Hydraulic suspension pre-pressing liquid filling tool

A technology of hydraulic mounting and liquid filling, which is applied in the direction of spring, shock absorber, spring/shock absorber, etc., can solve the problems of affecting the performance of hydraulic mounting, bulging and deformation of the leather cup, and large amount of filling liquid, etc., and achieves a simple structure. , general-purpose strong, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

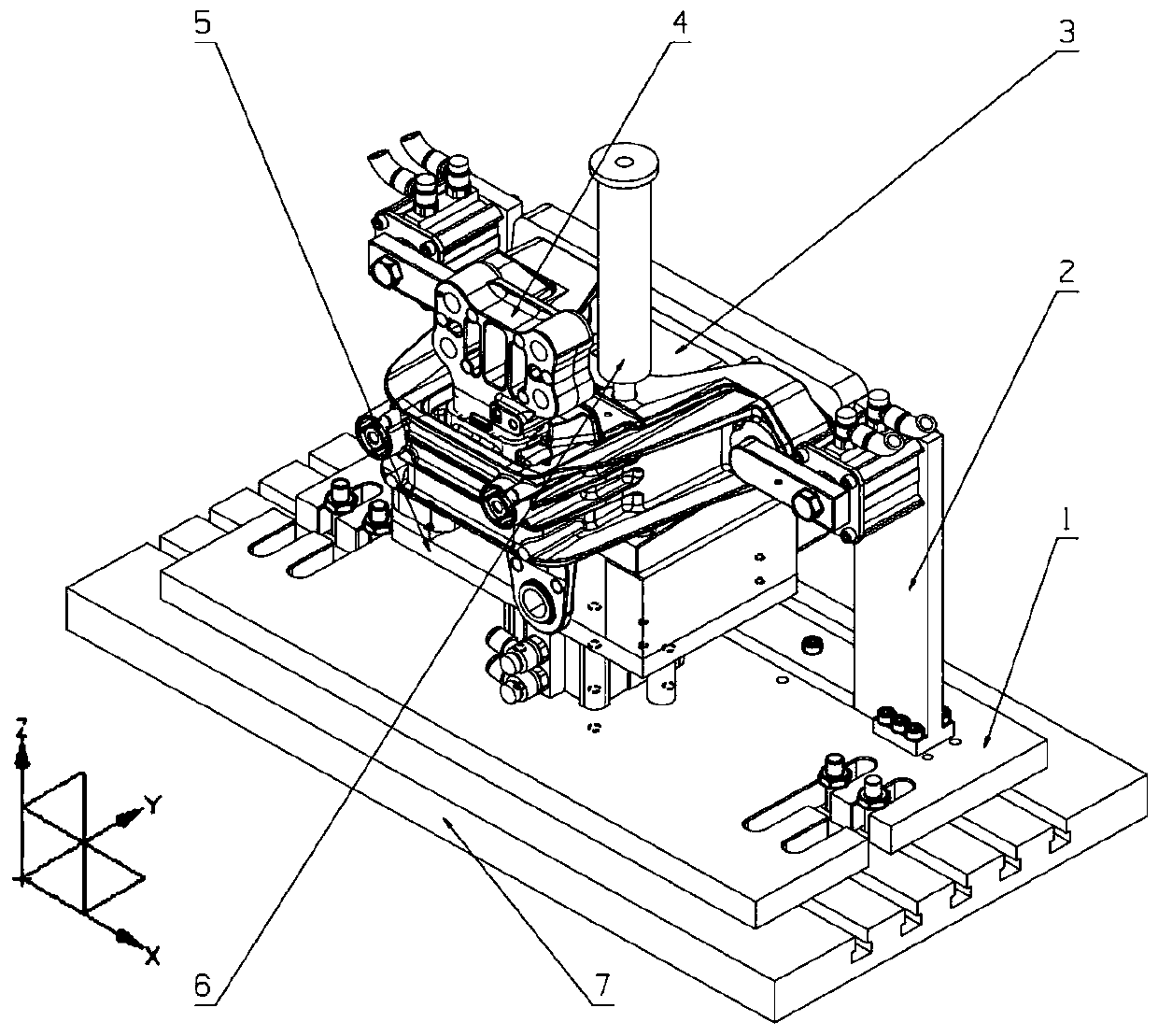

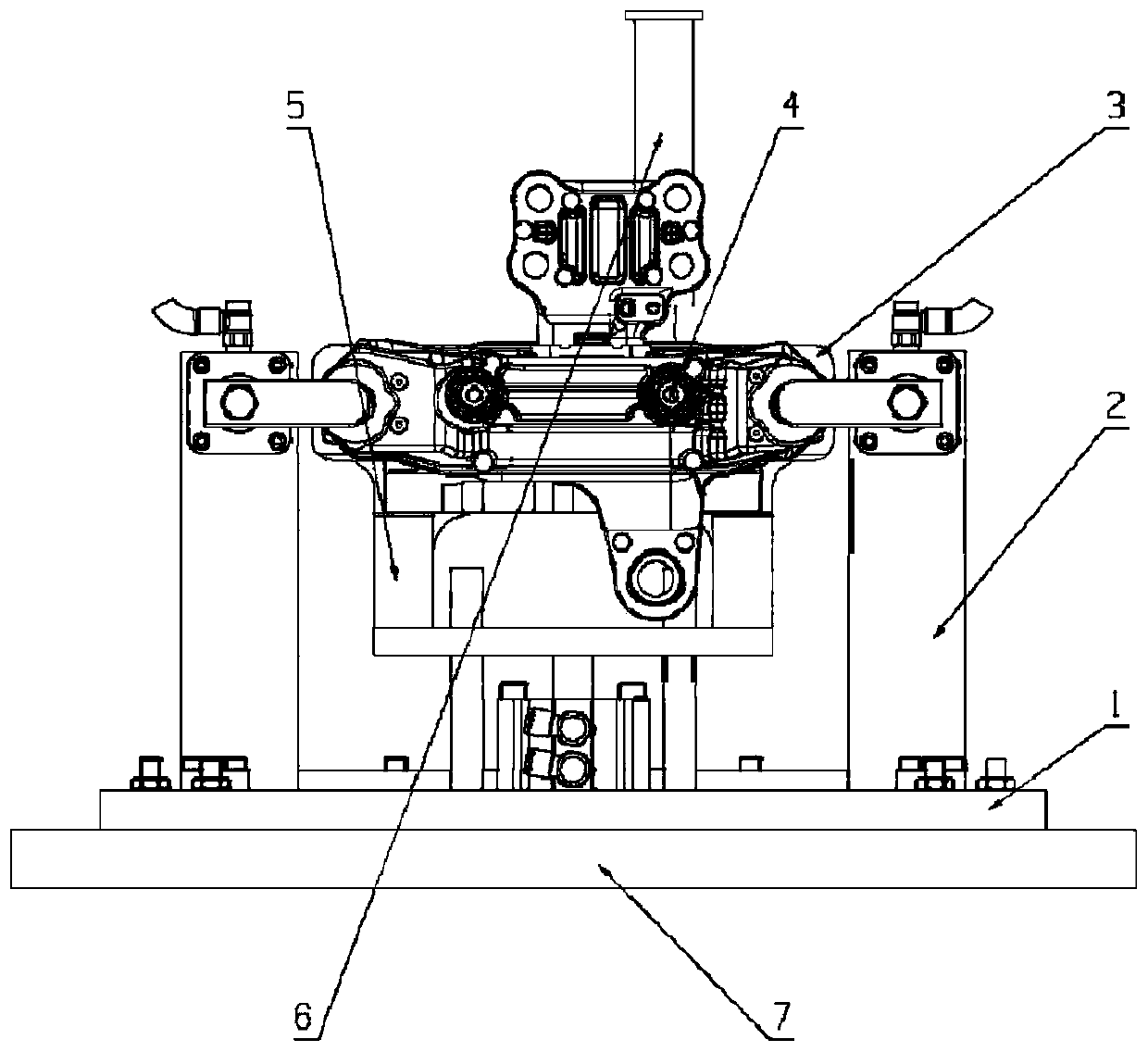

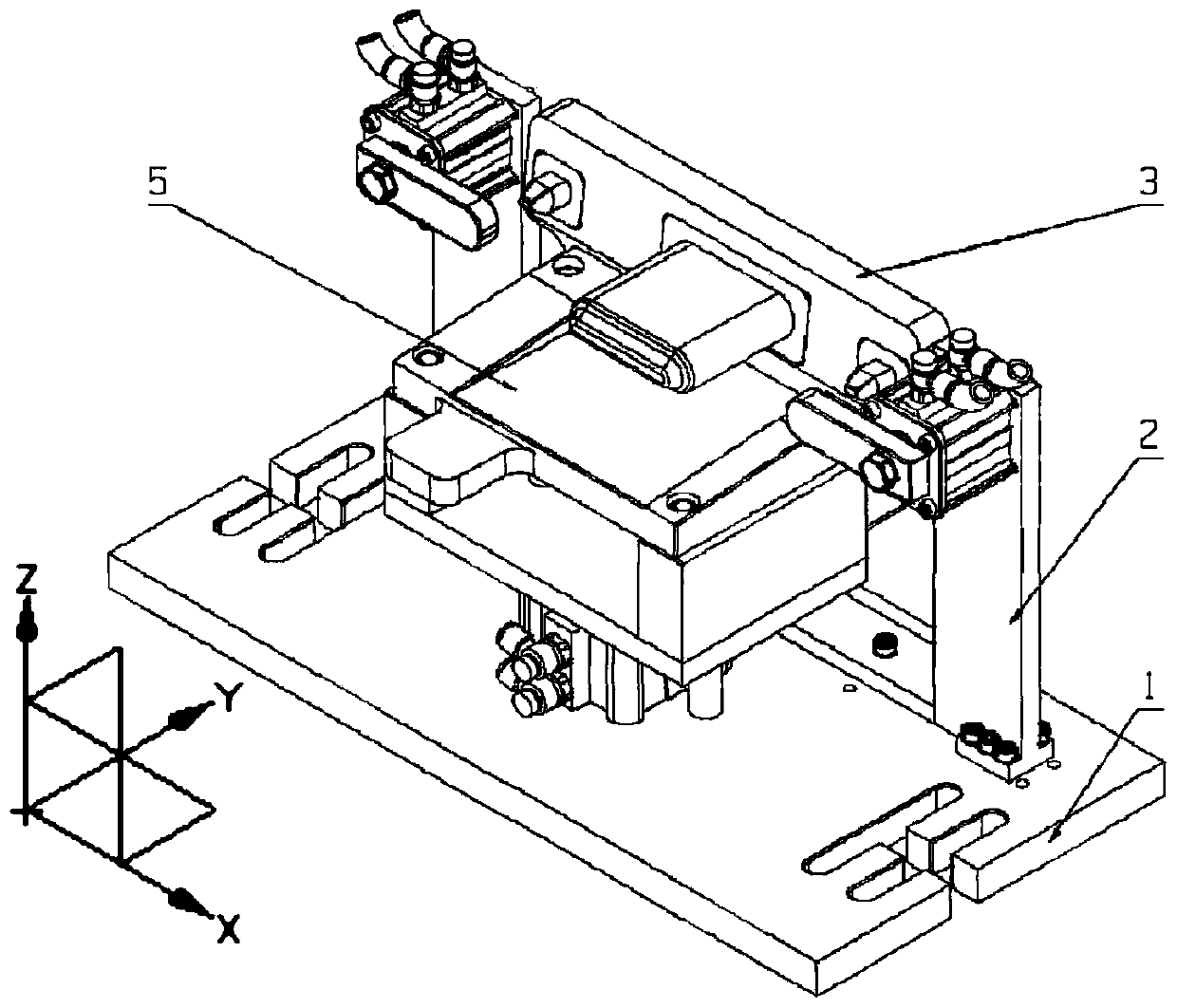

[0048] The invention will be further described below through specific examples and in conjunction with the accompanying drawings.

[0049] The embodiment of the present invention is a certain type of hydraulic mount 4, which is clamped and pre-pressurized. The X, Y, and Z directions in the following description coincide with the coordinate axis directions defined in the drawings.

[0050] Such as Figures 1 to 3 As shown, a hydraulic mount pre-pressurization filling tool includes a slide 1, two hydraulic mount clamping mechanisms 2, a pre-load positioning assembly 3 and a hydraulic mount support mechanism 5, the slide 1 can be used for filling liquid The position is adjusted on the machine platform 7, and after the position is adjusted, it is fixed on the liquid filling machine platform 7 by bolts, and the two hydraulic suspension clamping mechanisms 2 are symmetrically fixed on the slide seat 1 with bolts, which are used for hydraulic suspension. Apply a compressive force; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com