Method for repairing heavy metal polluted soil by chemical combined leaching

A technology of contaminated soil and combined leaching, applied in the field of soil remediation, can solve the problems of not using in-situ and ex-situ combined chemical leaching repair methods, etc., to avoid secondary pollution, low requirements and loss, and low power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

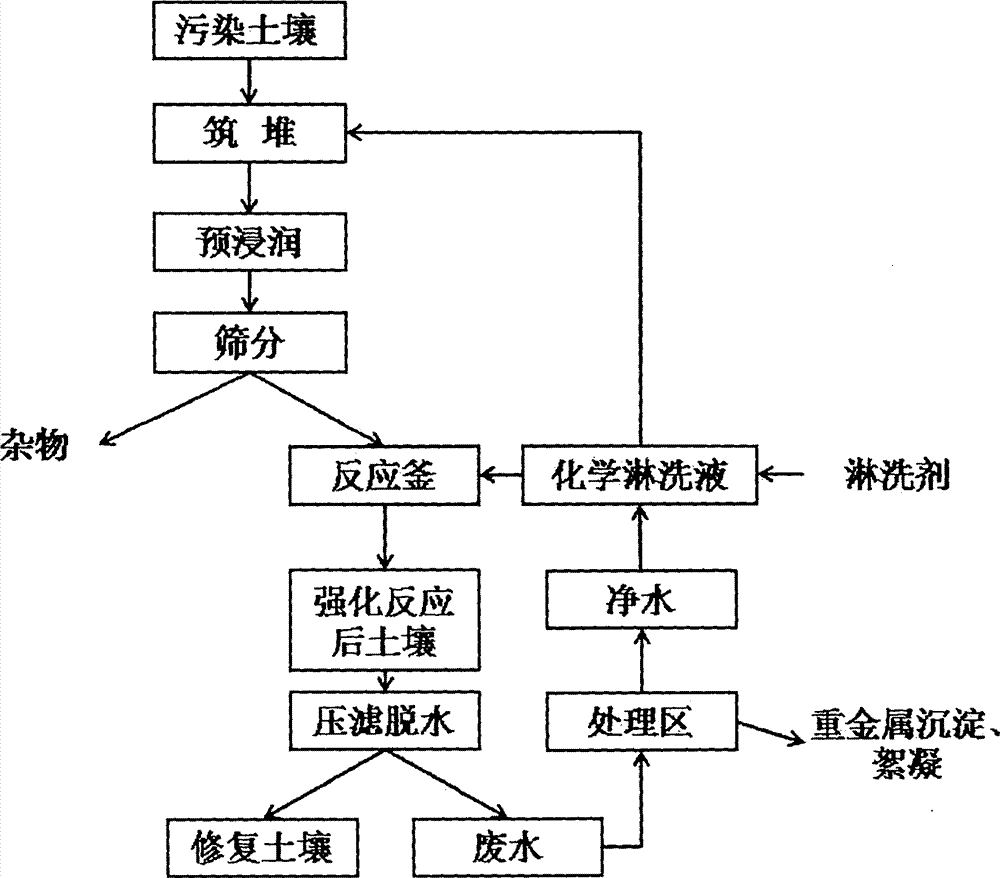

Image

Examples

Embodiment 1

[0035] (1) At the original site of heavy metal polluted soil, pile up 10m of the polluted soil to be treated 3 , spray chemical eluent to the heap to pre-soak the heap, the volume ratio of the chemical eluent to the polluted soil to be treated is 0.4:1, and pre-soak for 26 hours;

[0036] (2) dig up the heap after the pre-soaking is completed, and sieve;

[0037] (3) Transfer the sieved soil to the chemical reaction kettle, carry out stirring and strengthening reaction, add chemical eluent at the same time, the volume ratio of chemical eluent and polluted soil to be treated is 1.8: 1, the time of intensified reaction is 50 minutes;

[0038] (4) The soil after the strengthening reaction is dehydrated by pressure filtration to obtain repaired soil; the waste water obtained by pressure filtration is purified by adding a precipitant and a flocculant, which can be recycled. The repair results are shown in Table 1:

[0039] Table 1

[0040]

Embodiment 2

[0042] (1) At the original site of heavy metal polluted soil, pile up 10m of the polluted soil to be treated 3 , spray chemical eluent to the heap to pre-soak the heap, the volume ratio of the chemical eluent to the polluted soil to be treated is 0.6:1, pre-soak for 20 hours;

[0043] (2) dig up the heap after the pre-soaking is completed, and sieve;

[0044] (3) Transfer the sieved soil to the chemical reaction kettle, carry out stirring and strengthening reaction, add chemical eluent at the same time, the volume ratio of chemical eluent and the polluted soil to be treated is 3: 1, the time of intensified reaction for 20 minutes;

[0045] (4) The soil after the strengthening reaction is dehydrated by pressure filtration to obtain repaired soil; the waste water obtained by pressure filtration is purified by adding a precipitant and a flocculant, which can be recycled. The repair results are shown in Table 2:

[0046] Table 2

[0047]

Embodiment 3

[0049] (1) At the original site of heavy metal polluted soil, pile up 10m of the polluted soil to be treated 3 , spray chemical eluent to the heap to pre-soak the heap, the volume ratio of the chemical eluent to the polluted soil to be treated is 0.5:1, and pre-soak for 24 hours;

[0050] (2) dig up the heap after the pre-soaking is completed, and sieve;

[0051] (3) Transfer the sieved soil to the chemical reaction kettle, carry out stirring and strengthening reaction, add chemical eluent at the same time, the volume ratio of chemical eluent and the polluted soil to be treated is 2: 1, the time of intensified reaction for 30 minutes;

[0052] (4) The soil after the strengthening reaction is dehydrated by pressure filtration to obtain repaired soil; the waste water obtained by pressure filtration is purified by adding a precipitant and a flocculant, which can be recycled. The repair results are shown in Table 3:

[0053] table 3

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com