Servo motor shaft assembling equipment and method

A servo motor and shaft assembly technology, which is applied in the manufacture of stator/rotor bodies, centering/balancing rotors, etc., can solve problems such as shell damage, shaft misalignment through holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

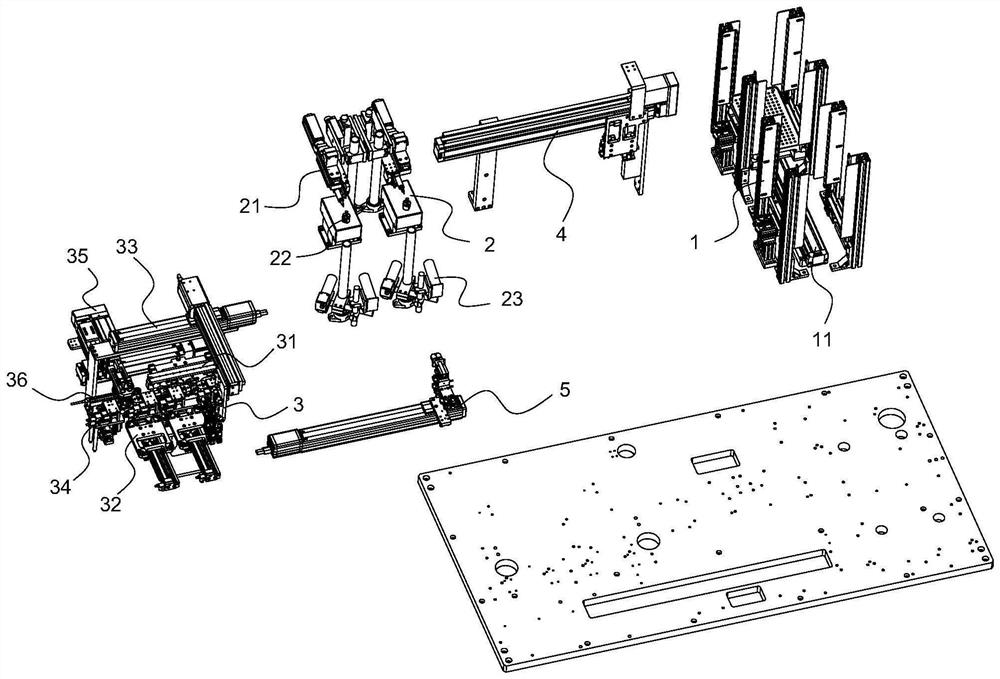

[0023] Such as figure 1 The shown servo motor shaft assembly equipment includes a bottom plate and a shaft feeding device 1 , a lubricating device 2 , a shaft insertion device 3 , a first conveying device 4 and a second conveying device 5 installed on the bottom plate. The shaft feeding device 1, the lubricating device 2 and the shaft inserting device 3 are fixed on the bottom plate in sequence, the shaft feeding device 1 and the lubricating device 2 are connected by the first conveying device 4, and the lubricating device 2 and the shaft inserting device 3 are passed through The second transport device 5 is connected. The shaft is placed on the pallet and enters the shaft feeding device 1. The shaft feeding device 1 is used for conveying the pallet. The first transport device 4 transfers the shaft on the pallet to the lubricating device 2. The lubricating device 2 is used to wipe the surface of the shaft. oil, the second conveying device 5 is used to carry the oiled shaft in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com