Catalyst for alkylation of toluene with methanol to produce paraxylene with coproduction of ethylene and application thereof

A technology of paraxylene and catalyst is applied in the field of catalysts for the co-production of ethylene from paraxylene with high selectivity by alkylation of toluene with methanol, which can solve the problem that the downstream application requirements of polyester cannot be met, the selectivity of PX and ethylene cannot have both, and the ethylene /The problem of low proportion of propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

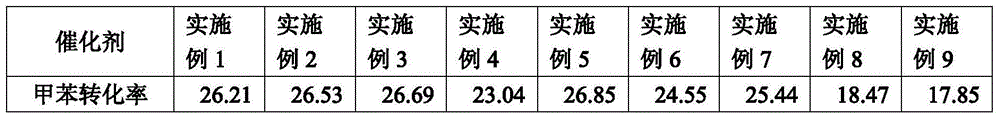

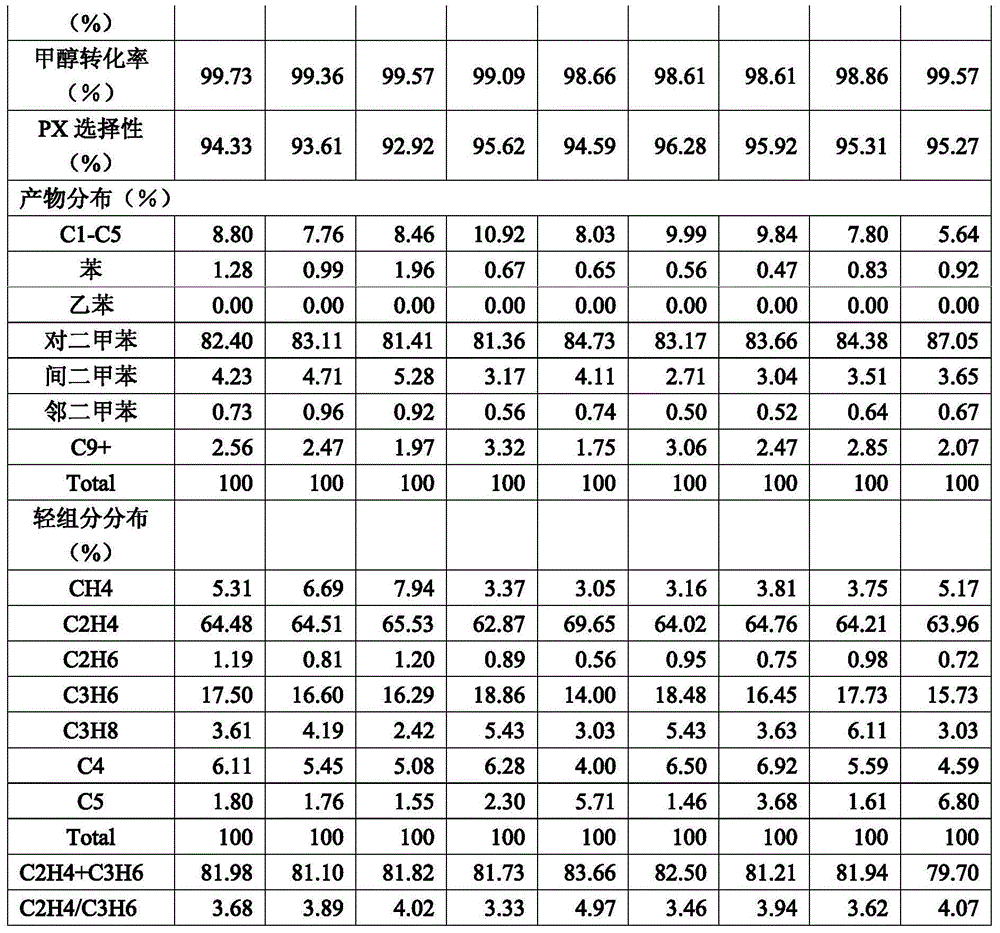

Examples

Embodiment 1

[0023] The desalinated water, ZSM-5 molecular sieve, matrix material and binder are mixed, sprayed and formed, and then calcined to obtain the original powder of the fluidized bed catalyst. Then, impregnating, drying, and calcining the original catalyst powder by using an aqueous solution of a phosphorus compound; and then impregnating, drying, and calcining an alkoxy compound anhydrous ethanol solution to obtain a catalyst. The weight percentage of ZSM-5 molecular sieve in the fluidized bed catalyst is 20%, and SiO in the ZSM-5 molecular sieve 2 with Al 2 o 3 The molar ratio of the matrix material is 200:1; the weight percentage of the matrix material is 50%, and the matrix material is kaolin; the weight percentage of the binder is 5%, and the binder is silica sol; the weight percentage of the phosphorus element is 10%, And the phosphorus-containing compound is phosphoric acid; the percentage by weight of the silicon element after the siloxane compound is impregnated in the...

Embodiment 2

[0025] The desalinated water, ZSM-5 molecular sieve, matrix material and binder are mixed, sprayed and formed, and then calcined to obtain the original powder of the fluidized bed catalyst. Then, the original catalyst powder is impregnated, dried, and calcined with an aqueous solution of a lanthanum compound; and then impregnated, dried, and calcined with an alkoxy compound anhydrous ethanol solution to obtain a catalyst. The weight percent of ZSM-5 molecular sieve is 40% in the fluidized bed catalyst, and SiO in the ZSM-5 molecular sieve 2 with Al 2 o 3 The molar ratio of the matrix material is 150:1; the weight percentage of the matrix material is 20%, and the matrix material is montmorillonite; the weight percentage of the binder is 25%, and the binder is silica sol; the weight percentage of the lanthanum element is 10 %, and the lanthanum-containing compound is lanthanum nitrate; the percentage by weight of silicon after impregnating the siloxane compound absolute ethano...

Embodiment 3

[0027] The desalinated water, ZSM-5 molecular sieve, matrix material and binder are mixed, sprayed and formed, and then calcined to obtain the original powder of the fluidized bed catalyst. Then use alkoxy compound absolute ethanol solution to impregnate, dry, and roast; then use magnesium compound aqueous solution to impregnate, dry, and roast to obtain the catalyst. The weight percentage of ZSM-5 molecular sieve in the fluidized bed catalyst is 70%, and ZSM-5 molecular sieve Medium SiO 2 with Al 2 o 3 The molar ratio of the matrix material is 20:1; the weight percentage of the matrix material is 20%, and the matrix material is silicon oxide; the weight percentage of the binder is 5%, and the binder is a mixture of silica sol and aluminum sol; siloxane The percentage by weight of silicon after impregnating the absolute ethanol solution of the compound is 0.01%, and the siloxane compound is phenylmethyl polysiloxane; the percentage by weight of magnesium element is 4.99%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com