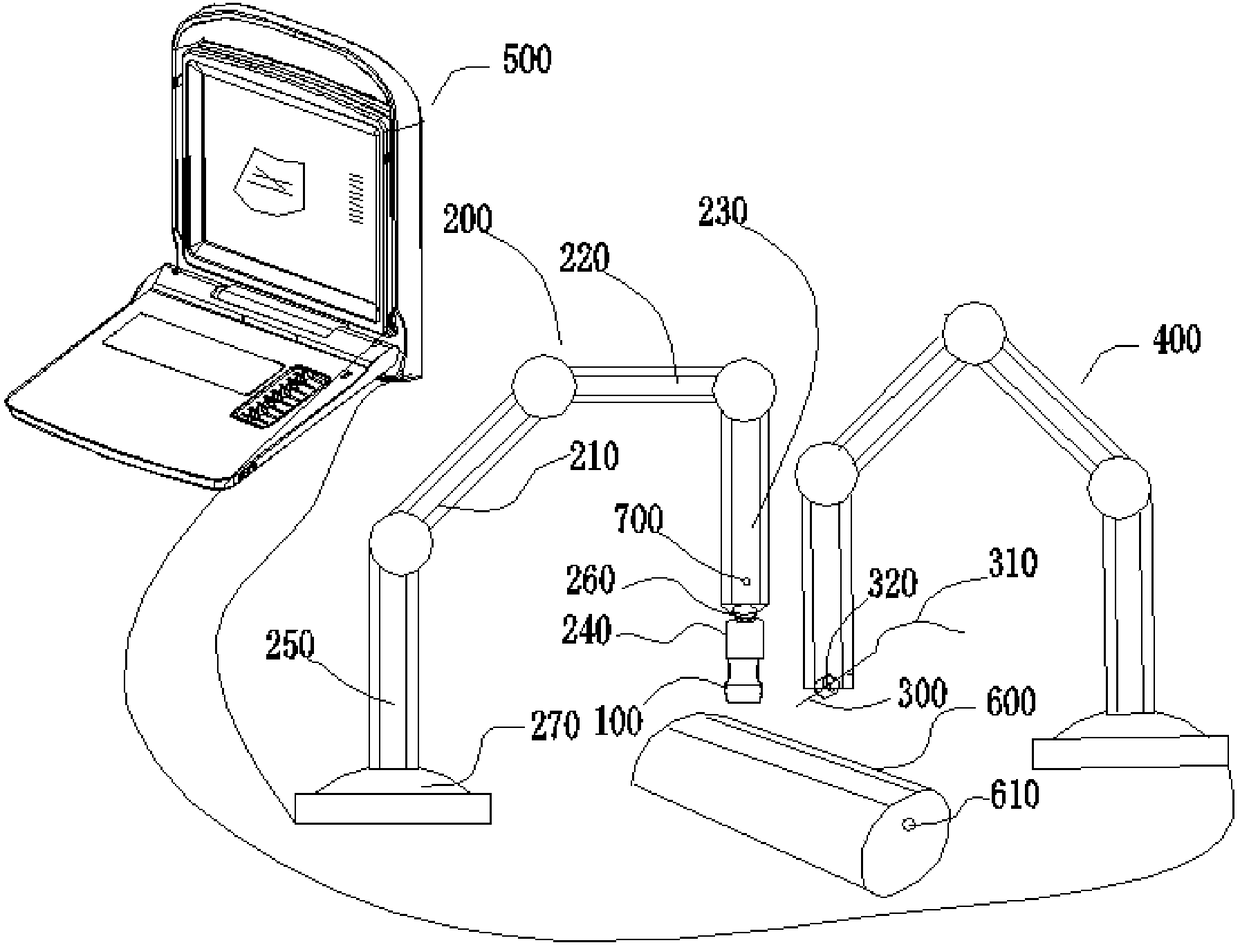

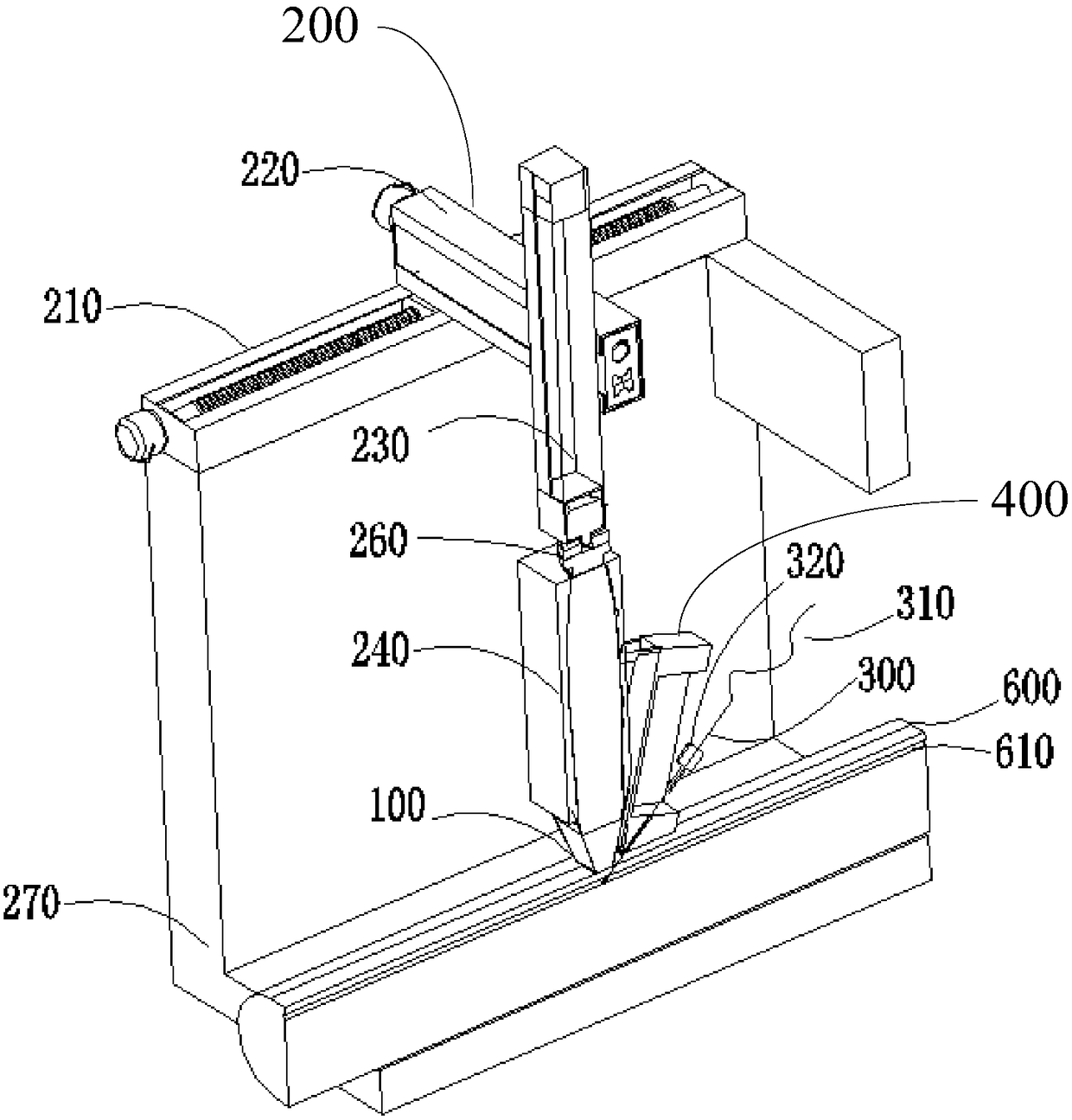

Ultrasonic guiding auxiliary device and system for needle

ActiveCN108814691AGuaranteed insertionGuaranteed comfortProgramme-controlled manipulatorSurgical needlesBiomedical engineeringUltrasound guided

The invention provides an ultrasonic guiding auxiliary device for a needle. The ultrasonic guiding auxiliary device includes a probe for transmitting an ultrasonic signal to a tissue to be punctured and injected and receiving an ultrasonic signal from the tissue to be punctured and injected, a first mechanical arm used for moving a probe to the tissue to be punctured and injected, a second mechanical arm for fixing the needle for puncturing and moving the needle to be close to the tissue to be punctured and injected and then causing the needle to penetrate into the tissue to be punctured and injected, and a host, wherein the host controls the first mechanical arm to move the probe to the tissue to be punctured and injected, and the probe transmits and receives the ultrasonic signal; the host synthesizes an ultrasonic image through the ultrasonic signal transmitted by the probe; the host at least calculates a puncture distance between the needle and the tissue to be punctured and injected and a puncture angle through the ultrasonic image; and the host controls the second mechanical arm to move the needle to the corresponding puncture distance and puncture distance according to the puncture distance and the puncture angle and then performs puncture. The ultrasonic guiding auxiliary device is used for guiding the accurate puncture of the needle.

Owner:CHISON MEDICAL TECH CO LTD

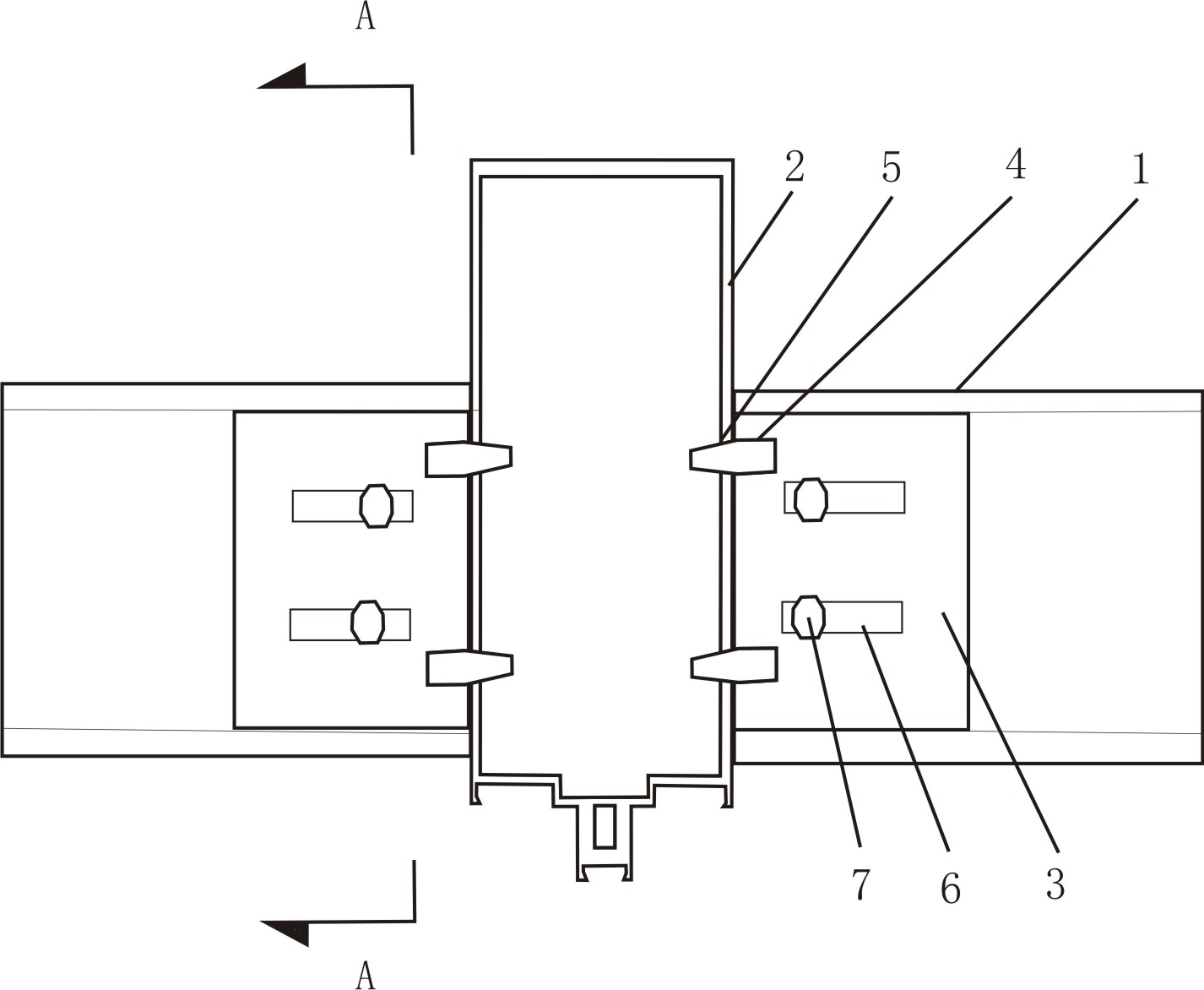

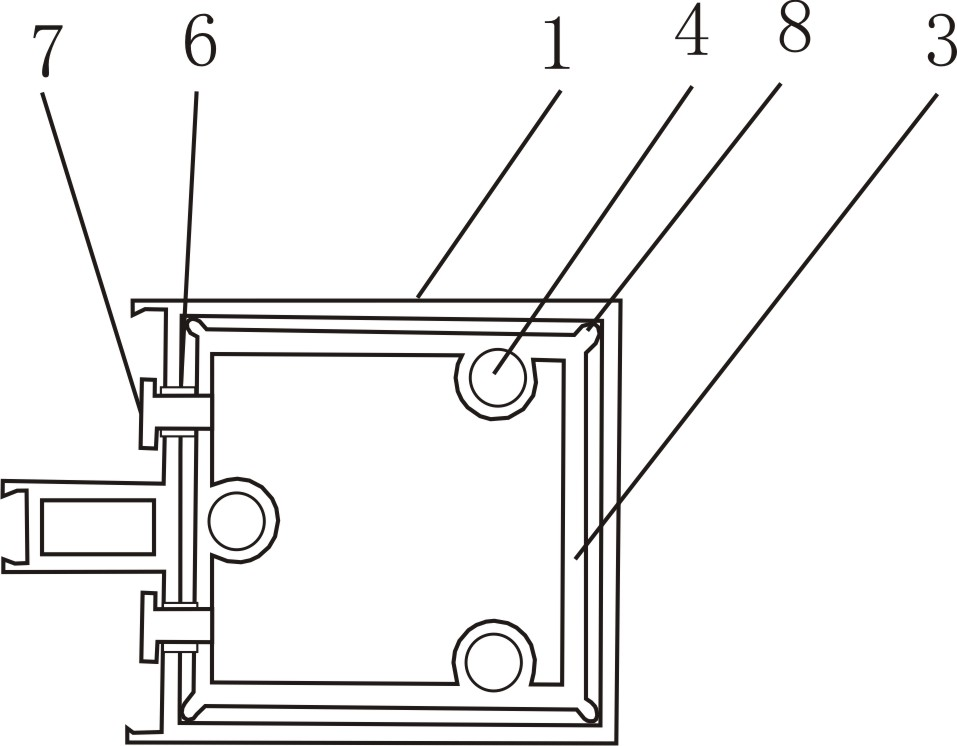

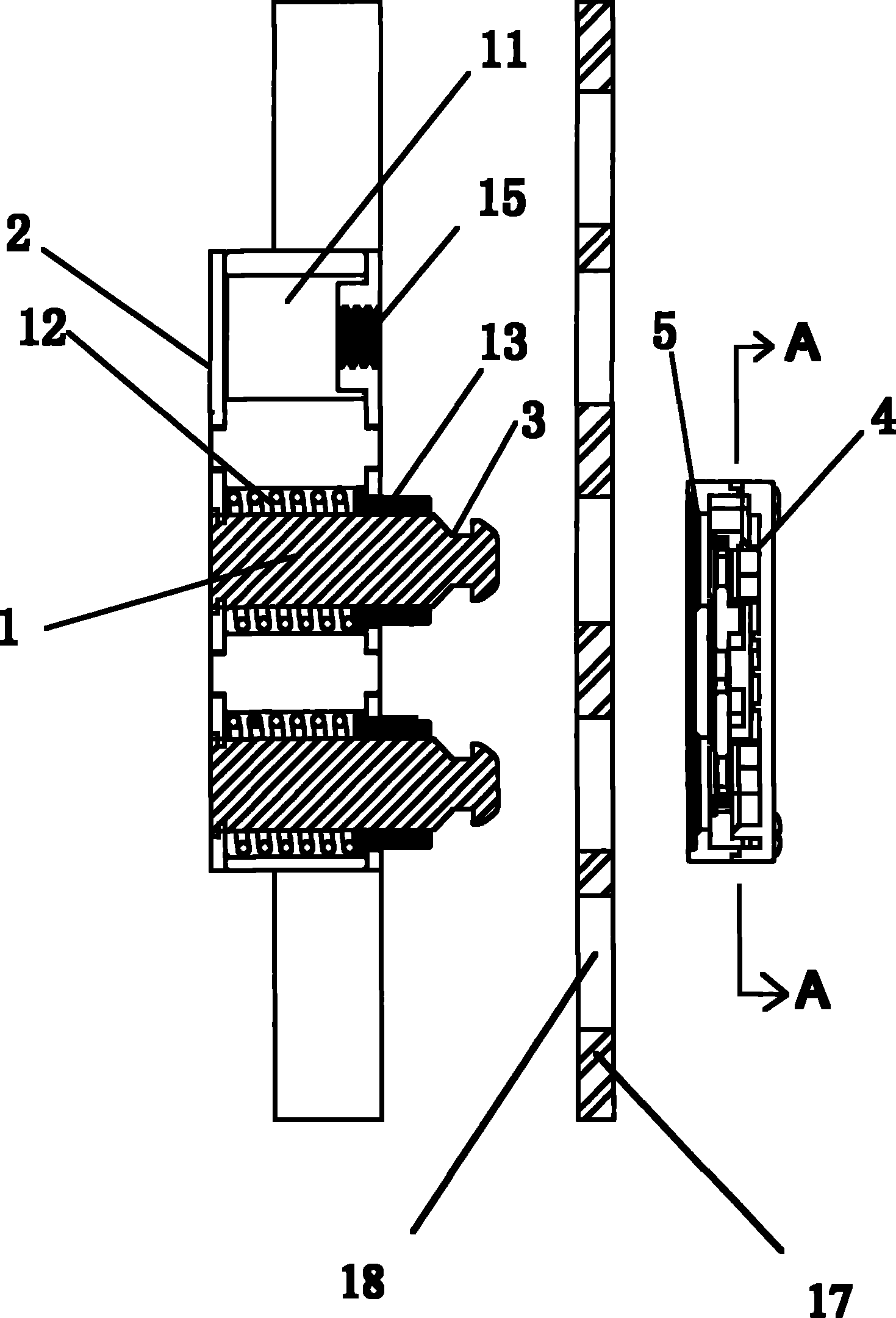

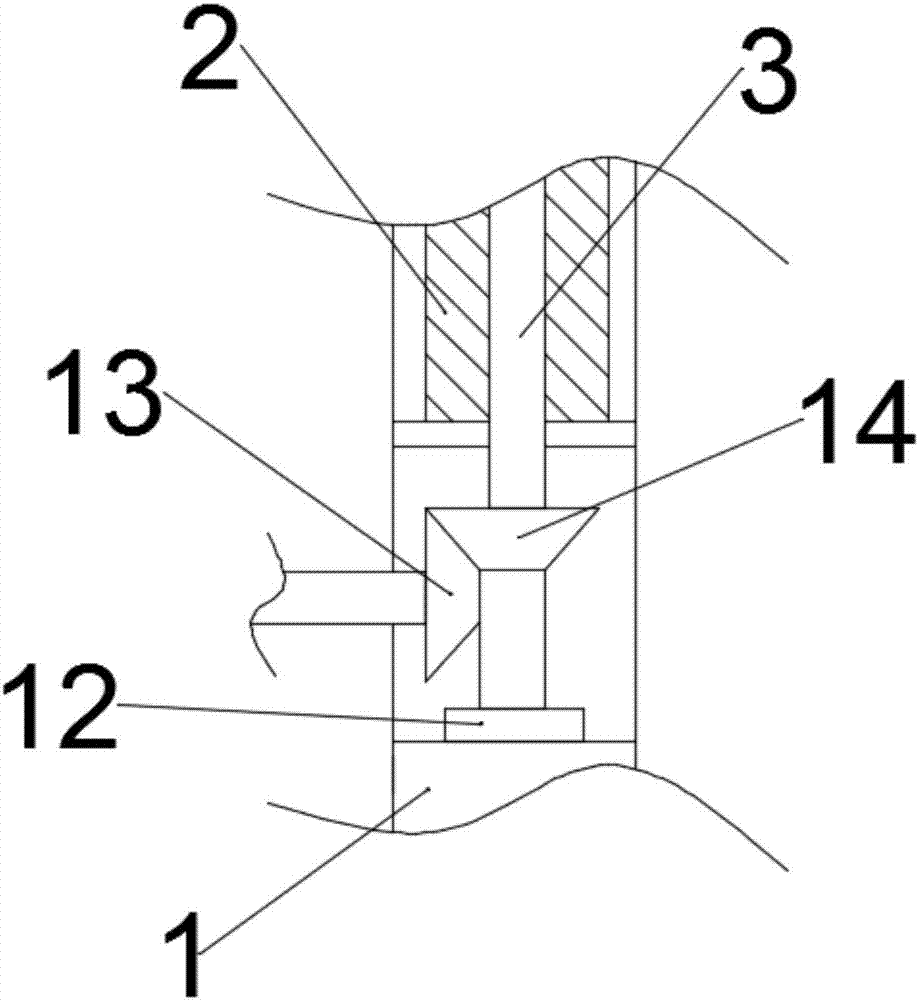

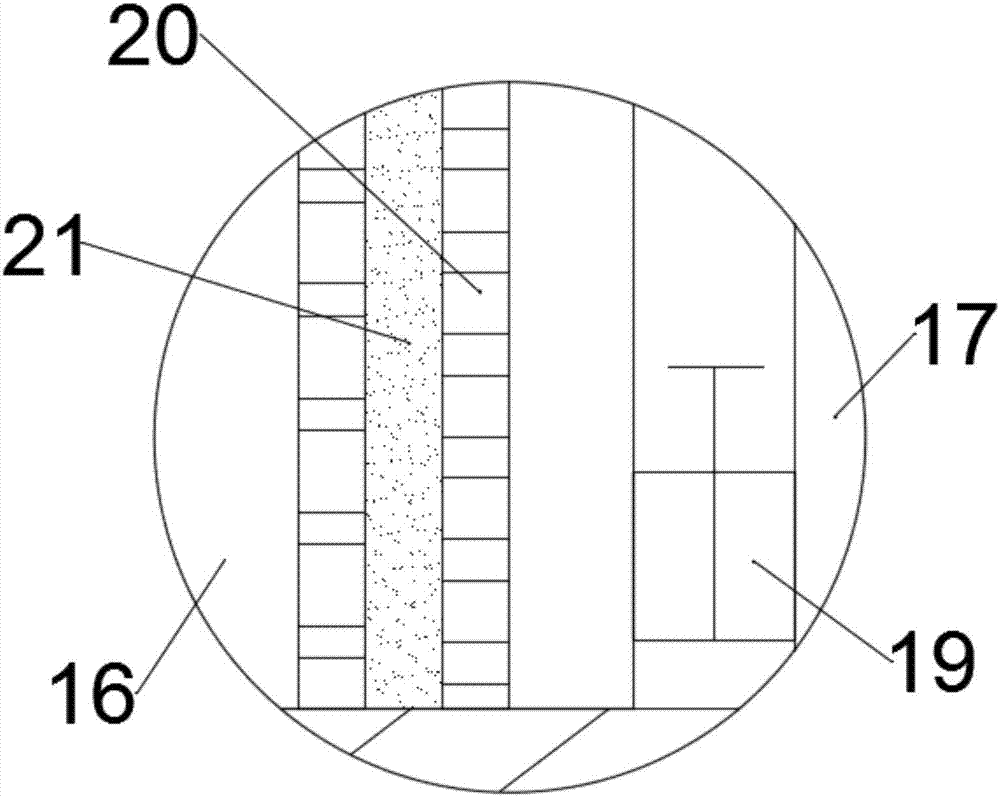

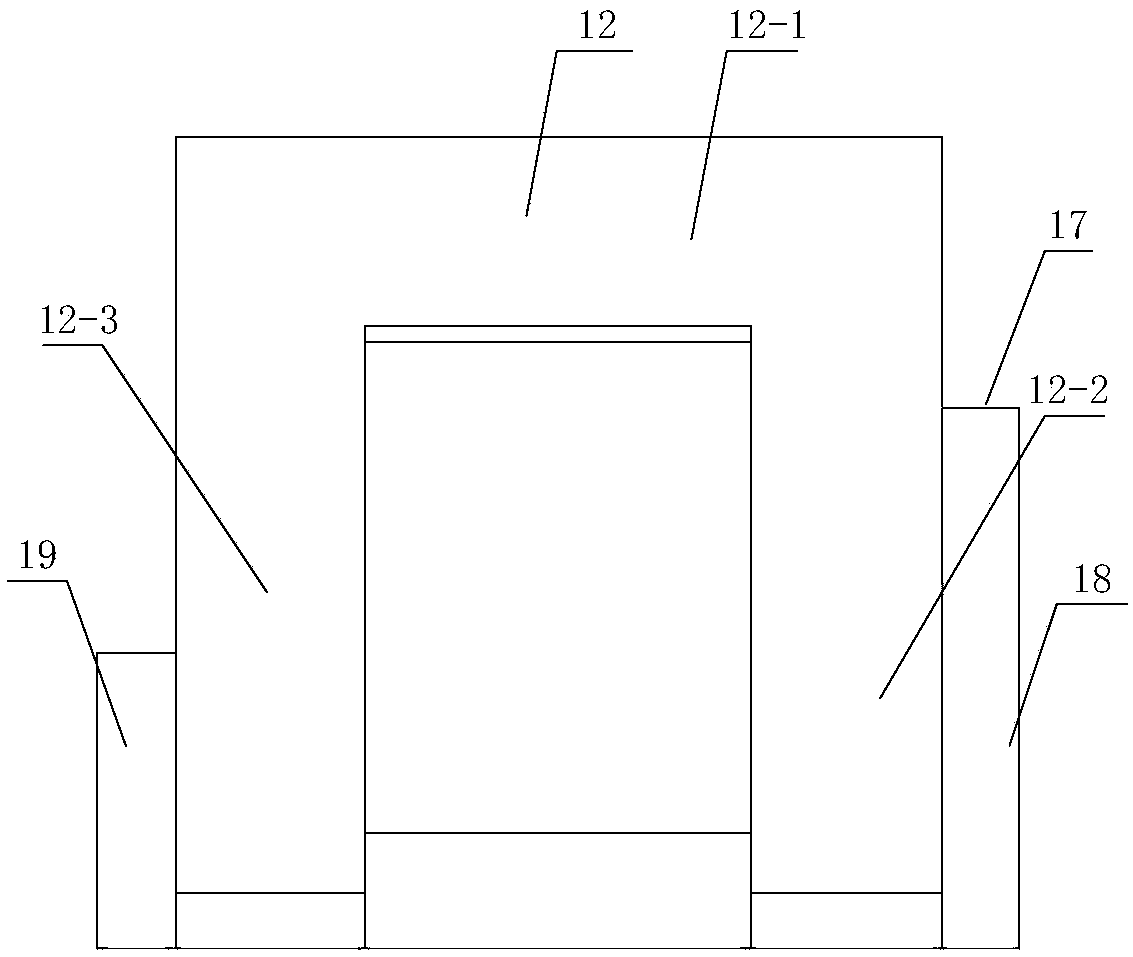

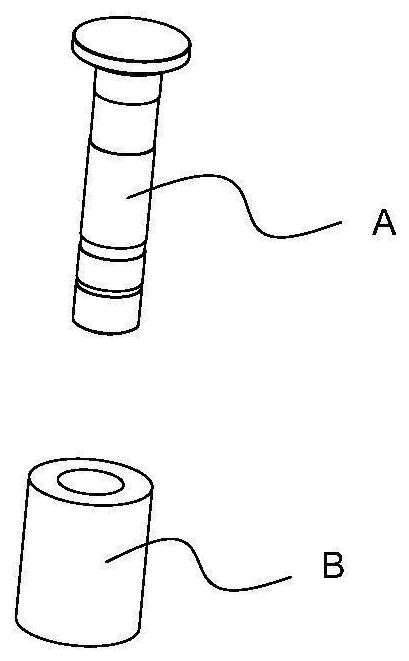

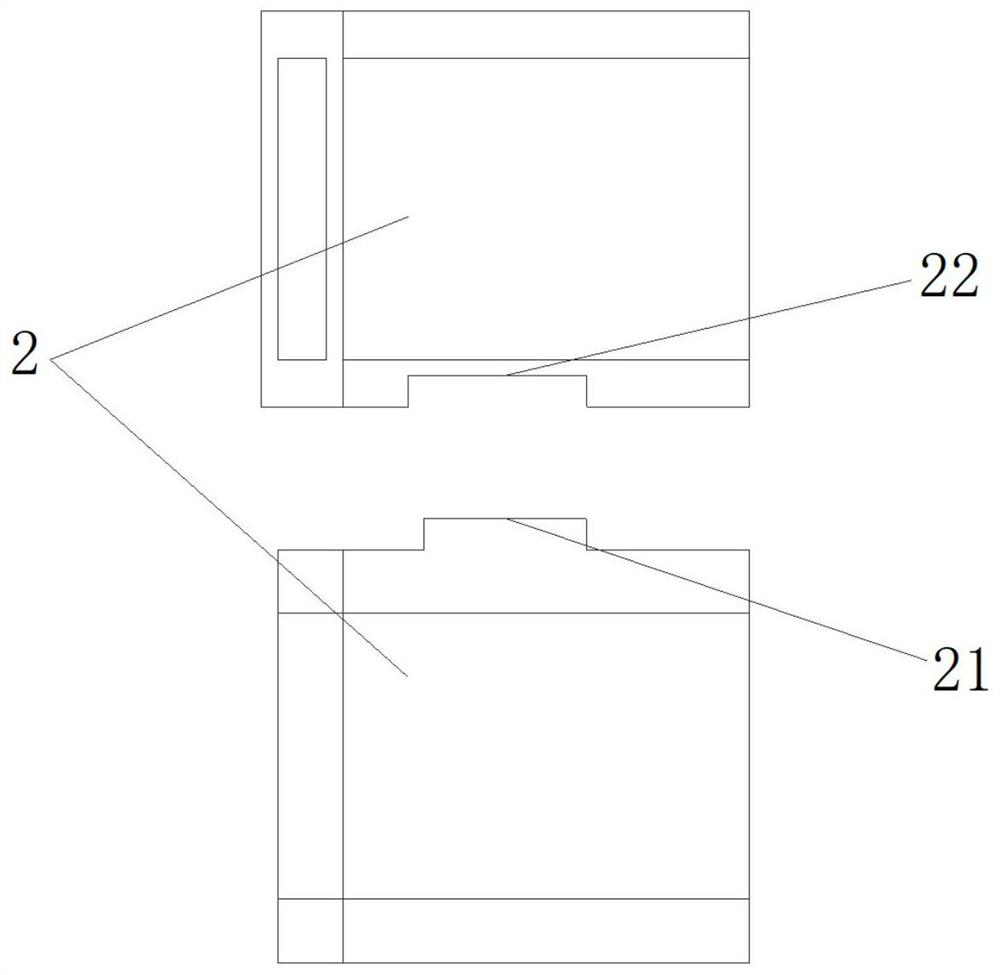

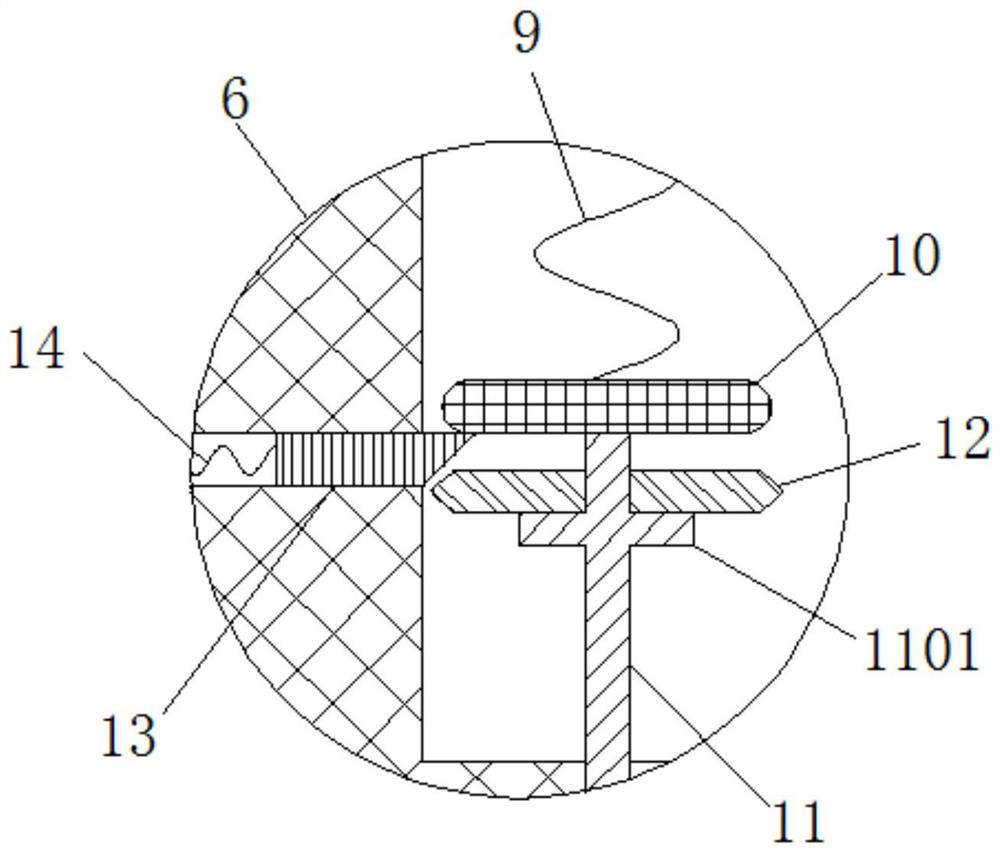

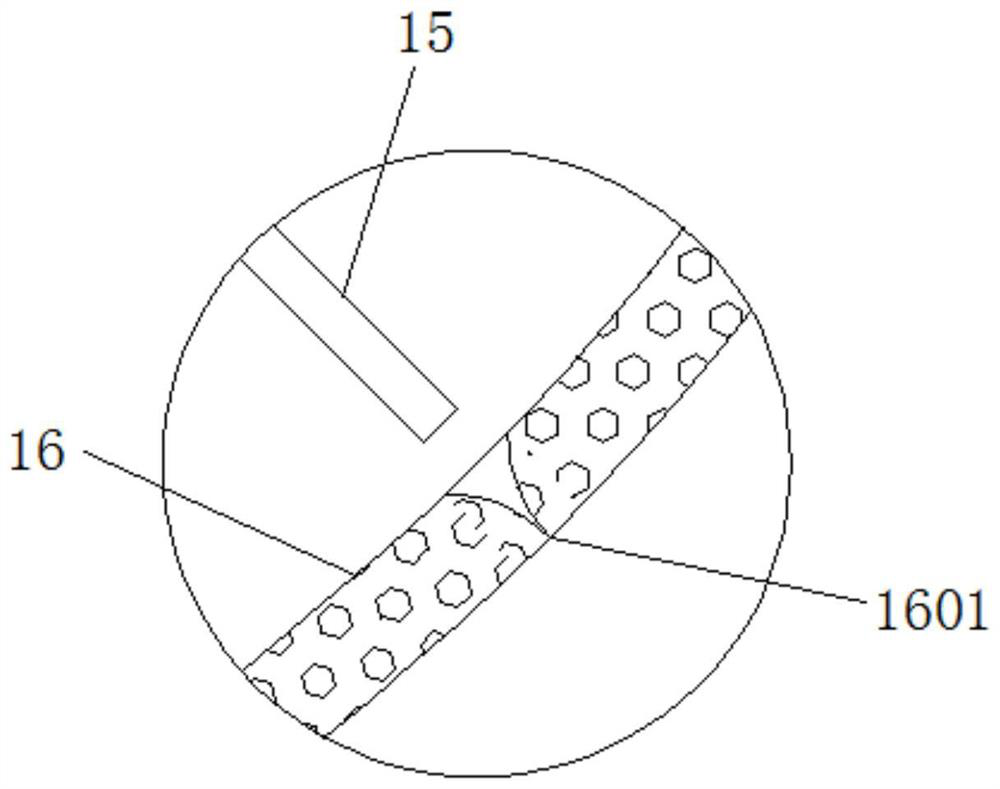

Connecting structure for upright posts and cross beams of glass curtain wall

ActiveCN101929211AGuaranteed insertionAvoid the disadvantages of being unable to disassembleCovering/liningsWallsEngineeringHole size

The invention discloses a connecting structure for upright posts and cross beams of a glass curtain wall, which comprises mortises and pins arranged at one ends, near the upright posts, of the cross beams; the section shapes of the mortises are consistent with that of inner holes of the cross beams; the pins are vertical to the upright posts; pin holes are arranged at positions corresponding to the pins of the upright posts; the size of the pin hole is matched with that of the pin; when the upright posts are connected with the cross beams, the pins pass through the pin holes; the pins are fixed on sides, near the upright posts, of the mortises; the mortises can move left and right on the cross beams; the cross beams are provided with position-adjusting holes; and the mortises are provided with fixing pieces and the fixing pieces pass through the position-adjusting holes. The connecting structure can guarantee all pins to be inserted in the upright posts, solve the problem that whether the pins are all in place cannot be judged in the mounting process, and eliminate the potential safety hazard; and the connecting structure has the characteristics of convenient mounting and maintenance, and overcomes the defect that the upright posts and the cross beams cannot be disassembled once the upright posts and the cross beams are connected.

Owner:ZHEJIANG YASHA CURTAIN WALL

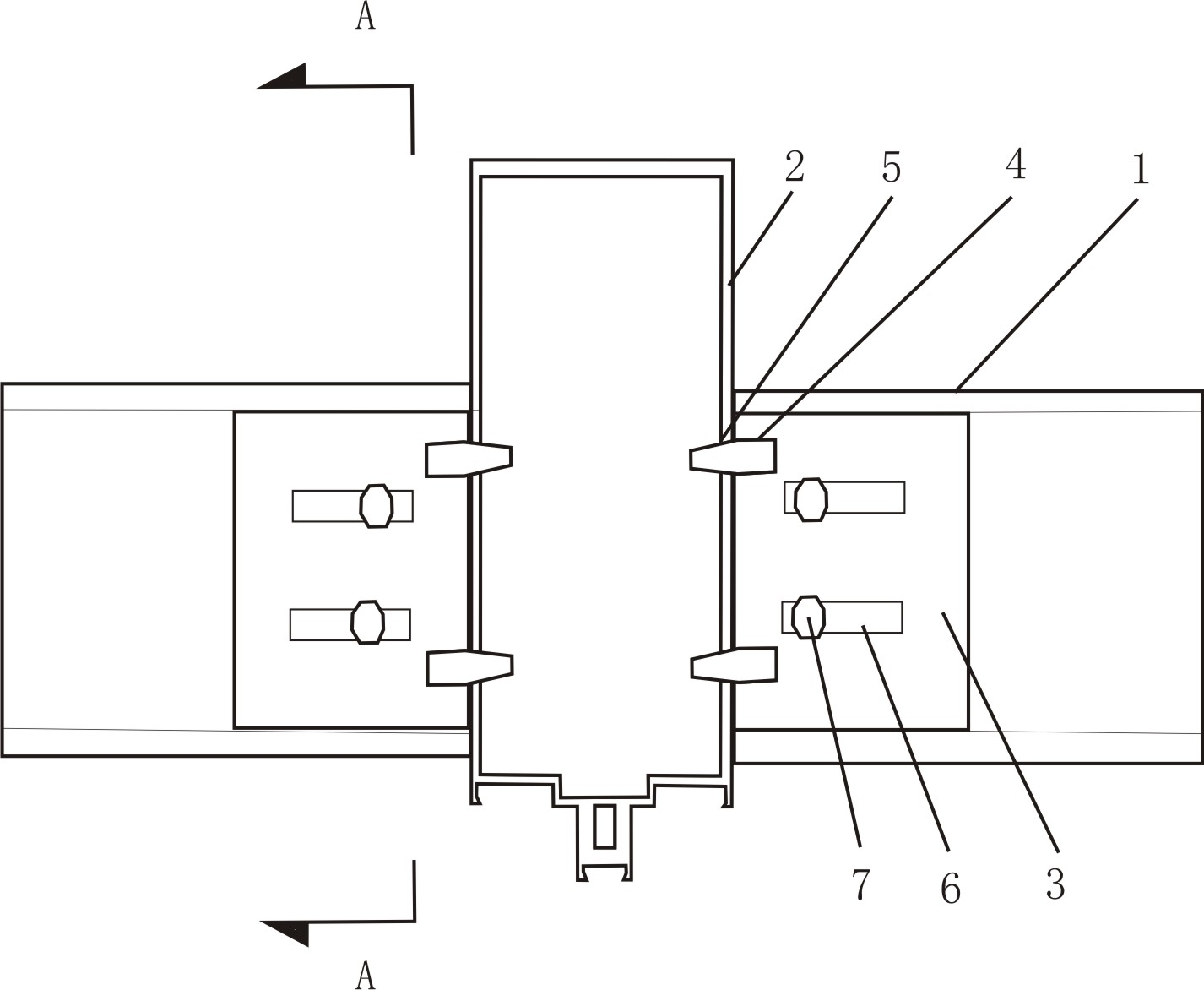

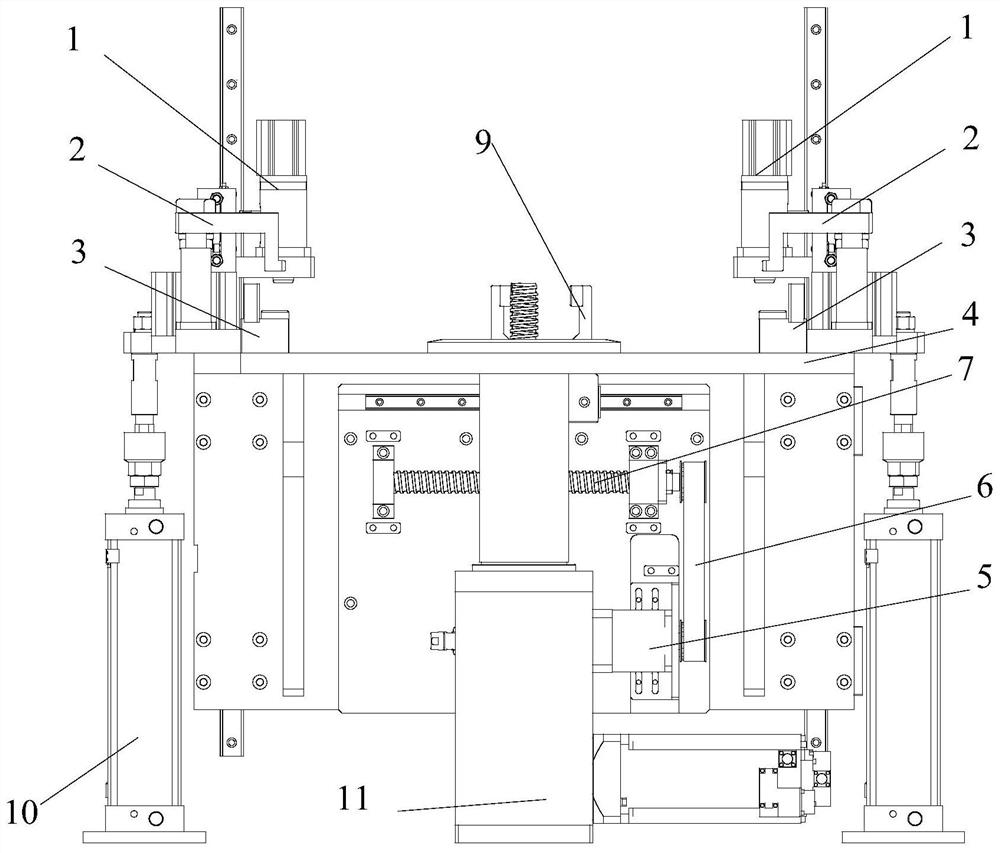

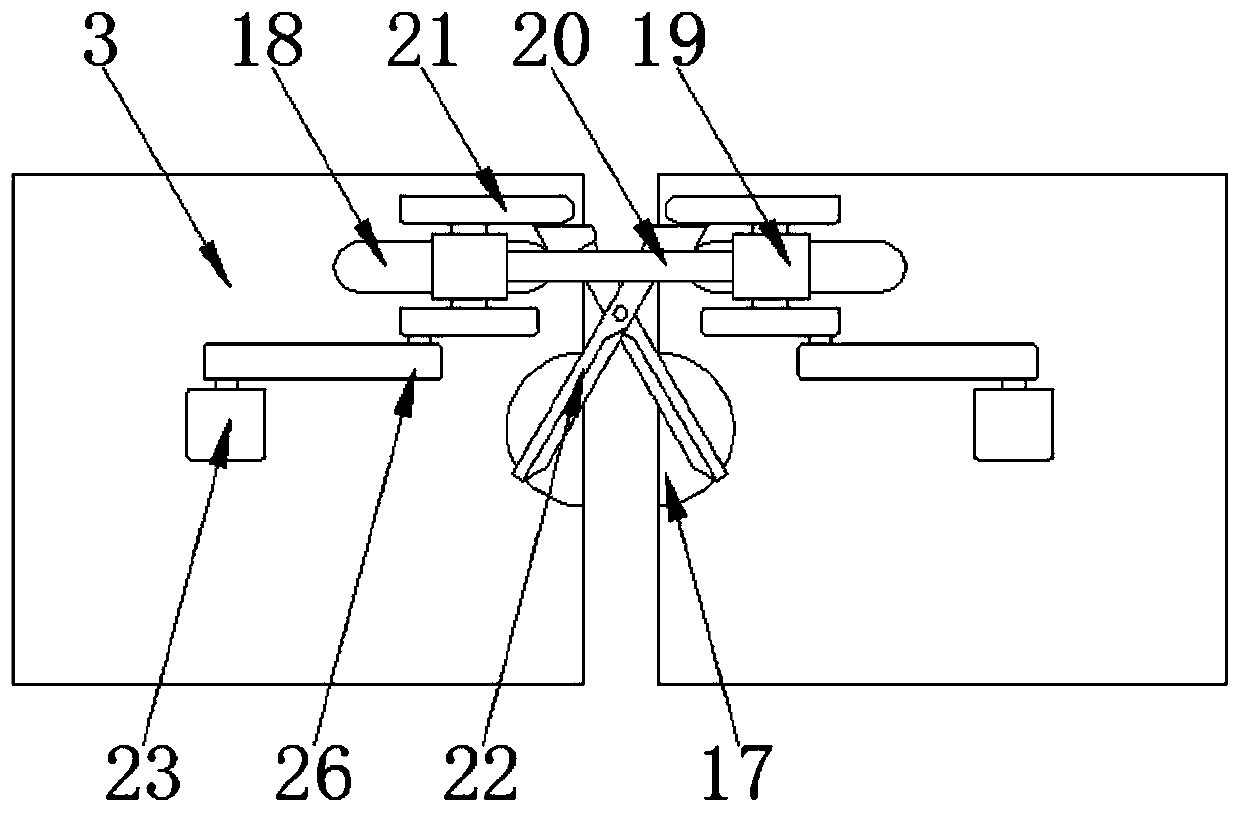

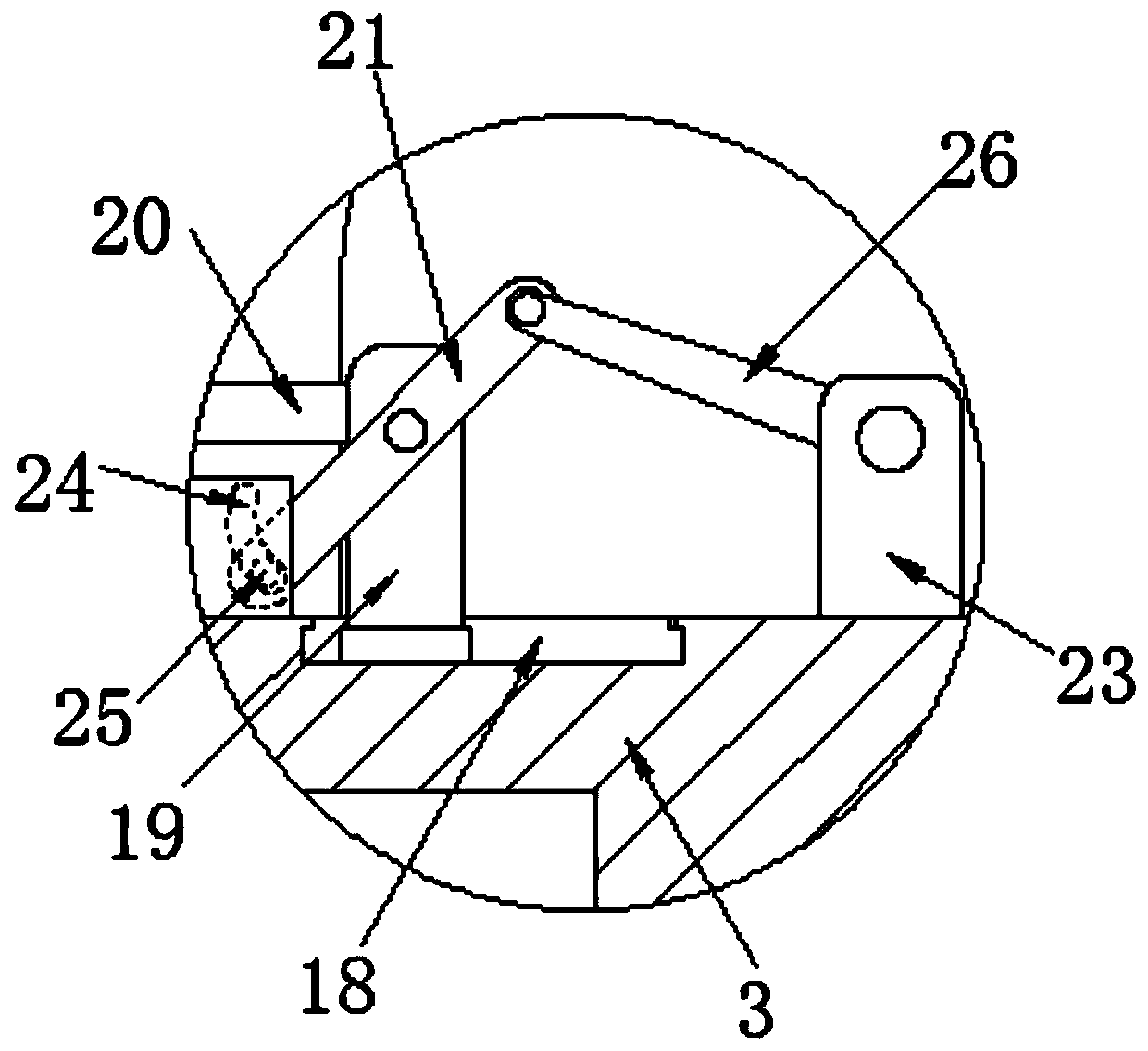

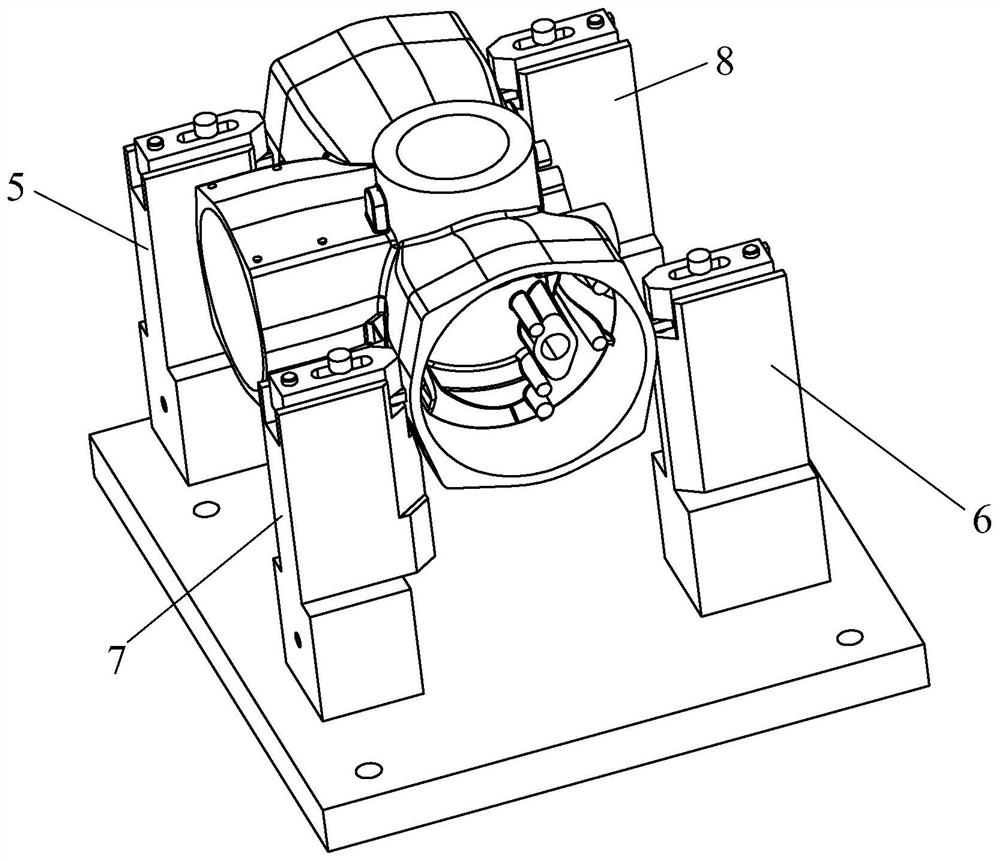

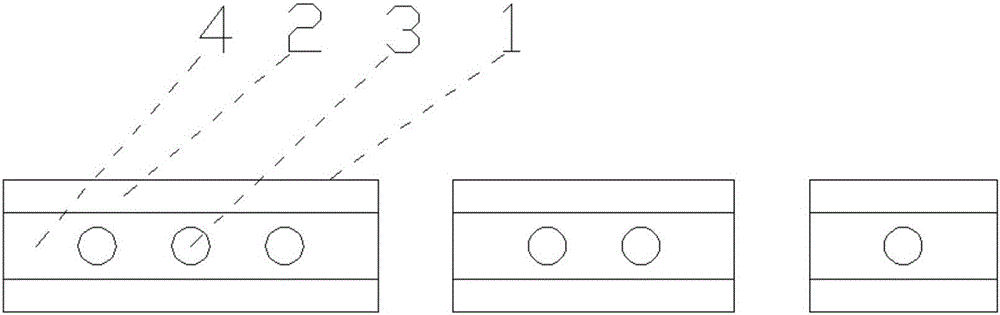

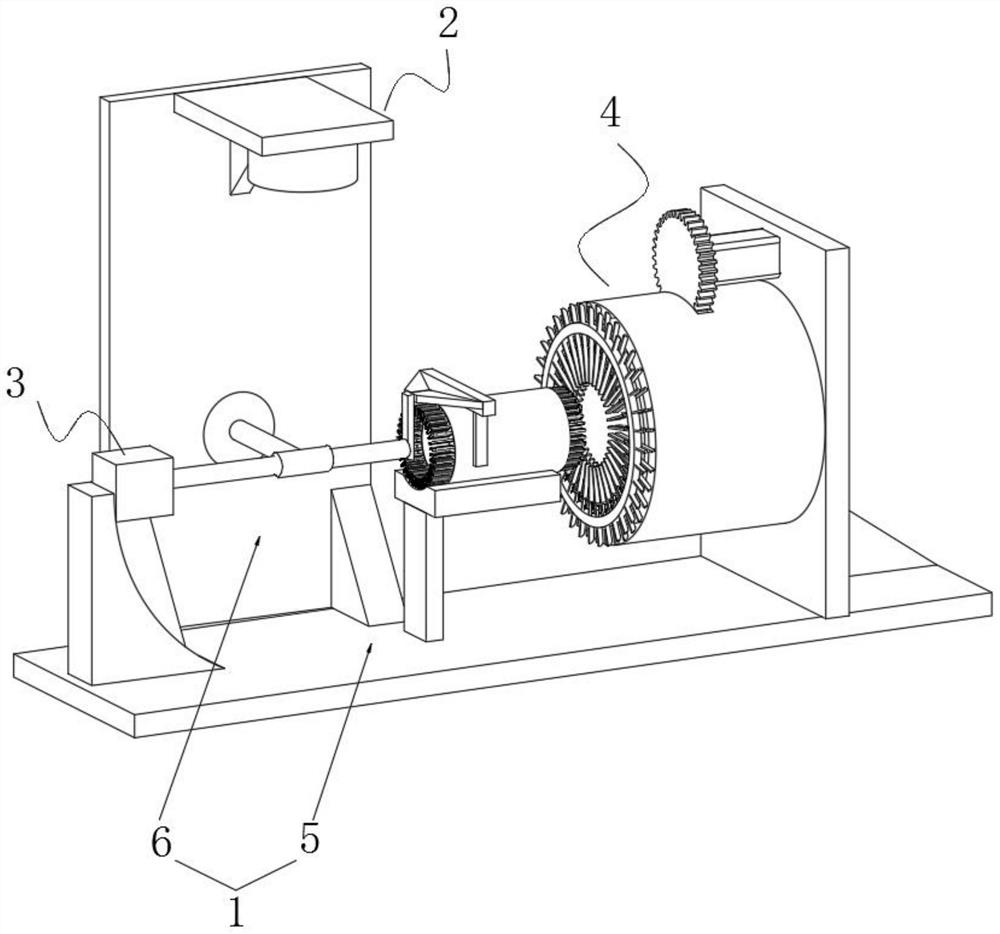

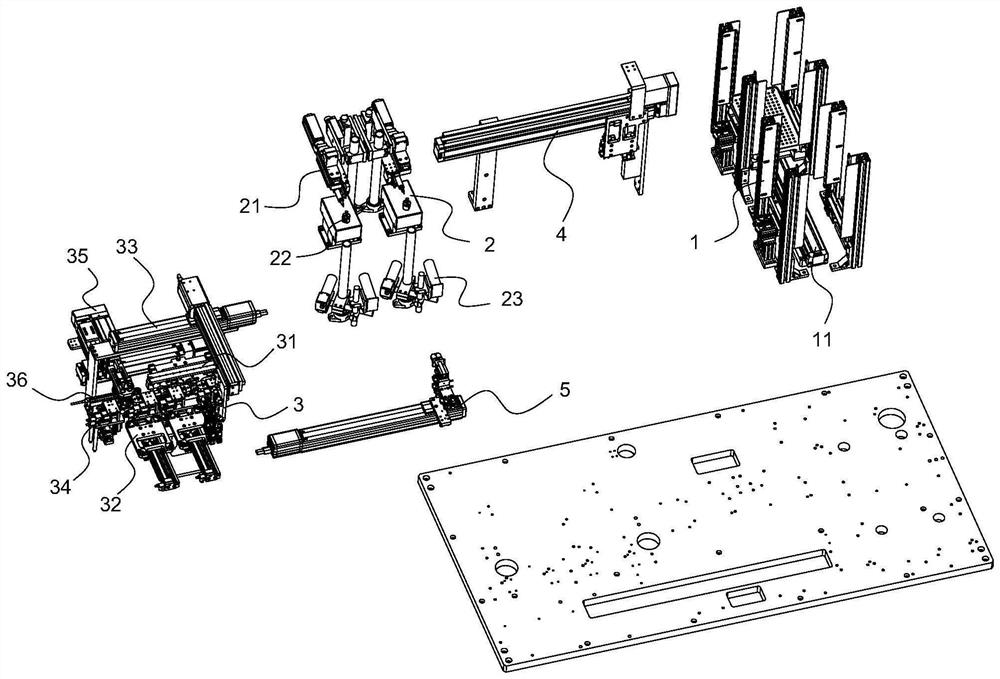

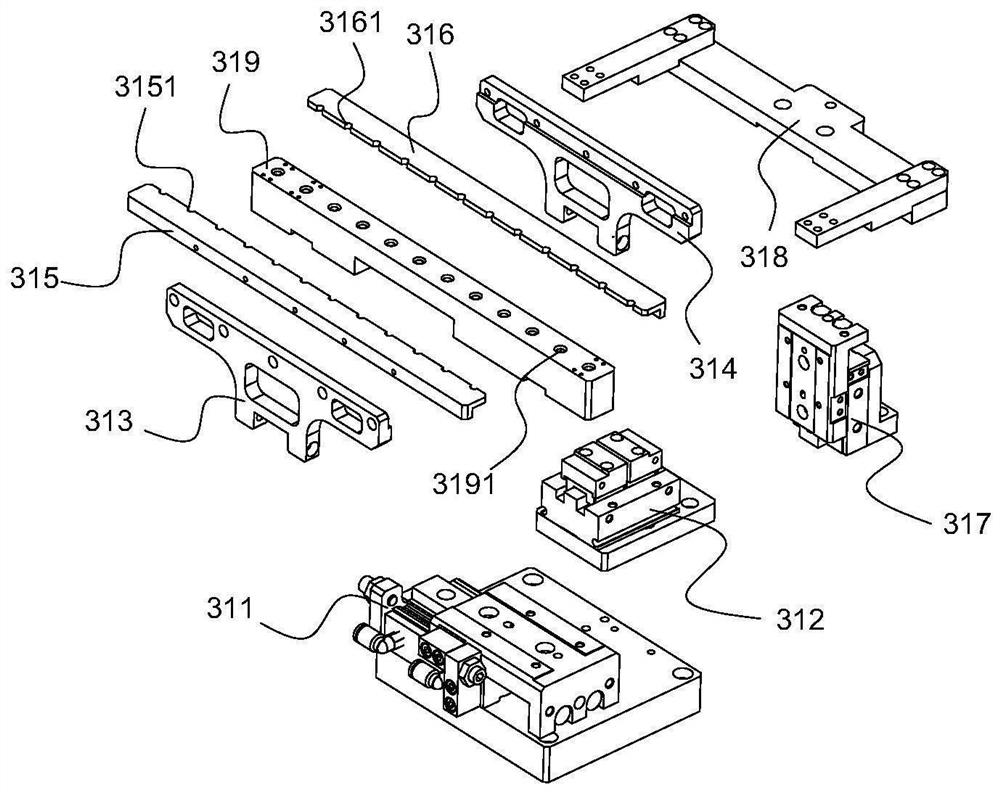

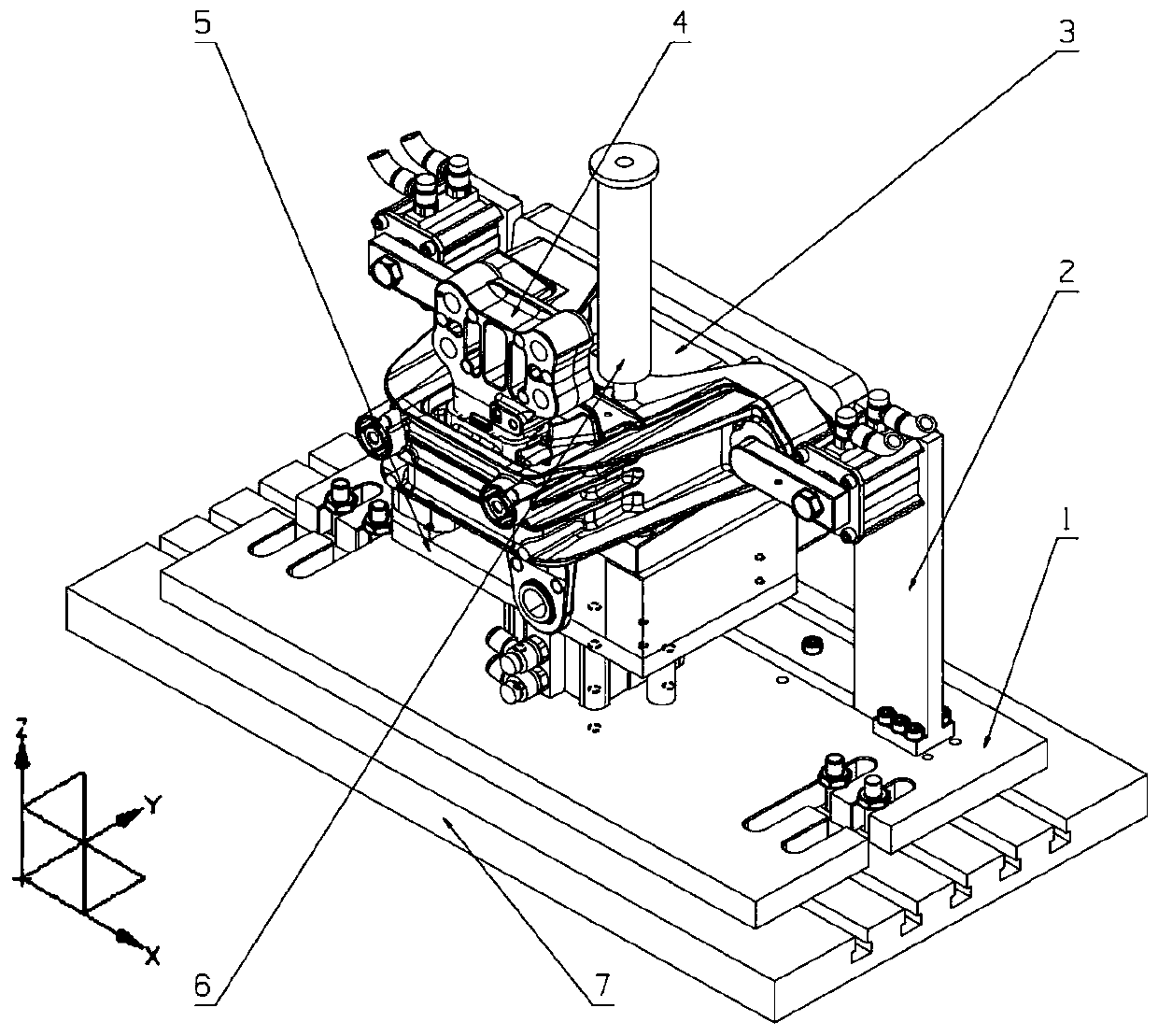

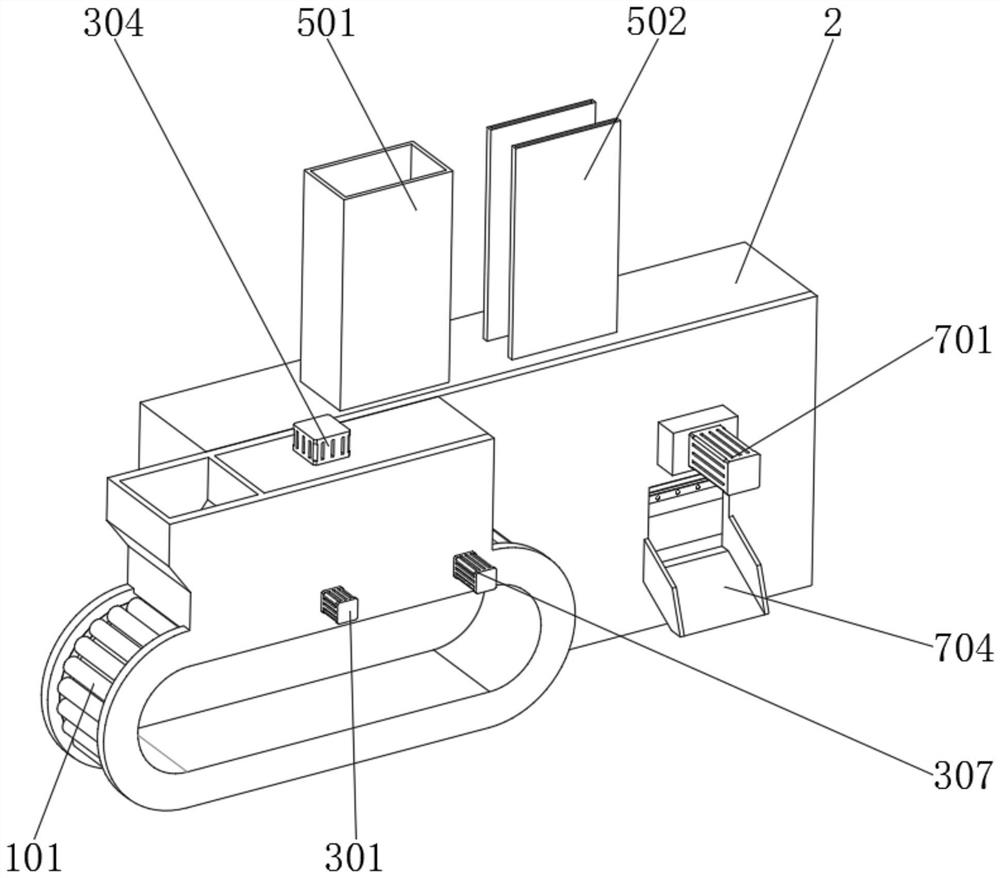

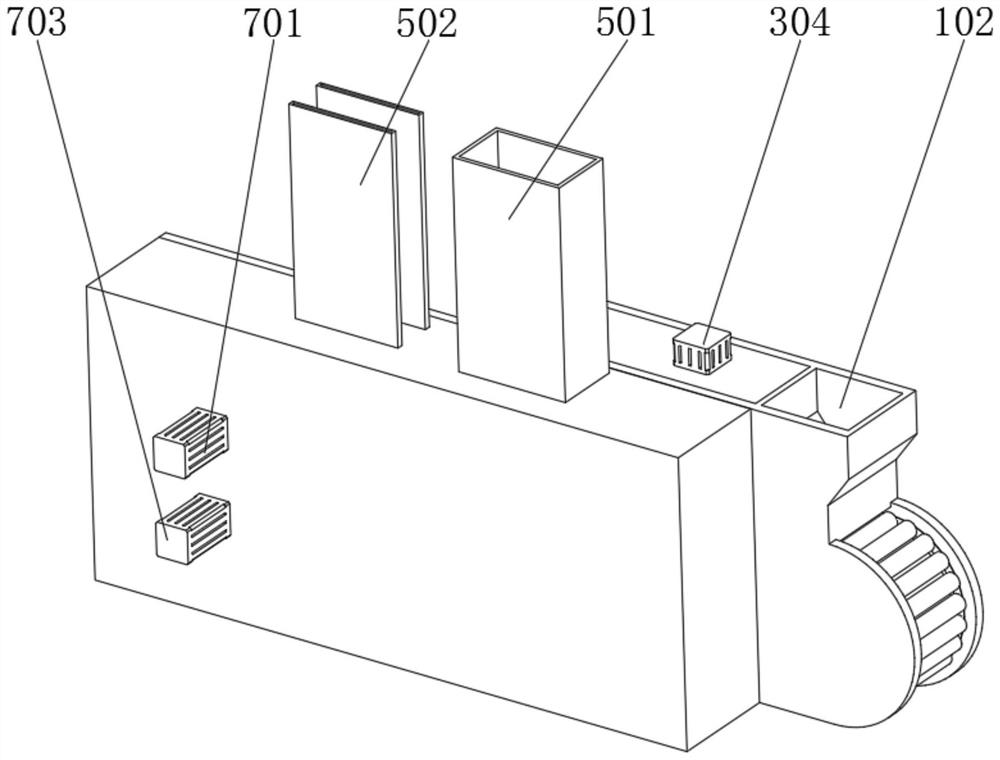

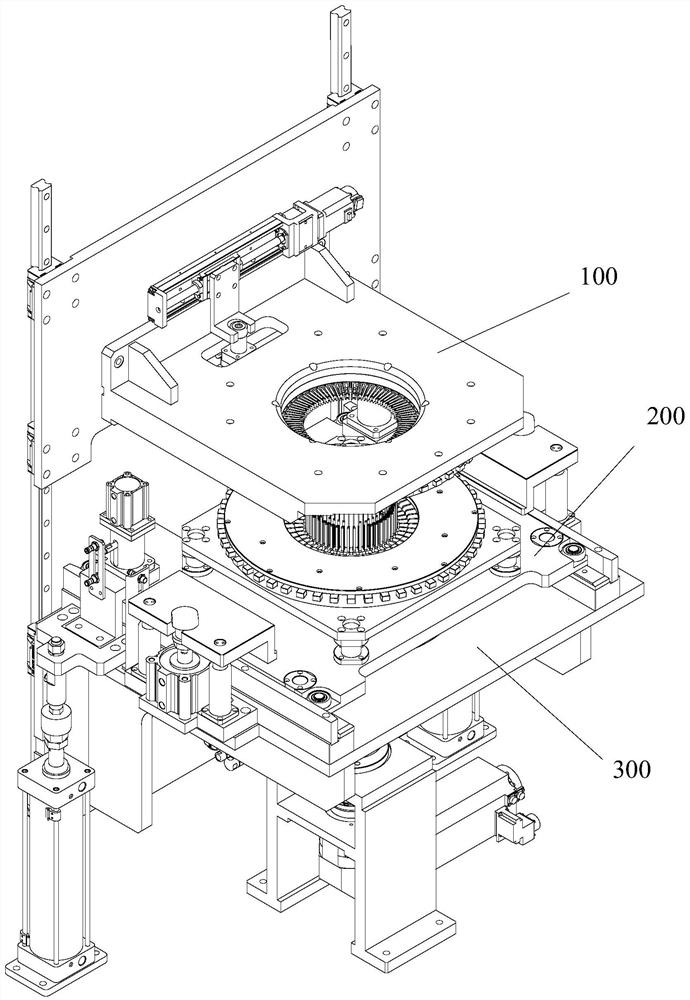

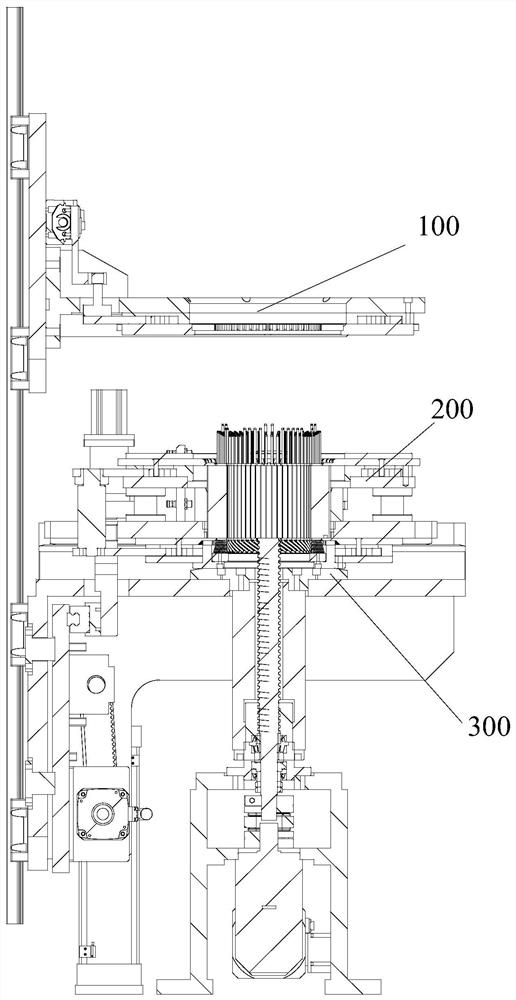

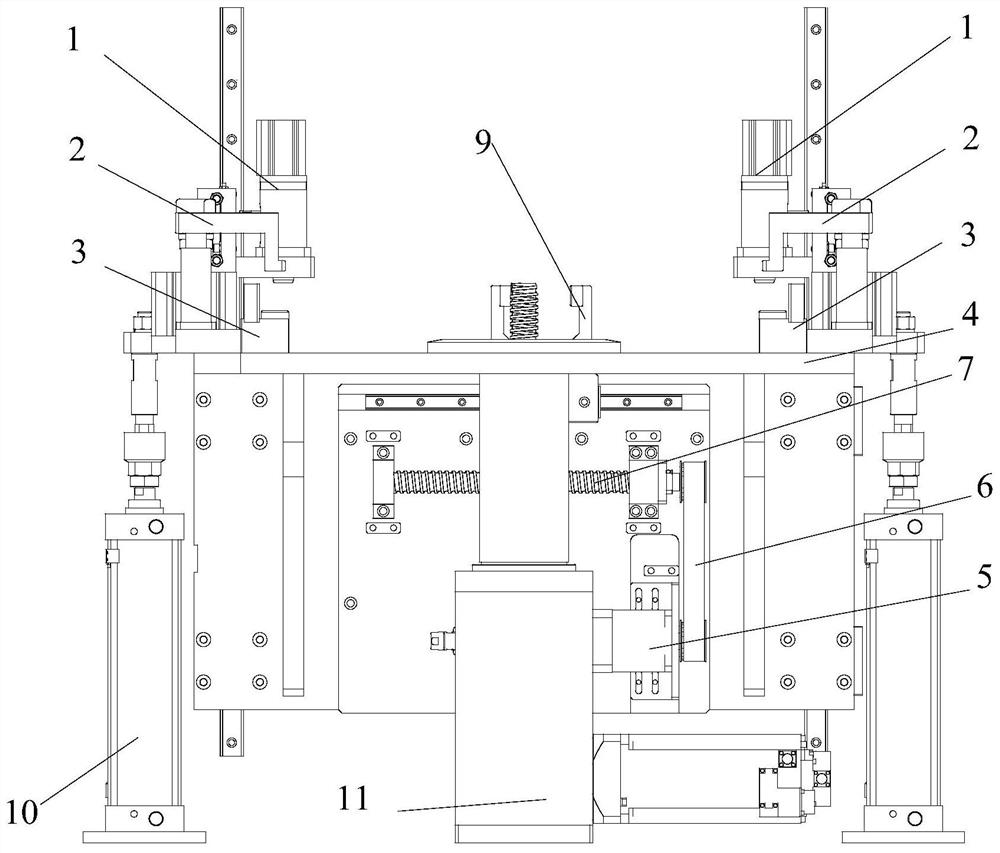

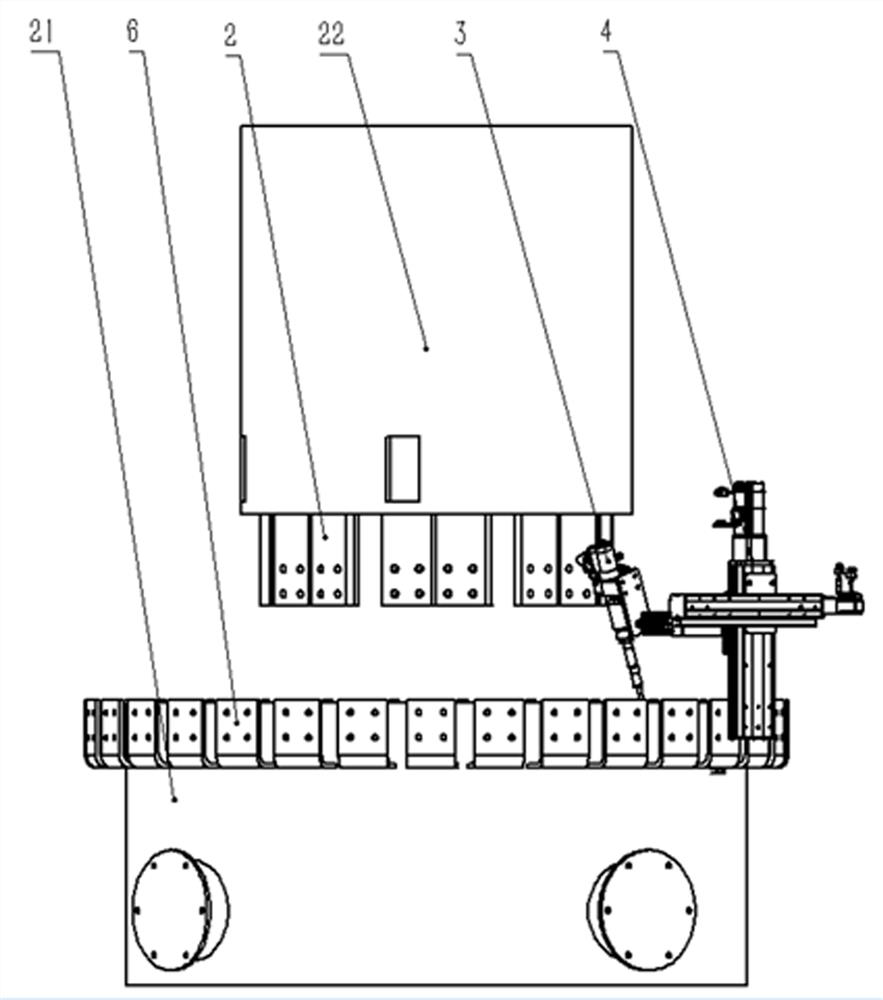

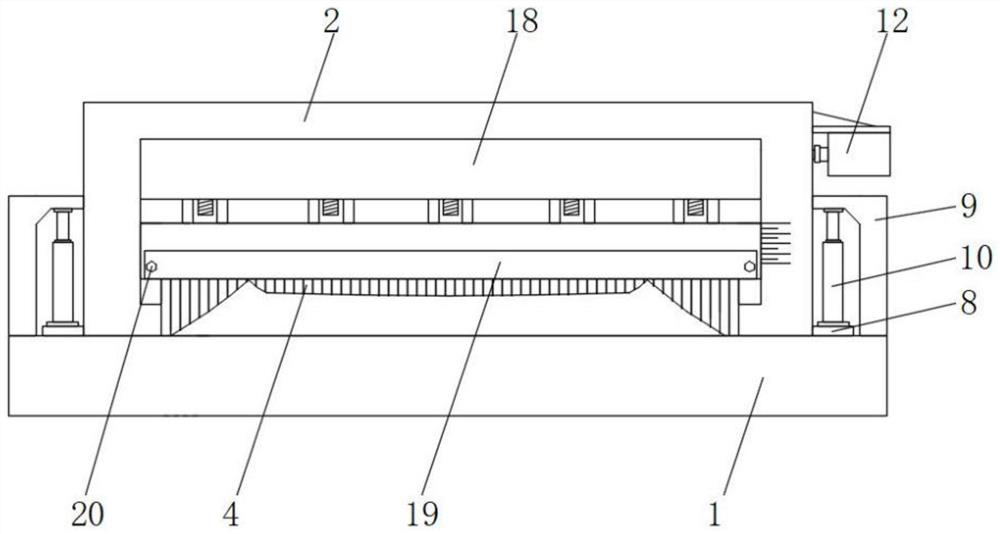

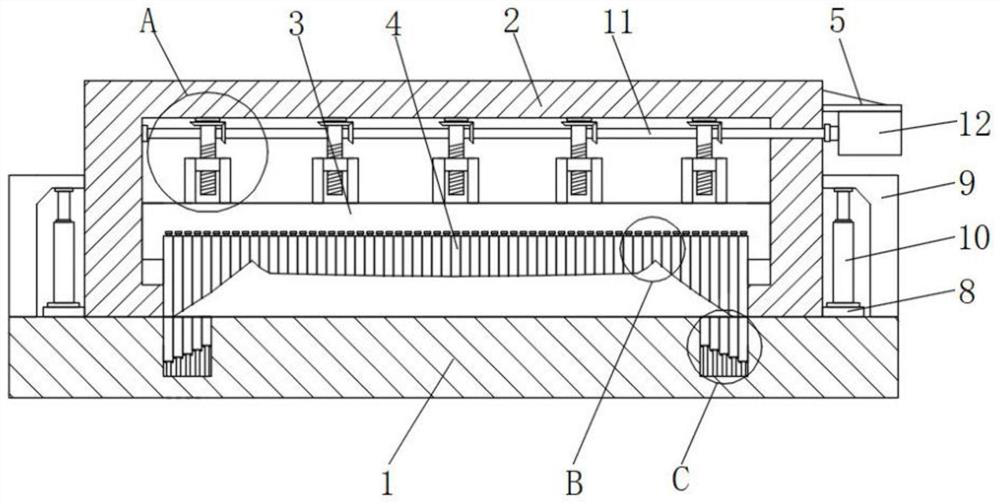

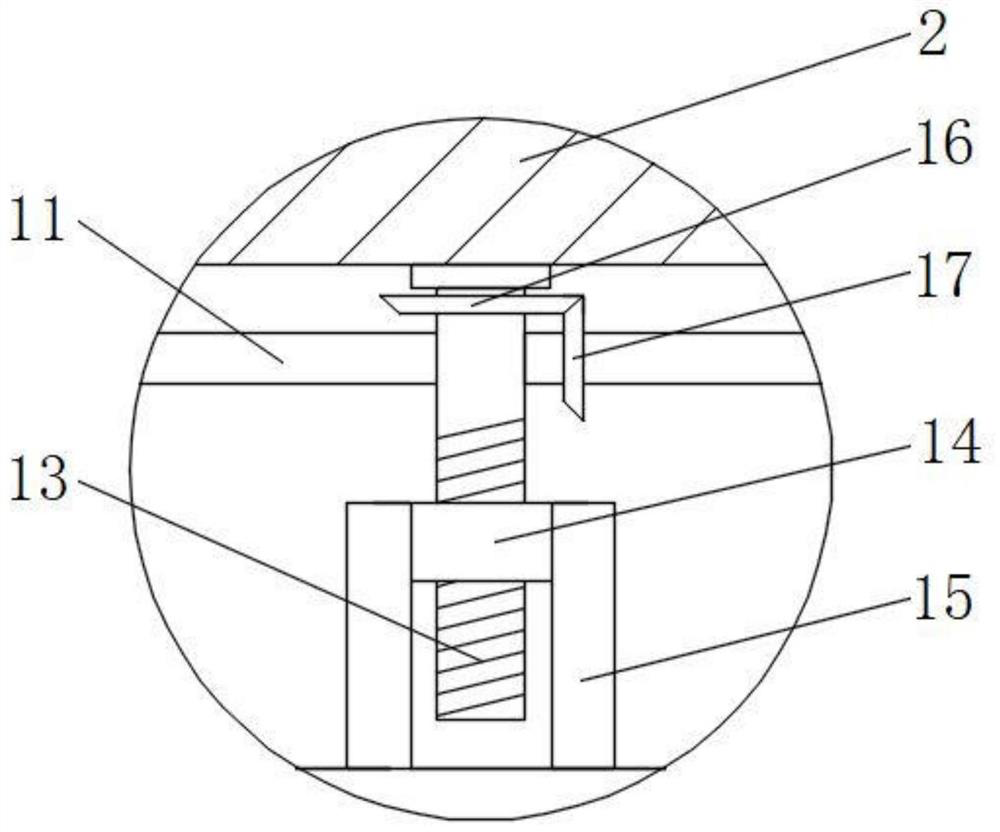

Device and method for twisting end part of stator of flat-wire motor

ActiveCN112039298ASave human effortImprove flaring efficiencyManufacturing stator/rotor bodiesElectrical and Electronics engineeringMechanical engineering

The invention discloses a device for twisting the end part of a stator of a flat-wire motor. The device comprises: a clamp positioning mechanism used for positioning and transporting the stator; a flaring mechanism used for enabling the end part of a stator coil to move along the radial direction of a stator iron core; an end twisting mechanism used for twisting a flared flat wire; and a base usedfor mounting the end twisting mechanism and the flaring mechanism. The invention further provides a method for twisting the end part of the stator of the flat-wire motor. The method comprises the steps of positioning, primary twisting and secondary twisting. The invention also discloses a method for layered flaring of the end part of the stator of the flat-wire motor. The method comprises the steps of positioning, primary flaring, secondary flaring and the like. By arranging the flaring mechanism, a contact surface of a flaring part and a flat wire is small, so it is guaranteed that each wirecan be inserted into an end twisting die, the accuracy of wire insertion is guaranteed, and the percent of pass of twisted ends is increased; and full-automatic flaring is achieved, so manpower is saved, flaring efficiency is improved, the accuracy of wire insertion can be guaranteed, and the percent of pass of twisting ends is increased.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

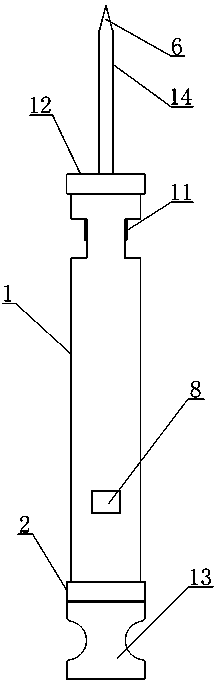

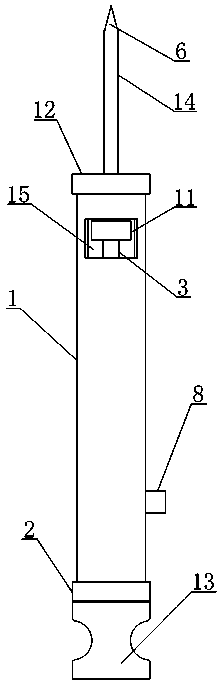

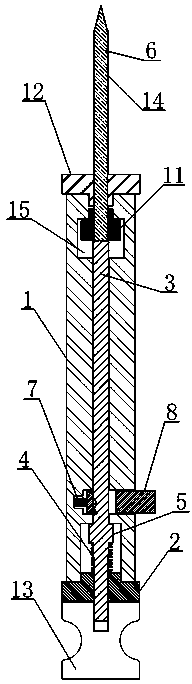

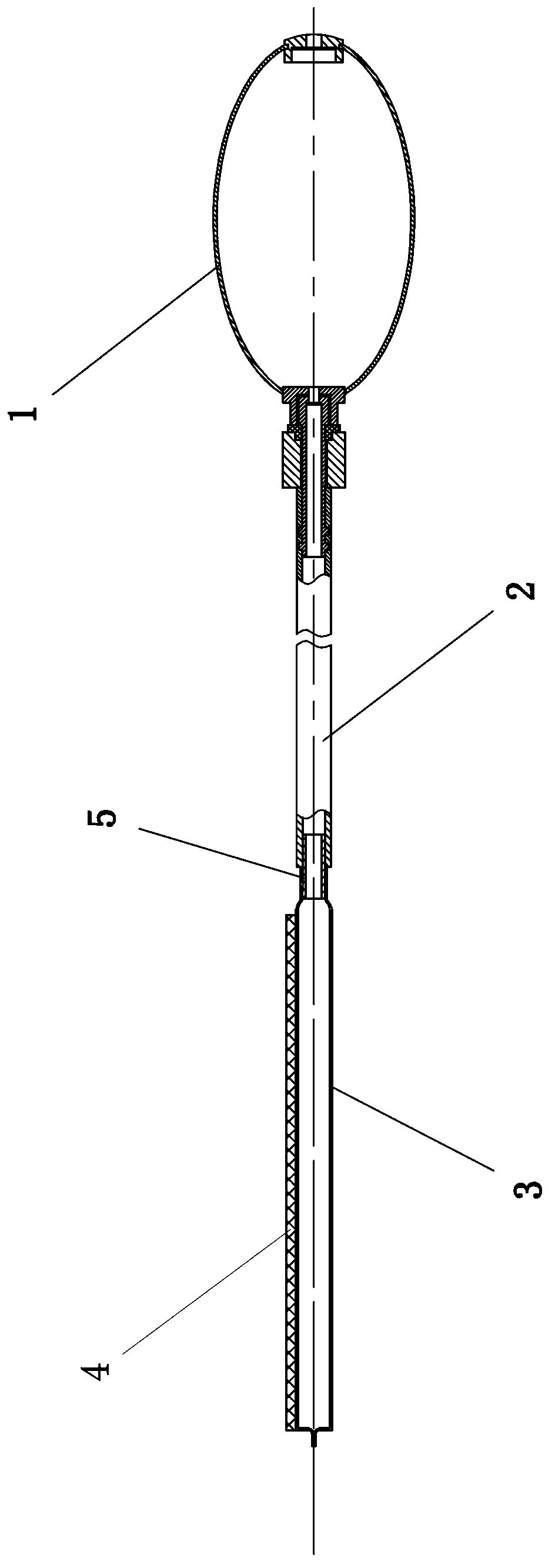

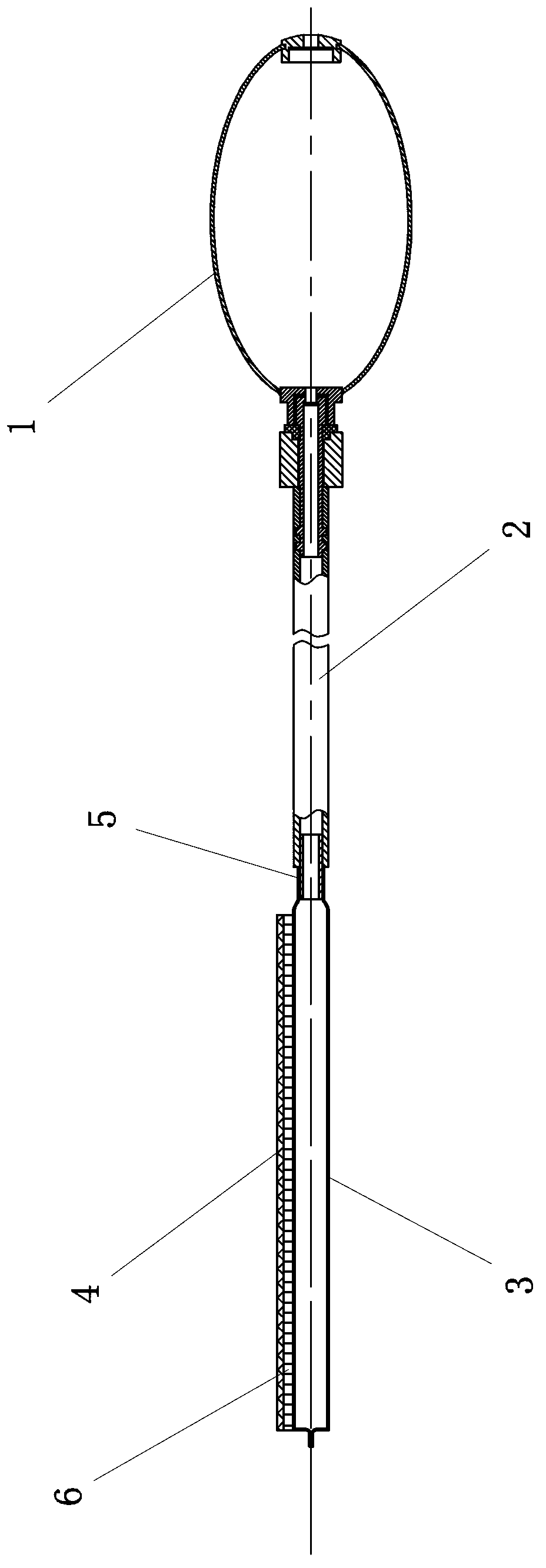

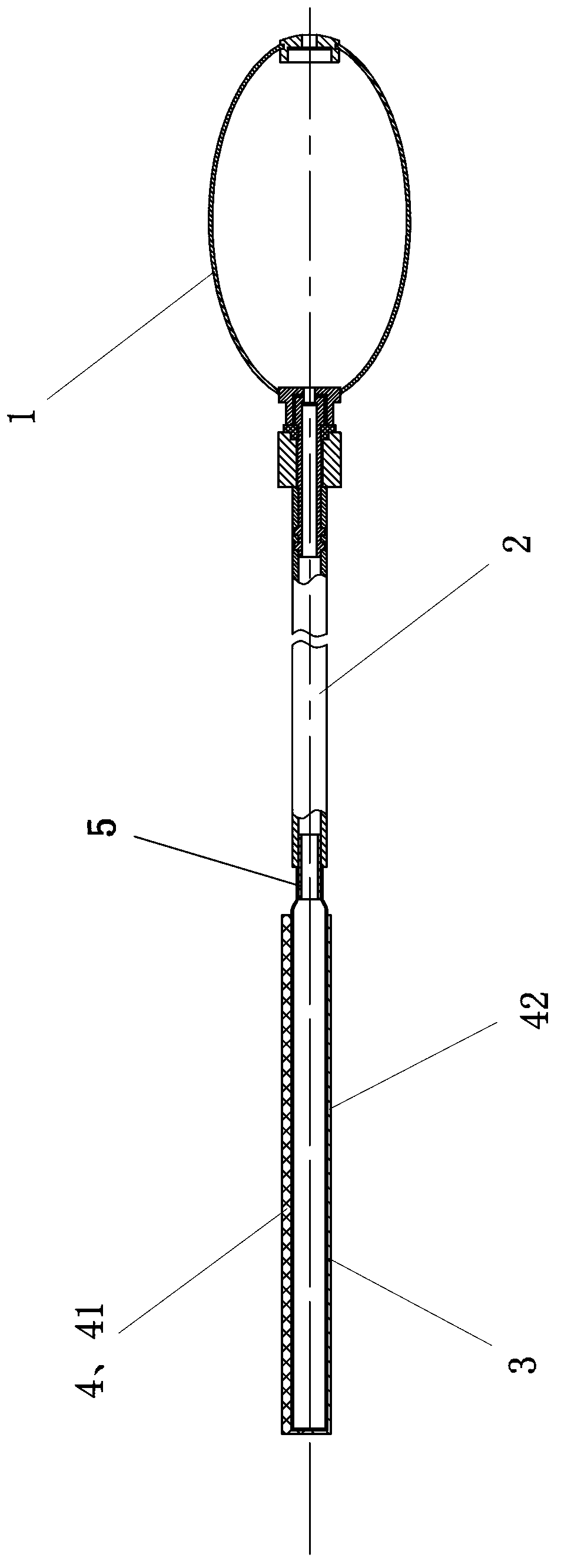

Gall bladder ejection puncture outfit

InactiveCN103815954AAvoid pushingGuaranteed insertionCannulasSurgical needlesCatheterDrainage catheter

The invention discloses a gall bladder ejection puncture outfit to solve the problem that a thick drainage catheter cannot be inserted at a time in the present clinical process of inserting a catheter into the gall bladder. The gall bladder ejection puncture outfit comprises an ejector base catheter, a back gland and a piston, wherein the back gland is arranged at one end of the ejector base catheter, the piston is arranged in the ejector base catheter and can move relative to the ejector base catheter, and one end of the piston extends out of the ejector base catheter and penetrates through the back gland. The end, close to the back gland, of the piston is sleeved with a spring located in the ejector base catheter, and the piston is further provided with a protrusion, wherein the protrusion and the back gland compress the spring together, and the protrusion controls the piston to move relative to the ejector base catheter; the end, far away from the back gland, of the piston is provided with a puncture needle with the needle point located outside the ejector base catheter; the ejector base catheter is internally provided with a locking piece used for preventing the piston from moving relative to the ejector base catheter through the elasticity of the spring. According to the gall bladder ejection puncture outfit, the thick drainage catheter can be inserted at a time, and the fixed-depth puncturing can be achieved during the puncturing process.

Owner:邹树

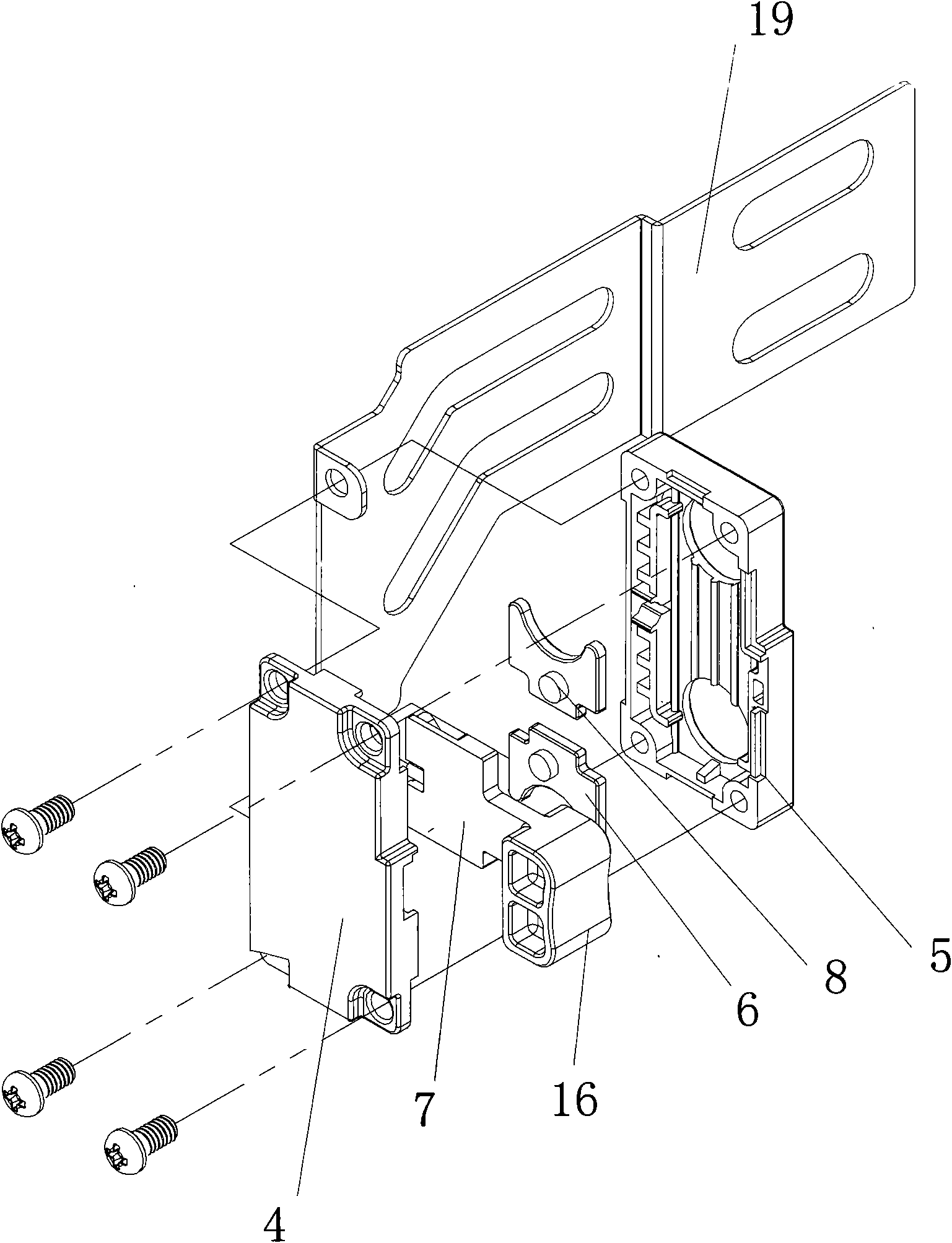

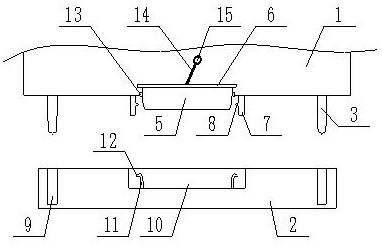

Locking mechanism for server slide rail

InactiveCN101815419AAchieve connectionImprove work efficiencyRack/frame constructionSupport structure mountingLocking mechanismEngineering

The invention relates to a locking mechanism for a server slide rail, which comprises a positioning device and a locking control device, wherein the positioning device comprises a positioning post fixedly connected to a positioning post bracket, and the locking control device comprises an upper cover and a lower cover which are fixedly connected together. A locking slide sheet and an unlocking slide sheet are arranged between the upper cover and the lower cover. The side edge, relative to a circular hole, of the locking slide sheet, is a circular locking edge; the locking slide sheet is provided with a driving lug boss; and one end of the unlocking slide sheet passes through the upper cover and the lower cover, while the other end is provided with a first restoring spring. The unlocking slide sheet is provided with a guide groove. The driving lug boss on the locking slide sheet is placed in the corresponding guide groove. During pressing one end of the unlocking slide sheet to press the first restoring spring, the driving lug boss drives the locking slide sheet to move inwards. By using the structure, the slide rail and a frame can be connected without other auxiliary tools, and the work efficiency is improved.

Owner:雅固拉国际精密工业(苏州)有限公司

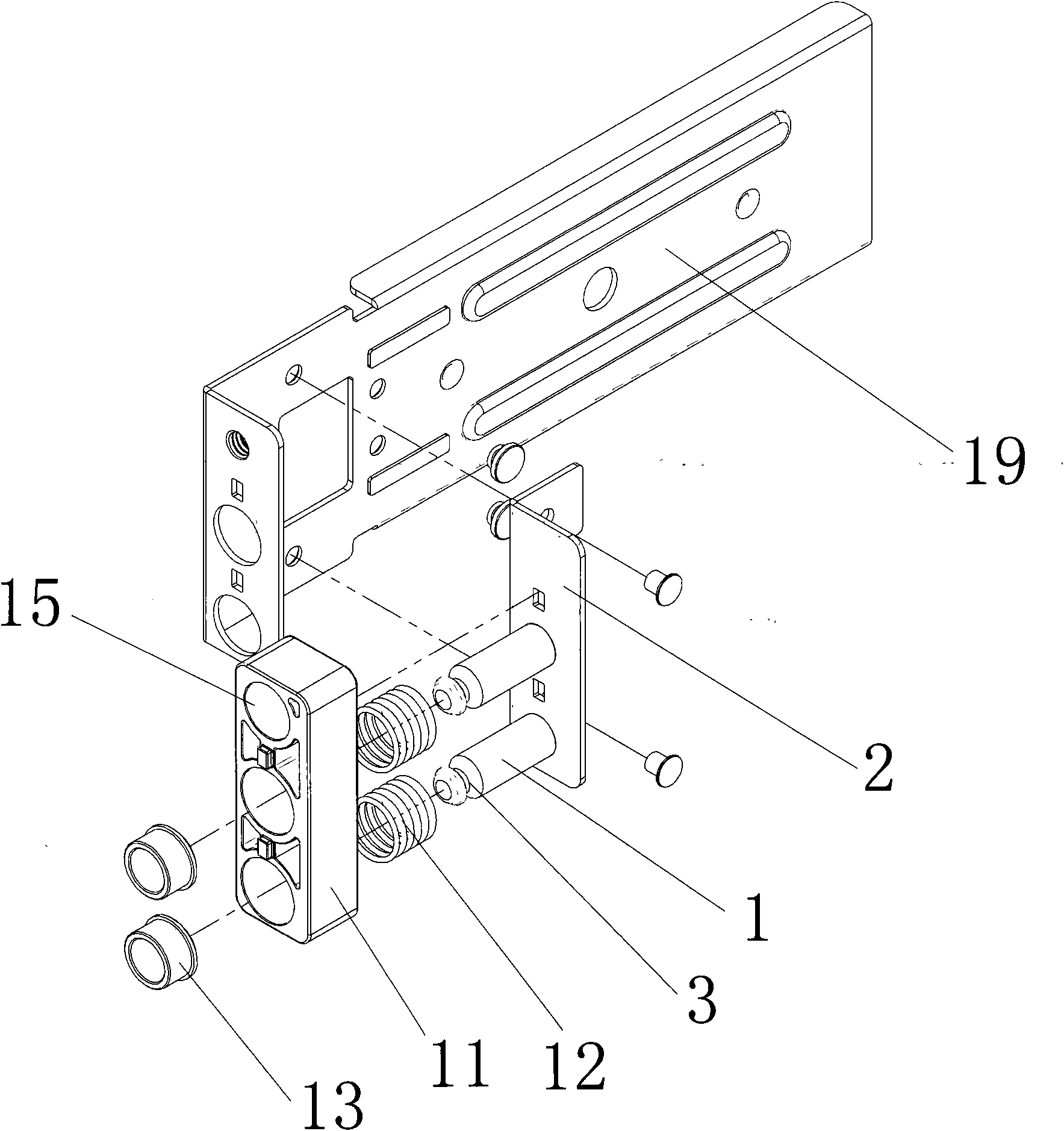

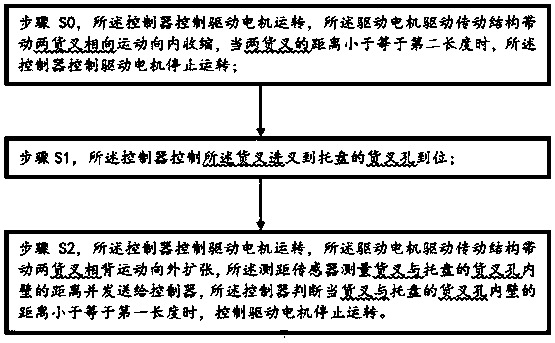

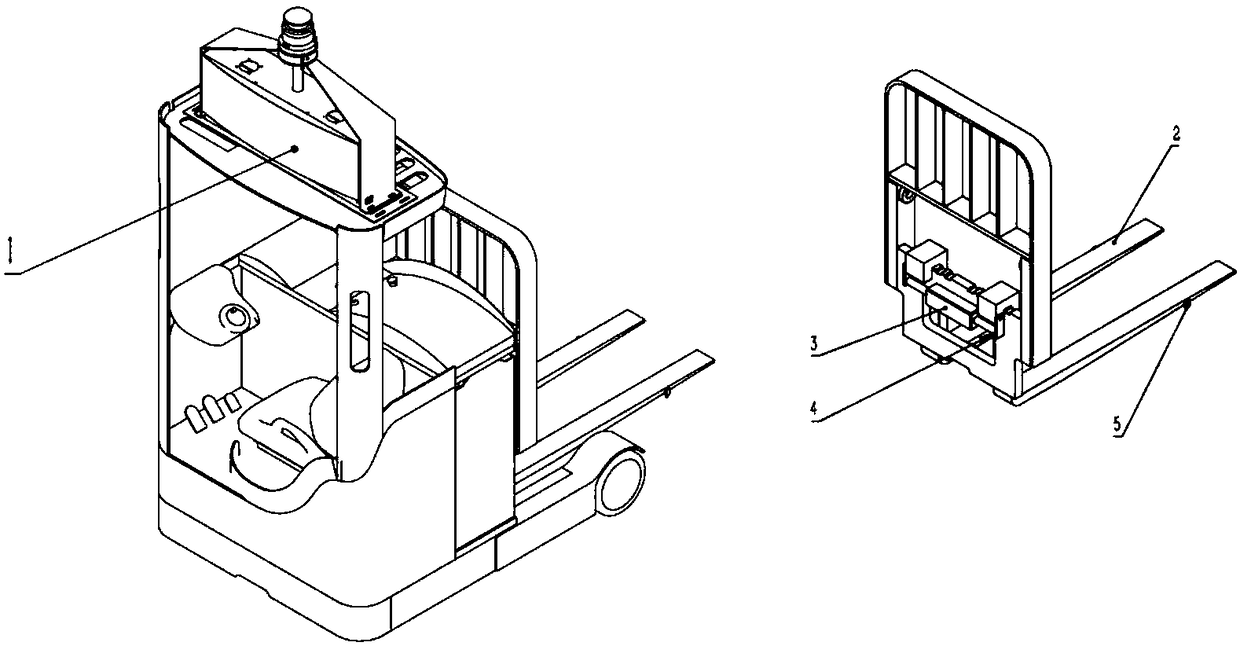

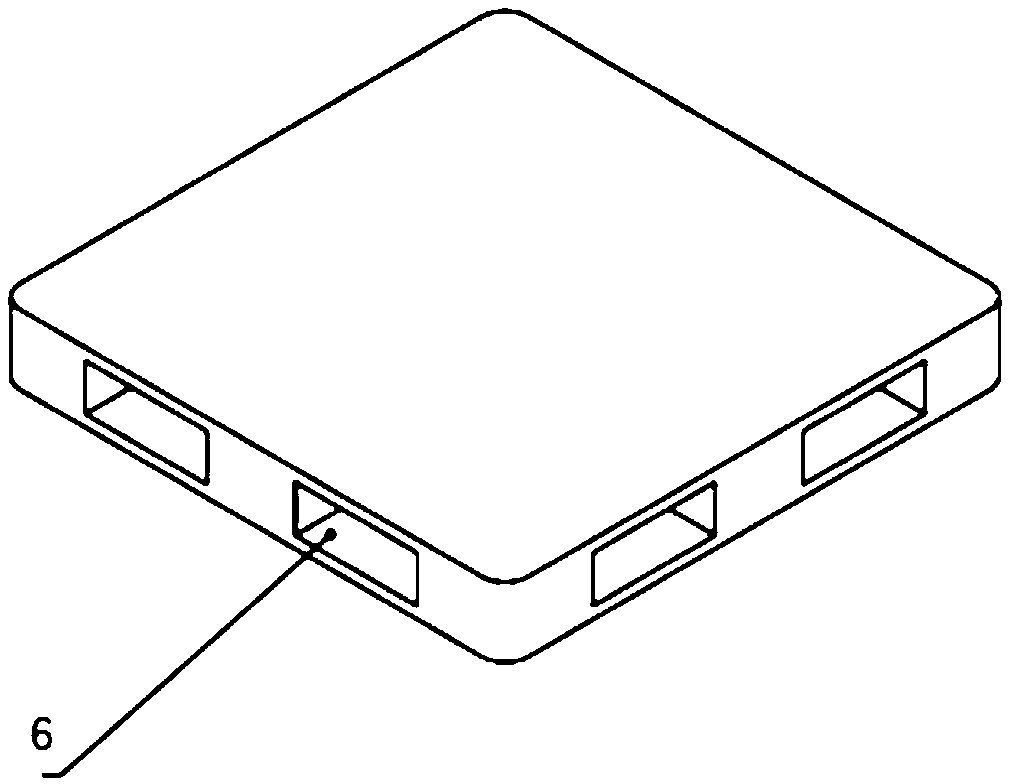

Automatic adjusting device and method for pallet fork distance of forklift-type automated guided vehicle (AGV)

The invention provides an automatic adjusting device and method for the pallet fork distance of a forklift-type automated guided vehicle (AGV). The automatic adjusting device for the pallet fork distance of the forklift-type AGV comprises a controller, a driving motor, a transmission structure and a distance measuring sensor connected with the controller, wherein the controller, the driving motor,the transmission structure and the distance measuring sensor are connected sequentially; and the forklift-type AGV is provided with two pallet forks arranged side by side, the transmission structureis connected with the pallet forks, after controlling the pallet forks to enter pallet fork holes of a pallet in place, the controller controls the driving motor to operate, the driving motor drives the transmission structure to drive the two pallet forks to move oppositely and expand outwards, the distances between the pallet forks and the inner walls of the pallet fork holes of the pallet are measured by the distance measuring sensor and sent to the controller, and when the controller judges that the distances between the pallet forks and the inner walls of the pallet fork holes of the pallet are each less than or equal to the first length, the driving motor is controlled to stop operating. The same forklift-type AGV can be suitable for pallets with different sizes simultaneously, thus the cost of a user is lowered, and the working efficiency is improved.

Owner:苏州罗伯特木牛流马物流技术有限公司

Blow molding equipment for blow molded container

The invention discloses blow molding equipment for a blow molded container, and relates to the technical field of the blow molding equipment. The blow molding equipment comprises a working table, a collecting hole is formed in the top of the working table, container molds are movably connected on the two sides of the top of the working table, appearance grooves are formed in the opposite sides ofthe two container molds, and a supporting frame is fixedly connected to the back face of the working table. According to the blow molding equipment for the blow molded container, second sliding grooves are formed in the tops of the container molds, so that when the two container molds move towards the sides away from each other, the positions of the second sliding blocks are not changed due to thefact that the two second sliding blocks are connected through a fixing rod, at the moment, swinging rods drive rotating rods to rotate, so that the sides, away from each other, of two sleeve blocks are moved, then the sharp sides of two blades can make contact with each other, through the structure, redundant materials can be cut off to fall off along with the container, and the redundant materials are prevented from falling into the appearance grooves.

Owner:宏全食品包装清新有限公司

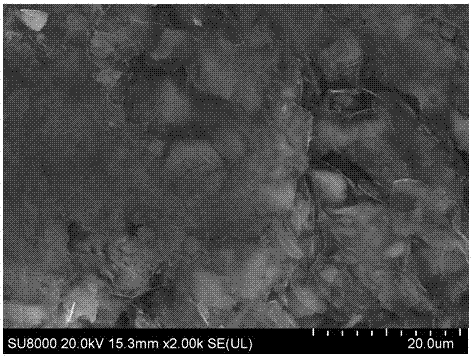

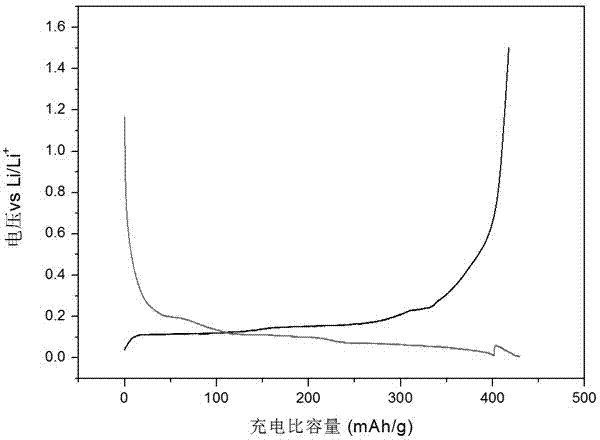

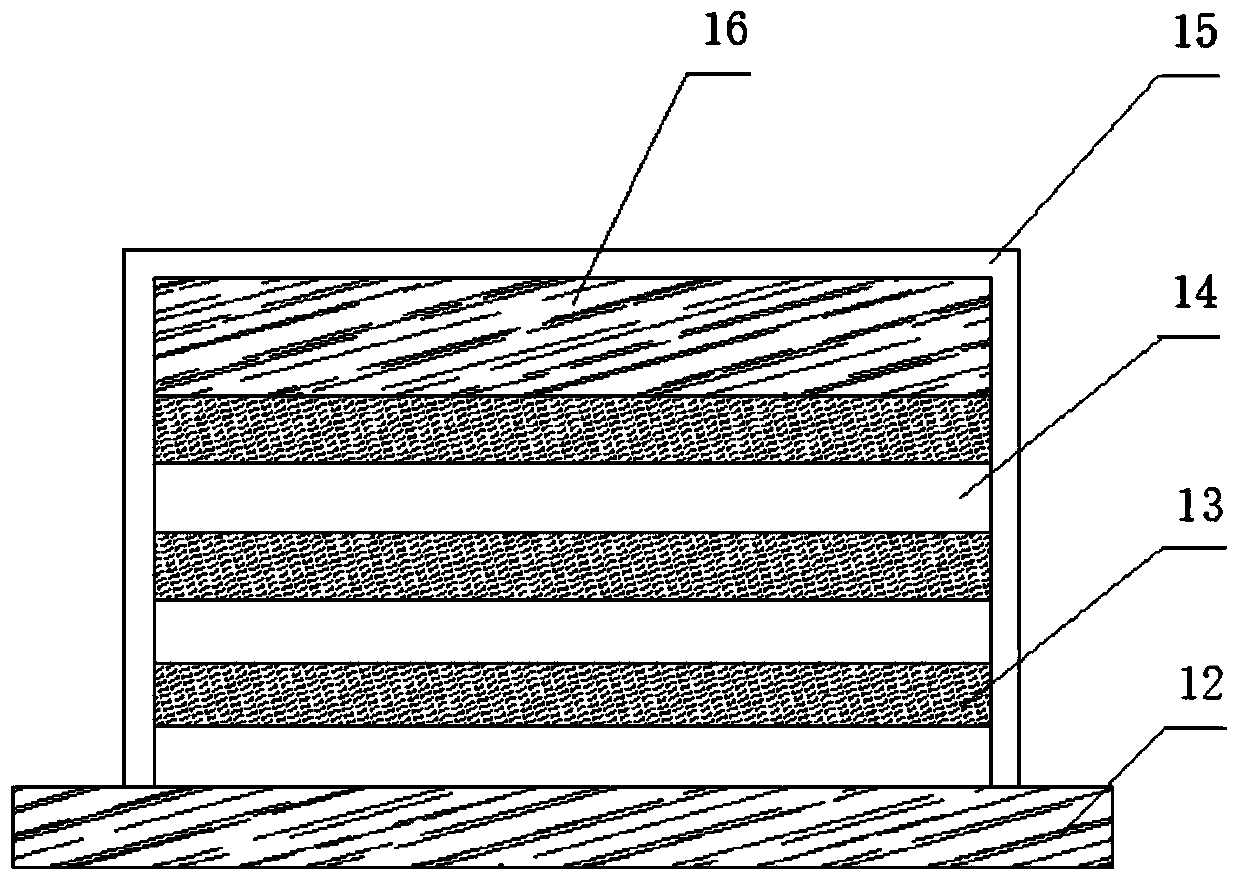

Preparation method of silicon carbon negative electrode material for lithium ion batteries

InactiveCN107369809AGuaranteed insertionGuaranteed cushioning effectElectrode thermal treatmentImpregnation manufacturingSodium-ion batteryGraphite

The invention relates to a preparation method of a silicon carbon negative electrode material for lithium ion batteries. The preparation method is characterized in that the preparation technology specifically comprises the following preparation steps: through expanded graphite pretreatment, precursor turbid liquid configuration, precursor preparation and silicon-enriched material preparation, sufficiently mixing a silicon-enriched material with other negative electrode carbon materials of lithium batteries, and obtaining the silicon carbon negative electrode material through ball-milling, wherein the silicon-enriched material accounts for 10% to 30% of total mass, and the other negative electrode carbon materials of lithium batteries comprise synthetic graphite. According to the method, silica powder is not used as a silicon source, on one hand, the material cost is reduced, and on the other hand, the insertion of silicon among expanded graphite layers is guaranteed, so that the buffer action of expanded graphite on silicon is guaranteed; and moreover, the method uses the other negative electrode carbon materials as a main carbon source, so that the flexibility of the material is improved, the cost is reduced, batch is easily realized, and the controllability of cost and performance are reached.

Owner:CHINA FIRST AUTOMOBILE

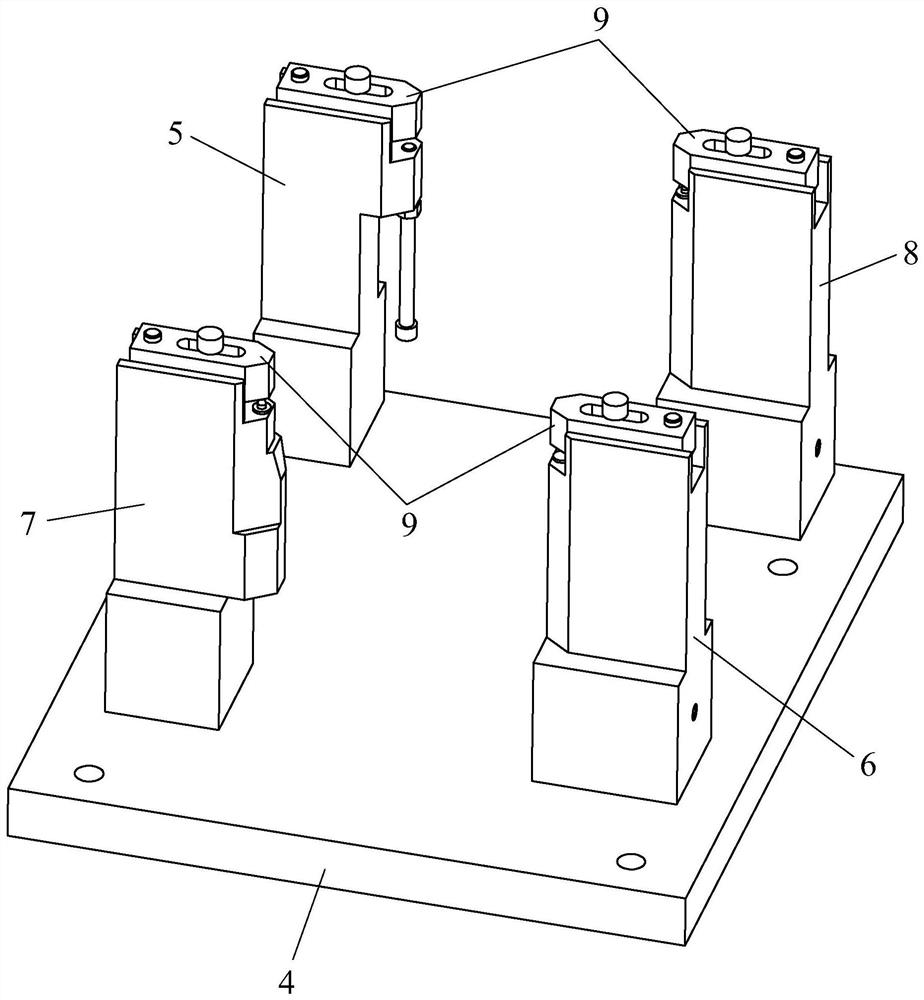

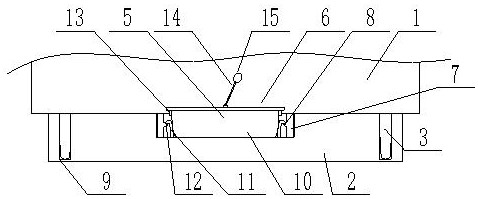

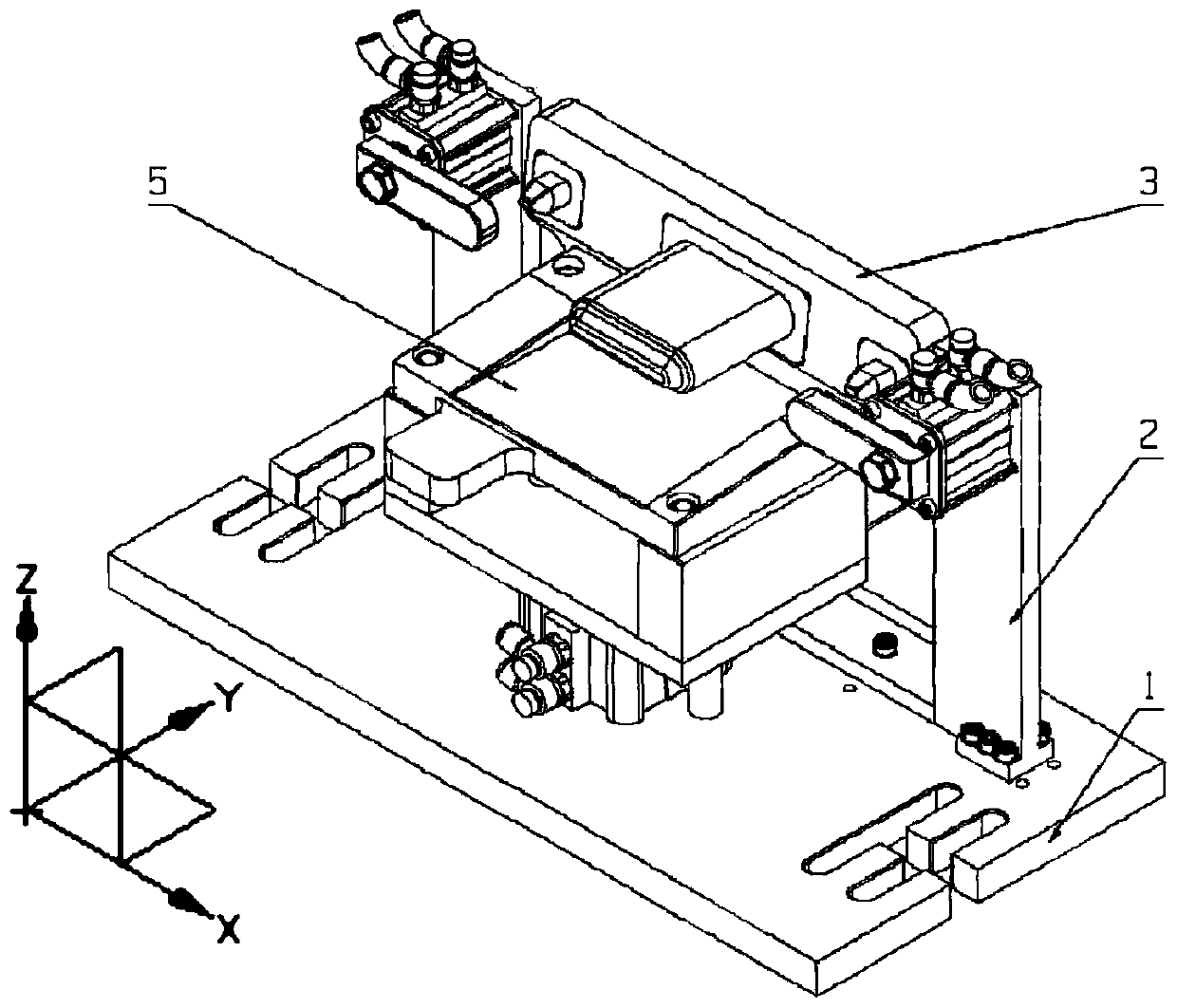

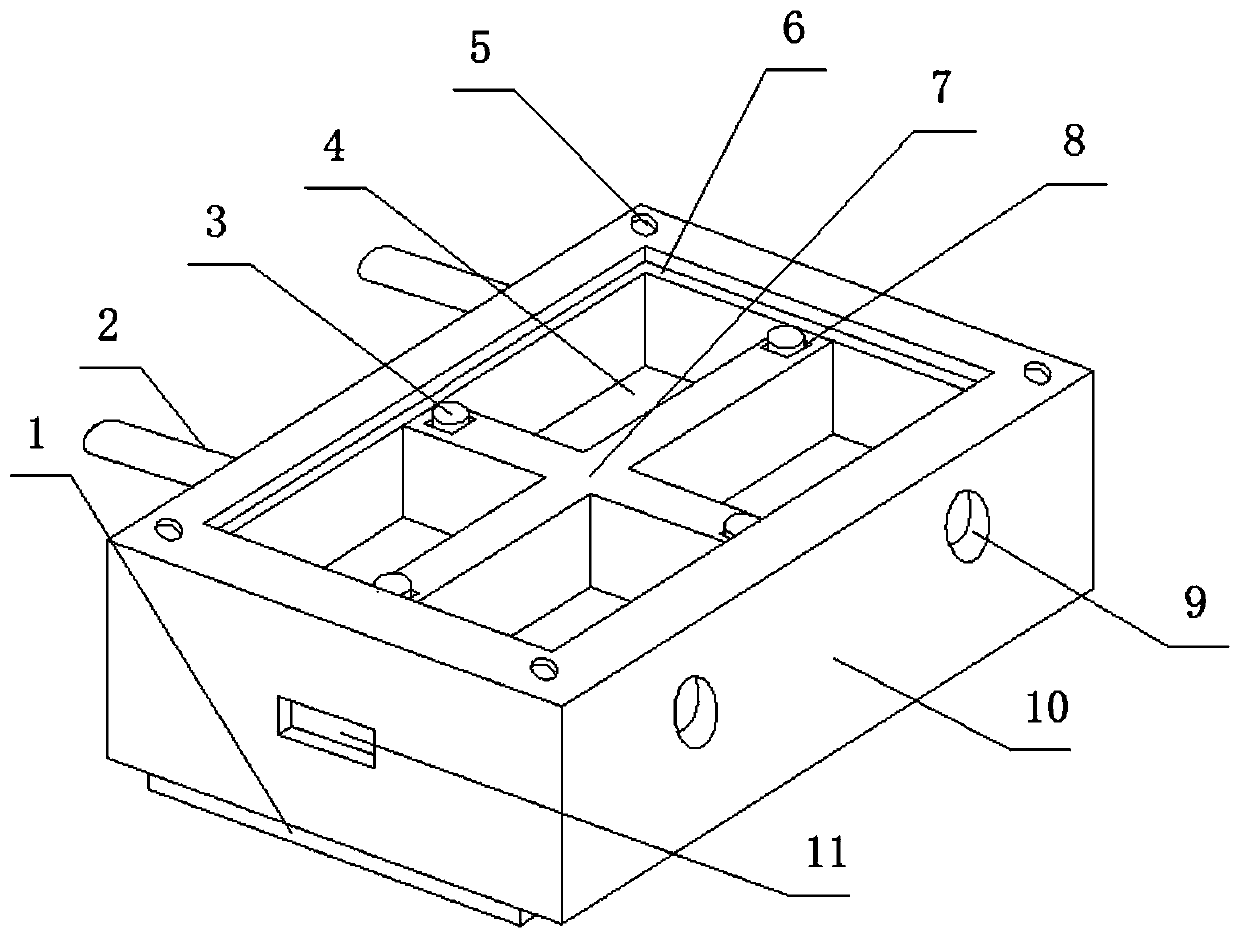

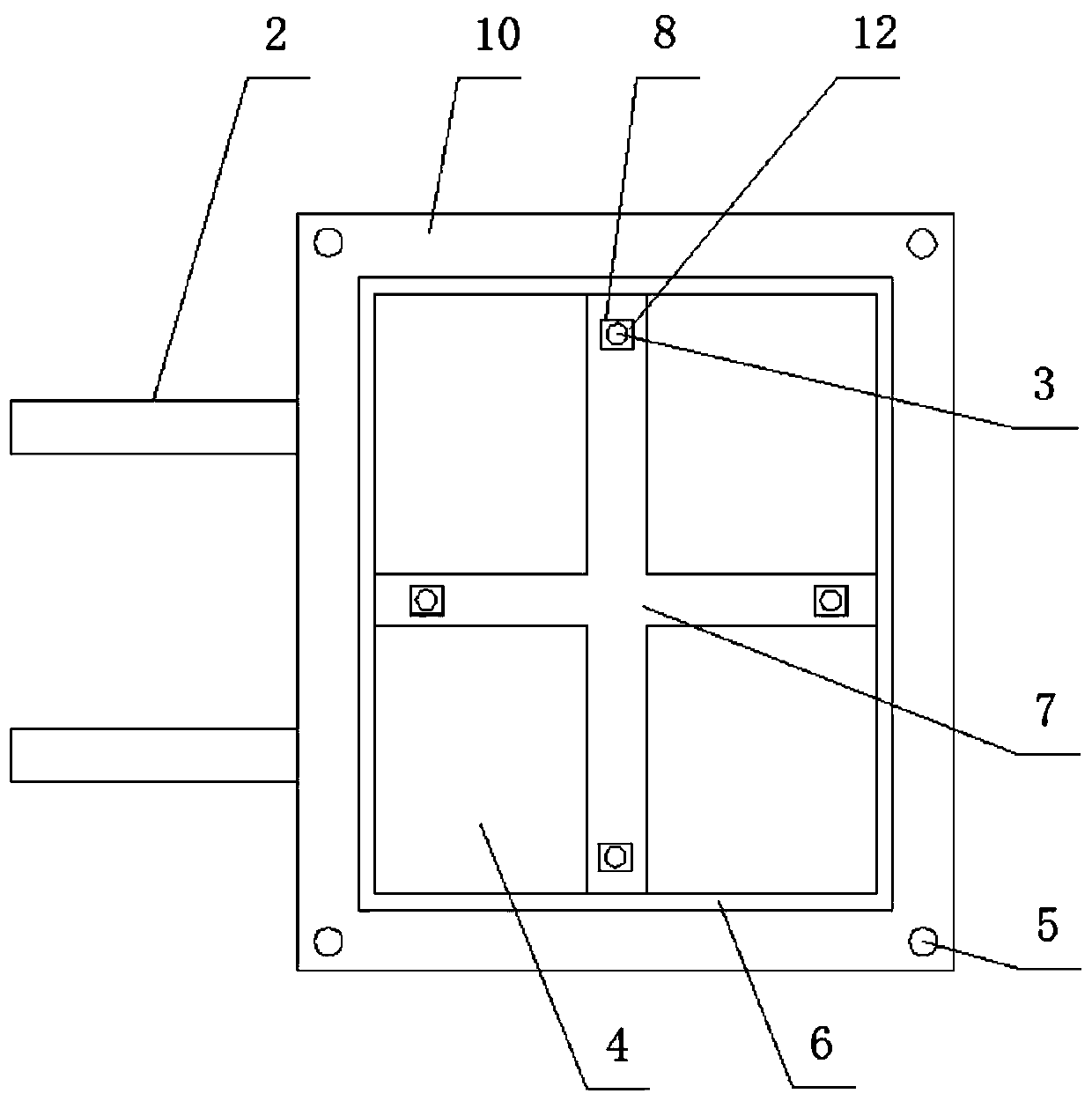

Positioning tool for valve body machining and positioning method thereof

PendingCN111922763AAvoid deformationEasy to operateWork clamping meansPositioning apparatusEngineeringMachining

The invention relates to a positioning tool for valve body machining and a positioning method thereof. A first positioning boss and a second positioning boss are pre-cast on the two sides of a valve body correspondingly, wherein the positioning tool comprises a tool bottom plate, a first positioning base, a second positioning base, a third positioning base and a fourth positioning base; the firstpositioning base, the second positioning base, the third positioning base and the fourth positioning base are installed on the tool bottom plate; an adjustable supporting column is installed on the first positioning base; a first fixed supporting platform is arranged on the second positioning base; the adjustable supporting column and the first fixed supporting platform are used for supporting thetwo first positioning bosses correspondingly; a floating supporting column is installed on the third positioning base; a second fixed supporting platform is installed on the fourth positioning base;and when the valve body is positioned, the floating supporting column and a positioning pin are used for being inserted into positioning inner groove holes in the bottom faces of the two second positioning bosses correspondingly. According to the positioning tool, the valve body is positioned through two fixed supports, one adjustable support and one floating support, operation is convenient, andthe positioning precision is high.

Owner:ZHEJIANG TOP CASTING MACHINERY TECH

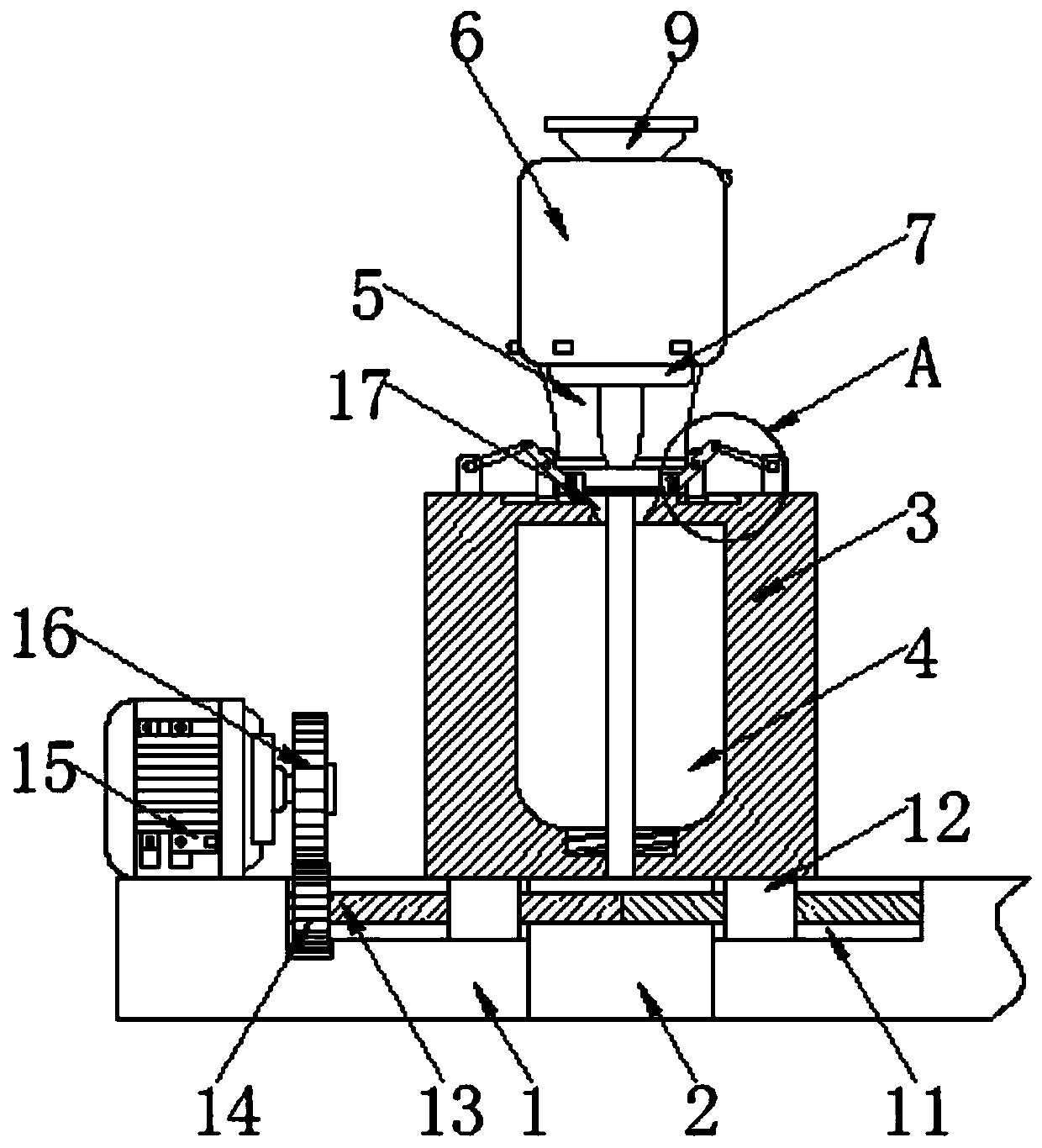

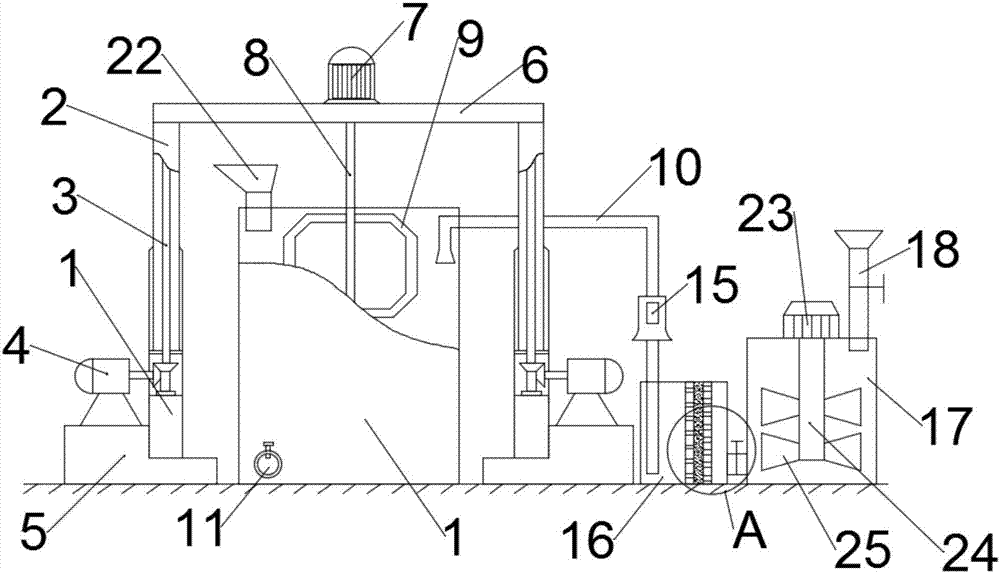

Electric lifting type chemical material purifying and mixing device

InactiveCN107126864AMeet the use requirementsAvoid unevennessTransportation and packagingRotary stirring mixersChemical solutionCompound (substance)

The invention discloses an electric lifting type chemical material purifying and mixing device. The electric lifting type chemical material purifying and mixing device comprises a stirring tank body, wherein an opening is formed in the top of the stirring tank body and the stirring tank body is arranged on an inner side bottom plate of a fixed supporting base; a supporting mounting block is arranged on each of the left and right sides of the fixed supporting base; vertical retractable outer barrels are fixedly arranged above the supporting mounting blocks; hoisting inner barrels are arranged above horizontal separation plates and barrels of the vertical retractable outer barrels sleeve the vertical retractable outer barrels; rotary screw rods are arranged at the central line positions in the barrels of the vertical retractable outer barrels; follow-up tapered gears are arranged below the horizontal separation plates and on rod bodies of the rotary screw rods; driving tapered gears are adaptively arranged on tooth surfaces of the follow-up tapered gears; a pipe body of an adding liquid pumping pipe is further provided with a liquid pump. By adopting the electric lifting type chemical material purifying and mixing device, stirring blades can be inserted into or released from a tank body inner cavity of the stirring tank body; stirring work of a chemical solution at different height positions in the tank body can be met and the whole stirring tank can be conveniently replaced.

Owner:侯小芳

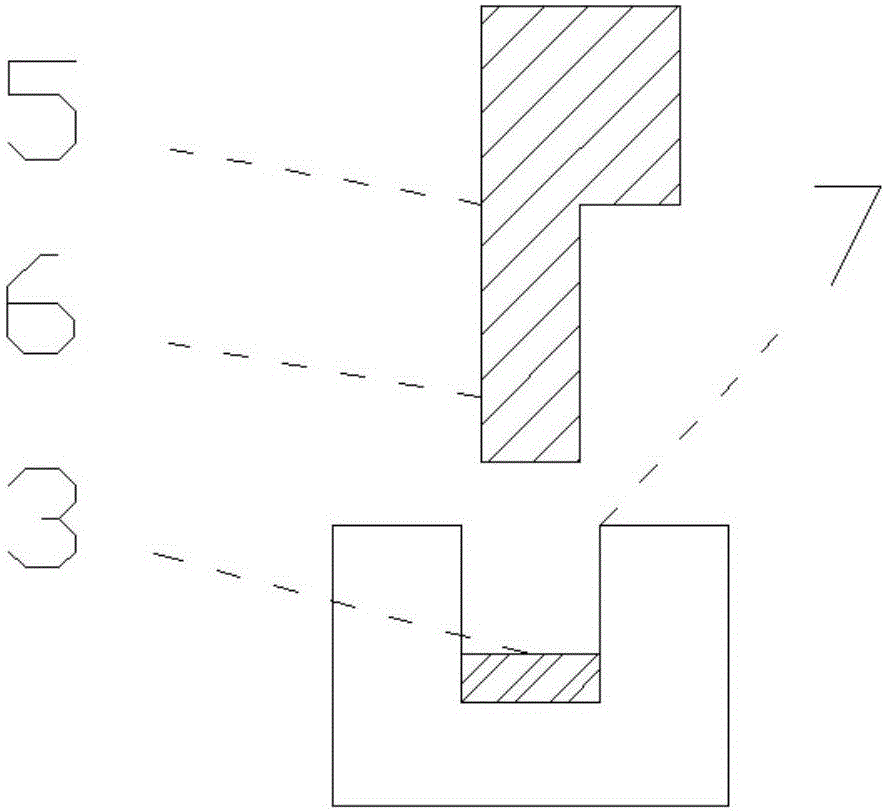

Bending machine pressing die, bending machine and die pressing method

The invention discloses a bending machine pressing die, a bending machine and a die pressing method, and belongs to the field of bending machine manufacturing. The bending machine pressing die comprises flat die pressing die bodies. The section of each flat die pressing die body is concave. Protrusions on the two sides of each flat die pressing die body are pressing die shoulders. A sunk part in the middle of each flat die pressing die body is a pressing die inner bottom. Each pressing die inner bottom is provided with a plurality of blind holes. Each blind hole is internally provided with a magnet of which the size is completely matched with that of the blind hole. The flat die pressing die bodies are composed of a plurality of independent pressing die sections; the position needing to be pressed and the area size of components needing to be pressed are detected in a disintegrated mode, and the length needing to be pressed of each section is calculated; and the multiple sections of flat die pressing die bodies of different lengths are manufactured according to the length needing to be pressed, the number of corresponding pressing times is disintegrated, and batch installation and pressing are conducted on the group number of the flat die pressing die bodies needed by pressing each time. The bending machine pressing die has the advantages of being simple in structure, easy to install and firm in installation, is high in pressing precision and good in pressing effect and can conduct pressing on specific positions.

Owner:安徽鑫威亚机械制造股份有限公司

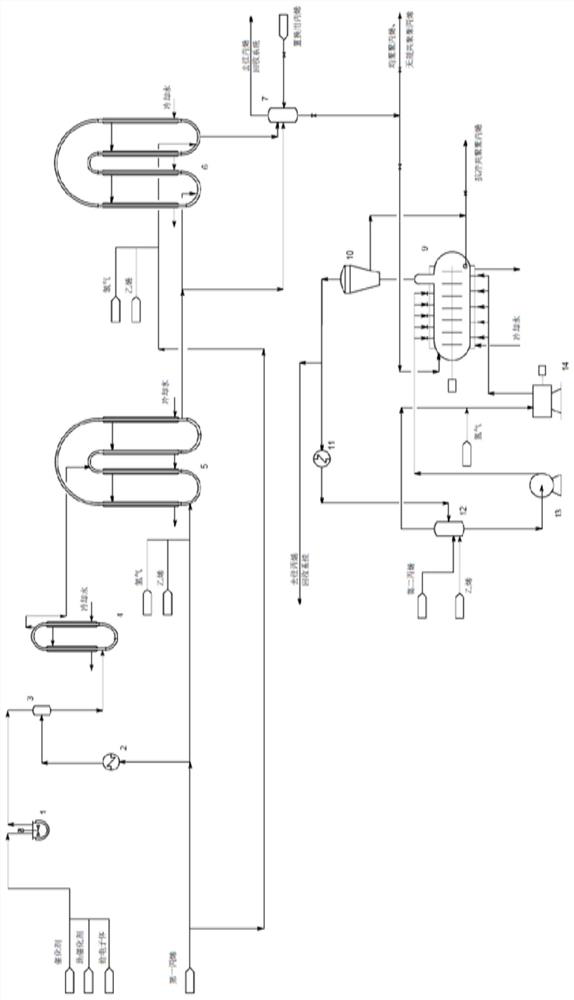

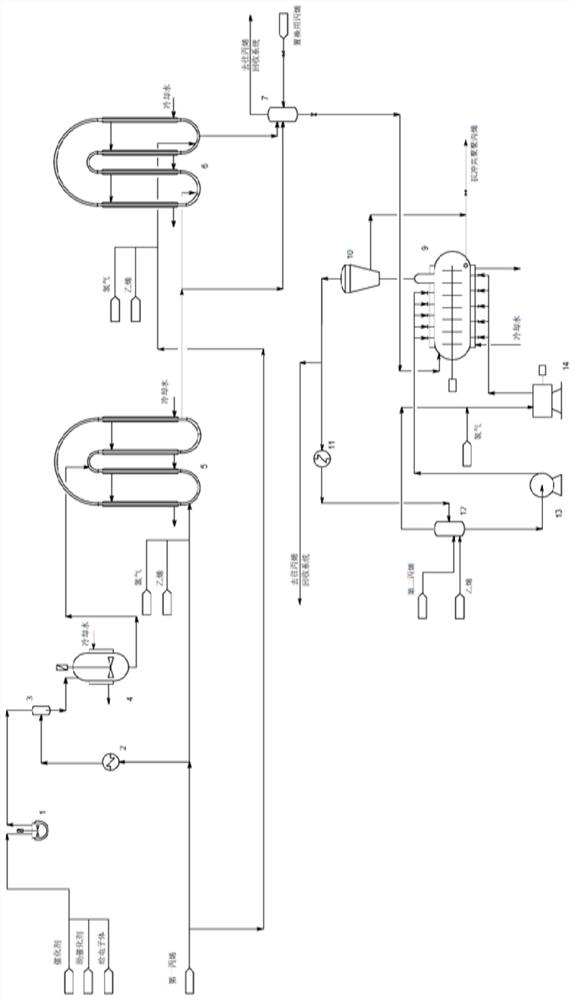

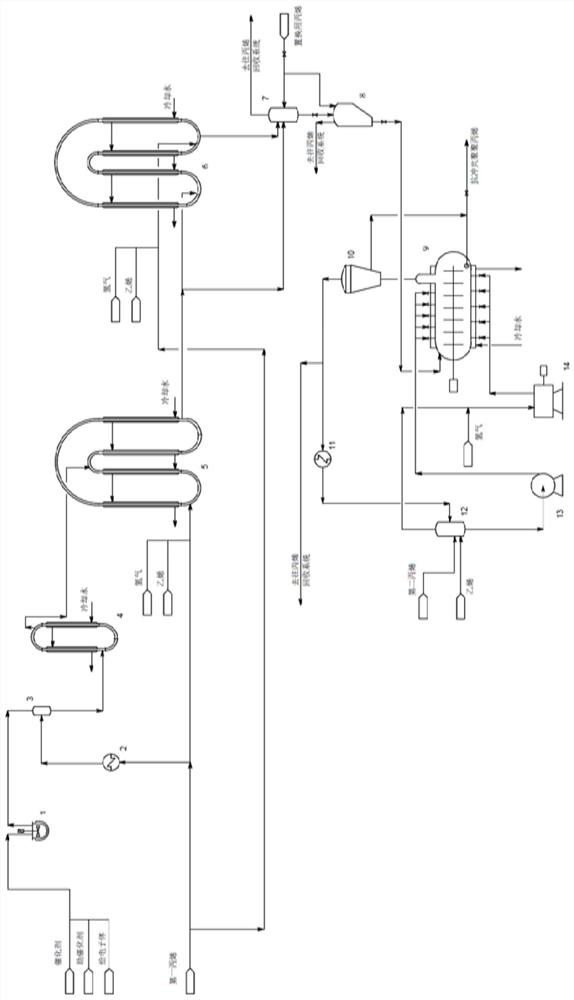

Preparation method of polypropylene

The invention relates to a preparation method of polypropylene. The method comprises the following steps: cooling first liquid-phase propylene, mixing the cooled first liquid-phase propylene with a polypropylene catalyst, and carrying out low-temperature prepolymerization reaction, feeding an obtained slurry containing the low-molecular-weight polypropylene prepolymer into a double-loop reactor, carrying out liquid-phase bulk slurry polymerization on the slurry and supplemented second liquid-phase propylene, hydrogen and ethylene monomers, and feeding part or all of polypropylene slurry flowing out of the first loop reactor into a second loop reactor, carrying out directflash evaporation on the polypropylene slurry flowing out of the second loop reactor to remove non-condensable gas and most of propylene monomers, and carrying out purification and granulationan obtained polypropylene intermediate to obtain the product; or carrying out copolymerization reaction on the polypropylene intermediate, and then carrying out powder purification and granulation to obtain the product. According to the preparation method disclosed by the invention, high-melt-index / high-rigidity and high-rubber-content impact-resistant co-polypropylene can be produced through flexible switching of devices, and meanwhile, high-isotacticity homo-polypropylene and random co-polypropylene can also be produced.

Owner:PETROCHINA CO LTD

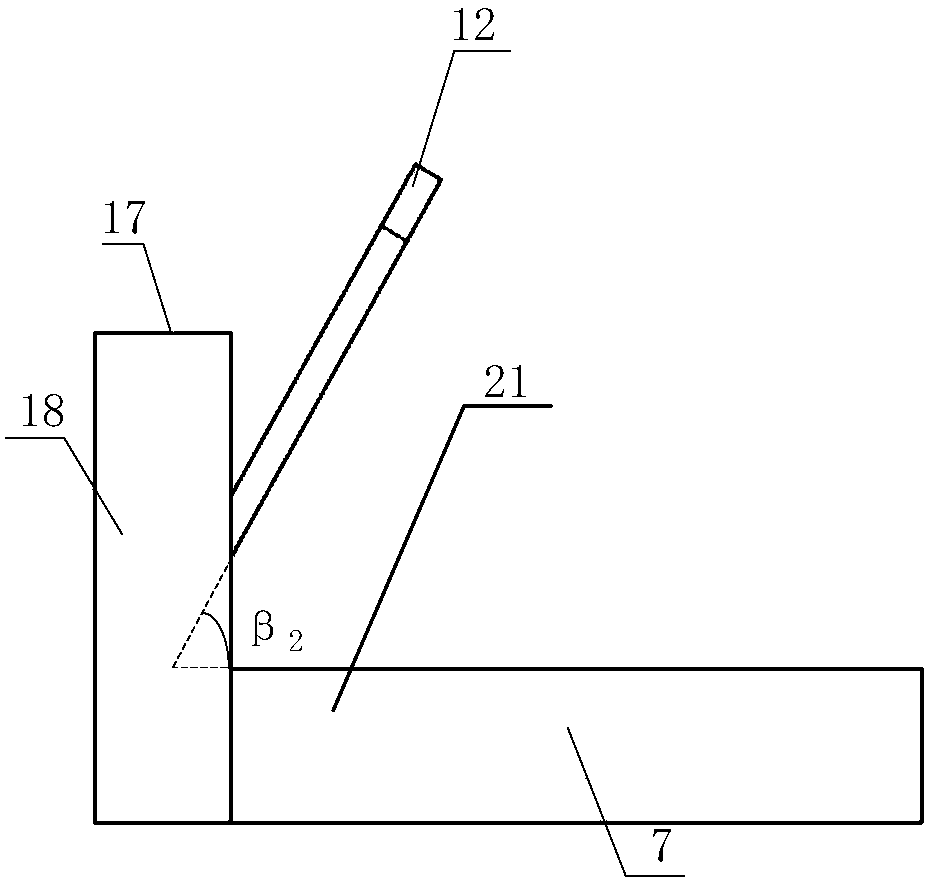

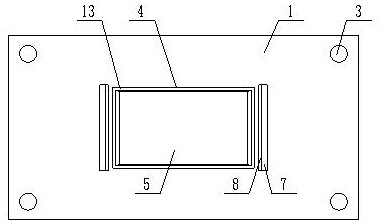

Clamp for measuring linearity of dovetail-shaped tenon of aeroengine blade

ActiveCN108981526ACompact structureEasy positioningAngles/taper measurementsLocking mechanismInstability

The invention discloses a clamp for measuring the linearity of a dovetail-shaped tenon of an aeroengine blade. An inclined positioning plate is fixedly installed via a support, a locking mechanism isfixedly installed on the inclined positioning plate, and a supporting mechanism is installed between the inclined positioning plate and a pedestal; and when the linearity of the tenon is measured, thesupporting mechanism supports the locking mechanism tightly, and the locking mechanism bears a force and clamps the tenon; an included angle between the inclined positioning plate of the clamp and the horizontal plane equals that between the metering side and the bottom side of the tenon, and it is ensured that the metering side can be arranged horizontally when the tenon is in a clamp; the uppermetering side of the tenon is positioned locally, the lower metering side is positioned wholly, and the problem of positioning instability in the detection process is avoided; and the meter is pushedin the metering side of the tenon to implement detection, uncertainty of three-point contact detection is eliminated, and the detection quality is improved. The measuring clamp is compact in structure, blade positioning operation is simple, rapid and safe, maintenance is simple, the manufacturing cost of the clamp is reduced, and the component processing cost is reduced.

Owner:AECC AVIATION POWER CO LTD

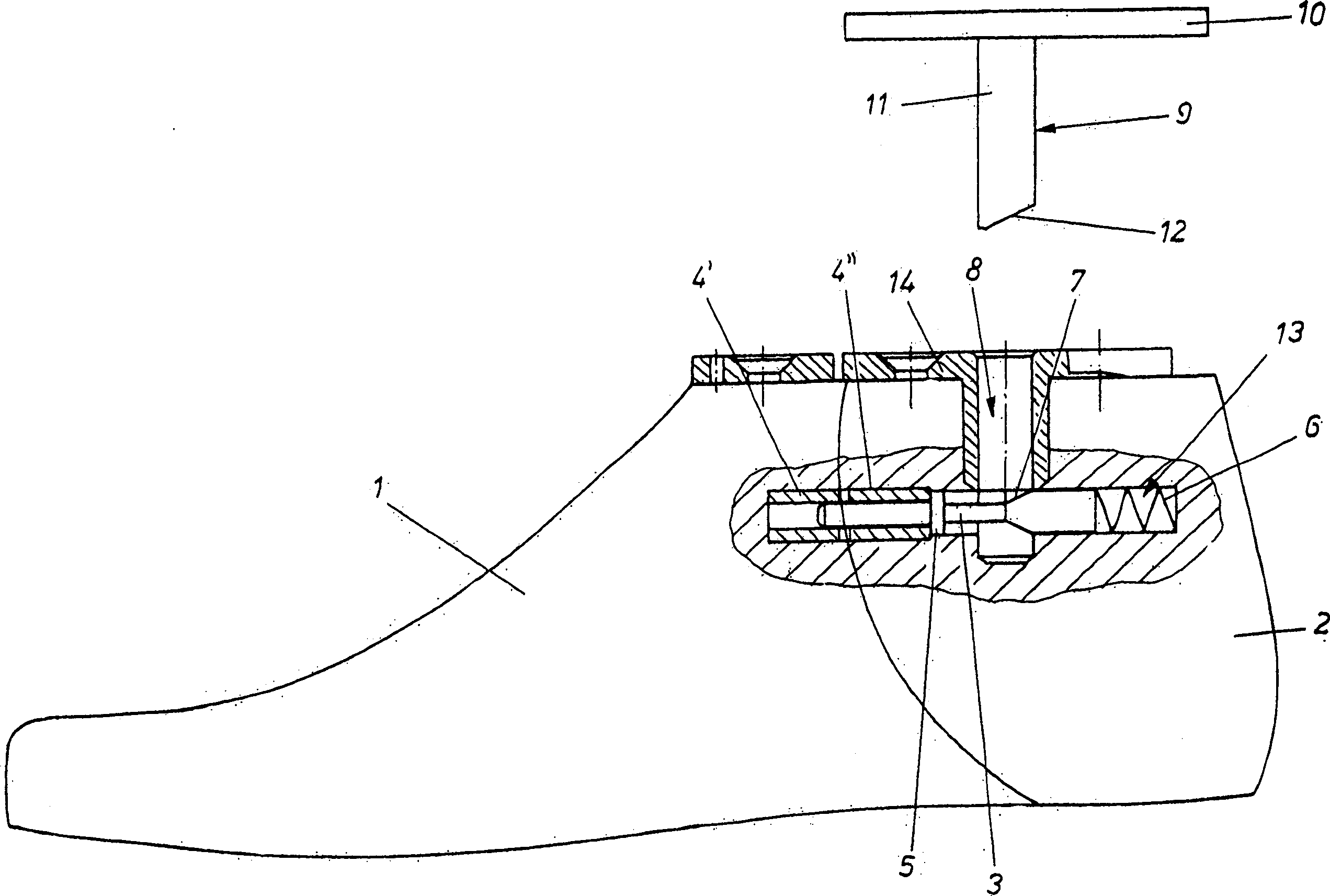

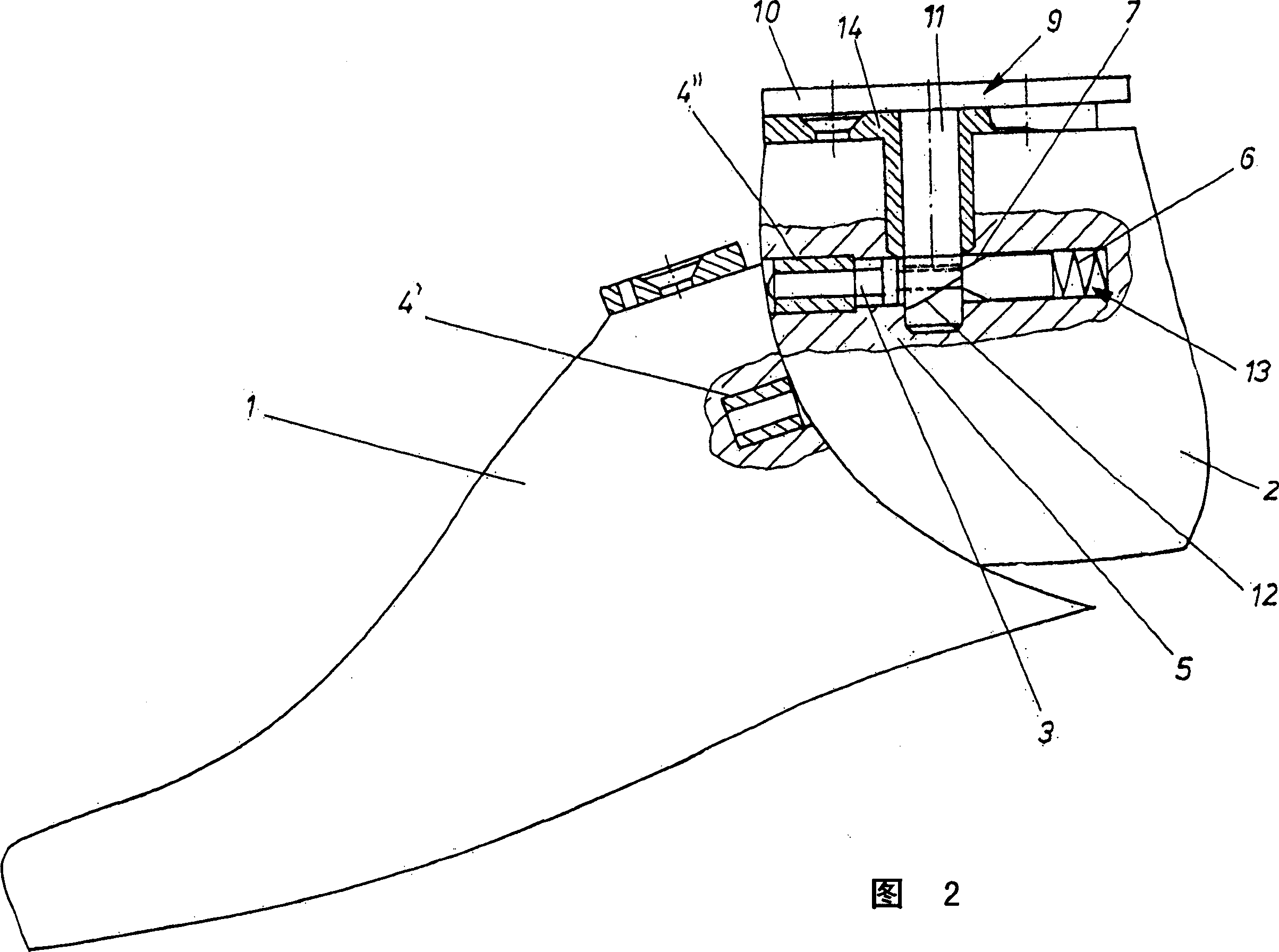

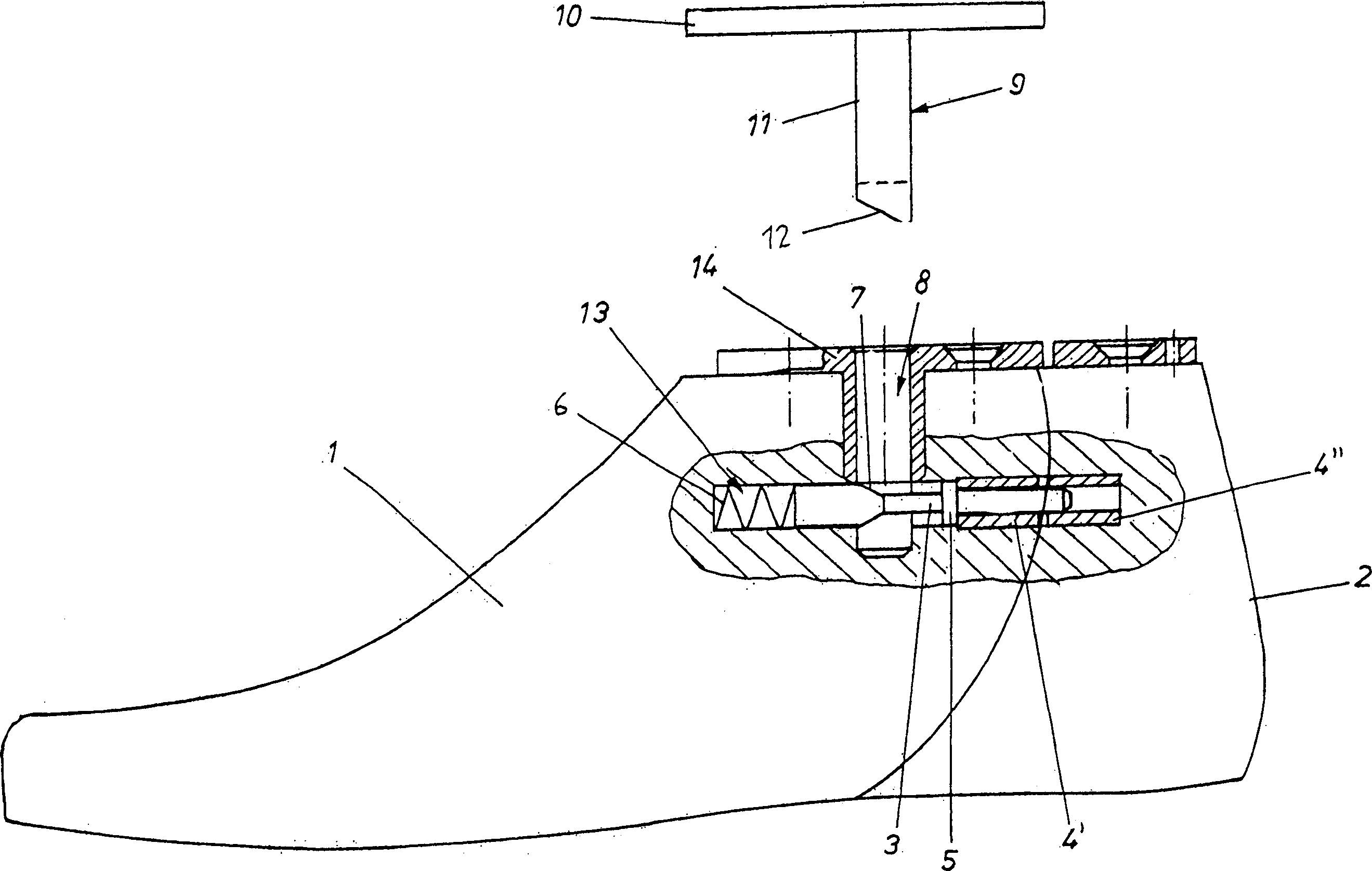

Shoe tree of multi-component

Owner:FAGUS GRECON GRETEN

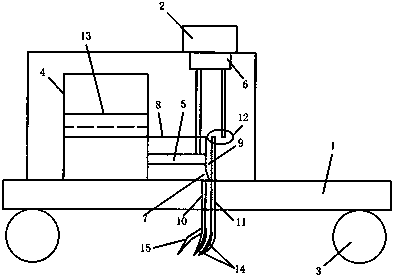

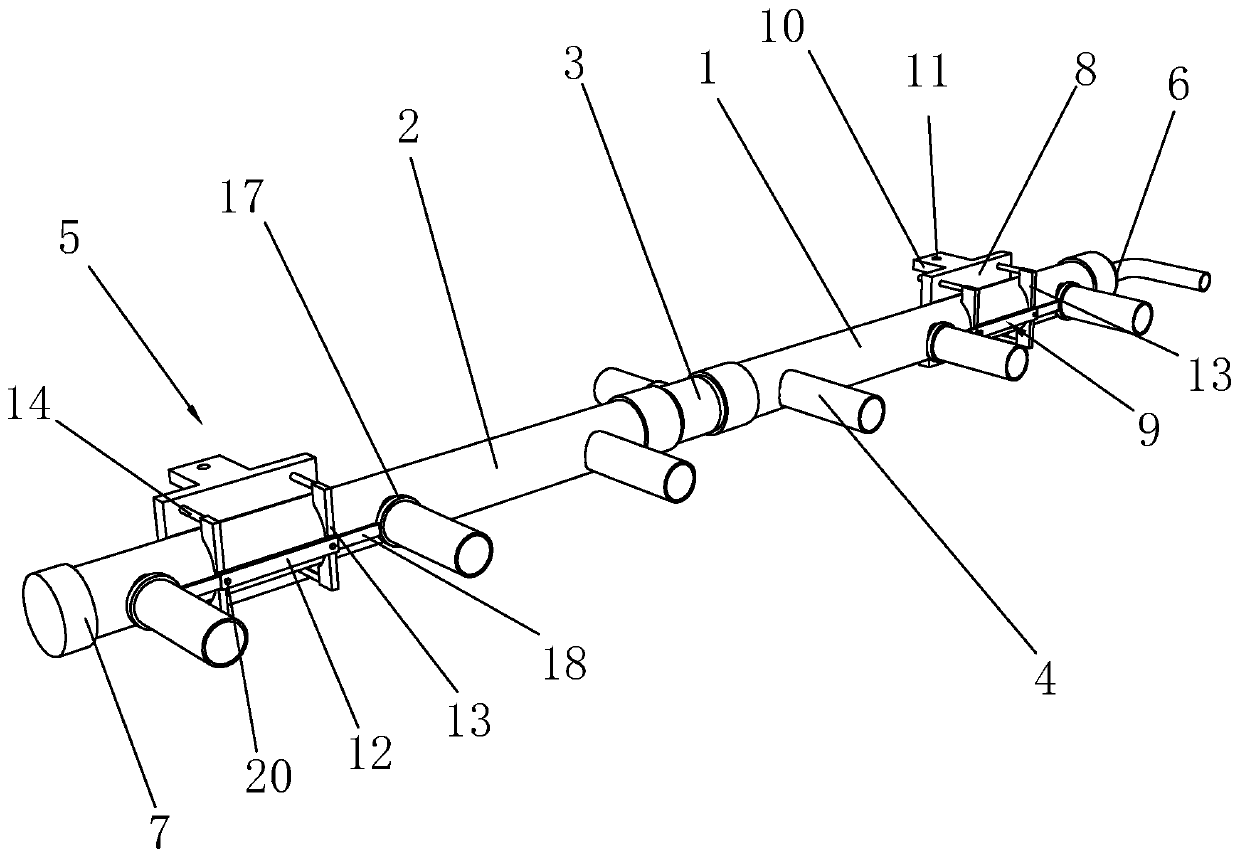

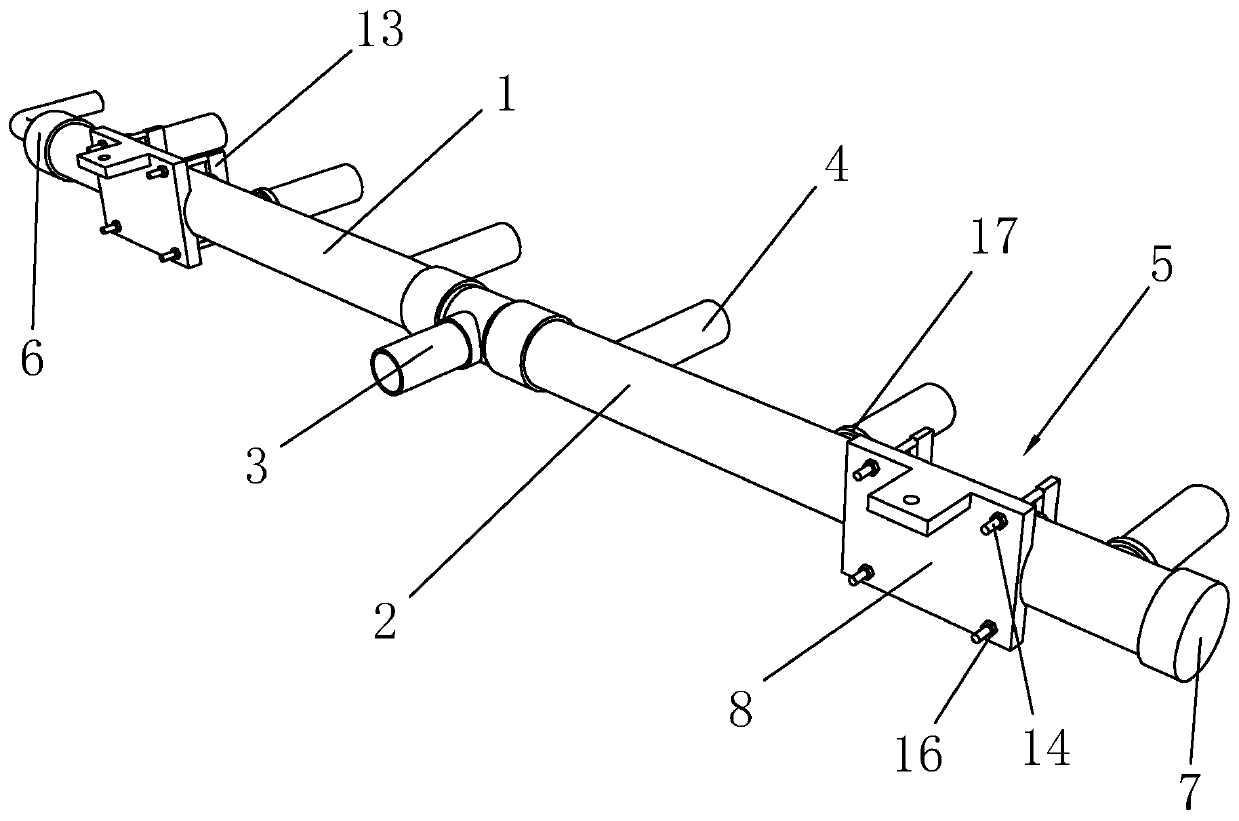

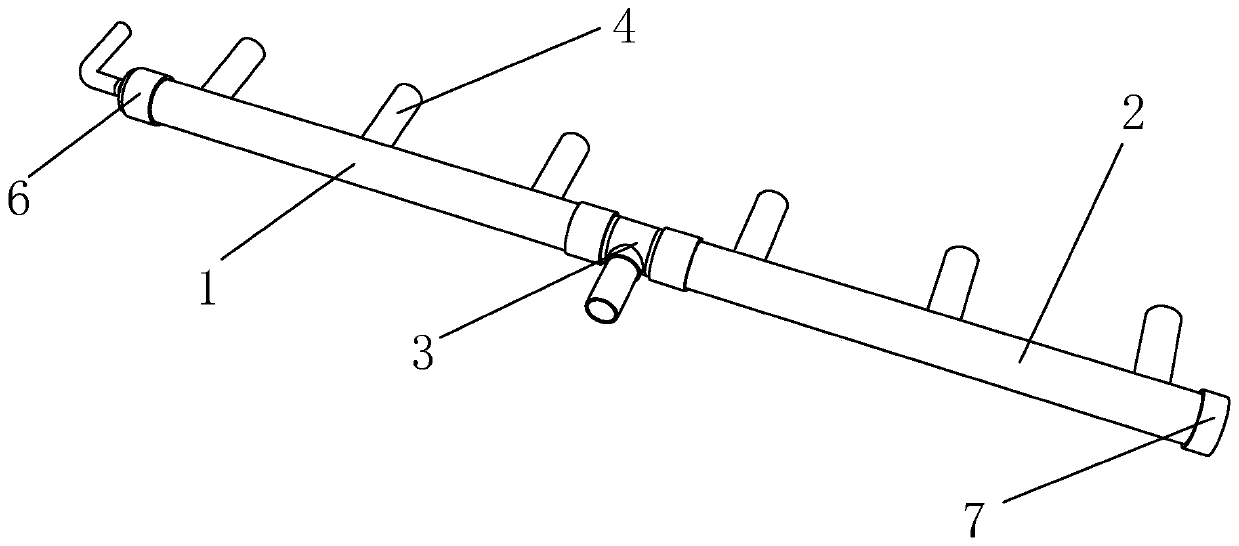

Improved rice transplanter

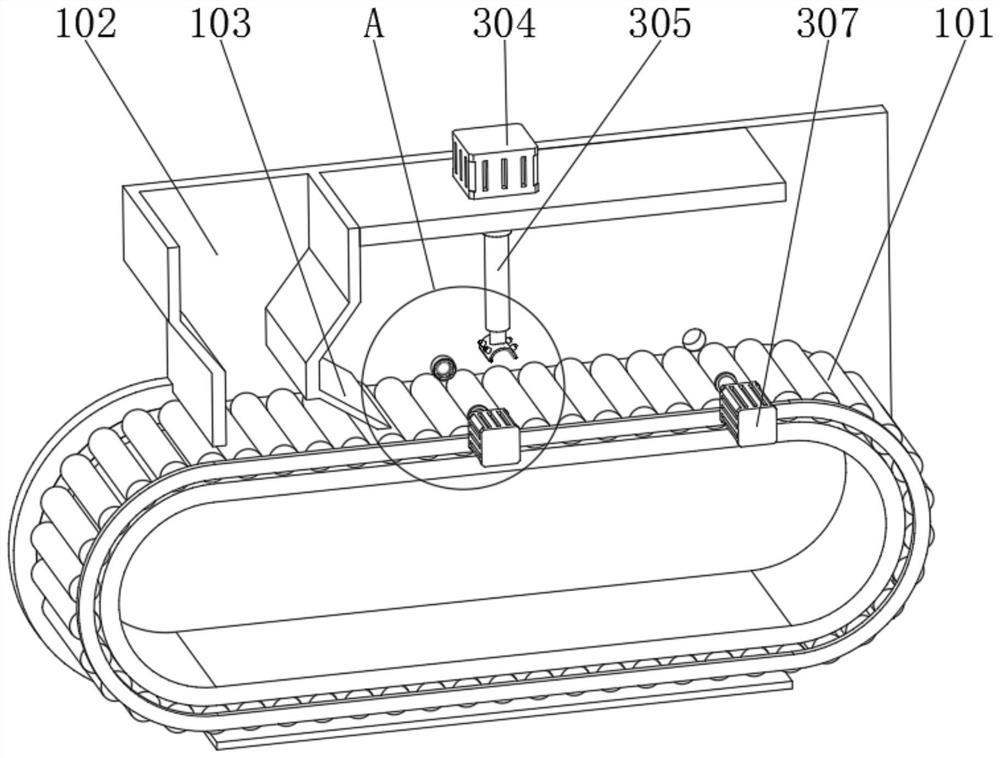

InactiveCN109220102AGuaranteed insertionHigh degree of automationTransplantingThroatAgricultural engineering

The invention discloses an improved rice transplanter. The improved rice transplanter includes a frame and an engine disposed on the frame. The lower end of the frame is provided with traveling wheelsdriven by the engine, and the frame is provided with a seedling box, a branching device and a rice transplanter. The branching device is arranged at the outlet of the seedling box, and the branchingdevice is provided with a branching lever, the branching lever is connected to a speed governor, the speed governor is connected with the engine, and a throat is arranged at the outlet of the branching device. The structure of the transplanter includes a fixed clamp and a movable clamp, and the movable clamp is connected to the speed governor through a cam. The improved rice transplanter providedby the invention can solve the deficiencies of the prior art, and has the advantages of simple structure, high insertion efficiency and neat line spacing.

Owner:XIANGTAN COUNTY FUMIN SMALL SIZED TRANSPLANTER MFG PLANT

Power equipment box fixing mechanism

ActiveCN111853504AEasy to connectReduce complexitySubstation/switching arrangement detailsMachine supportsElectric power equipmentEngineering

The invention discloses a power equipment box fixing mechanism. The power equipment box fixing mechanism comprises a power equipment box and a matched mounting plate, wherein support legs are arrangedon the bottom surface of the power equipment box; the four support legs are positioned at the four corners of the bottom surface of the power equipment box respectively; an opening is formed in the bottom surface of the power equipment box; the opening is a rectangular opening; the opening is in communication with the inner cavity of the power equipment box; a plug body is arranged in the opening; the plug body is matched with the opening in shape and size; the upper surface of the plug body is fixedly connected with a baffle plate; and a pulling ring is fixedly arranged on the upper surfaceof the baffle plate. The power equipment box fixing mechanism has the beneficial effects of simple structure and rapidness and convenience in mounting.

Owner:大唐万宁天然气发电有限责任公司

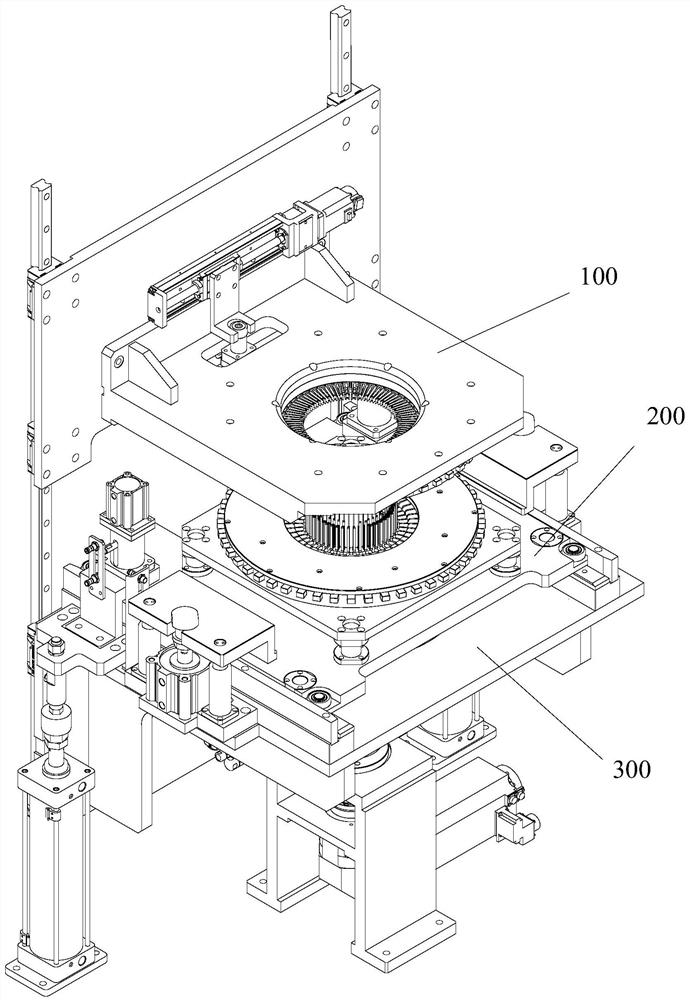

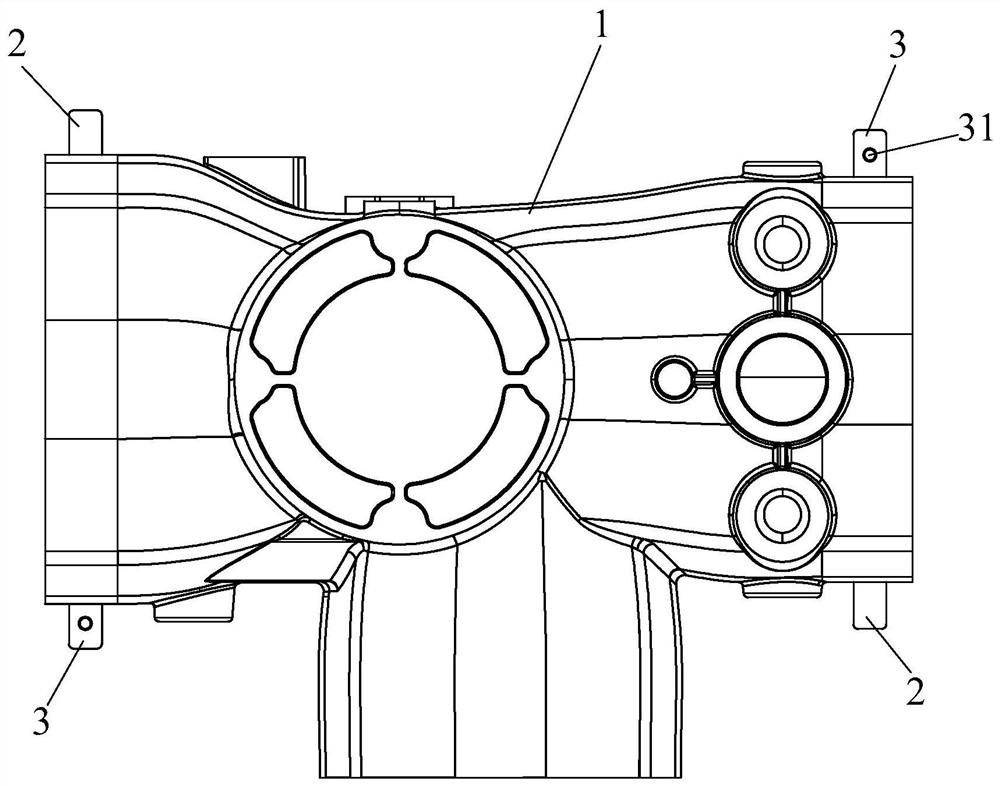

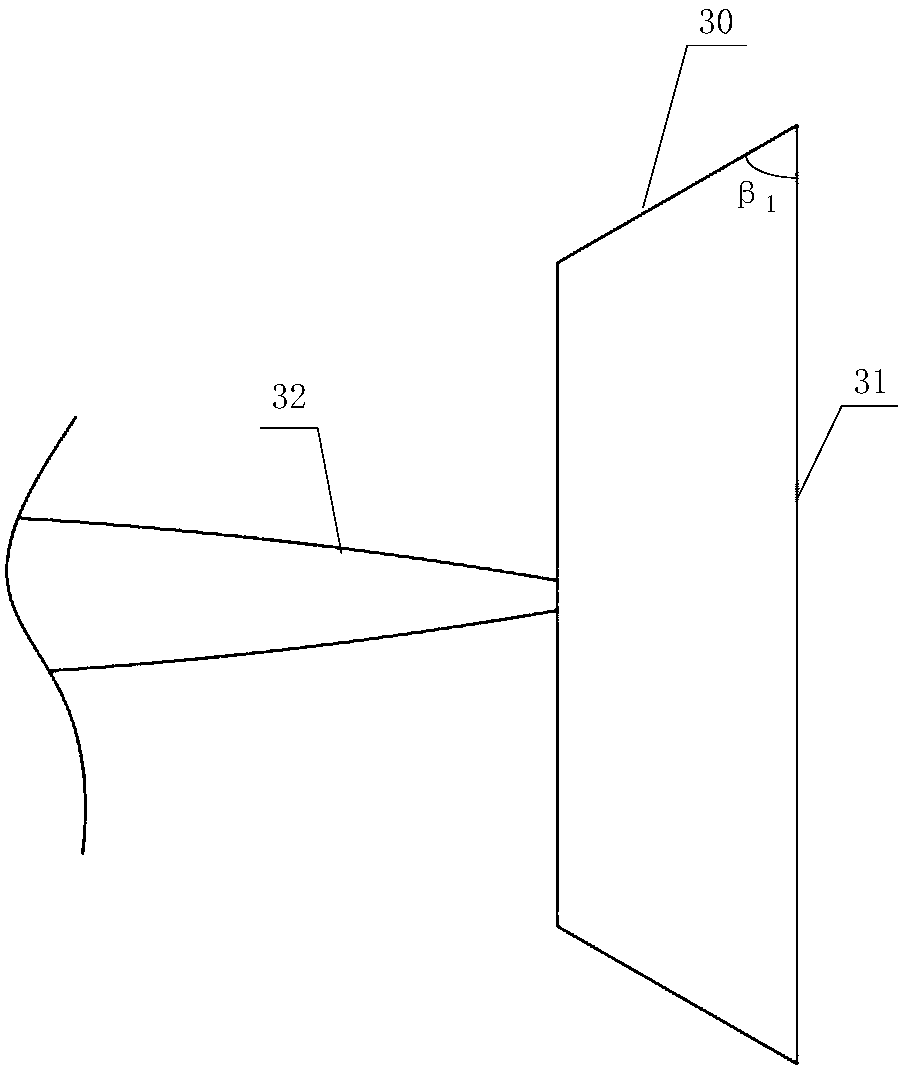

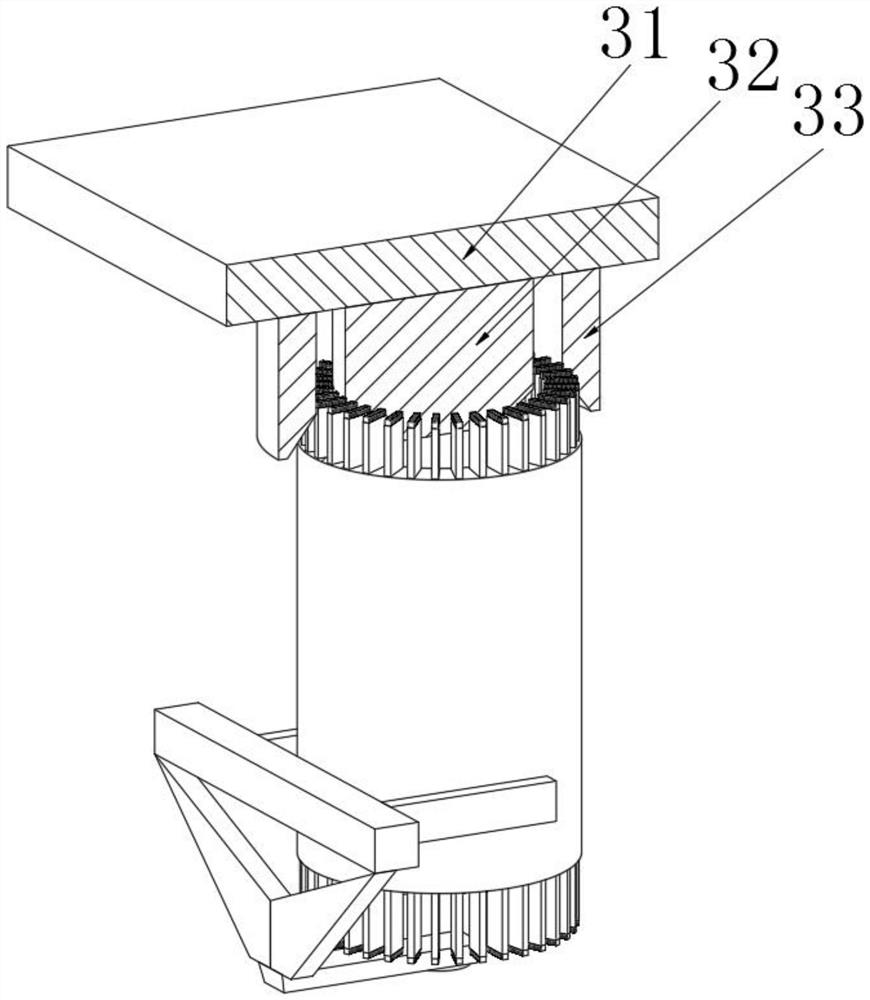

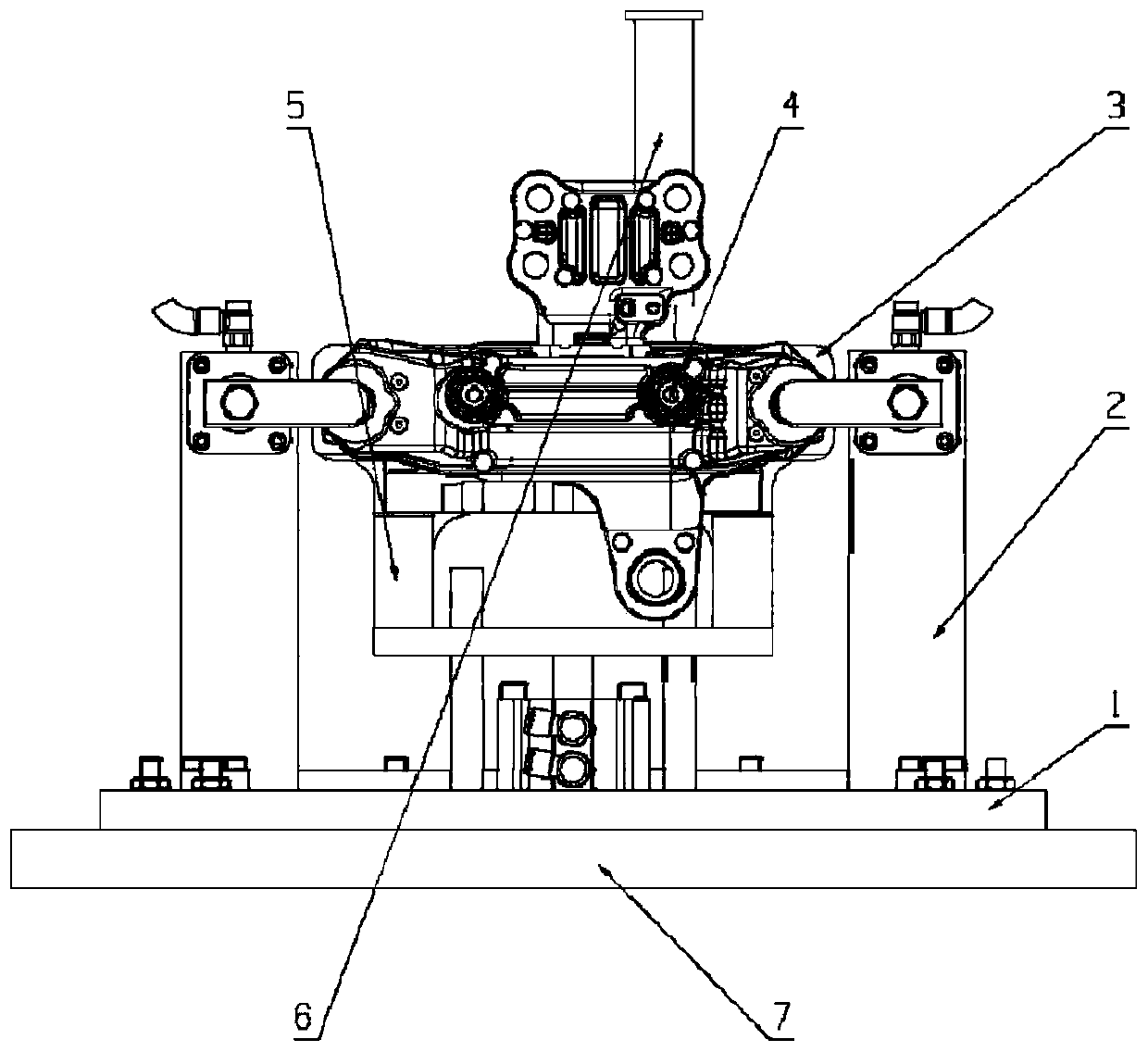

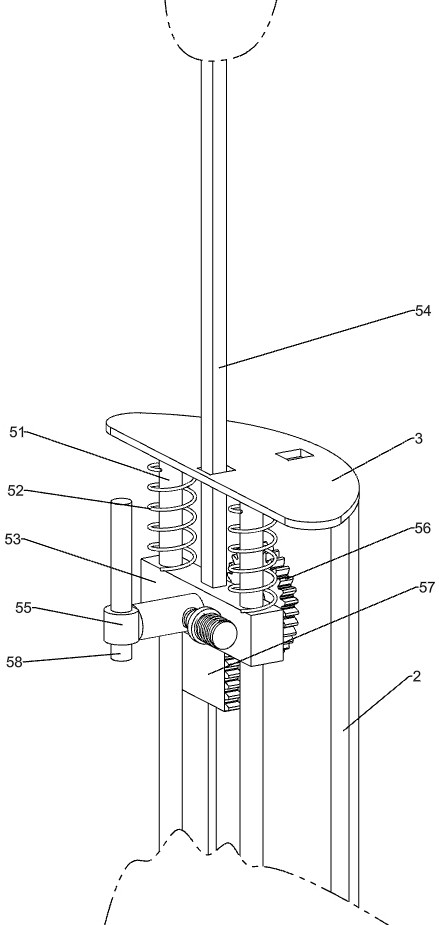

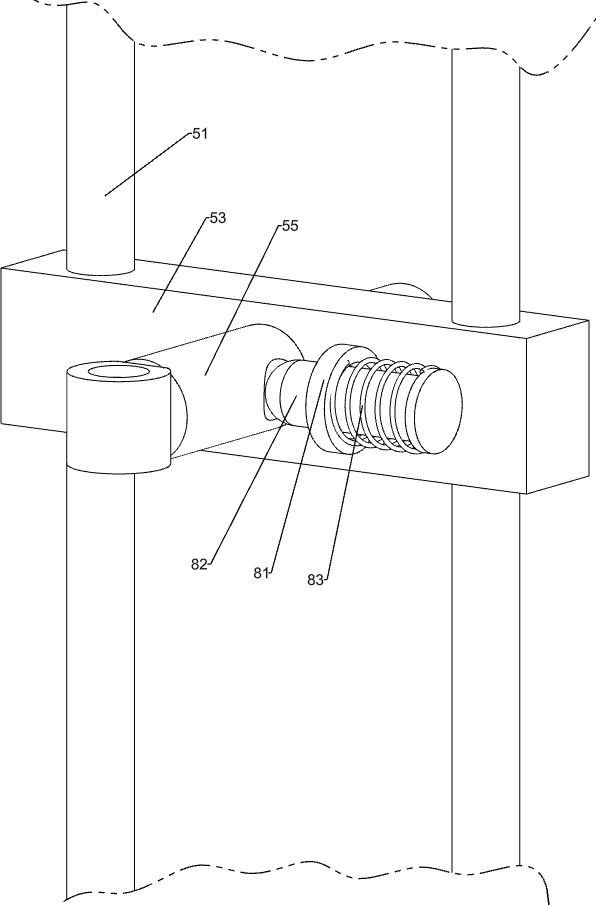

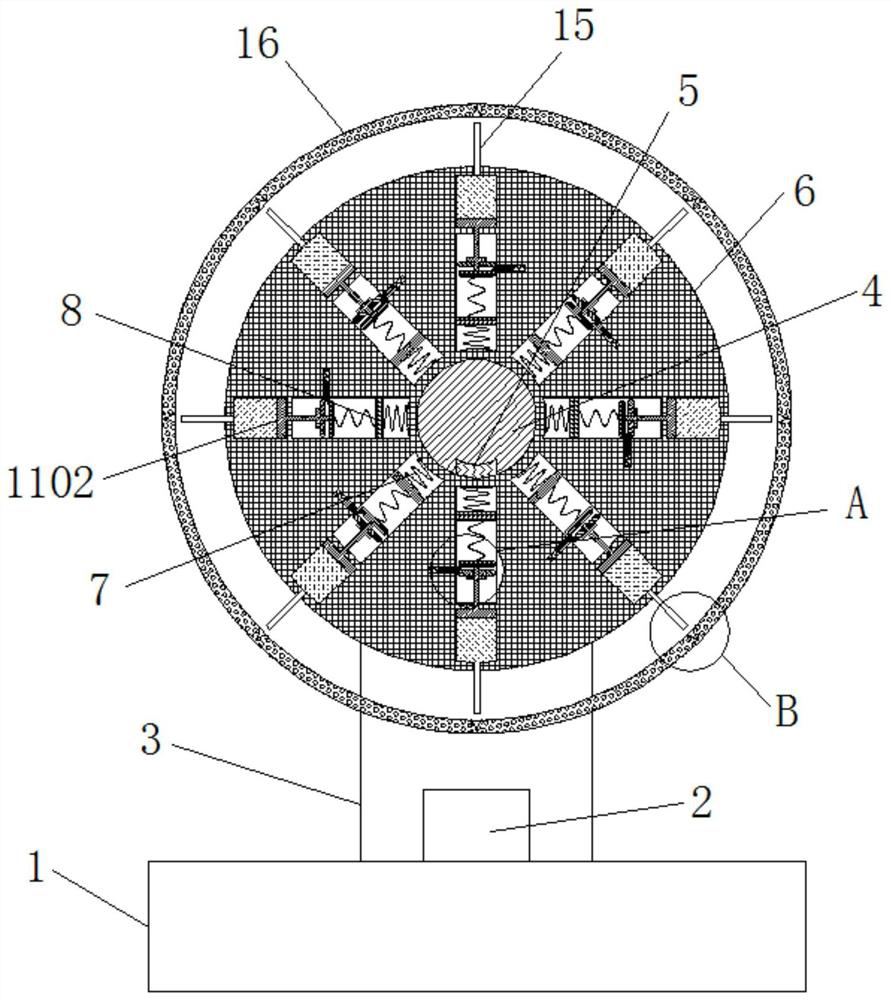

Flat wire stator end twisting device and method thereof

ActiveCN114260388AAuto-adjustGuaranteed insertionShaping toolsElectric machinesStructural engineeringControl theory

The invention discloses a flat wire stator end twisting device and a method thereof.The flat wire stator end twisting device comprises a rack, the rack is provided with a radial deflection adjusting mechanism, a taking mechanism and a circumferential deflection adjusting mechanism, the rack comprises a base and a side plate, the side plate is vertically installed on the base, the top end of the base is fixedly connected with supporting legs, and the supporting legs are fixedly connected with the side plate. According to the flat wire stator end head twisting device and method, the radial deflection adjusting mechanism is arranged, the radial angle of a flat wire is limited and corrected through the inner ring shaping plate and the outer ring shaping plate, automatic correction of the flat wire bent in the radial direction in a stator is achieved, the working efficiency is improved, and the working efficiency is improved. According to the utility model, the circumferential deflection adjusting mechanism is matched to automatically align the circumferentially bent flat wires in the stator, so that each flat wire can be inserted into the head twisting die, the accuracy of wire insertion is ensured, the qualified rate of head twisting is improved, the manpower is saved, and the production efficiency is improved.

Owner:ZHEJIANG ZHONGCHE SHANGCHI ELECTRIC CO LTD

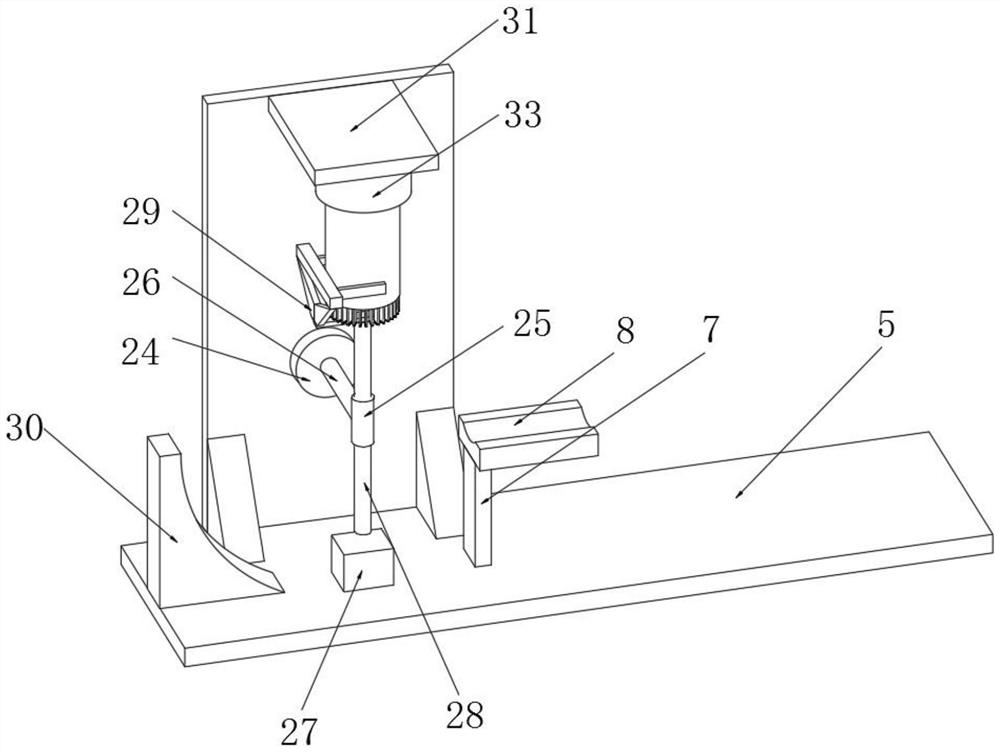

Servo motor shaft assembling equipment and method

InactiveCN111817510AGuaranteed insertionManufacturing stator/rotor bodiesCentering/balancing rotorsControl engineeringElectric machinery

The invention relates to the field of motor assembly, in particular to servo motor shaft assembly equipment, which comprises a bottom plate, a shaft feeding device, a lubricating device, a shaft inserting device, a first carrying device and a second carrying device which are mounted on the bottom plate, wherein the shaft inserting device comprises a shaft arranging mechanism, an outer shell feeding mechanism, a carrying mechanism, a double-station assembling mechanism and a shaft pressing mechanism; the double-station assembling mechanism comprises an assembling frame and a first assembling assembly; a left positioning hole and a right positioning hole are formed in a jig, and the first positioning rod is located under the left positioning hole; and the second positioning rod is located under the right positioning hole. According to the servo motor shaft assembling equipment and the method, the through hole in the shell is preferentially positioned, the outer shell is immediately fixedafter positioning is completed, thereby guaranteeing that the shaft can be inserted into the through hole.

Owner:王加县

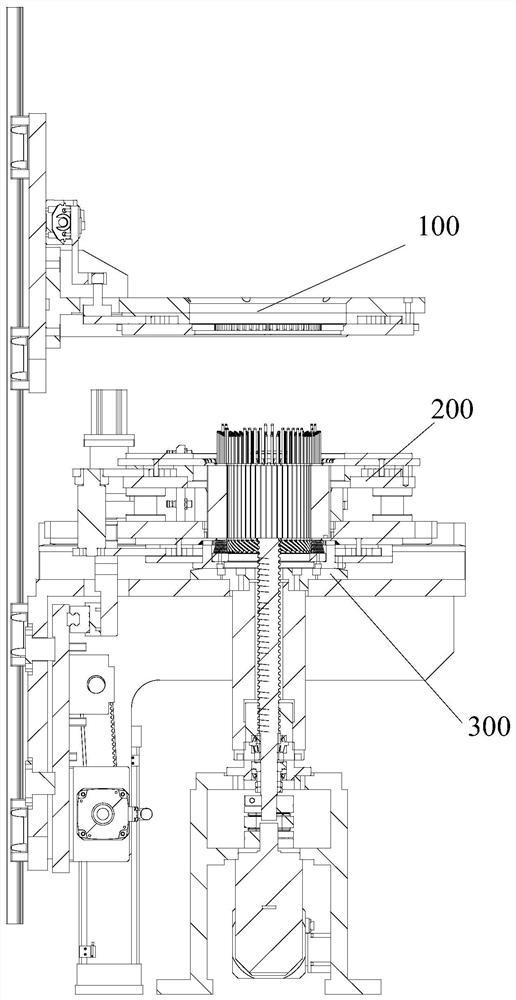

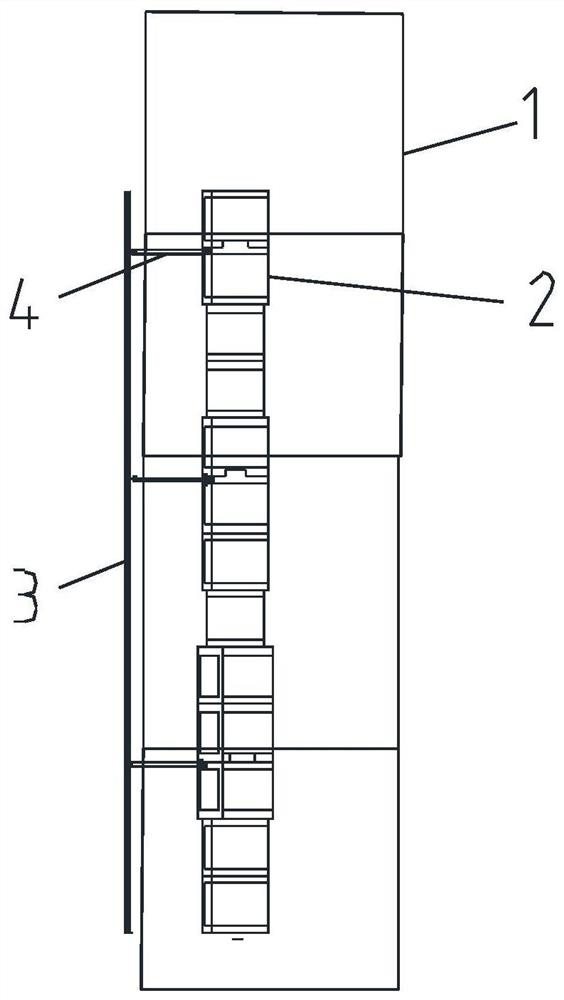

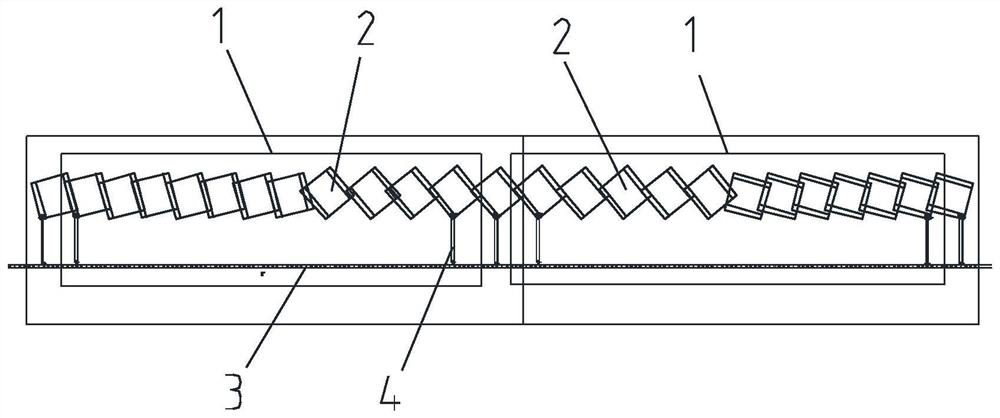

Assembled resin module wall structure

PendingCN114809511AEasy to assembleFirmly assembledCovering/liningsWallsEngineeringMechanical engineering

The invention discloses an assembled resin module wall body structure which comprises module wall body units (1), a plurality of module wall body units are spliced to form a resin module wall body, and each module wall body unit is fixedly installed on a building component (3) through a plurality of sets of pull rod assemblies (4). Each modular wall body unit is formed by sequentially splicing a plurality of resin modules (2) in the transverse direction and the vertical direction, connecting protruding blocks (21) or connecting grooves (22) are formed in the resin modules, and the connecting protruding blocks and the connecting grooves are connected in a matched and inserted mode, so that every two adjacent modular wall body units are spliced and assembled through the resin modules. According to the resin module wall, the module wall units are assembled in a blocking mode to form the resin module wall, so that the requirements of high-precision prefabrication in a factory, convenient transportation and convenient on-site installation are met, and resin decoration models such as the resin module walls of various forms and sizes can be formed through assembly.

Owner:中建八局总承包建设有限公司

Heat exchanger header air gathering pipe assembly and manufacturing method thereof

PendingCN111482779AEasy to disassembleFlexible and reliable connectionResistance electrode holdersWelding/soldering/cutting articlesPipe weldingStructural engineering

The invention discloses a heat exchanger header air gathering pipe assembly. A stainless steel connecting pipe and stable frames are included. The stainless steel connecting pipe comprises a first stainless steel connecting pipe body and a second stainless steel connecting pipe body which are each provided with at least two steel branch pipes and the corresponding stable frame. A manufacturing method of the heat exchanger header air gathering pipe assembly comprises the following steps that firstly, stainless steel connecting pipe and steel branch pipe preparing is conducted; secondly, stainless steel connecting pipe and steel branch pipe welding work is conducted; and thirdly, air gathering pipe assembly assembling is conducted. According to the heat exchanger header air gathering pipe assembly and the manufacturing method thereof, the stainless steel connecting pipe is divided into two connecting pipe bodies, and when one connecting pipe body goes wrong, only the connecting pipe bodywith the fault needs to be replaced; and the design of the stable frames is adopted, and actual installation of the air gathering pipe assembly can be facilitated. A welding device is adopted in theheat exchanger header air gathering pipe assembly, electric resistance welding work between the stainless steel connecting pipe and the steel branch pipes is achieved, simultaneous welding work is conducted between the multiple steel branch pipes and the stainless steel connecting pipe at the same time, and the electric resistance welding rate and quality are effectively improved.

Owner:绍兴科辉电器有限公司

Hydraulic suspension pre-pressing liquid filling tool

PendingCN110529543ASimple structureEasy to operateSpringsShock absorbersMechanical engineeringEngineering

The invention discloses a hydraulic suspension pre-pressing liquid filling tool which comprises a sliding seat which is connected to a liquid filling platform in a position adjustable manner; two hydraulic suspension clamping mechanisms which are symmetrically fixed on the sliding seat and are used for applying pressing force to the hydraulic suspension; a hydraulic suspension supporting mechanismwhich is fixedly arranged on the sliding seat, is positioned between the two hydraulic suspension clamping mechanisms and is used for supporting the hydraulic suspension; and a pre-pressing fixing assembly which is fixedly installed on the hydraulic suspension supporting mechanism, is provided with a shaping protruding part which is matched with a leather cup of the hydraulic suspension in shapeand prevents the leather cup of the hydraulic suspension from deforming in the liquid filling process, and is matched with the two hydraulic suspension clamping mechanisms to clamp and fix the hydraulic suspension. The hydraulic suspension pre-pressing liquid filling tool has the advantages of being simple in structure, reliable in work, high in universality, easy to operate, low in manufacturingcost and the like, and the consistency of the liquid filling amount can be effectively guaranteed.

Owner:SOUTH CHINA UNIV OF TECH +1

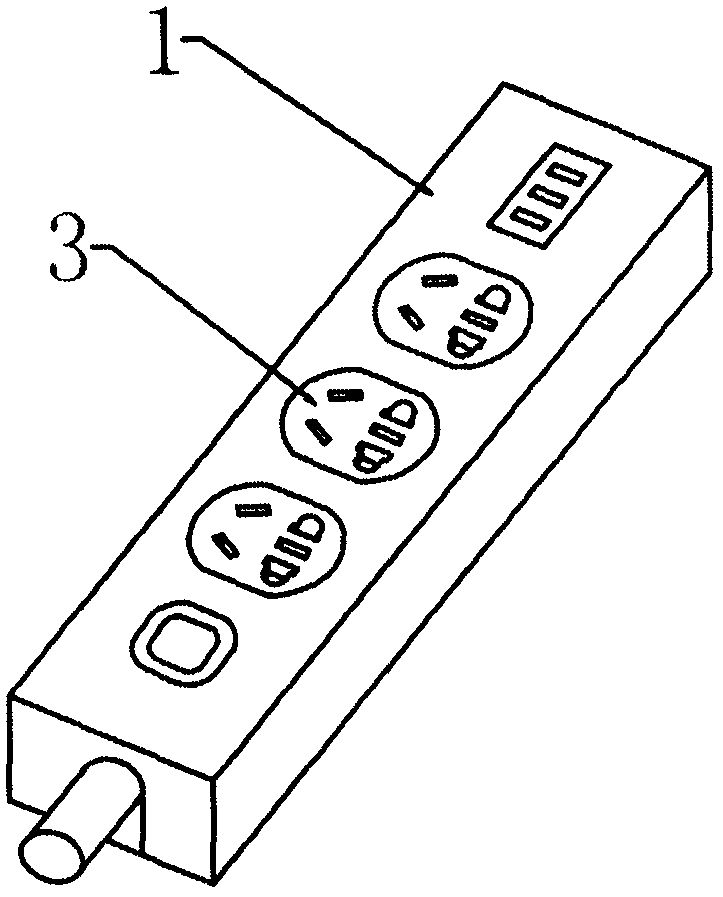

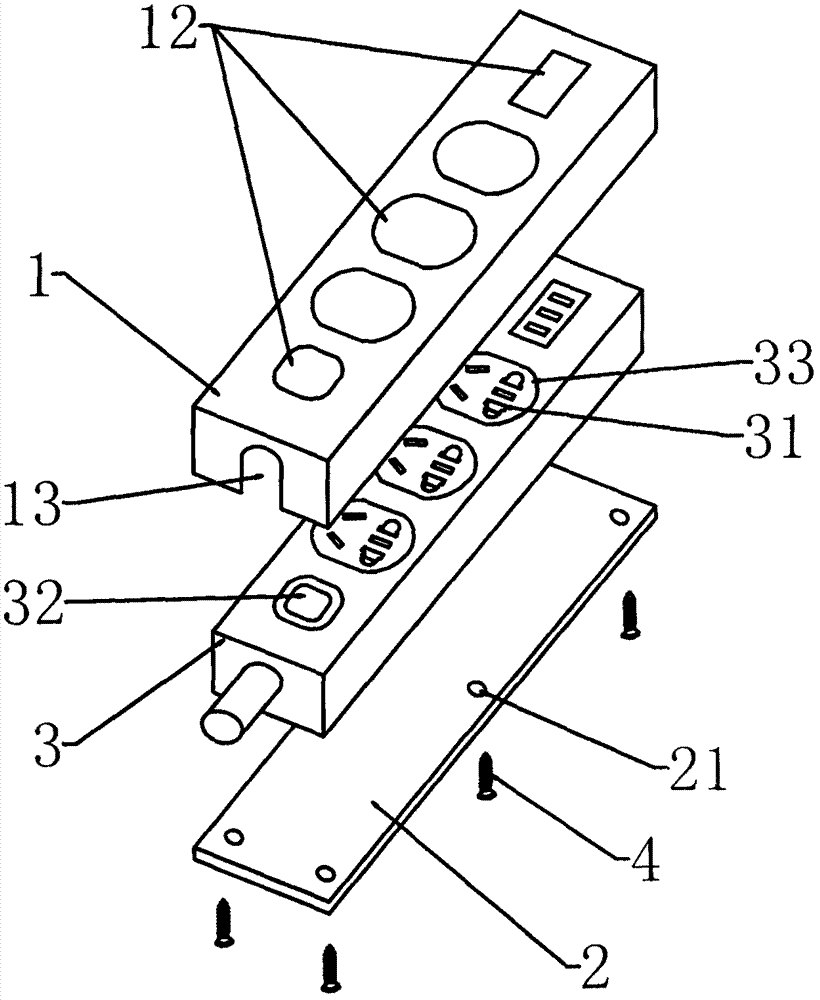

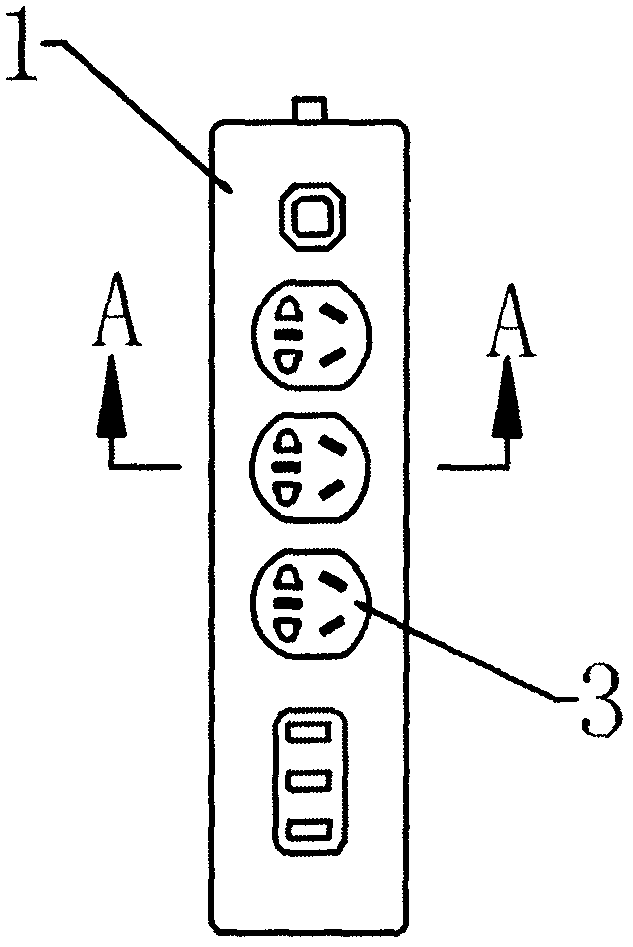

Outer coat for patch board and patch board

PendingCN106953193APrevent agingAvoid damage and leakageCoupling contact membersPatch panelHome appliance

The invention relates to the field of household electrical appliances, and provides an outer coat for a patch board and the patch board. The outer coat for the patch board comprises a box body and a bottom plate, the bottom plate cooperates with the box body, the bottom plate is detachably connected with the box body, the box body is three-dimensional, at least one accommodating chamber accommodating patch boards are arranged in the box body side by side, an upper end face of the box body is provided with through holes corresponding to sockets, a switch and other function members of the patch board, and a side wall of each accommodating chamber is provided with a through groove for a patch board bus to pass through. The patch board is used with the over coat for the patch board, protruding parts are disposed at positions of the sockets of the patch board, shapes of the protruding parts match shapes of the through holes, and heights of the protruding parts are not less than a thickness of a top wall of the box body. The patch board with the over coat comprises the over coat for the patch board and the patch board used with the over coat for the patch board.

Owner:NINGBO DIMINGSI ELECTRONICS

Lithium battery automatic spot welding machine

InactiveCN113523663ALabor savingGuarantee product qualityWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingMechanical engineering

The invention relates to the technical field of lithium battery spot welding, and discloses a lithium battery automatic spot welding machine which comprises: a conveying frame used for pouring lithium batteries, arranging and conveying the lithium batteries; a processing box which is used for processing the lithium batteries inside the processing box; an overturning and inserting mechanism which is used for overturning the lithium batteries with the inverted positive and negative electrodes in the conveying process and inserting the lithium batteries; a mounting frame which is used for inserting the lithium batteries into a slotted hole in the mounting frame and carrying out subsequent welding processing; and a storage bin which is used for storing the mounting frame and nickel sheets for automatic mounting and welding. According to the lithium battery automatic spot welding machine, the lithium batteries are conveyed and detected, a sensor feeds back a detection result to achieve detection of positive and negative electrodes, then overturning is conducted through the overturning mechanism, and the transmission mechanism grabs the mounting frame to conduct mounting of the lithium batteries, mounting of nickel sheets and final welding, so that automatic production of the lithium battery pack is achieved, a large amount of labor force is reduced, production quality is guaranteed, and production efficiency is improved.

Owner:深圳比斯特自动化设备有限公司

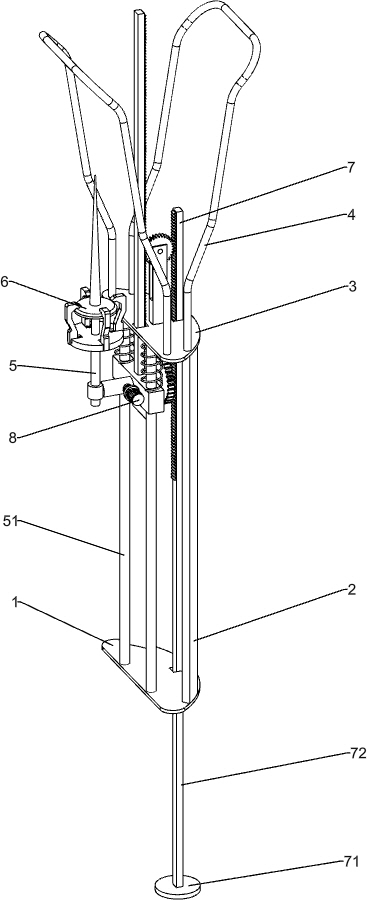

Quick nailing instrument for agriculture

ActiveCN111788973AReduce the difficulty of operationAvoid offsetPlant protective coveringsAgricultural engineeringAgriculture

The invention relates to a nailing instrument, in particular to a quick nailing instrument for agriculture, and aims to solve technical problem of how to provide a quick nailing instrument, which is simple to operate, does not require a worker to squat and improves work efficiency of the workers, for agriculture. In order to solve the technical problem, the invention provides the quick nailing instrument for agriculture. The quick nailing instrument comprises a bottom plate, a top plate, a handle frame, a turnover assembly and a clamping assembly, wherein a support plate is installed at the top of the bottom plate; the top plate is connected to the top of the support plate; the handle frame is connected to the top plate; the turnover assembly is connected between the bottom plate and the top plate; the clamping assembly is connected to the turnover assembly and is matched with the turnover assembly. Through the turnover assembly and the clamping assembly, the worker does not need to squat with nails in one hand and a hammer in the other hand to nail grass shading cloth, so that the operation difficulty of the worker is reduced.

Owner:NANJING HANXIYUE AUTOMATION TECH CO LTD

Method and inflatable rag for cleaning washing gap of roller washing machine

InactiveCN103128086AEasy to cleanGuaranteed insertionHollow article cleaningChemicalsPulp and paper industryAirbag

The invention discloses a method and an inflatable rag for cleaning a washing gap of a roller washing machine. The method includes adopting the inflatable rag to physically clean the washing gap of the roller washing machine, and then adopting particle detergent to chemically clean the washing gap of the roller washing machine. The inflatable rag comprises an inflating and deflating device, a rubber pipe, an inflating airbag and a rag body. One end of the rubber pipe is fixed on the inflating and deflating device, and the other end of the rubber pipe is connected to the inflating airbag through a connecting pipe. The rag body is fixedly or detachably connected to the inflating airbag which is made of rubber. A dirt sump is arranged on the rag body, and a valve is arranged on the inflating and deflating device. According to the characteristic of narrow front room of the washing gap of the roller washing machine, the inflatable rag is designed for physically cleaning the washing gap, and then the sodium carbonate particles are used for chemically clean the same, so that difficulty in cleaning the washing gap of the roller washing machine is overcome.

Owner:CHANGZHOU INST OF TECH

Device and method for twisting end of stator of flat wire motor

ActiveCN112039298BImprove pass rateReduce contact surfaceManufacturing stator/rotor bodiesElectric machineStator coil

The invention discloses a device for twisting the end of the stator of a flat wire motor, which comprises a fixture positioning mechanism for positioning and transporting the stator; The mechanism is used for twisting the flared flat wire; and the base is used for installing the twisting mechanism and the flaring mechanism. The invention also proposes a method for turning the end of the stator of the flat wire motor, which includes the steps of: positioning, turning the head for the first time, and turning the head again. A method for layered flaring of a stator end of a flat wire motor, comprising the steps of positioning, primary flaring, secondary flaring, and the like. By setting the flaring mechanism, the contact surface between the flaring parts and the flat wire is small, ensuring that each wire can be inserted into the twisting die, ensuring the accuracy of the insertion and improving the pass rate of the twisting head, and realizing automatic flaring, both It saves manpower, improves the flaring efficiency, and can ensure the accuracy of wire insertion and improve the pass rate of twisting heads.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

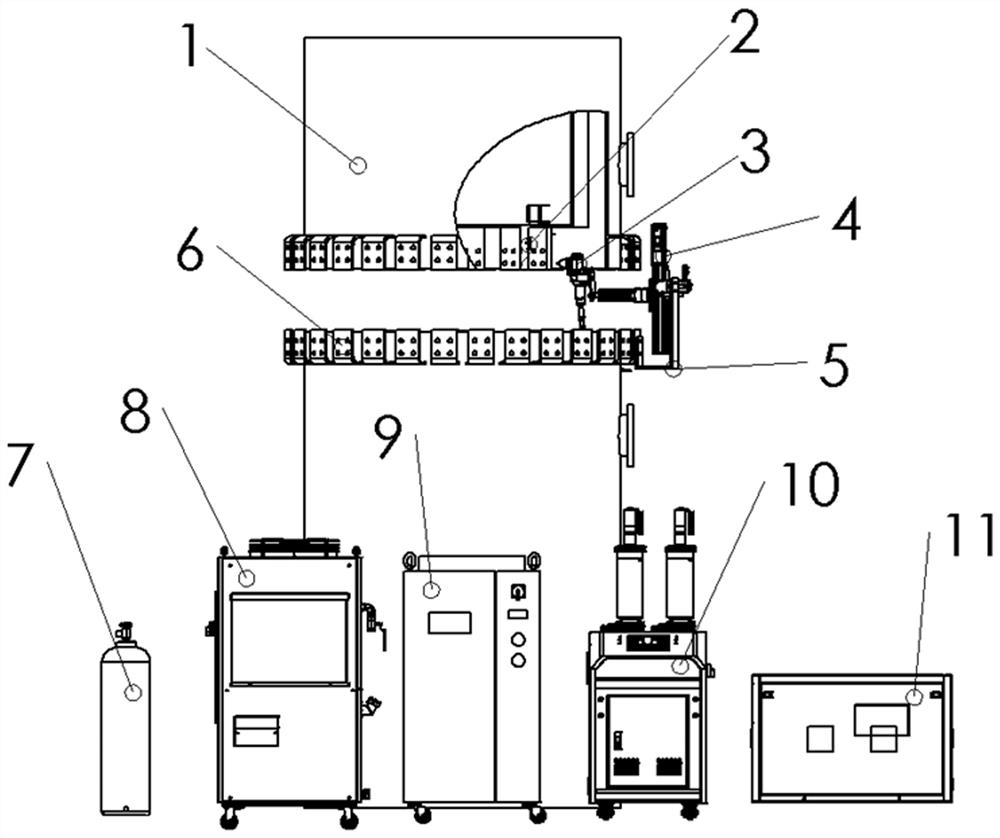

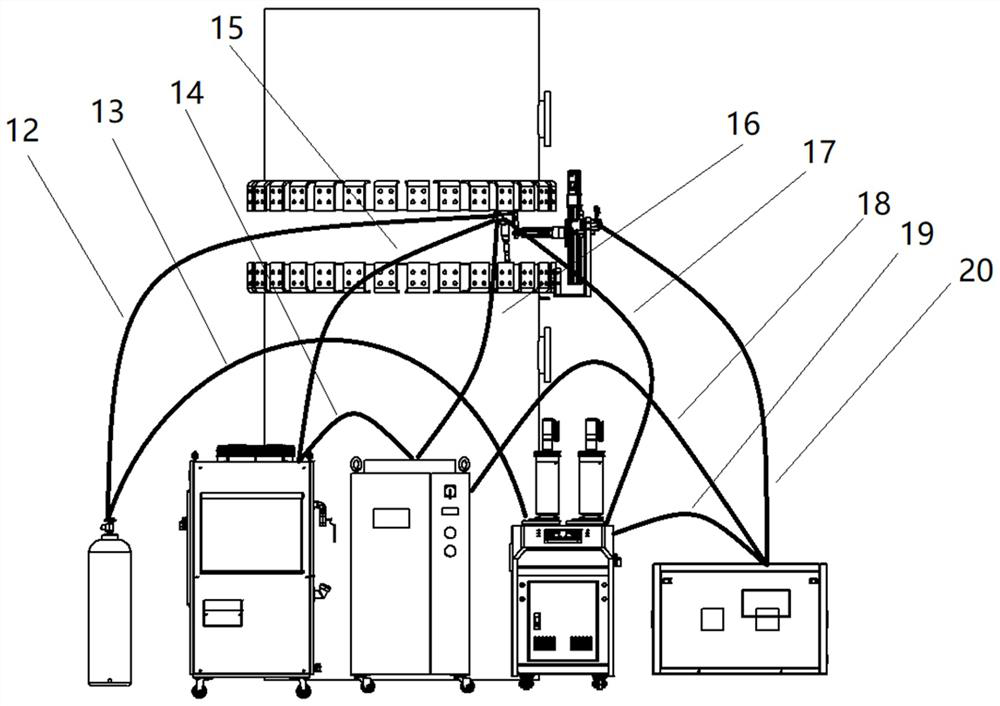

Large-current enclosed aluminum bus fitting terminal on-site repair device and repair method thereof

PendingCN112553619AShorten repair timeHigh bonding strengthMetallic material coating processesPhysicsErbium lasers

The invention relates to a large-current enclosed aluminum bus fitting terminal on-site repair device and a repair method thereof. The large-current enclosed aluminum bus fitting terminal on-site repair device comprises an inert gas source, a cooling device, a laser device, an automatic powder feeder and a power supply, and the inert gas source is used for providing protective gas for a laser cladding head. The cooling device is used for cooling the laser device and the laser cladding head. The laser device is connected to the laser cladding head through an optical fiber and is used for transmitting laser energy beams to the laser cladding head. The power supply is used for supplying power to the laser device, the automatic powder feeder and a three-axis movement mechanism. According to the device and the method, the problem that an enclosed bus fitting terminal cannot be repaired on site and can only be repaired by returning to a factory with a long period is solved.

Owner:CHINA YANGTZE POWER +1

Anti-seismic building block for house building

InactiveCN109989517AGood fitSolid masonryConstruction materialProtective buildings/sheltersRebarHouse building

The invention discloses an anti-seismic building block for a house building. The building block comprises a cross-shaped supporting plate and a building block. The cross-shaped supporting plate is mounted in the perimeter of the building block, steel bar holes are formed in the positions, close to the four corners, of the outer wall of the upper end of the building block, a fixed frame is arrangedon the outer wall of the lower end of the building block, buckles are arranged on the outer walls of the front end and the rear end of the building block, a connecting hole is formed in the outer wall of the right end of the building block, and a connecting column is arranged on the outer wall of the left end of the building block. The buckles are arranged at the front and rear ends of the building block, so that people can carry the building block conveniently, firstly, the connecting column on the outer wall of the left end of the building block is aligned with the connecting hole in another building block, the fixed frame of another building block is aligned with a fixing clamping groove of the building block below, so that the steel bars are inserted into the steel bar holes in the building block after stacking is completed, concrete is poured into a pouring pool, operation is easy, masonry is firmer due to the fact that the integrating degree between the building blocks is very good, and the anti-seismic performance of the building block is more excellent under the action of an anti-seismic pad.

Owner:JIANGSU ZHENGWEI CONSTR

Die plate with adjustable outlet size

InactiveCN111761802ASolve the problem that the export size cannot be adjustedAvoid replacementTyresStructural engineeringMechanical engineering

The invention discloses a die plate with an adjustable outlet size. The die plate comprises a die plate lower plate and a die plate upper plate, the middle part of the die plate upper plate is slidably connected with a movable seat, an insert block group is arranged at the bottom of the movable seat, the bottom part of the insert block group is in a tread profile shape, the insert block group is formed by splicing insert blocks, a cushion block is arranged on the surface of the die plate lower plate, a fixed rod is fixedly connected in the die plate lower plate, both ends of the die plate upper plate are fixedly connected with fixed seats, both sides of the top of the die plate lower plate are fixedly connected with fixed frames, the top parts of the fixed seats are fixedly connected withhydraulic rods, the working ends of the hydraulic rods are fixedly connected with the fixed frames, and a height adjusting device is arranged between the movable seat and the die plate upper plate. The invention relates to the technical field of tire production devices. The die plate with the adjustable outlet size solves the problem that the outlet size of the die plate cannot be adjusted, and avoids the need of replacing the entire die plate when one part is damaged at the same time, so that production costs are reduced.

Owner:MAANSHAN WEILIJIAN MACHINERY TECH CO LTD

Convenient-to-store sampling device for detecting pH value of cosmetics

InactiveCN111879564AAvoid wear and tearEasy to storeMaterial analysis by observing effect on chemical indicatorWithdrawing sample devicesPhysicsEngineering

The invention relates to the technical field of cosmetics, and discloses a convenient-to-store sampling device for detecting the pH value of cosmetics, which comprises a base, an arc-shaped magnetic block is arranged on the lower side of the interior of a fixed shaft, a rectangular magnetic block is connected to the outer side of a first spring, a sliding rod is connected to the outer side end ofa disc, and a stop block is arranged on the inner side of the sliding rod; a piston is connected to the outer side end of the sliding rod, a retreating ring is slidably connected to the outer side ofthe sliding rod, a sliding block is connected to the clockwise side of the sliding rod, and a conical groove corresponding to the sampling pipe is formed in the protective soft layer. An arc-shaped magnetic block attracts a rectangular magnetic block to move in the direction of a fixed shaft, the rectangular magnetic block drives a disc to move upwards through a second spring, the disc drives a sliding rod and a retreating ring to move upwards, and the sliding rod drives a piston to store liquid in a rotary disc through a sampling pipe; according to the structure, the problems that an existingcosmetic sampling device cannot perform multi-group sampling at one time, occupies large space and is inconvenient to store are solved.

Owner:广州薇珞迷化妆品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com