Method for separating low carbon olefin mixed gas by rectifying and absorbing

A low-carbon olefin and mixed gas technology, applied in the field of low-carbon olefin refining, can solve the problems of high cost of cold box, incomplete separation, etc., and achieve the effects of cost reduction, less loss of absorbent, and less loss of solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

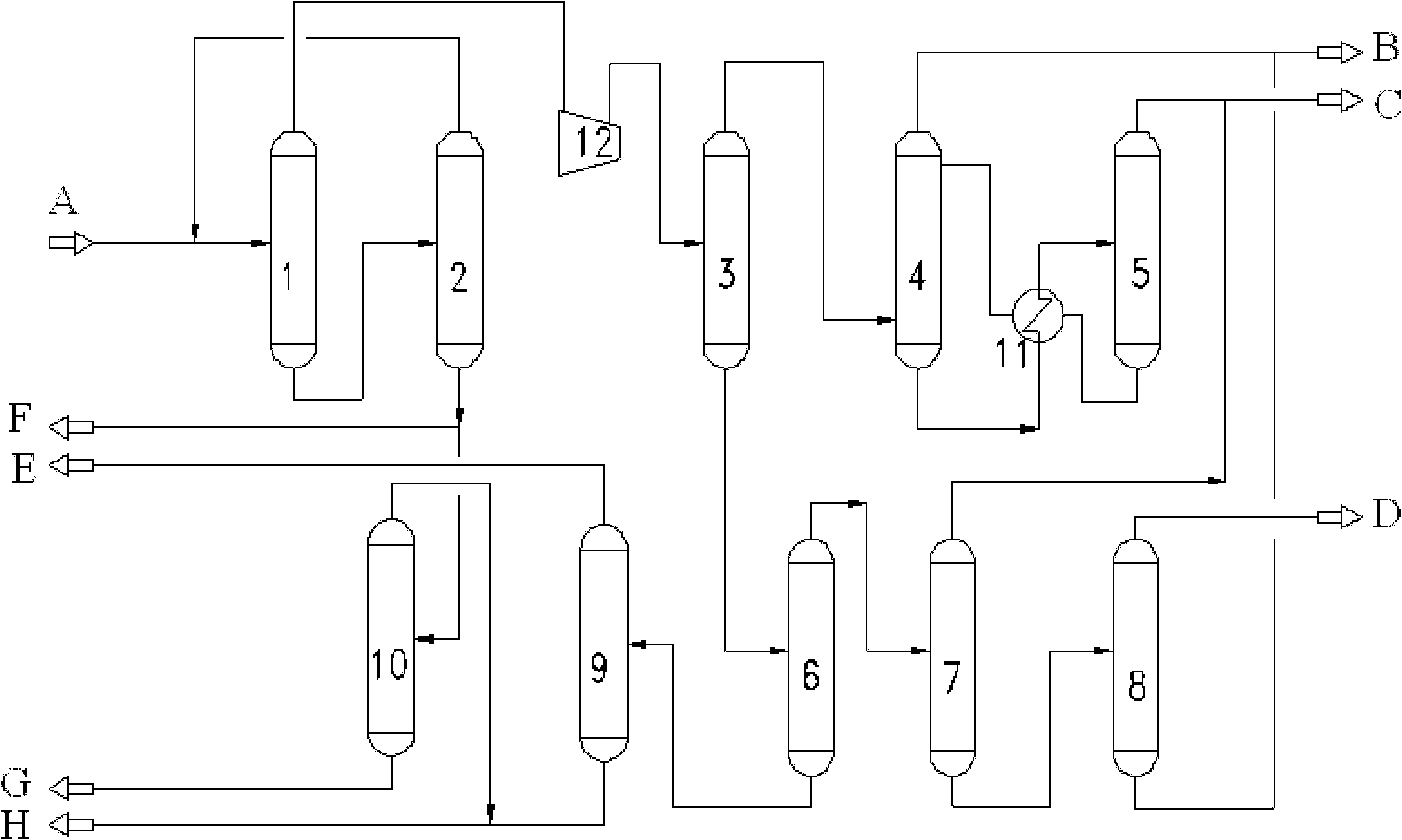

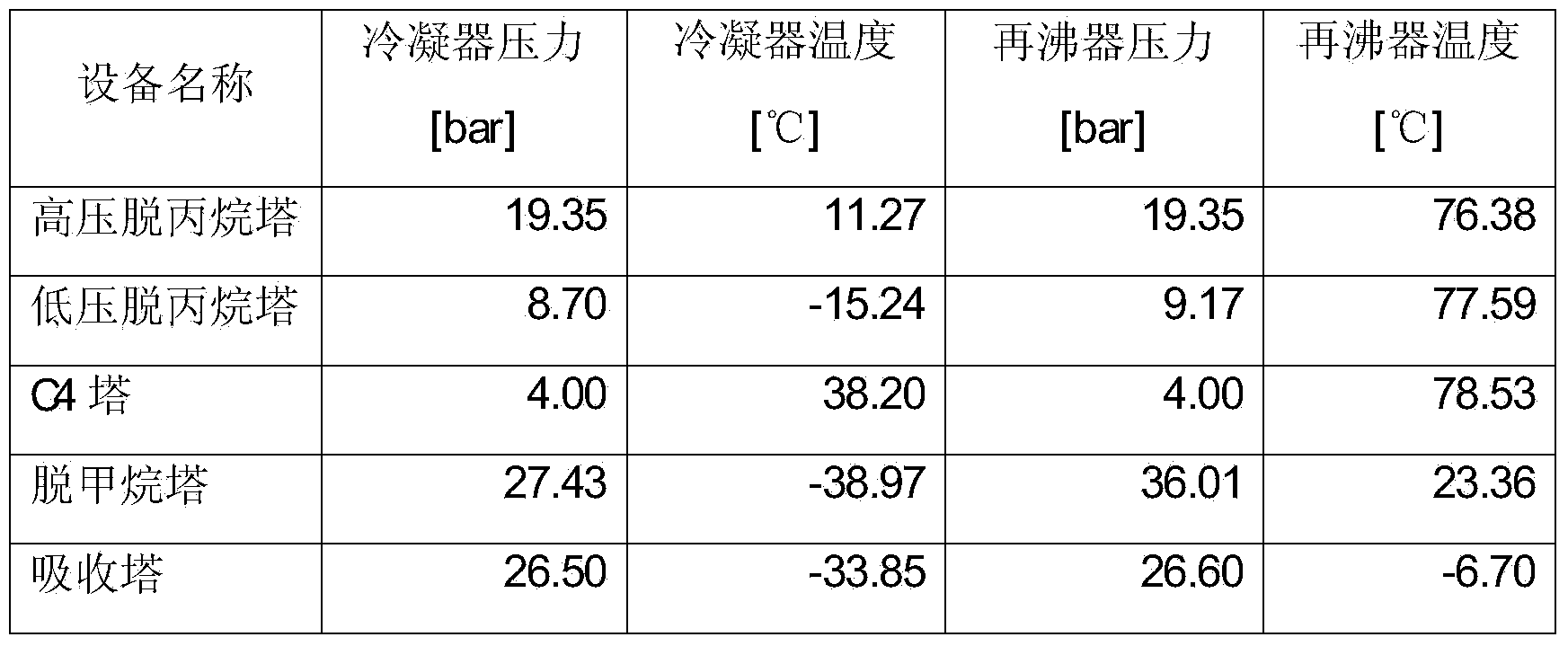

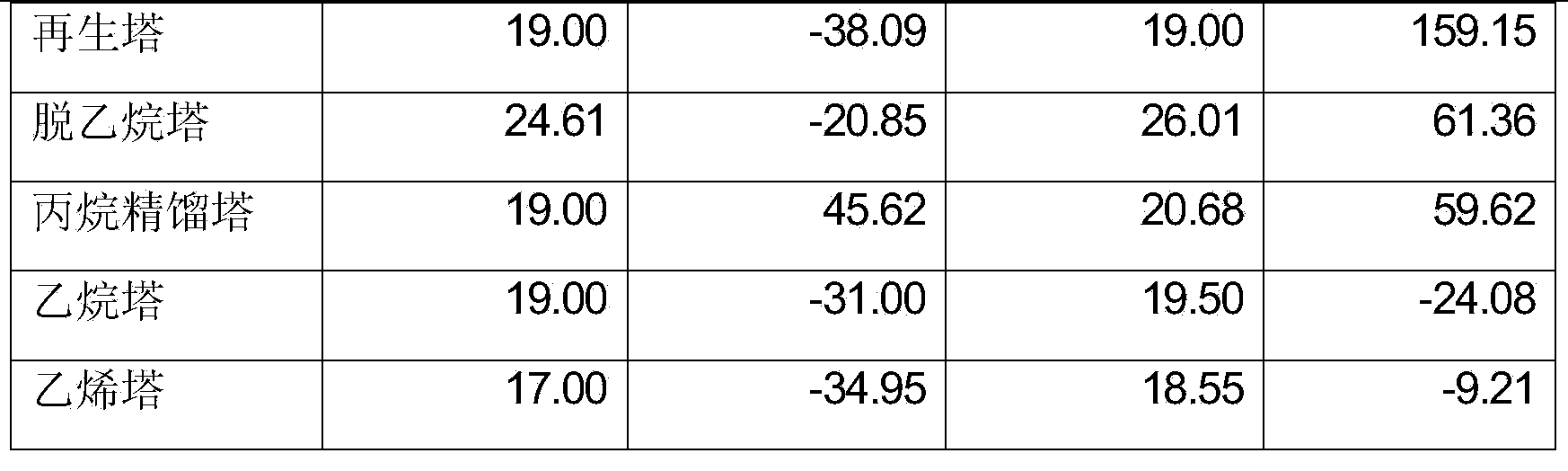

[0032] Attached below figure 1 The process flow of the present invention is further described through specific examples.

[0033] The method of separating low-carbon olefin mixed gas by rectification and absorption includes the following steps: pass the compressed and dried low-carbon olefin mixed gas A and liquid into the high-pressure de-propanizer 1, and collect it from the bottom of the high-pressure de-propanizer 1. The C4+ rich in C3 enters the low-pressure de-propanizer 2, and the top liquid of the low-pressure de-propanizer 2 is pumped into the high-pressure de-propanizer 1. The gas collected from the upper part of the high-pressure depropanizer 1 is passed to the process gas compressor 12. The boosted gas is cooled and enters the demethanizer 3, and the gas from the top of the demethanizer 3 enters the bottom of the absorption tower 4, from the upper part of the absorption tower 4 The absorbent is introduced, and after mass transfer, the C1 and lighter components B that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com