Dual-riser petroleum hydrocarbon feed stock catalytic conversion method and device

A catalytic conversion method and double riser technology are applied in the field of double riser catalytic conversion of petroleum hydrocarbon raw materials, which can solve problems such as increasing the feasibility of engineering implementation, reduce thermal cracking reaction, improve catalytic conversion reaction, and improve oil-agent contact. the effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

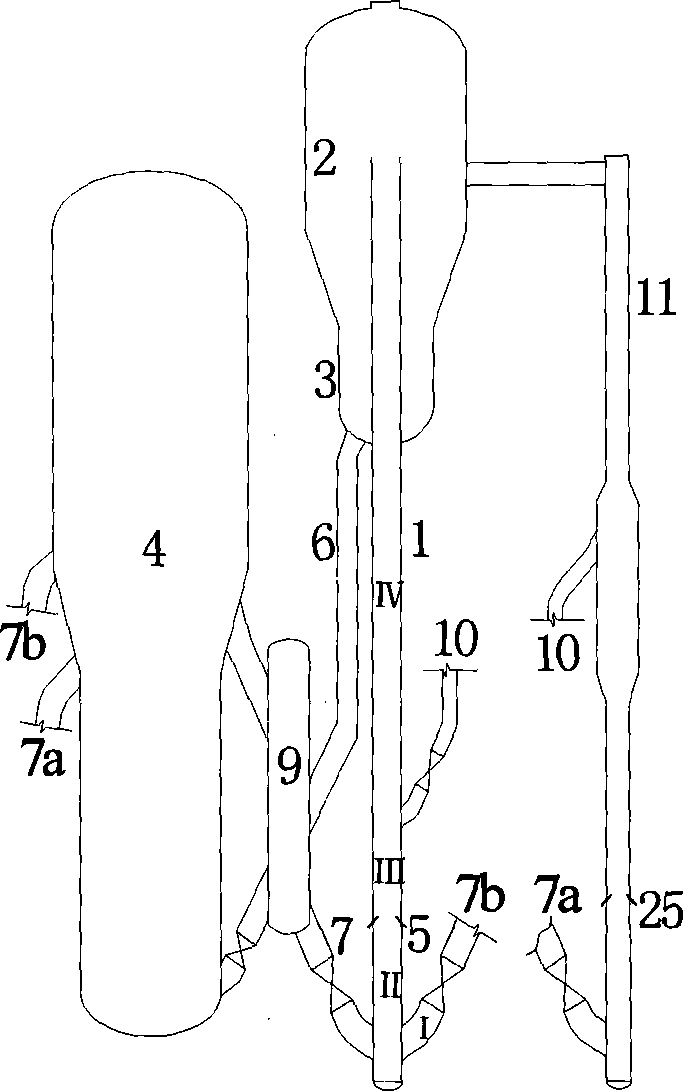

[0036] Example 1: see figure 1 . The temperature-reduced regenerated catalyst that enters from the regeneration riser 7 and is cooled by the catalyst cooler 9 is mixed with a part of the hot regenerated catalyst that enters from the regeneration riser 7b in the pre-lift section II at the bottom of the heavy raw material riser reactor 1. The atomized heavy raw material entering through the feed nozzle 5 is contacted to participate in the catalytic reaction, and the reaction mixture is upwardly contacted with the active relay catalyst from the light raw material riser reactor 11 through the catalyst relay pipe 10 and enters the reaction section IV to continue reaction to complete the catalytic conversion of heavy raw materials; a part of the hot regenerated catalyst enters the bottom of the light raw material riser reactor 11 from the regeneration standpipe 7a, and under the action of the lifting medium, it is upwardly connected with the atomized light raw material that enters t...

Embodiment 2

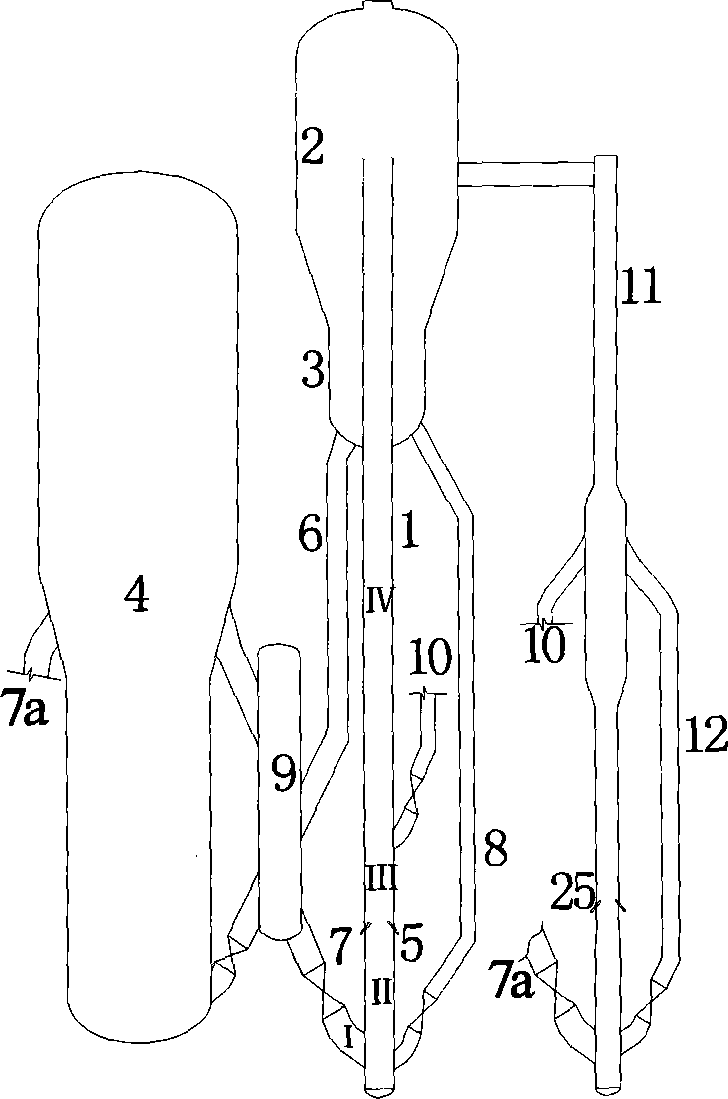

[0038] Example 2: see image 3 . After the self-reflux standby catalyst from the catalyst return pipe 8 is mixed with the cooled regenerated catalyst formed by the regeneration standpipe 7 and cooled by the catalyst cooler 9 in the pre-lift section II at the bottom of the heavy raw material riser reactor 1, Upward contact with the atomized heavy feedstock oil entering through the feed nozzle 5 to participate in the catalytic reaction; the reaction mixture upwardly contacts with the active relay catalyst from the light raw material riser reactor 11 introduced by the catalyst relay pipe 10 and reacts afterwards Section IV continues to react to complete the catalytic conversion of heavy raw materials; a part of the hot regenerated catalyst enters the bottom of the light raw material riser reactor 11 from the regeneration standpipe 7a, and under the action of the lifting medium, it is separated from the light raw material riser reactor 11. After being mixed with the self-refluxed...

Embodiment 3

[0039] Embodiment 3: see Figure 4 . The cooled regenerated catalyst that enters from the regeneration standpipe 7 and is cooled by the catalyst cooler 9 enters the pre-lift section II at the bottom of the heavy raw material riser reactor 1, and upwardly meets the atomized heavy raw material oil that enters through the feed nozzle 5. The contact participates in the catalytic reaction; the reaction mixture is upwardly contacted with the active relay catalyst from the light raw material riser reactor 11 through the catalyst relay pipe 10, and continues to react in the post-reaction section IV to complete the catalytic conversion of the heavy raw material; a part of the heat The regenerated catalyst enters the bottom of the light raw material riser reactor 11 from the regeneration standpipe 7a. Under the action of the lifting medium, it mixes with the self-reflux standby catalyst that is refluxed from the rear reaction section of the light raw material riser reactor 11. The atom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com