Basalt fiber gridding cloth wrapped rock wool composite heat-preserving plate and manufacturing method thereof

A fiber mesh cloth and fiber mesh technology, which is used in thermal insulation, building components, fire protection, etc., can solve the problems of poor thermal insulation effect, short service life, low tensile strength, etc., achieve good fire resistance, and improve overall tensile strength. The effect of high strength and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

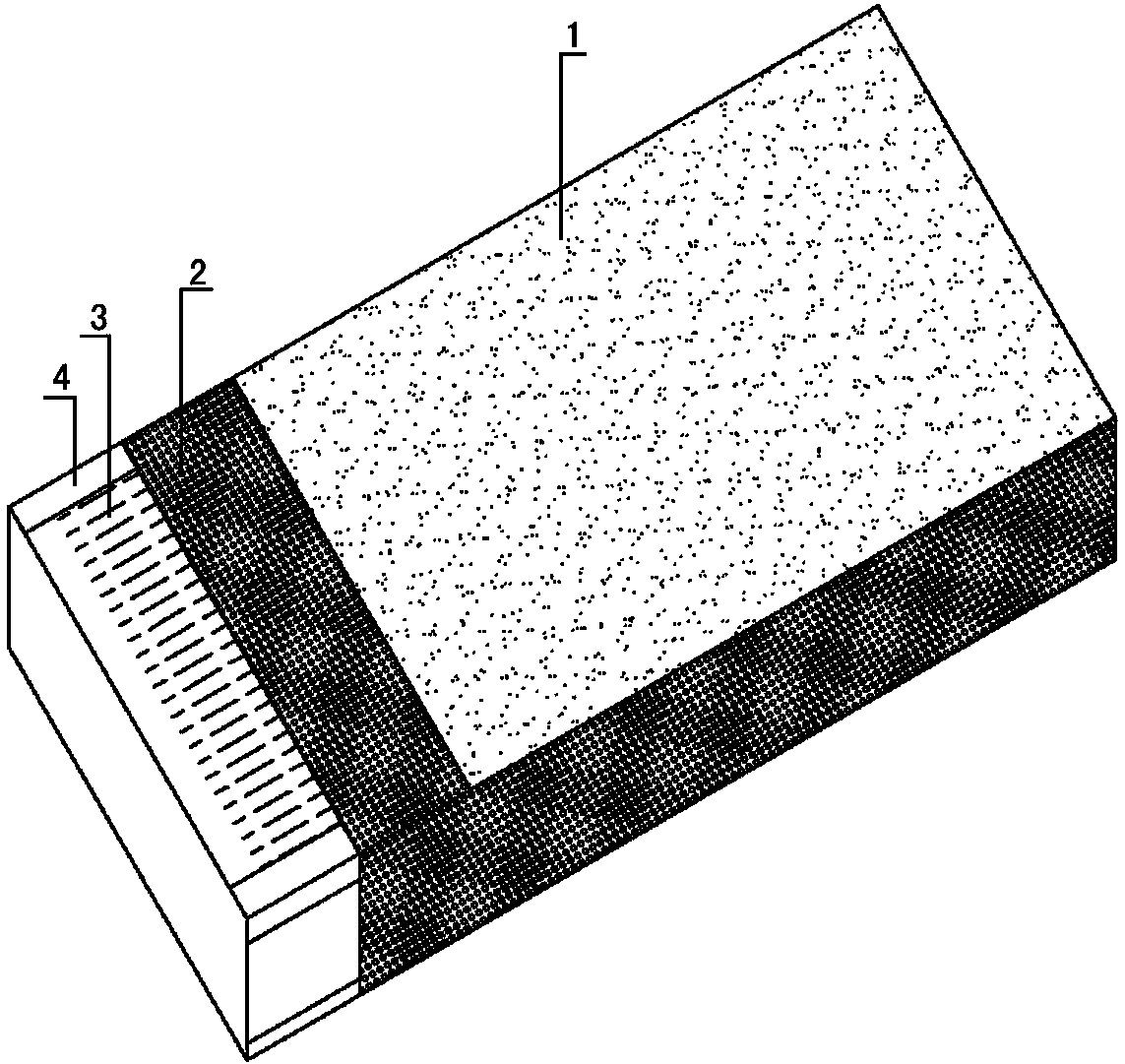

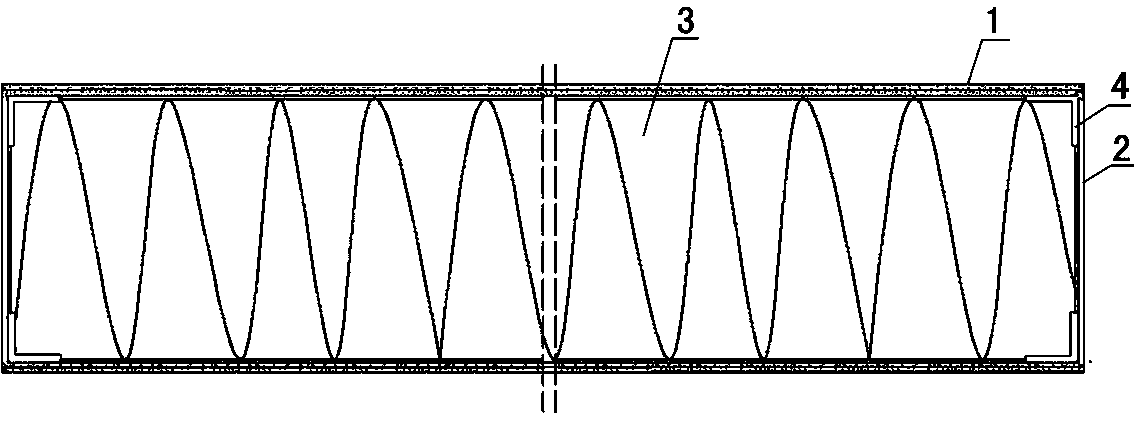

[0033] Examples see Figure 1-3 As shown, this basalt fiber mesh cloth coated rock wool composite insulation board includes a heat preservation board and mesh cloth wrapped on the upper and lower surfaces and the left and right sides of the insulation board.

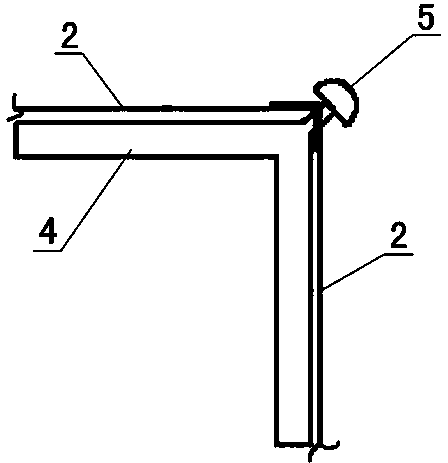

[0034] The thermal insulation board is composed of a plurality of vertical thread rock wool strips 3 (intermediate insulation layer), and the fiber direction of the vertical thread rock wool strips 3 is perpendicular to the upper and lower surfaces of the thermal insulation board, and the four corners of the thermal insulation board are covered with PVC Corner 4, and the PVC corner 4 on one of the corners of the insulation board is provided with a row of teeth 5 corresponding to the grid cloth mesh on the grid cloth.

[0035] In this embodiment, the teeth opening 5 is hemispherical, and the hemispherical shape is because it is most convenient to hang the basalt fiber mesh cloth 2 . Of course, in other embodiments, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com