Large-current enclosed aluminum bus fitting terminal on-site repair device and repair method thereof

An aluminum busbar, high-current technology, applied in the direction of metal material coating process, coating, etc., can solve the problem of closed busbar hardware terminals cannot be repaired on site, to reduce the failure rate, simple programming, convenient storage and transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

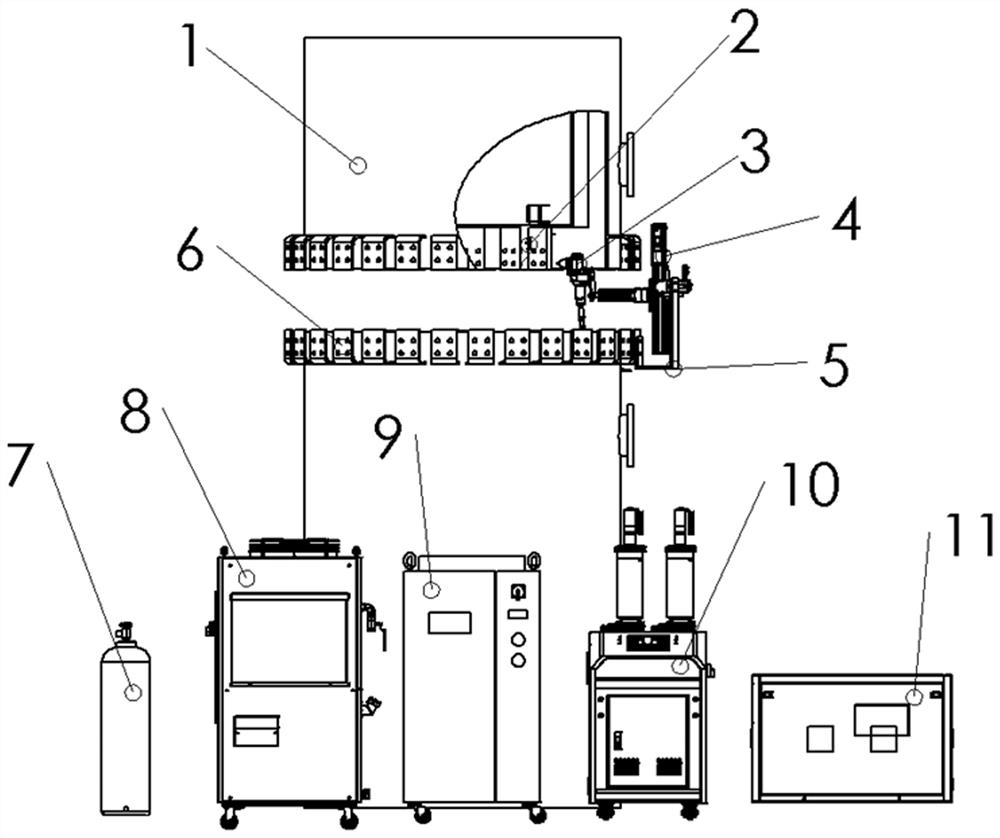

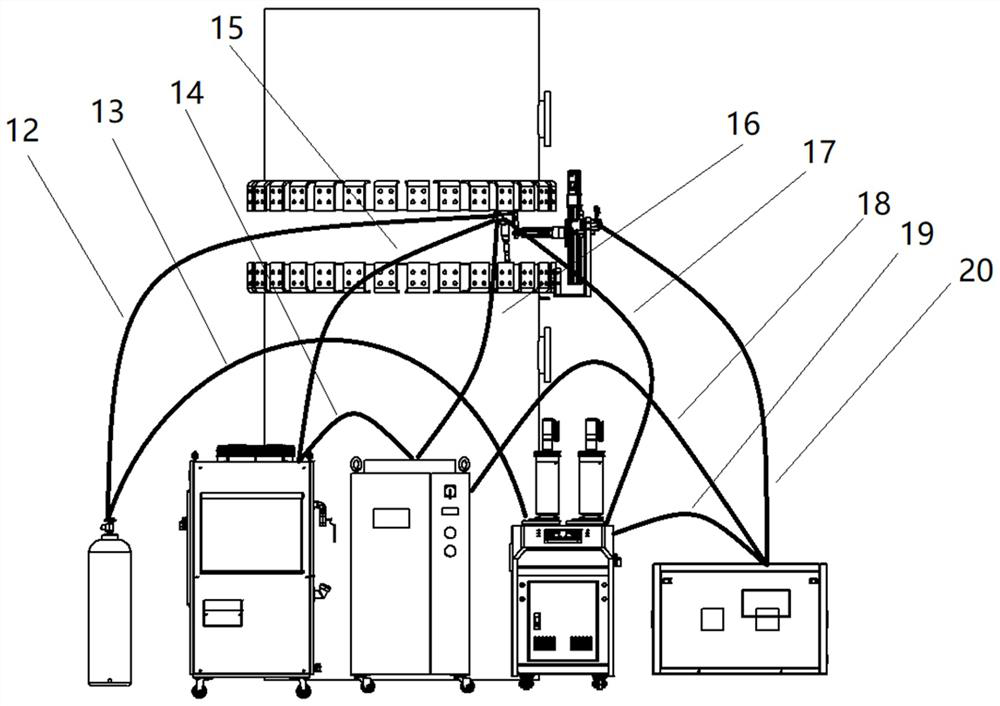

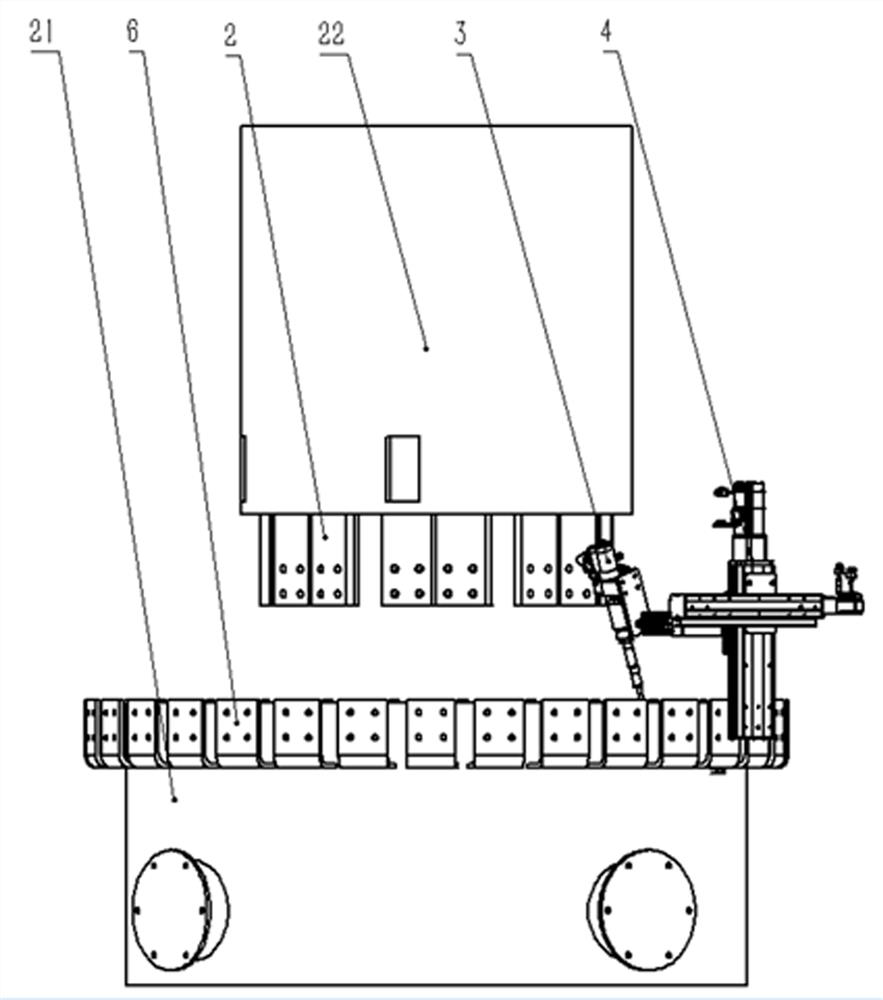

[0030] The preferred solution is as Figure 1 to Figure 6 As shown, a large-current closed aluminum bus bar fitting terminal field repair device and repair method thereof, including an inert gas source, a cooling device, a laser 9, an automatic powder feeder 10 and a power supply, is characterized in that: the inert gas source is used to feed the laser The cladding head 3 provides shielding gas; the cooling device is used to cool the laser 9 and the laser cladding head 3; the laser 9 is connected to the laser cladding head 3 through an optical fiber 16, and the laser 9 is used to transmit the laser energy beam to the laser cladding head 3 ; The power supply is used to provide power to the laser 9, the automatic powder feeder 10 and the three-axis motion mechanism 4.

[0031] Further, the inert gas source is an inert gas bottle 7, the cooling device is a water cooler 8, the power supply is an electrical control cabinet 11, and the inert gas bottle 7 is connected to the laser cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com