Impact resistant copolymerized polypropylene and preparation method thereof

A technology of impact-resistant copolymerization and polypropylene, which is applied in the field of polymer material processing, can solve the problems that impact-resistant copolymerized polypropylene is difficult to maintain long-term stable operation, easy to generate lumps, easy to block the discharge line and conveying valve, etc. Achieve the effect of long-term stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

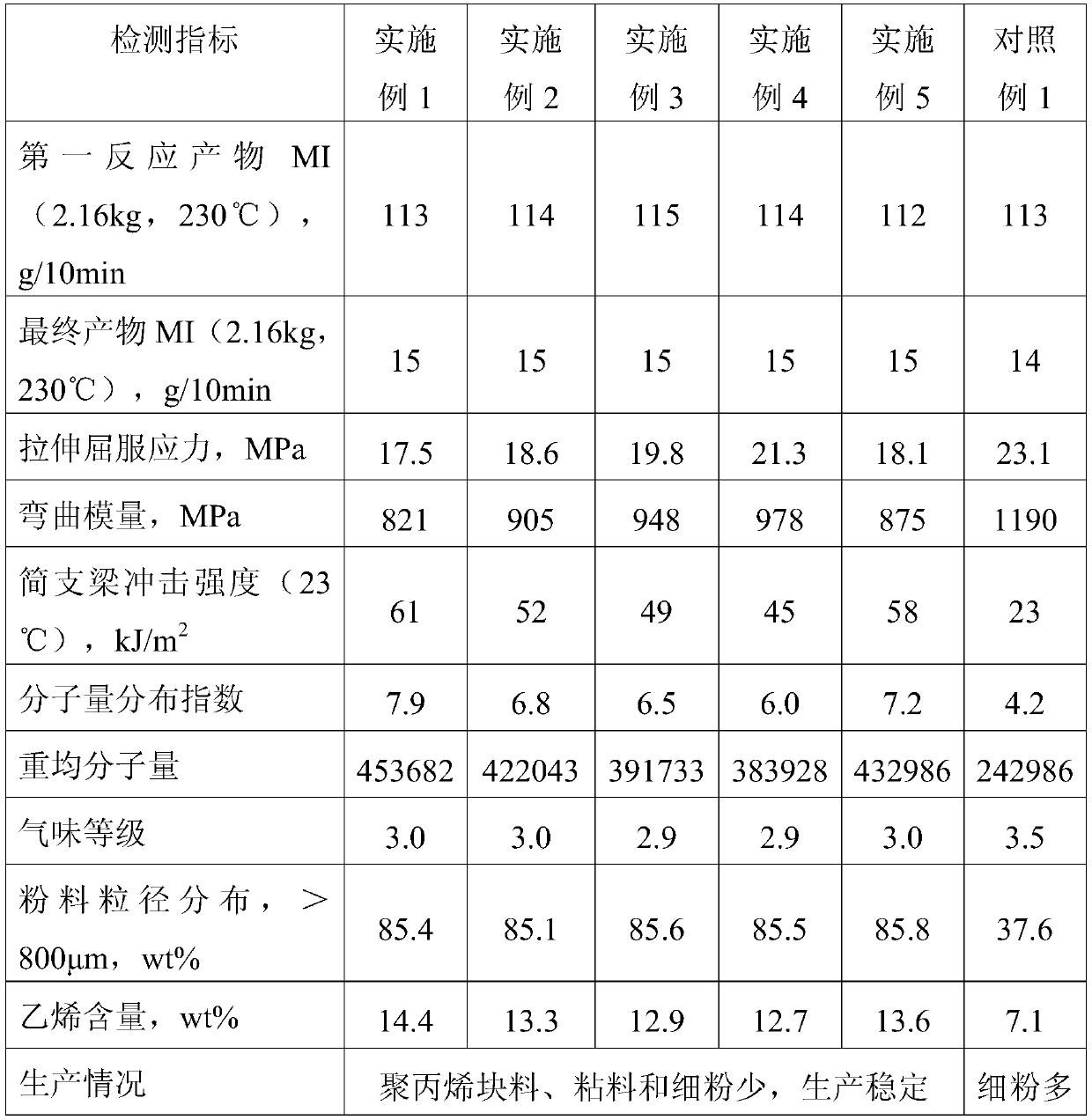

Examples

Embodiment 1

[0044] This embodiment provides a method for preparing impact copolymer polypropylene, and the steps are as follows:

[0045] 1. The first polymerization reaction

[0046] The prepolymerization catalyst, the co-catalyst triethylaluminum and the modifier n-propyltriethoxysilane are added to the first gas phase reactor, and propylene and hydrogen are fed into the first gas phase reactor to perform the first polymerization reaction. The first reaction product.

[0047] Among them, the molar ratio of aluminum in triethylaluminum to magnesium in the prepolymerization catalyst Al / Mg is 7:1, and the molar ratio of aluminum in triethylaluminum to silicon in the modifier silane is Al / Mg. / Si is 7:1, and the molar ratio of hydrogen to propylene is 9:1;

[0048] The temperature of the first polymerization reaction is 64°C, the absolute pressure is 2.2 MPa, and the powder level is 70%.

[0049] 2. Separate the first reaction product

[0050] The first reaction product in the first gas phase reacto...

Embodiment 2

[0061] This embodiment provides a method for preparing impact copolymer polypropylene, and the steps are as follows:

[0062] 1. The first polymerization reaction

[0063] The prepolymerization catalyst, the co-catalyst triethylaluminum and the modifier n-propyltriethoxysilane are added to the first gas phase reactor, and propylene and hydrogen are fed into the first gas phase reactor to perform the first polymerization reaction. The first reaction product.

[0064] Among them, the molar ratio of aluminum in triethylaluminum to magnesium in the prepolymerization catalyst Al / Mg is 7:1, and the molar ratio of aluminum in triethylaluminum to silicon in the modifier is Al / Mg. Si is 7:1, and the molar ratio of hydrogen to propylene is 9:1;

[0065] The temperature of the first polymerization reaction is 64°C, the absolute pressure is 2.2 MPa, and the powder level is 70%.

[0066] 2. Separate the first reaction product

[0067] The first reaction product in the first gas phase reactor is fed...

Embodiment 3

[0078] This embodiment provides a method for preparing impact copolymer polypropylene, and the steps are as follows:

[0079] 1. The first polymerization reaction

[0080] The prepolymerization catalyst, the co-catalyst triethylaluminum and the modifier n-propyltriethoxysilane are added to the first gas phase reactor, and propylene and hydrogen are introduced into the first gas phase reactor to carry out the first polymerization reaction. The first reaction product.

[0081] Among them, the molar ratio of aluminum in triethylaluminum to magnesium in the prepolymerization catalyst Al / Mg is 7:1, and the molar ratio of aluminum in triethylaluminum to silicon in the modifier is Al / Mg. Si is 7:1; the molar ratio of hydrogen to propylene is 9:1;

[0082] The temperature of the first polymerization reaction was 64°C, the absolute pressure was 2.2 MPa, and the powder level was 70%.

[0083] 2. Separate the first reaction product

[0084] The first reaction product in the first gas phase reacto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com