Patents

Literature

64results about How to "Improve access" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

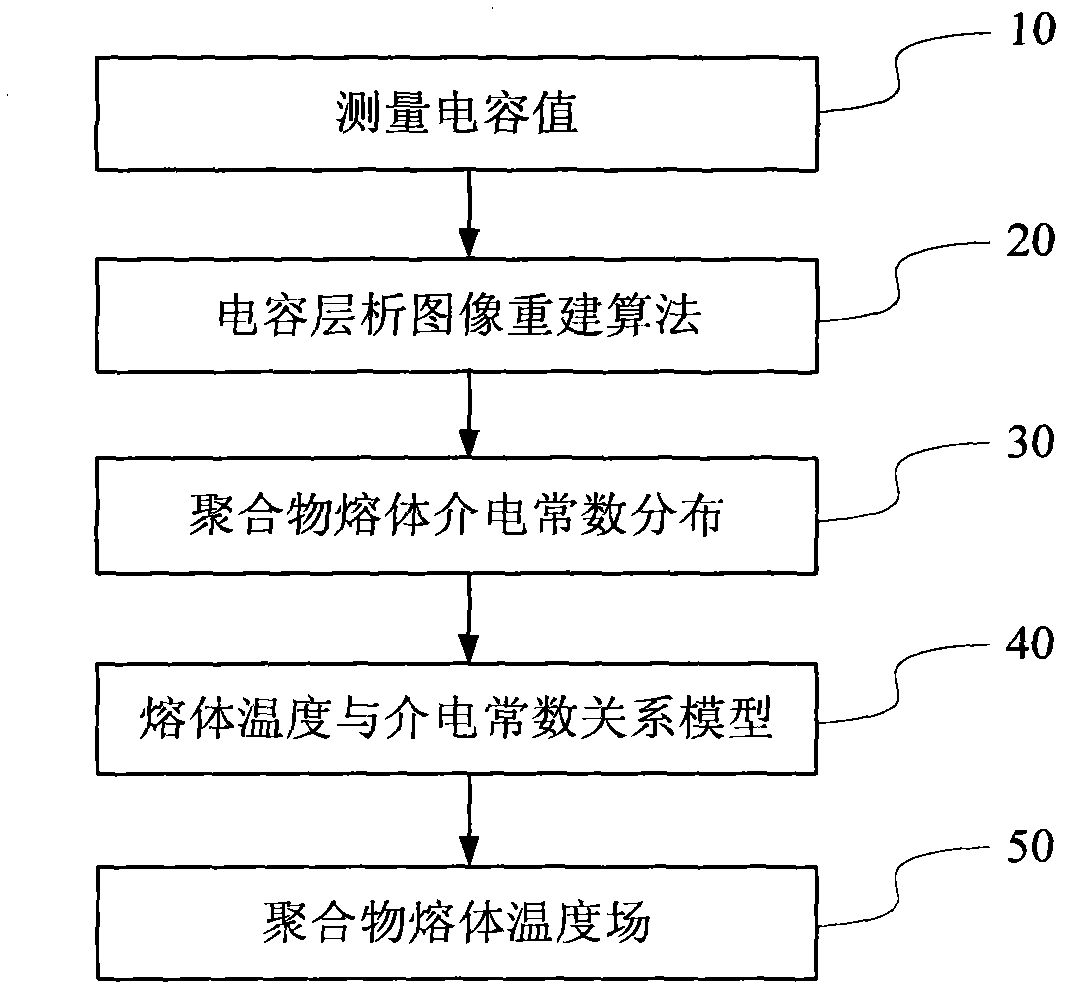

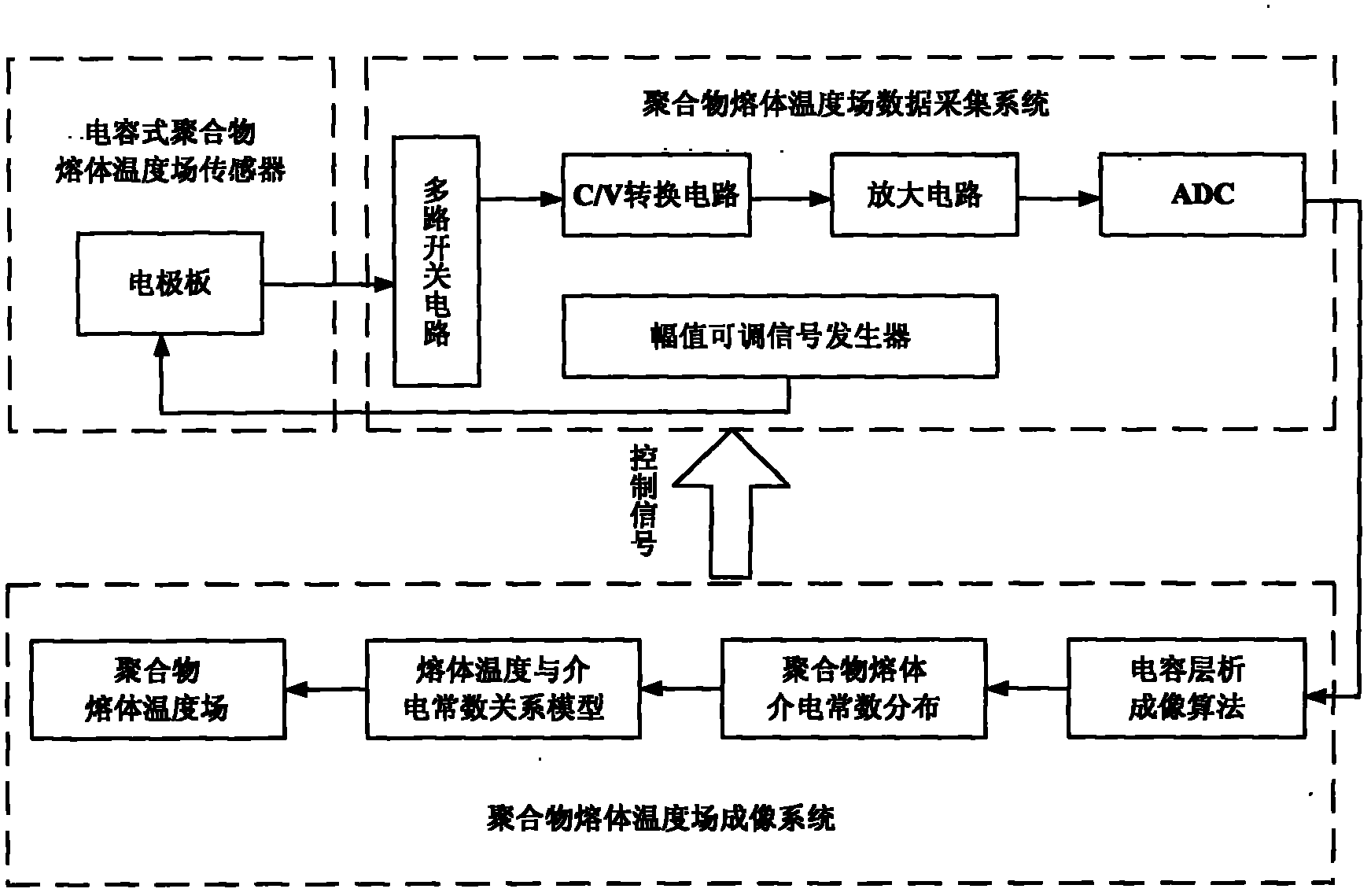

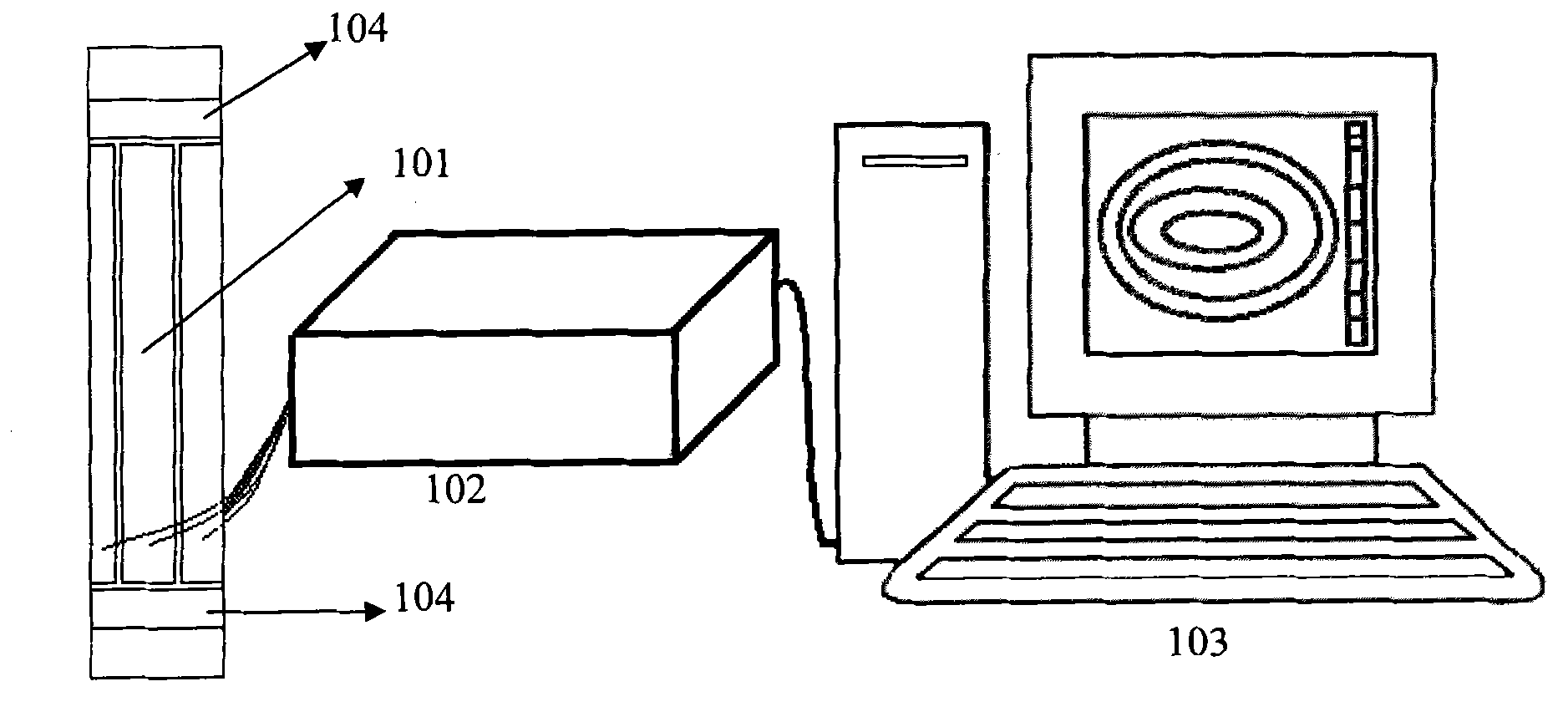

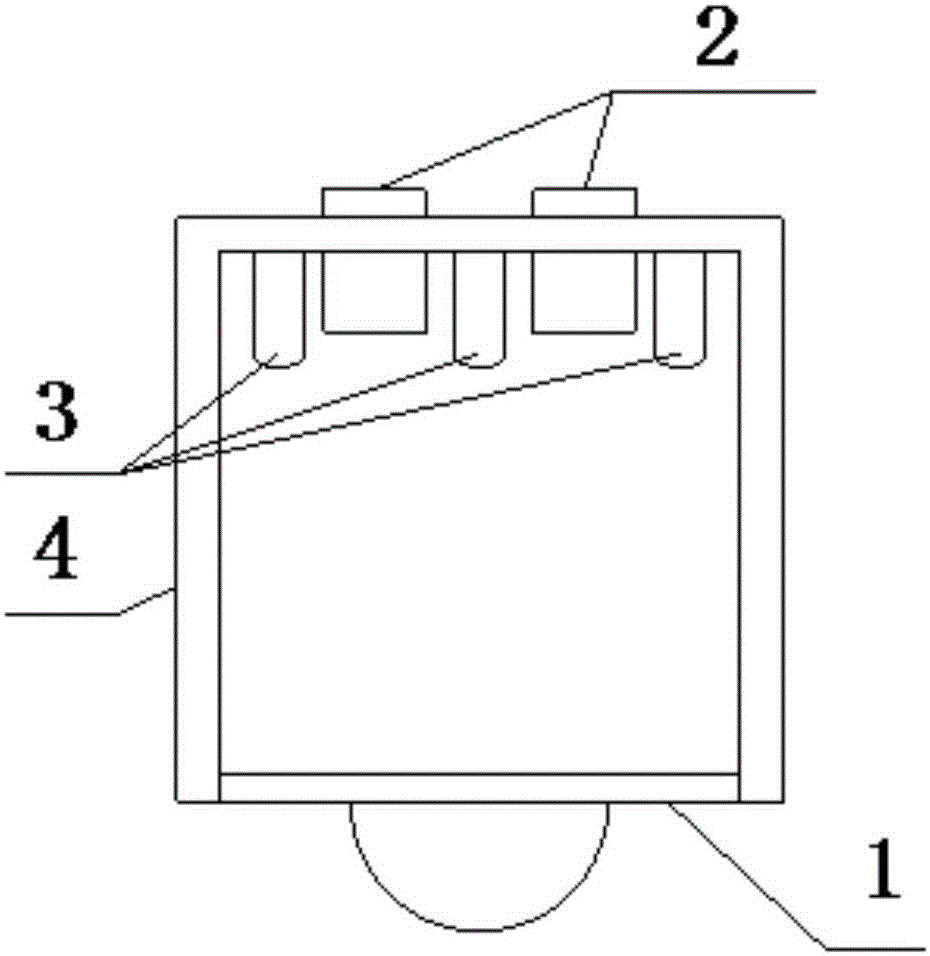

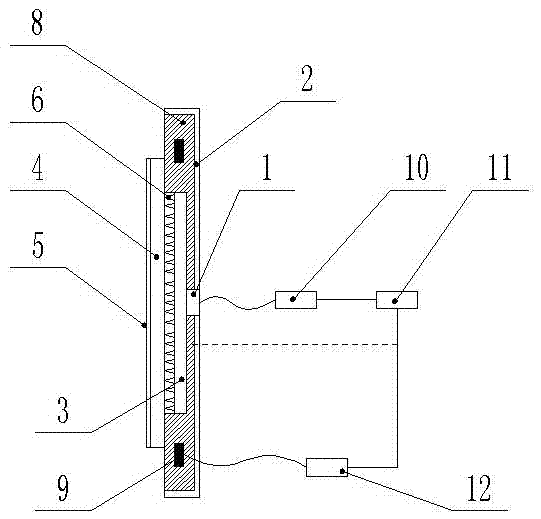

Method and system for measuring polymer melt temperature field based on capacitance tomography

InactiveCN102620855AImprove accessQuick responseThermometers using electric/magnetic elementsUsing electrical meansTomographyPolymer melt

The invention discloses a method and a system for measuring a polymer melt temperature field based on capacitance tomography. The method comprises the following steps of: measuring a capacitance value of a capacitance pole plate of a capacitance type polymer melt temperature field sensor, which is calibrated; according to a capacitance tomography image reconstruction algorithm, reconstructing polymer melt dielectric constant distribution based on the measured capacitance value; establishing a relationship model of polymer melt dielectric constant and temperature; and according to the relationship model, converting the polymer melt dielectric constant distribution into the corresponding polymer melt temperature field. By the invention, the polymer melt temperature acquisition ability of a person is improved, the method is superior to the conventional partial single-point measurement mode, the problem of difficulty in measurement of the polymer melt temperature field in the conventional temperature measurement method is solved, and the method has the advantages of non-invasiveness, high response speed, simple structure and the like.

Owner:SOUTH CHINA UNIV OF TECH

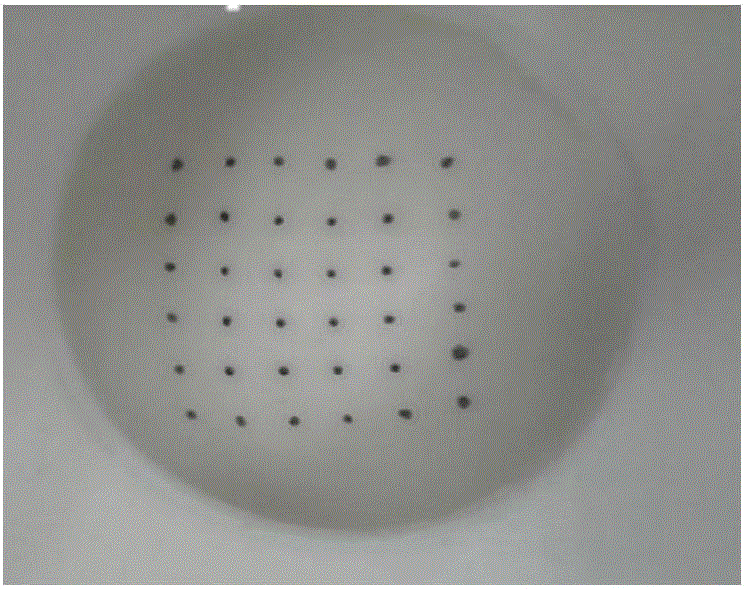

Tactile sensor based on elastomer three-dimensional deformation and detection method

InactiveCN106092382AImprove accessImprove stabilityForce measurement by elastic gauge deformationElastomerEngineering

The invention relates to a tactile sensor based on elastomer three-dimensional deformation and a detection method. The sensor part mainly comprises an elastomer, a binocular camera and a lighting source, wherein the binocular camera and the lighting source are both located above the elastomer; the binocular camera acquires image information through deformation of the elastomer and the contact force can be solved; and then, the direction and the distribution of the contact force are calculated. Through designing a brand new structure, the three-dimensional deformation of the elastomer is acquired for analysis and calculation to obtain the size and the direction of the contact force, the structure is simple, wiring is convenient, and the whole cost can be greatly reduced.

Owner:SHANDONG UNIV

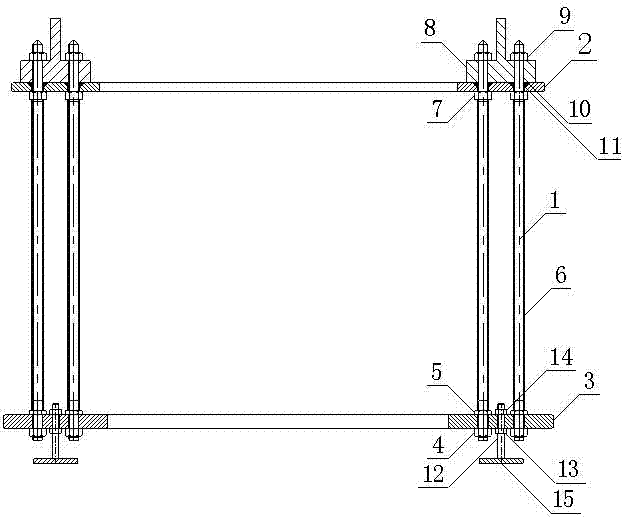

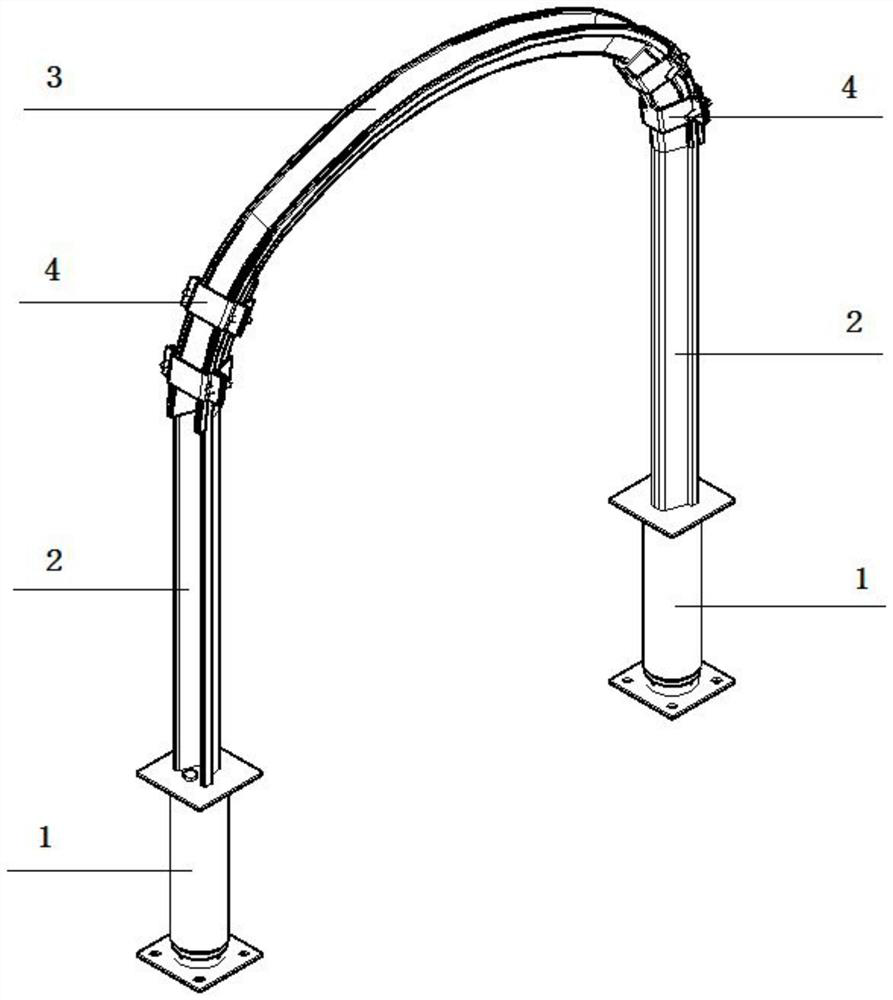

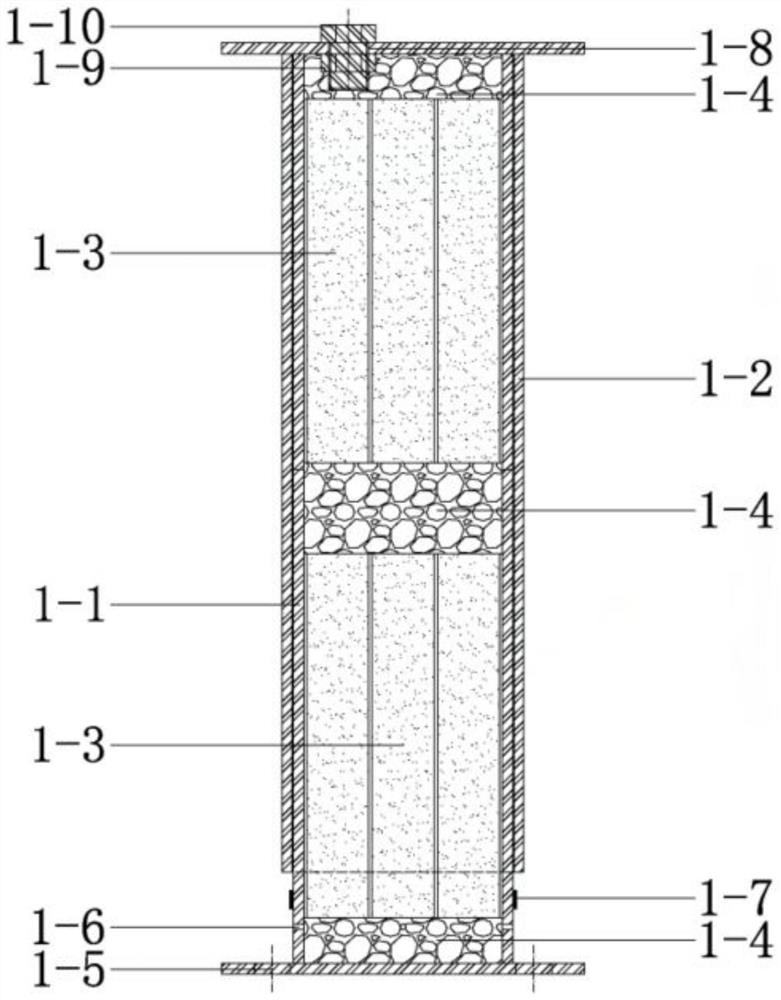

Wind power generation tower prestress anchor bolt cage

InactiveCN103938647AImprove force transmission performanceOverall goodBulkheads/pilesSteel platesEngineering

The invention relates to a wind power generation tower prestress anchor bolt cage which comprises an anchor bolt, an upper flange and a lower flange. The anchor bolt penetrates through an anchoring nut, the lower flange, a positioning nut, an anchor bolt casing pipe, an adjusting nut, the upper flange, a T-shaped flange at the bottom of a wind power generation tower and a locking nut in sequence. The upper flange is an annular steel plate, an anchor bolt hole is an inverted-cone hole, and the adjusting nut can support the upper flange and adjust the levelness of the upper flange; the lower flange is an annular steel plate, a lower flange support bolt and a support nut bear the weight of the lower flange and can adjust the levelness of the lower flange, the lower flange is fixed through a pressing nut, and the lower flange support bolt is supported on a base plate. According to the wind power generation tower prestress anchor bolt cage, the anchor bolt and foundation concrete are separated through the anchor bolt casting pipe, the anchor bolt applies pretension force, and the concrete is subjected to the stress; the position and levelness of the upper flange are adjusted through the adjusting nut; the inverted-cone hole of the upper flange enables the center area, the inner edge and the outer edge of the T-shaped flange at the bottom to be pressed against the upper flange more tightly, and the inverted-cone hole is filled with sealing materials. The wind power generation tower prestress anchor bolt cage enables the integrality of the connection of a tower frame and the foundation to be good, is even in rigidity, and improves durability and anti-fatigue performance of connection.

Owner:闵怡红

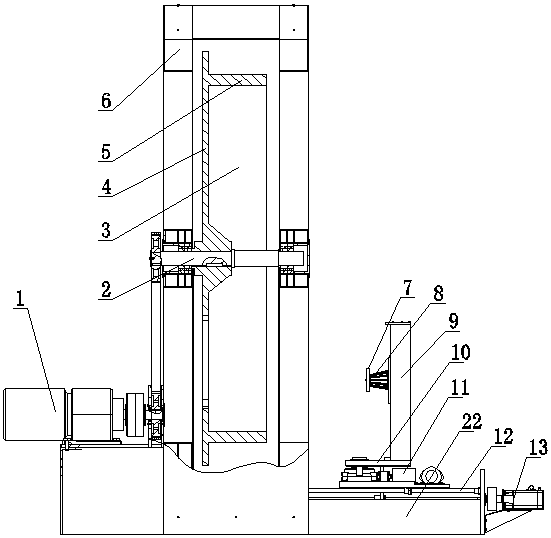

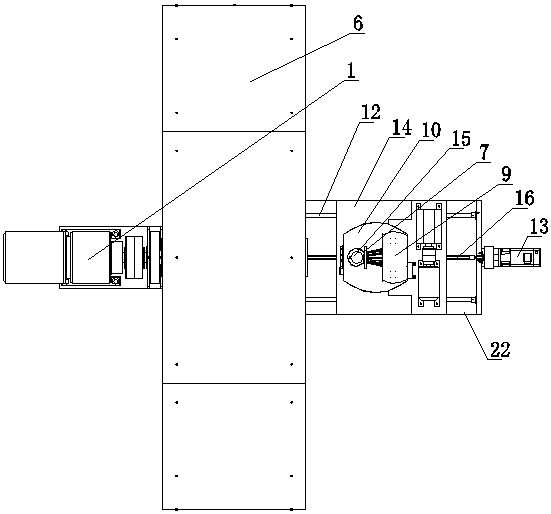

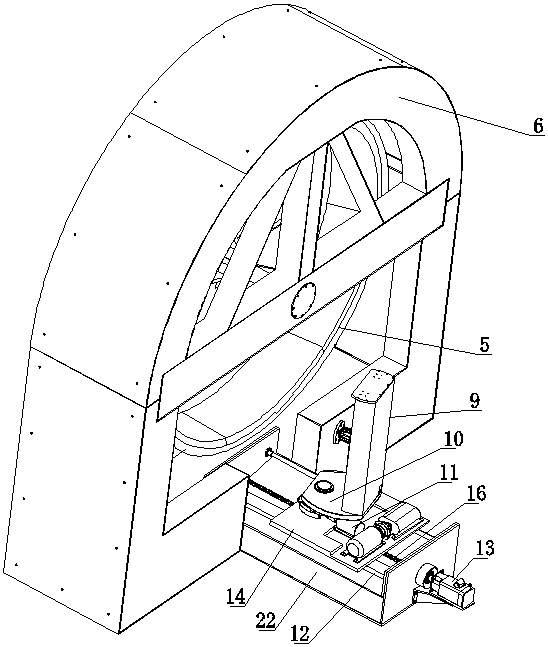

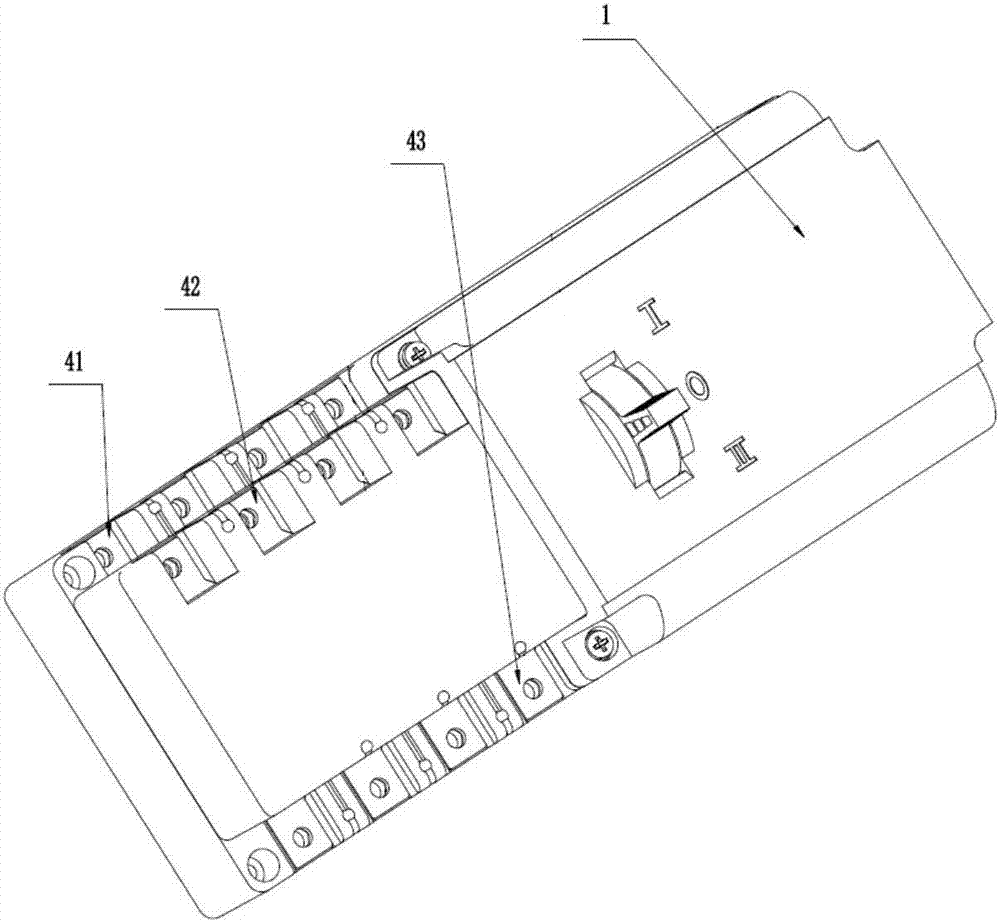

Movable protection mechanism of tokamak vacuum indoor diagnosis device

InactiveCN101510451AImprove accessNuclear energy generationThermonuclear fusion reactorCircular discProtection mechanism

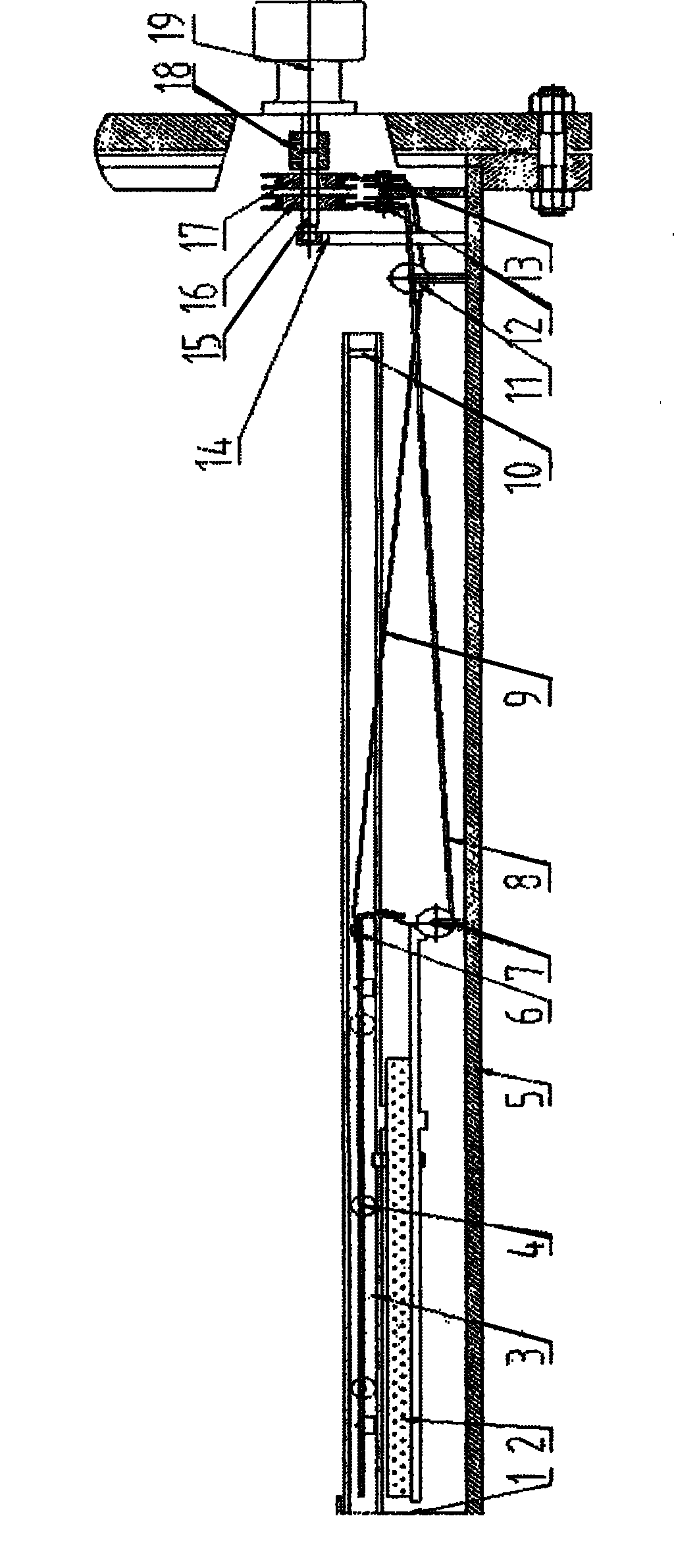

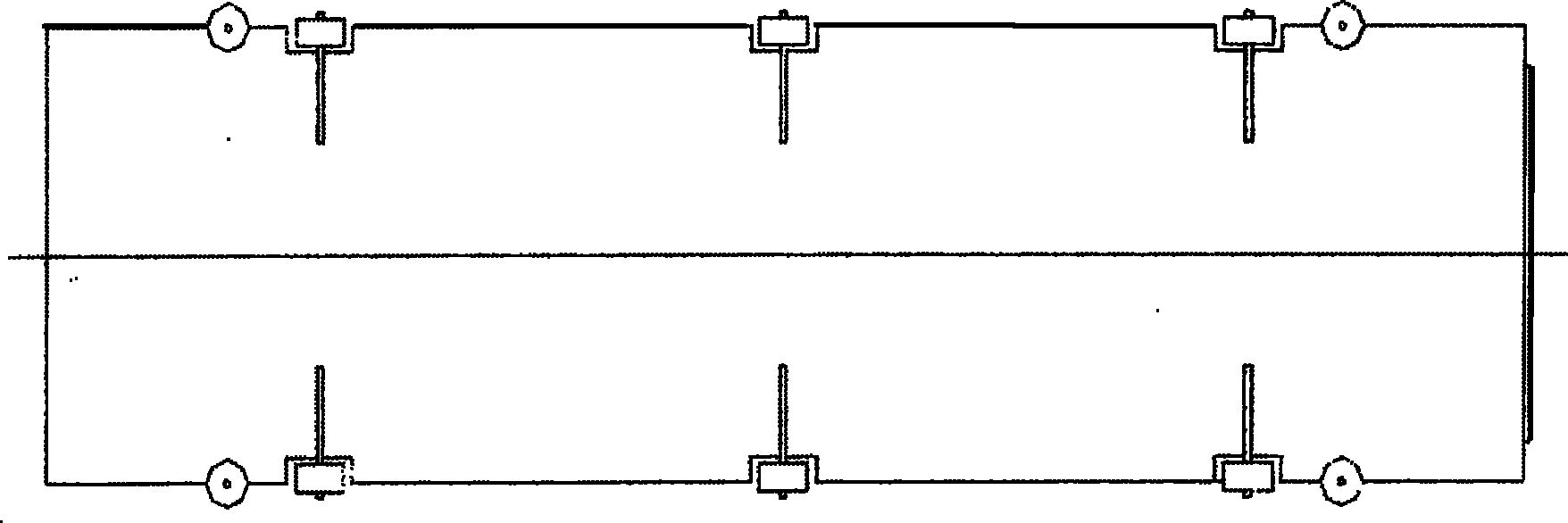

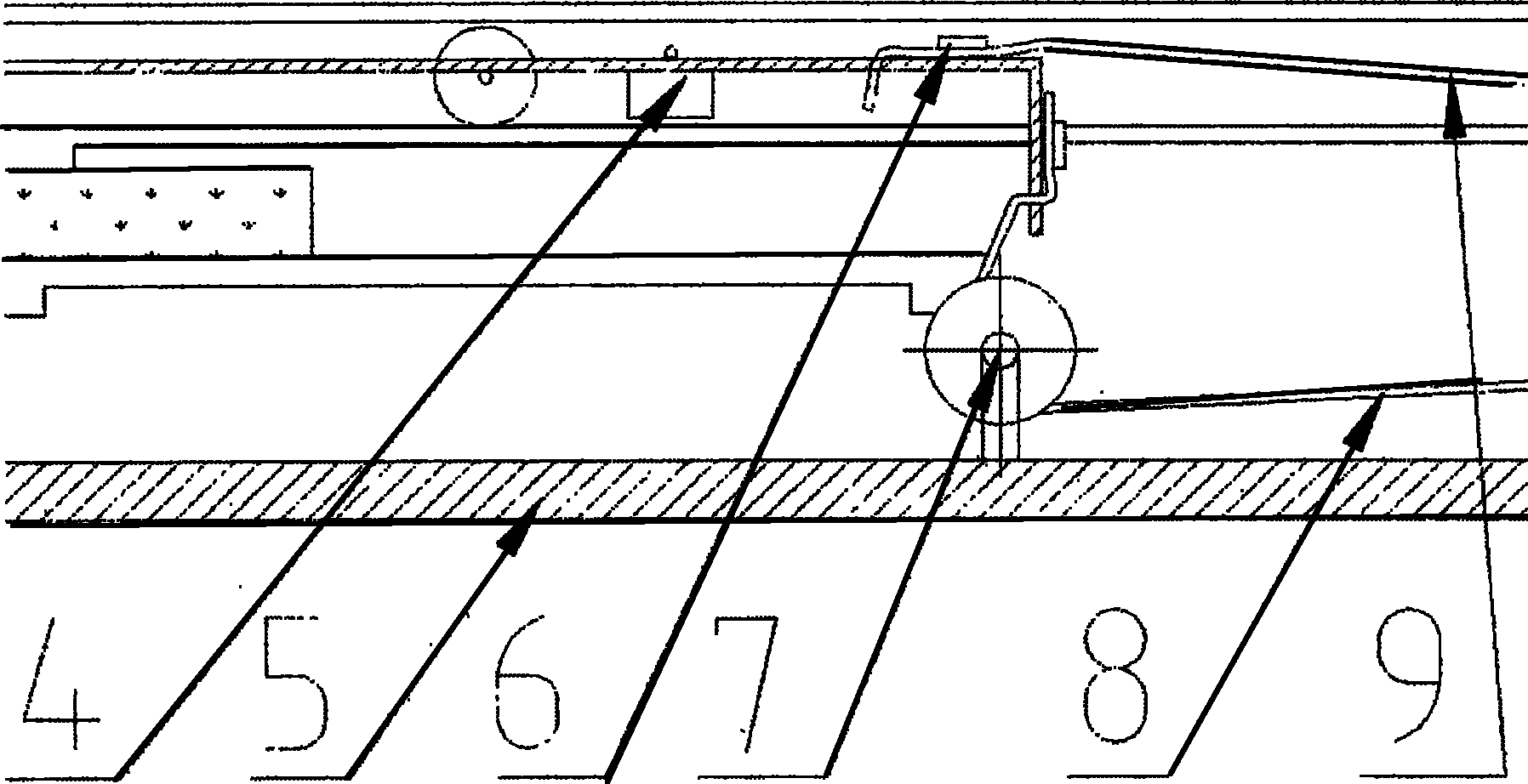

The invention discloses a movable protection mechanism for a Tokamak vacuum indoor diagnosis device, which comprises a sliding baffle for protecting the diagnosis device, wherein, the movement of the sliding baffle is controlled by a first steel wire rope and a second steel wire ropes fixedly linked on the sliding baffle; under the leading of a fixed pulley, the first steel wire rope and the second steel wire rope respectively enwind on a first disk and a second disk on a transmission shaft and are respectively fixedly linked with the first disk and the second disk; and the rotation of the transmission shaft is realized by a vacuum mechanical rotating shaft through a coupler. The first steel wire rope and the second steel wire rope are drawn and released on the first disk and the second disk by rotating the vacuum mechanical rotating shaft, thereby realizing the forward and backward movement of the sliding baffle in a support track so as to protect the diagnosis device when being opened or closed. The movable protection mechanism avoids the phenomenon that high-temperature roasting probably leads to the fixed clamping of a long-stroke mechanism. The movable protection mechanism is successfully applied to protecting EAST superconducting Tokamak H(alpha) diagnosis devices (optical mirrors), and ensures that the reflecting mirrors are not damaged during the processing course of vacuum walls.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Comprehensive tire abrasion testing machine

ActiveCN107860673AImprove accessThe test effect is goodInvestigating abrasion/wear resistanceRoad surfaceEngineering

The invention provides a comprehensive tire abrasion testing machine and relates to the technical field of tire abrasion testing machines. The comprehensive tire abrasion testing machine comprises a frame, wherein a rotation shaft is mounted on the frame; a power source is arranged and is connected with the rotation shaft through a transmission device; a rotation drum is arranged on the rotation shaft on the front side of the frame; a circular testing groove coaxial with the rotation shaft is formed in the rotation drum; a lateral deflection table is arranged on the front side of the rotationdrum and is connected with a rotation table driving device used for driving the lateral deflection table to rotate; a tire loading frame is arranged on the lateral deflection table; a guide rail is arranged on the tire loading frame; a sliding seat is arranged on the guide rail; a sliding seat driving device is arranged and is connected with the sliding seat; a tire shaft is arranged on the sliding seat; a wheel hub mounting disc is arranged at the end of the tire shaft; a force measuring sensor is arranged between the sliding seat driving device and the sliding seat. The comprehensive tire abrasion testing machine has the advantages that the tire is internally tangent to the road surface, the volume is small, the production cost and the usage cost are low, and the testing results are accurate.

Owner:HARBIN INST OF TECH AT WEIHAI

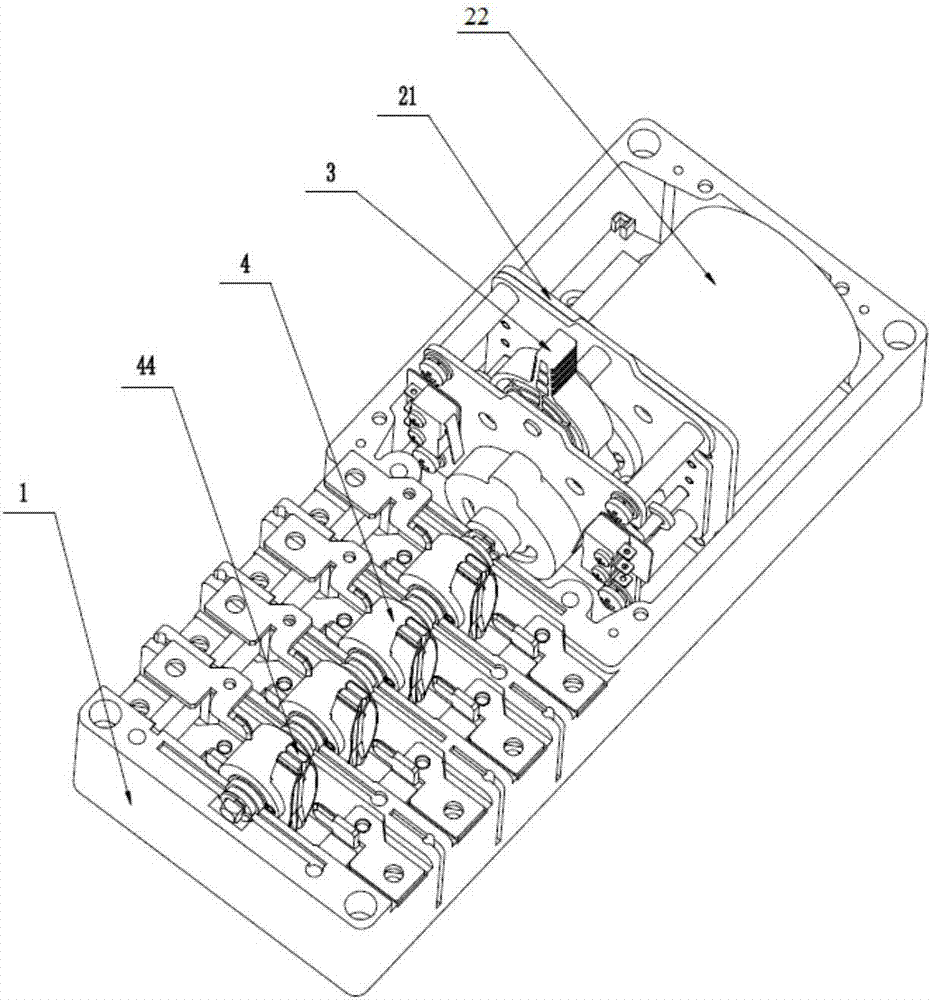

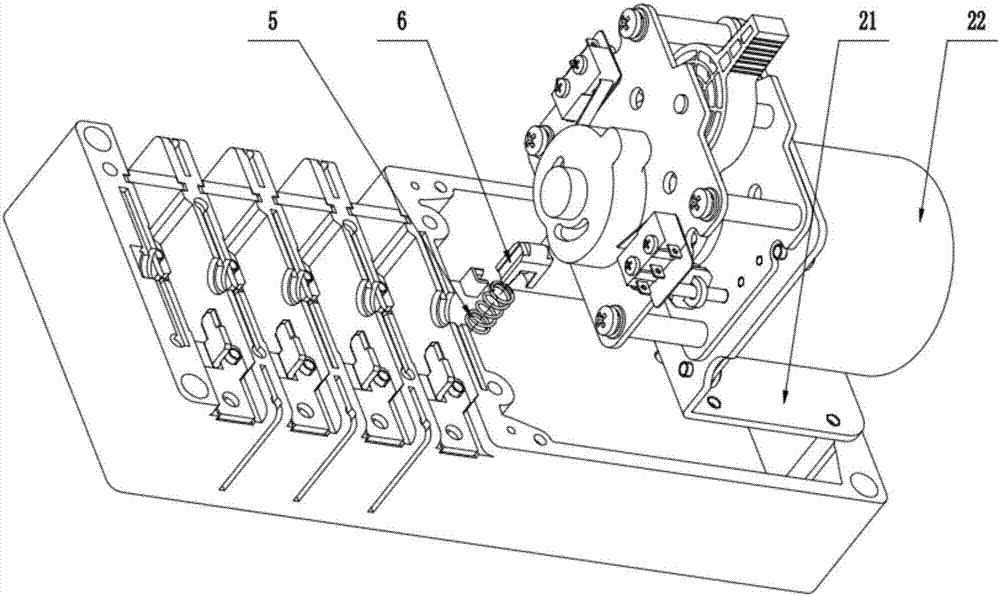

PC-class automatic changeover switch device with energy storage mechanism

The invention relates to a PC-class automatic changeover switch device with an energy storage mechanism. The device comprises a base, a contact system which is arranged on the base, the energy storage mechanism which is in transmission connection with the contact system and a drive motor which is in transmission connection with the energy storage mechanism, wherein the drive motor is fixed on the base through a motor support; the energy storage mechanism comprises an energy storage support unit, an energy storage gear, an energy storage handle, an energy storage spring assembly and an energy storage cam, wherein the energy storage support unit is fixedly connected to the motor support; the energy storage gear is arranged in the energy storage support unit and is in transmission connection with the drive motor; the energy storage handle which is arranged above the energy storage gear and the bottom of the energy storage handle which is engaged with the energy storage gear; the energy storage spring assembly cooperates with the energy storage gear; and the energy storage cam is coaxial to the energy storage gear, is arranged at the outer side of the energy storage support unit and is in transmission connection with the contact system. Compared with the prior art, the device has simple and compact overall structure and convenient processing and manufacturing, and the energy storage mechanism is provided, so that when the automatic changeover switch rotates, the phenomenon of clamping stagnation or failed linkage cannot occur, and the device is safe and reliable.

Owner:DELIXI ELECTRIC

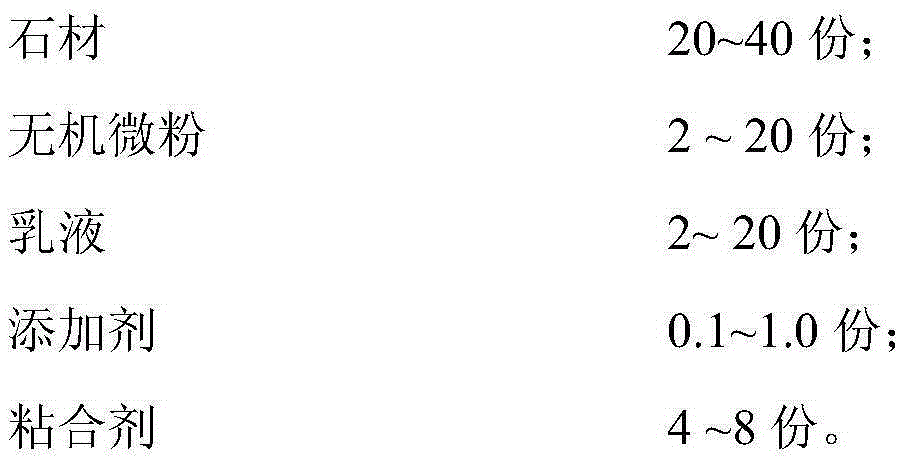

Composite stone material and preparation method of same

ActiveCN105236853ADecorativeImprove thermal insulation performanceWater-setting substance layered productEmulsionSurface layer

The invention discloses a composite stone material and a preparation method of the same. The composite stone material includes a stone material base layer and a sheet material layer, wherein the composite stone material includes the following raw materials, by weight: 20-40 parts of a stone material, 2-20 parts of inorganic micro powder, 2-20 parts of emulsion, 0.1-1.0 part of an additive and 4-8 parts of a binder. The preparation method includes the steps of: uniformly stirring the inorganic micro powder, the additive and other components according to certain process, and performing die-filling, allowing the materials to stand to foam the materials, maintaining the materials, and drying, cutting and polishing the materials to obtain the light-weight energy-saving sheet material; and binding the stone material to the light-weight heat-preservation sheet material through the binder, wherein the stone material is the decorative surface layer and the light-weight heat-preservation sheet material is a lining layer, to produce the composite stone material when the binder is hardened. The preparation method is simple. The composite stone material is excellent in comprehensive mechanical performance and is low in heat conductive coefficient, has a heat-preservation and -insulation effect, is green, energy-saving and environment-friendly, and can be widely used in various indoor and outdoor decoration projects having strict energy-saving demand.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

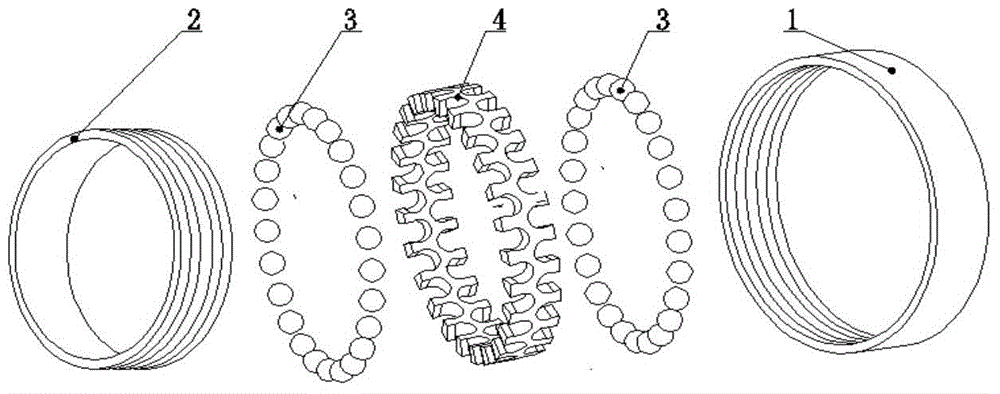

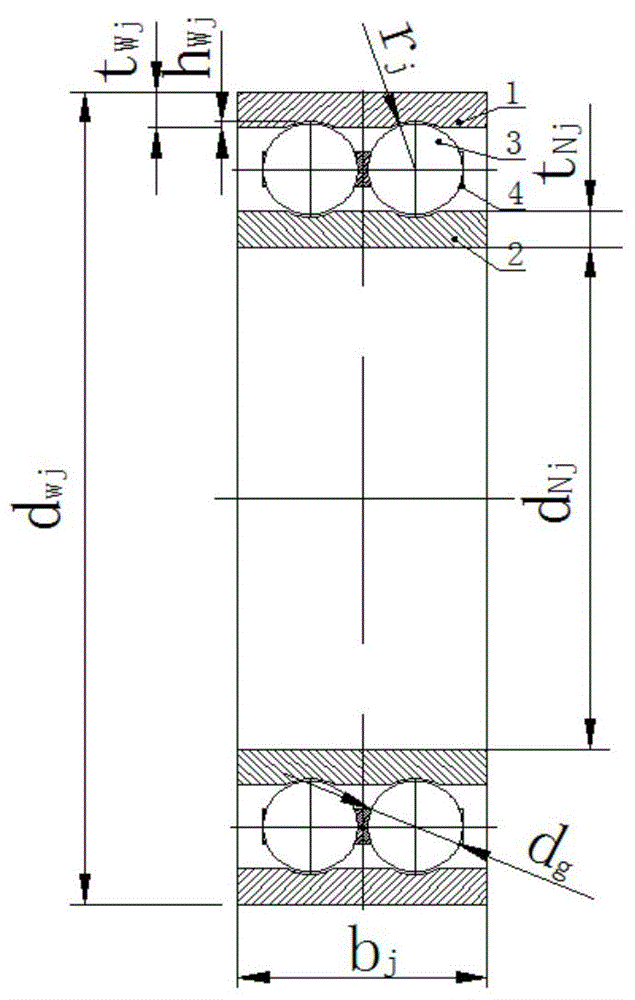

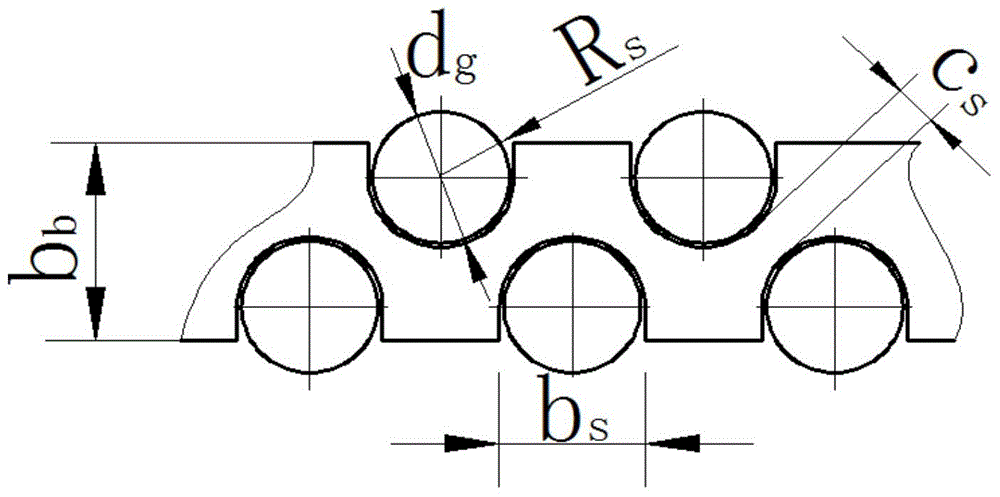

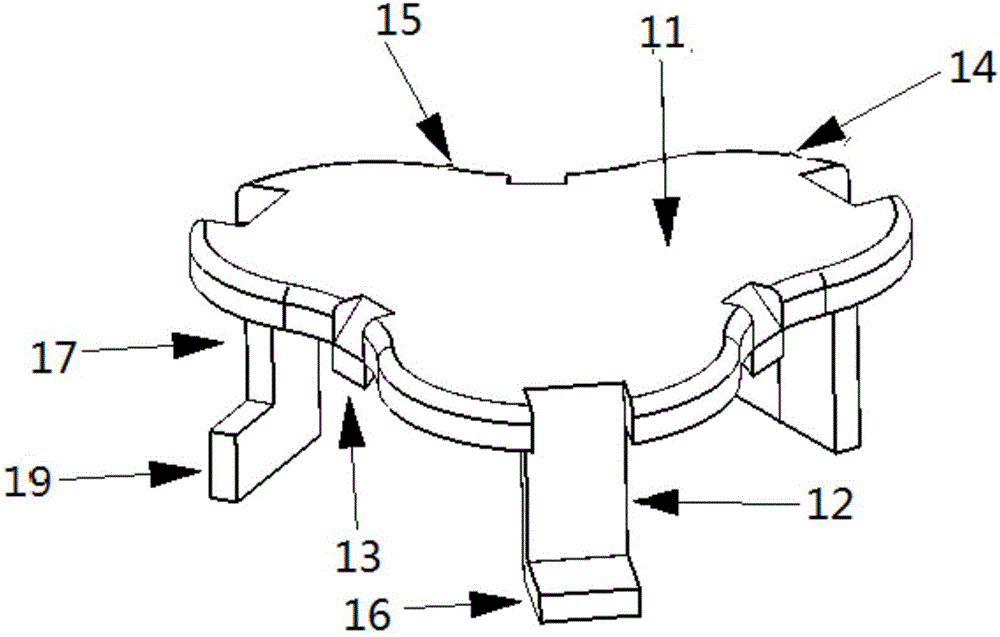

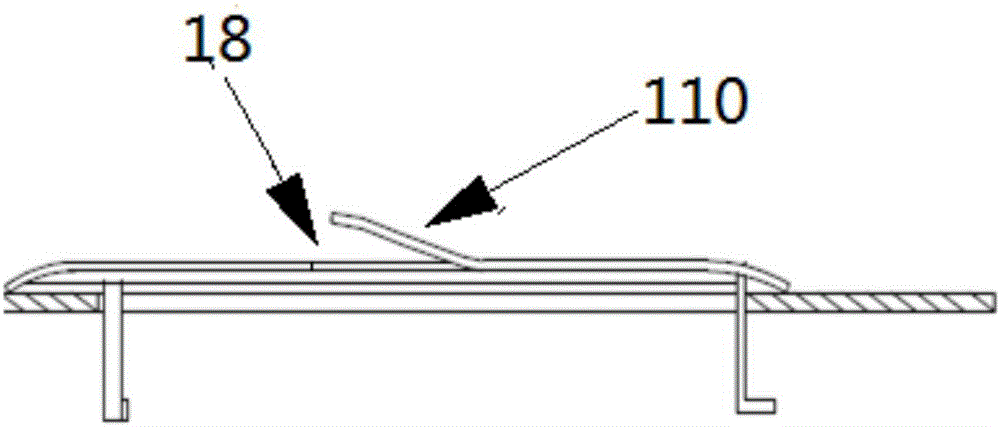

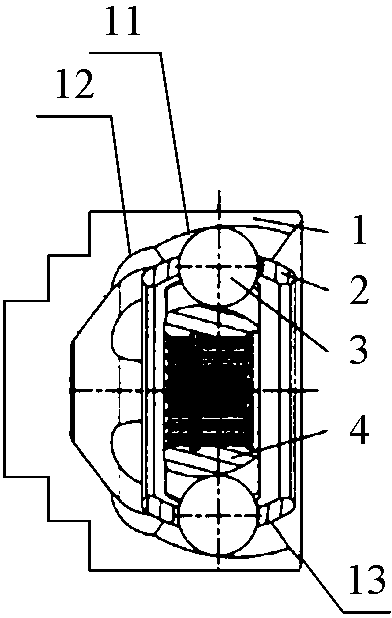

Double-row ball thin-walled flexible bearing and harmonic gear reducer

ActiveCN105156469AIncreased axial and circumferential stiffness and load carrying capacityImprove accessRolling contact bearingsToothed gearingsDistortionEllipse

The invention discloses a double-row ball thin-walled flexible bearing and a harmonic gear reducer. The double-row ball thin-walled flexible bearing comprises an outer ring, an inner ring coaxially disposed in the outer ring, an annular integral holder disposed between the outer ring and the inner ring, and rolling elements. Two rows of semicircle-shaped ball socket holes with openings in staggered arrangement are disposed along the outer circumference of the holder, the semicircle-shaped ball socket holes with openings in the same row have the same opening directions and are arrange in a uniformly-spaced manner, the semicircle-shaped ball socket holes with openings in the different rows have the opposite opening directions. The rolling elements are disposed in the ball socket holes of the holder, and are positioned on the arc-shaped raceways on the outer ring and the inner ring. The double-row ball thin-walled flexible bearings sleeve outer walls of the elliptical cams to form a wave generator subassembly. The rigidity in radial and circumferential direction and bearing capability of the harmonic gear reducer are improved, and then the contact status between the rigid and flexible wheels in the working process are improved, and distortion and snapping teeth of the flexible wheel under high overload are avoided, so that the working life of the harmonic gear reducer is prolonged.

Owner:NANJING UNIV OF SCI & TECH

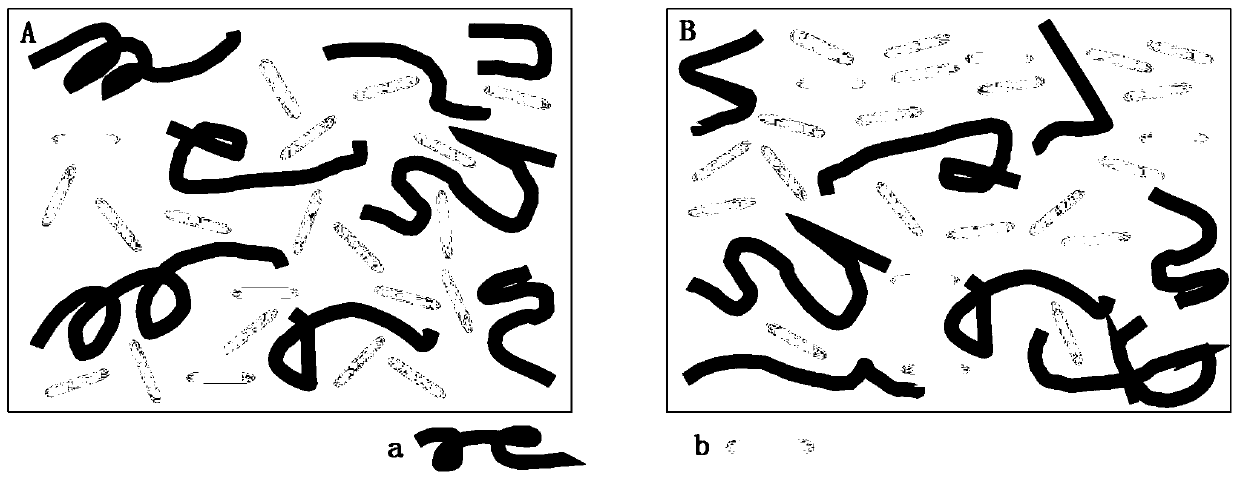

Centrifugal assistant light active layer stratified organic solar cell based on spinning-coating process, and preparation method thereof

ActiveCN110504371AImprove interface contactImprove performance parametersSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellNitrogen gas

The invention relates to the field of the organic semiconductor thin-film solar cell, and specifically discloses a centrifugal assistant light active layer stratified organic solar cell based on spinning-coating process, and a preparation method thereof. The preparation method comprises the following steps: S1, cleaning a baseplate composed of a transparent substrate and an ITO transparent conductive cathode layer, and blow-drying by using nitrogen after cleaning; S2, spinning-coating, printing or spraying PEDOT: PSS precursor solution on the ITO transparent conductive cathode layer surface, and preparing an anode buffer layer, and performing low-temperature baking on the formed thin-film; S3, preparing a PBDB-ITIC light active layer on the anode buffer layer by adopting the spinning-coating process; S4, adhering the baseplate spun-coated with the PBDB-T:ITIC light active layer to a vertical sidewall to perform rotary centrifuging; S5, performing thermal annealing treatment on the PBDB-T:ITIC light active layer in a glovebox; S6, evaporating LiF on the PBDB-T:ITIC light active layer surface under the condition that the vacuum degree is 3*10<3>Pa, and preparing a cathode buffer layer; and S7, evaporating a metal cathode layer on the cathode buffer layer. And an aim of improving various performance parameters of the organic solar cell is finally improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

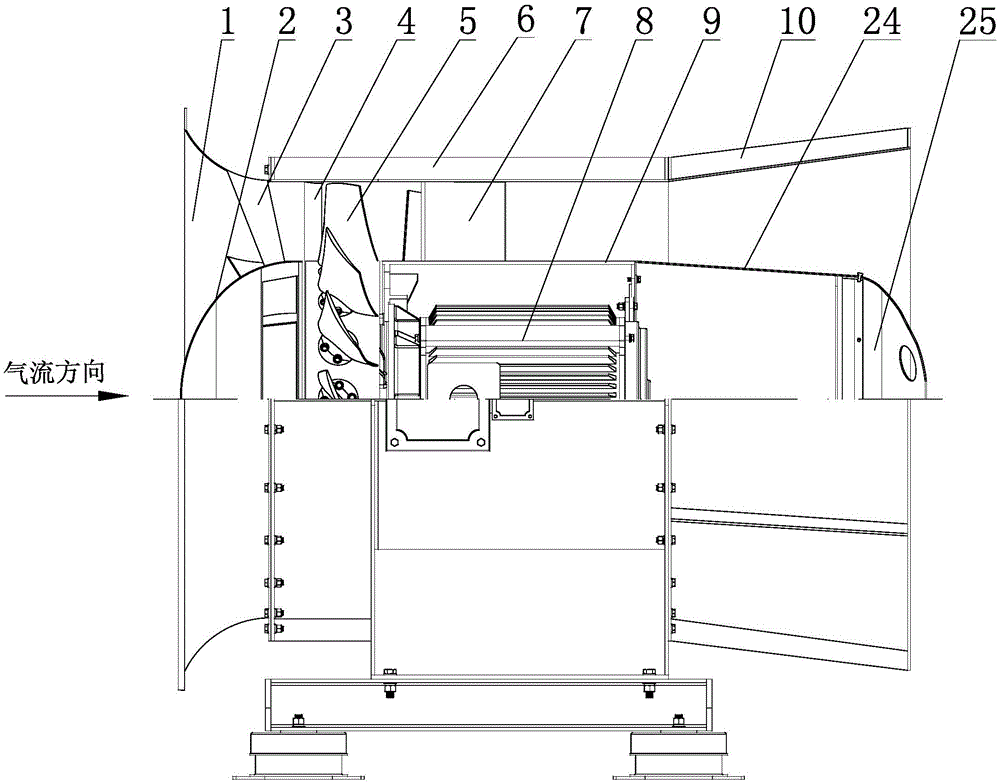

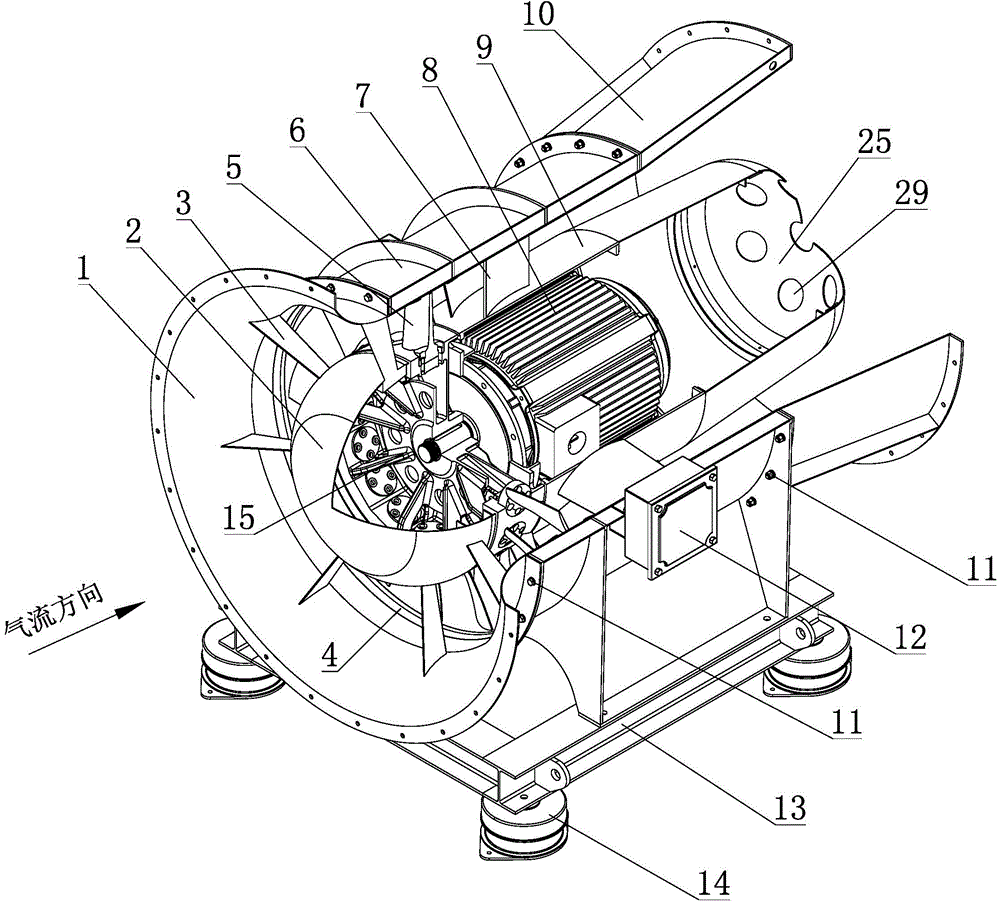

Axial flow fan for nuclear power station containment continuous ventilation system

InactiveCN104564744AImprove reliabilityEnsure flat contactPump componentsPump installationsImpellerNuclear power

The invention relates to a high pressure axial flow fan applied to various high pressure axial flow ventilation system, particularly relates to an axial flow fan for a nuclear power station containment continuous ventilation system, and belongs to the technical field of axial flow fans. The fan comprises a fairing, an impeller and an inner barrel assembly which are arranged in a casing sequentially in the air flow moving direction. The casing is composed of a collector, a fan outer barrel and a diffuser which are sequentially arranged in the air flow moving direction. The fairing is fixedly connected with the collector through a front inlet guide vane. The inner barrel assembly comprises a motor installed in a barrel body, the impeller is installed on an output shaft of the motor, and the outer wall of the barrel body is fixedly connected with the fan outer barrel through the guide vane. The axial flow fan has the advantages of being high in efficiency, saving energy, being low in noise and high in stability and the like.

Owner:ZHEJIANG JINDUN FANS HLDG

Lithium-rich manganese base material lithium ion battery anode and lithium ion battery provided with same

ActiveCN106784789AImprove accessIncrease internal resistanceElectrode carriers/collectorsSecondary cellsFiberHigh rate

The invention relates to an lithium-rich manganese base material lithium ion battery anode which comprises an anode current collector and an anode material layer coating the anode current collector. The anode material layer comprises an anode active substance which is of a lithium-rich manganese base material, the anode current collector is of a conductive substrate with the surface coated with a first conductive coating and a second conductive coating, the first conductive coating is a mixture of a conductive agent and polyvinylidene fluoride, the conductive agent is one or several of conductive carbon black, conductive graphite, a carbon nano tube, grapheme and carbon fiber, the first conductive coating is coated on the surface of the conductive substrate, the second conductive coating is a mixture of polyaniline and polyvinylidene fluoride, and the second conductive coating is coated on the surface of the first conductive coating. The invention further provides a lithium ion battery provided with the lithium-rich manganese base material lithium ion battery anode. The lithium ion battery has the advantages of low internal direct-current resistance, high rate performance, long cycle life and the like.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

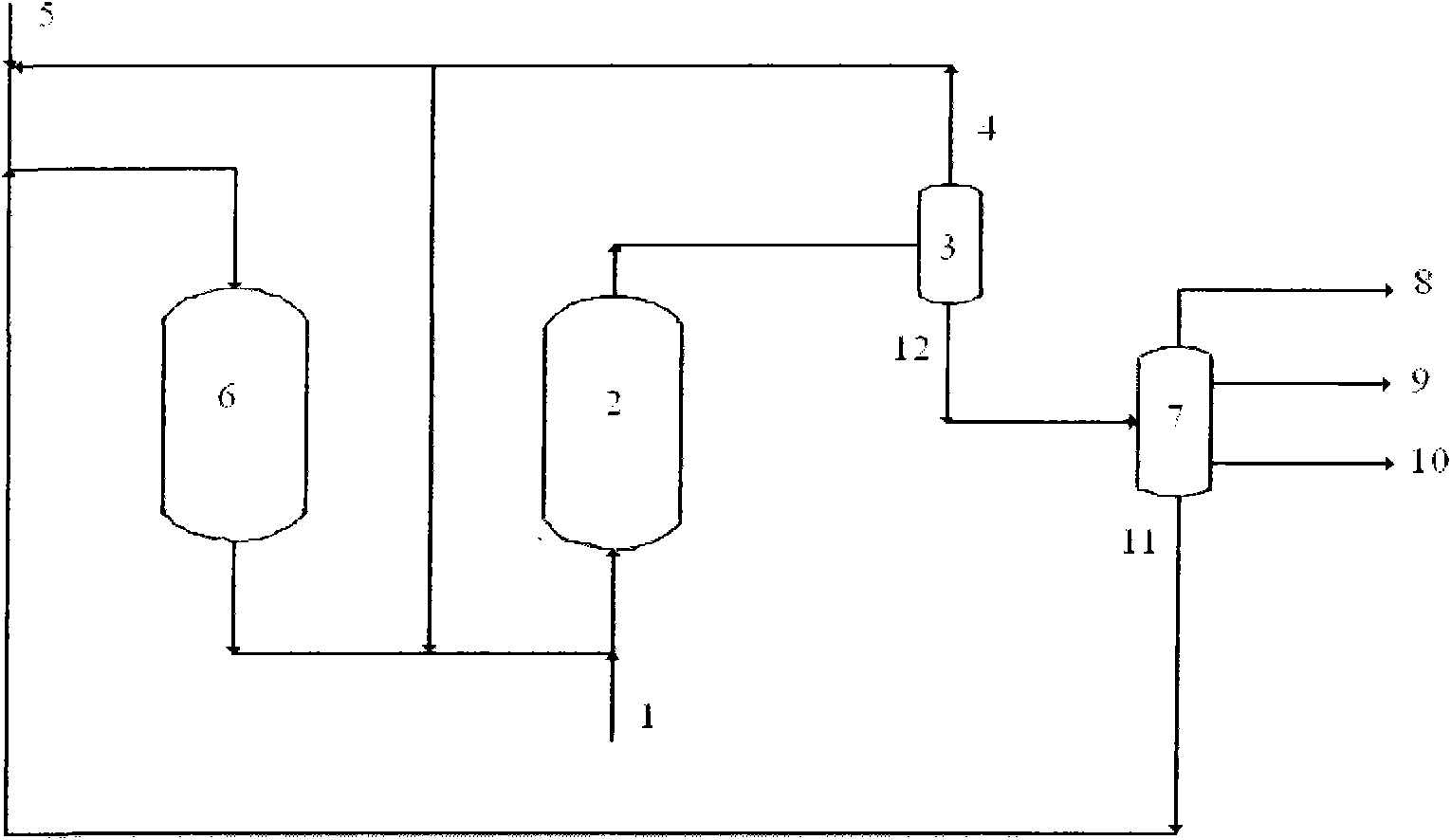

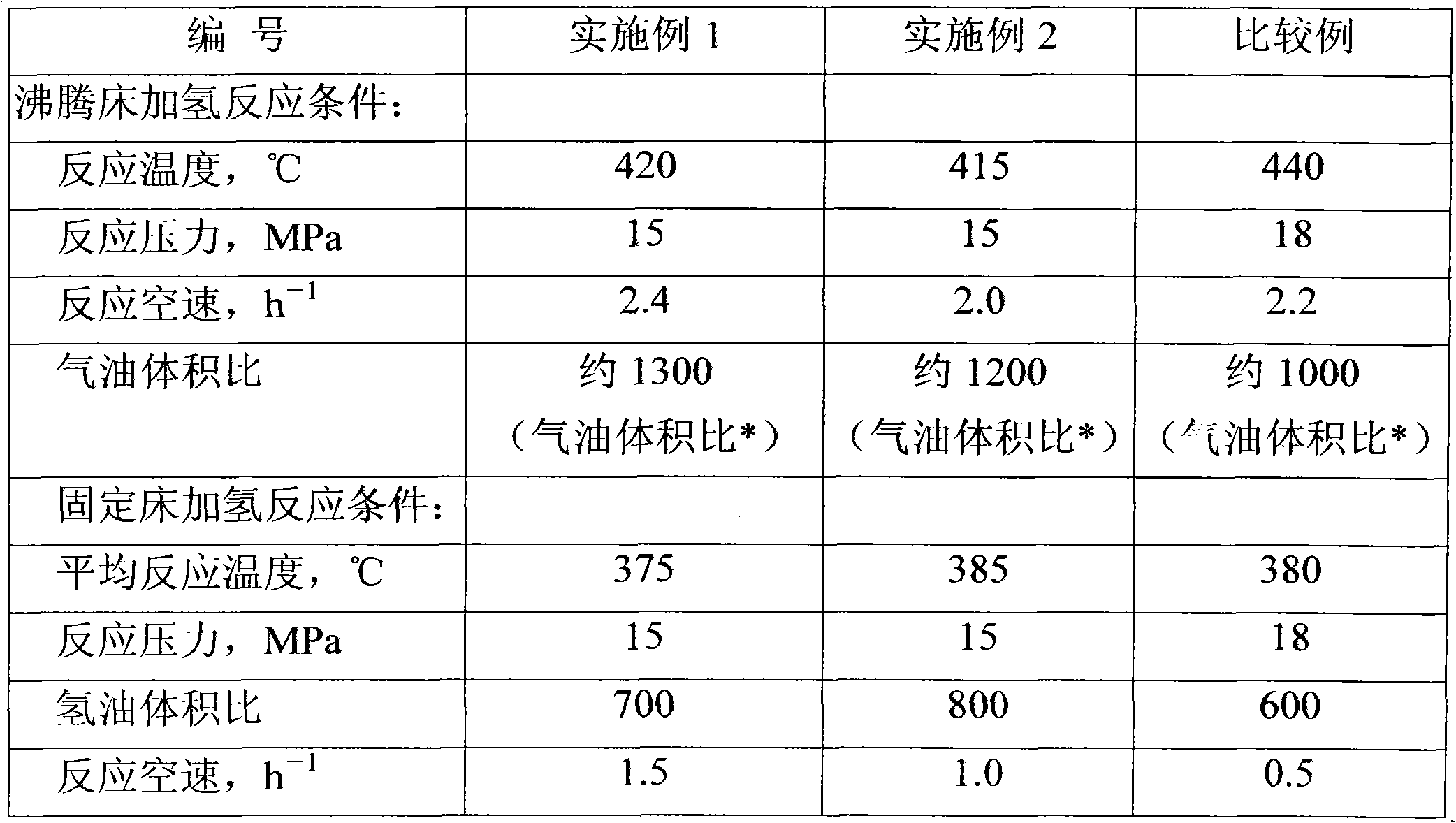

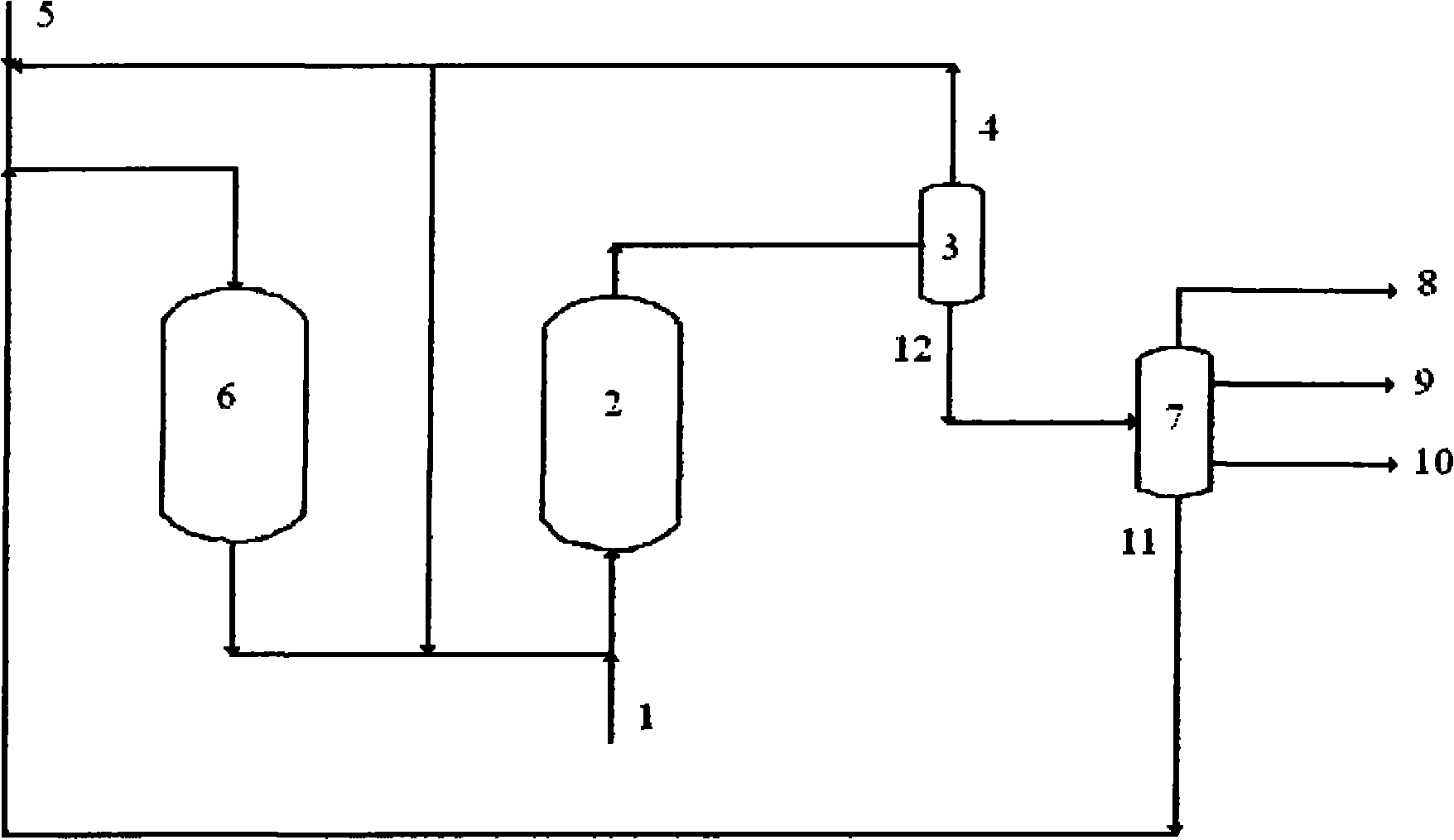

Process of hydrogenation of heavy oil feedstock

ActiveCN102041082AImprove hydrogenation performanceQuality improvementTreatment with hydrotreatment processesHydrogenFixed bed

The invention discloses a process of hydrogenation of heavy oil feedstock, especially the process of hydrogenation of heavy oil feedstock using combination of boiling bed and fixed bed technologies. The process comprises the following steps: mixing heavy oil feedstock and the product obtained from the fixed bed hydrogenation; adding the mixture into boiling bed hydrogenation reactor, separating the materials obtained from boiling bed hydrogenation into to hydrogen-rich gas and liquid; recycling the hydrogen-rich gas; loading the liquid into the fractionate tower and for fractioning to obtain lightweight product and tail oil; mixing the tail oil and hydrogen, and adding the mixture into the fixed bed hydrogenation reactor; and adding all the materials obtained from fixed bed hydrogenation into the boiling bed hydrogenation reactor. Compared with existing technology, the method of the invention effectively combines the boiling bed and the fixed bed hydrogenation technology characteristics, allows the product obtained from fixed bed hydrogenation directly to enter the boiling bed reactor, thereby improves the flow state of the boiling bed feed, and enhances heat and mass transfer effects among gas, liquid and solid. Simultaneously, product properties are obviously improved after the tail oil obtained from the boiling bed hydrogenation is hydrogenated by the fixed bed. Employing the operation mode of the heavy oil hydrogenation can improve the product quality significantly and increase yield of the light oil obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

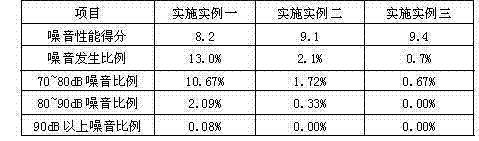

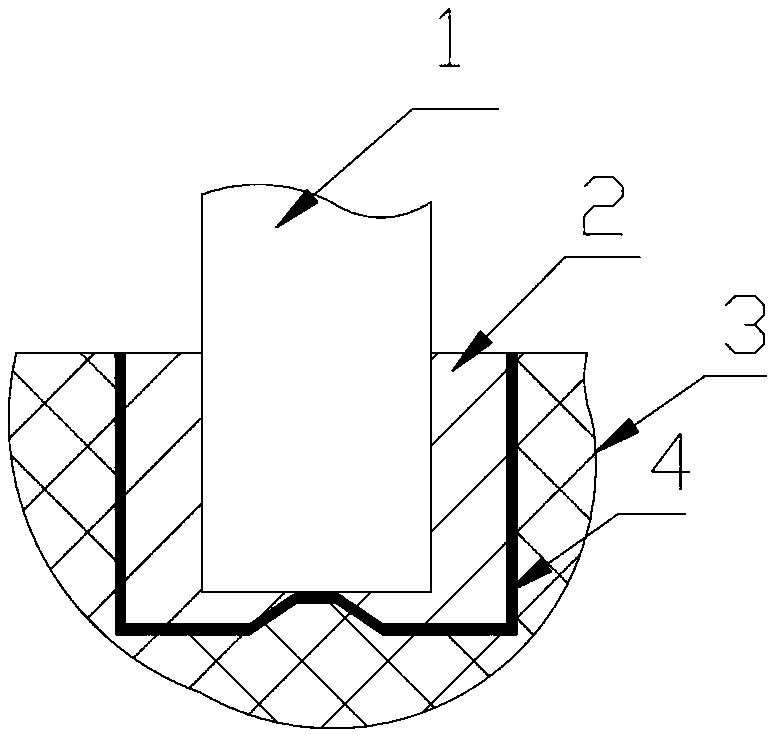

Low-noise ceramic brake pad and preparation method thereof

Main components of a low-noise ceramic brake pad comprise ceramic fibers, sisal fibers, polyacrylonitrile fibers, FKF complex mineral fibers, boric acid modified phenolic resin, a titanate coupling agent, chlorinated paraffin, superfine fully-vulcanized powdered rubber, a brown fused alumina friction increasing material, flaky aluminium powder, nanoscale molybdenum disulfide, mica, calcium sulfate whiskers and titanium dioxide whiskers. Starting from reduction of the noise of the ceramic brake pad, the friction noise is reduced remarkably while the high friction performance of the ceramic brake pad is met by strictly controlling the use quantities and matching of enhanced fibers, adhesives, filler, friction powder and lubrication materials and adding organic enhanced fibers.

Owner:QINGDAO UNIV

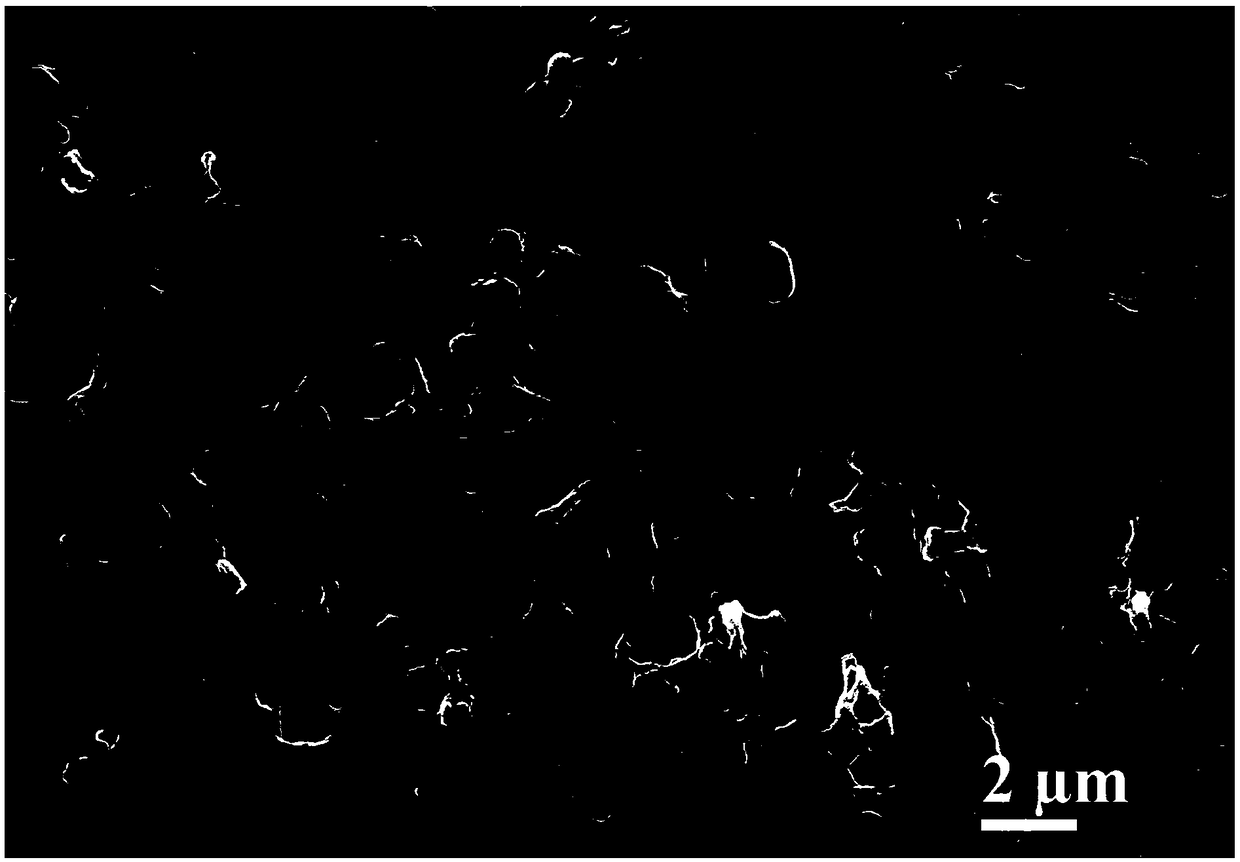

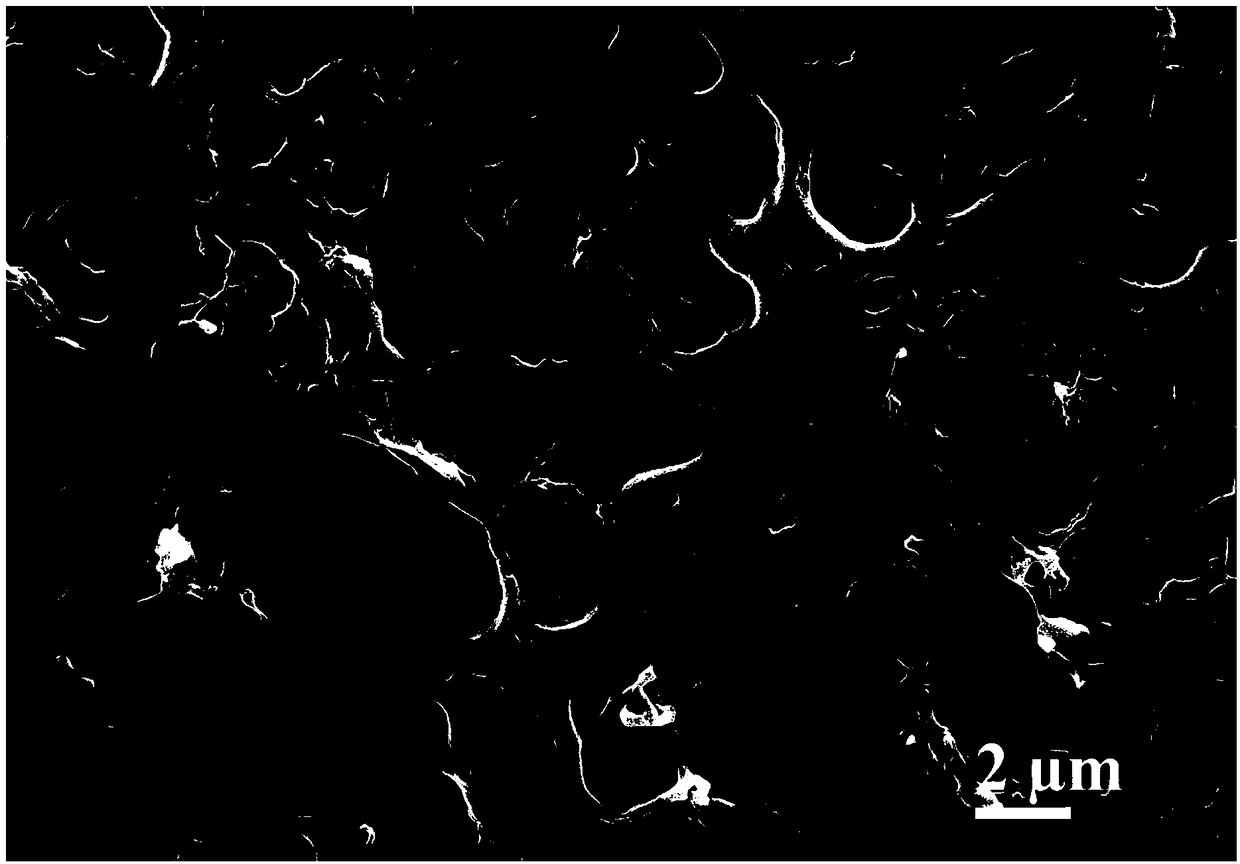

Construction method for proton exchange membrane with three-dimensional high specific surface area surface, and high performance membrane electrode based on proton exchange membrane

The invention discloses a construction method for a proton exchange membrane with a three-dimensional high specific surface area surface, and a high performance membrane electrode based on a proton exchange membrane. The method comprises the following steps: (1) preprocessing the proton exchange membrane; (2) mixing one or multiple types of pore-forming agent and perfluorinated sulfonic acid resinsolution which can be easily removed in water or low-boiling-point solvent, and carrying out ultrasound to form porous-layer slurry; (3) adopting a coating technology to coat one side of the proton exchange membrane layer with the porous-layer slurry to obtain a porous membrane precursor; (4) carrying out acid treatment on the porous membrane precursor, and washing with distilled water to obtainthe porous membrane used for a proton exchange membrane fuel battery. Compared with a commercial proton exchange membrane, the porous membrane prepared with the method has the advantages of regular three-dimensional porous structure and large specific surface area on a premise that membrane thickness is not obviously increased, and the performance of the final prepared membrane electrode of the proton exchange membrane fuel battery is improved.

Owner:SOUTH CHINA UNIV OF TECH

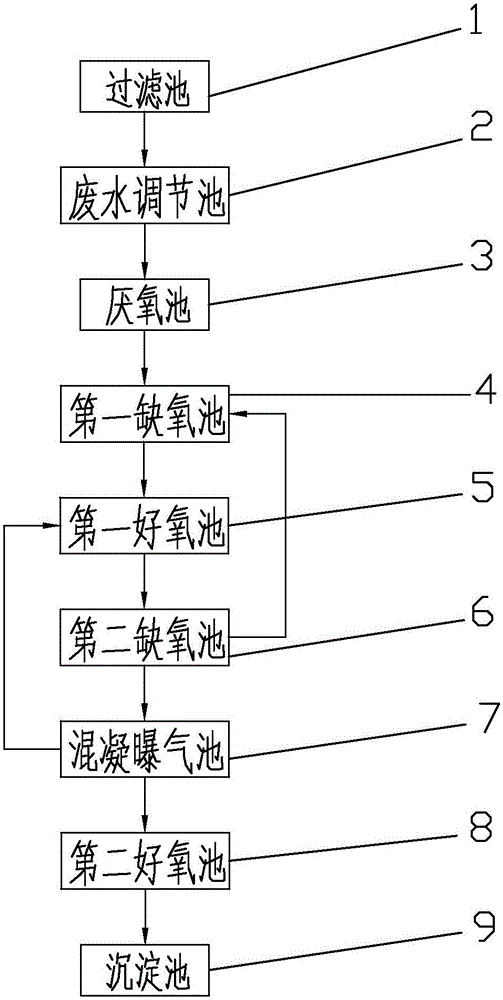

Treatment method applied to chemical industrial wastewater

InactiveCN106007207ASolve processing problemsReduce the content of harmful substancesWater treatment parameter controlTreatment using aerobic processesHazardous substanceTherapeutic effect

The invention discloses a treatment method applied to chemical industrial wastewater. The treatment method comprises the following treatment steps of (a) chemical industrial wastewater pretreatment, (b) biochemical treatment of chemical industrial wastewater and (c) physical treatment of chemical industrial wastewater. According to the treatment method, the chemical industrial wastewater is sequentially subjected to the chemical industrial wastewater pretreatment, the biochemical treatment of chemical industrial wastewater and the physical treatment of chemical industrial wastewater, and the chemical industrial wastewater reaching the discharge standard is obtained. The treatment method is especially suitable for treatment of organic chemical industrial wastewater having strong biological toxicity and poor biochemical properties and can deeply treat chemical industrial wastewater, the harmful matter content in the treated wastewater is reduced to the most degree, the lower treatment degree is avoided, and accordingly the problem that treated wastewater still cause large environmental pollution is solved. In addition, in the wastewater treatment process, all links can be performed in order, the treatment method is simple in structure, scientific, convenient, strong in pertinence, high in automation degree, low in actural application cost, advanced in technology and good in treatment effect, and the chemical industrial wastewater treatment problem is well solved.

Owner:衢州市协成化工有限公司

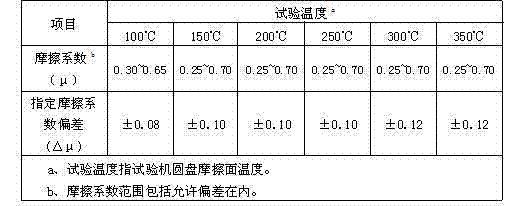

Safe friction material with low noise and preparation method of friction plate

The invention aims at providing a friction material with high friction coefficient and safety performance and low noise and a preparation method of a friction plate. The friction material comprises the following components in percentage by weight: 4-10% of resin, 6-10% of coke powder, 0.5-5% of nitrile powder, 1-8% of tire powder, 1-4% of corundum, 9-20% of graphite, 1-3% of iron black, 4-5% of chromite powder, 1-3% of active carbon, 2-5% of friction powder, 20-30% of fiber and 30-55% of filler; and the preparation method of the friction plate prepared from the friction material comprises the following steps of (1) material blending, namely preparing a blended material of the friction material; (2) pre-pressing, namely pre-molding the blended material; (3) hot pressing, namely placing a pressed blank into a mould to carry out hot pressing, and then, carrying out exhaust gas disposal at intervals; (4) thermal treatment, namely heating from the room temperature to the temperature of 185 DEG C in stages at constant speed, and preserving the heat; and (5) size processing. The friction material is applied to the field of friction materials.

Owner:ZHUHAI HUALI FRICTION MATERIAL

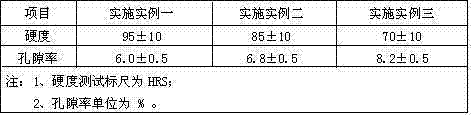

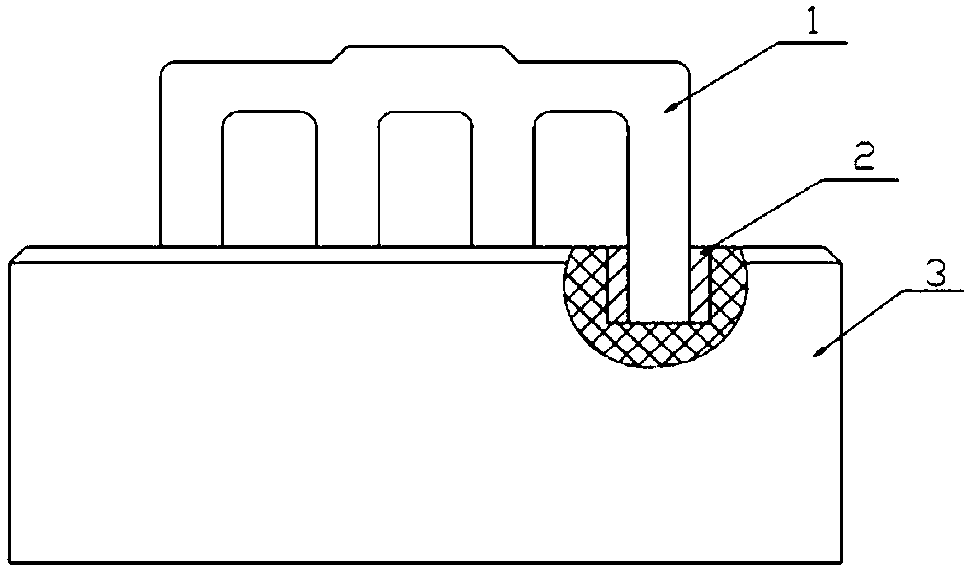

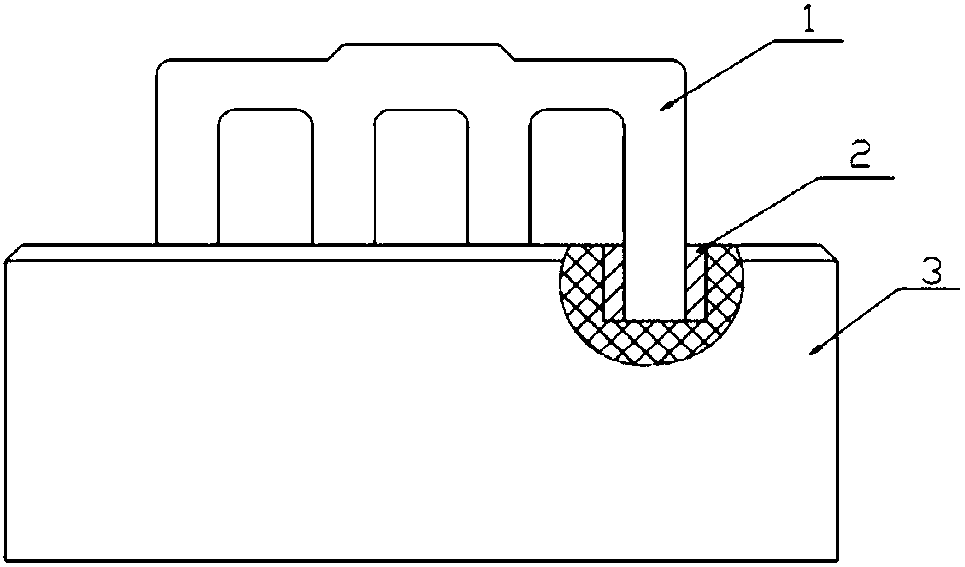

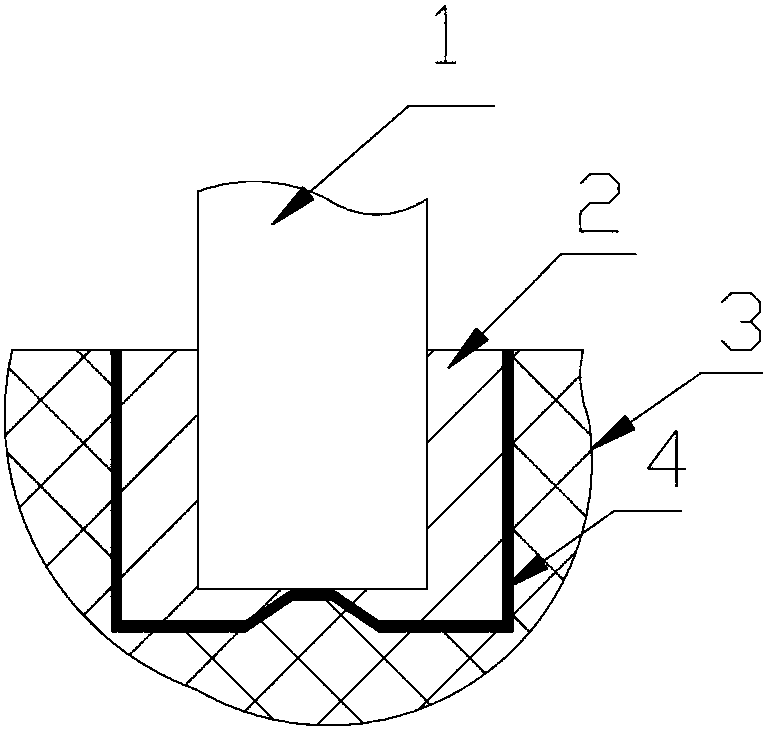

A structure and method for reducing the steel-carbon pressure drop of an aluminum electrolytic anode

The invention discloses a structure and method for reducing aluminum electrolysis anode steel-carbon voltage drop. The structure comprises an anode steel claw, a phosphorous pig iron ring and a carbonblock, wherein the carbon block is provided with a cylindrical carbon bowl; a claw head of the steel claw is inserted into the carbon bowl; and the phosphorous pig iron ring is cast between the clawhead and a circular seam of the carbon bowl. The structure is characterized in that an easily-conductive metal plating layer is plated on the surface, making contact with the steel claw and the phosphorous pig iron, of the carbon bowl. The implementation method includes the steps that in the aluminum electrolysis anode assembling process, the easily-conductive metal plating layer is plated on thesurface of the carbon bowl of the anode carbon block and then connected with the phosphorous pig iron used for the steel claw in a casting mode, and a new anode is assembled and then used for an electrolytic bath. By means of the structure and the method, the situation of poor connection between the carbon block and metal in an aluminum electrolysis anode can be effectively avoided, the steel clawis more fully and compactly connected with the carbon block, the contact resistance is reduced, and the reduction of the anode steel-carbon voltage drop and reduction of power consumption are achieved. By means of the structure and method provided by the invention, the anode steel-carbon voltage drop can be reduced by at least 20 mV on average, and therefore the power consumption per ton aluminumis effectively reduced.

Owner:ANGANG STEEL CO LTD

Medical electrode sheet

InactiveCN106924873AGuaranteed StrengthAvoid stimulationDiagnostic recording/measuringSensorsEngineeringElectrically conductive adhesive

The invention discloses a medical electrode sheet, which comprises a lead buckle, a backing sticker, a conductive electrode, a conductive adhesive and a release film, wherein the conductive electrode is arranged at the left side of the backing sticker; the conductive adhesive is arranged at the left side of the backing sticker; the conductive electrode and the conductive adhesive are both located in a groove of the backing sticker; the conductive electrode is located between the backing sticker and the conductive adhesive; the release film covers the surface of the conductive adhesive; one face, facing the conductive adhesive, of the conductive electrode is provided with projections distributed at uniform intervals; the projections are distributed on the conductive electrode according to a concentric circle form; the areas of cross sections, parallel with the conductive adhesive, of the projections are gradually reduced in a direction from the conductive electrode to the conductive adhesive, and a conical cylinder or tetrahedron structure form is formed; and the tail end of each projection is a plane or a spherical surface. processing and manufacturing are facilitated; contact with the skin is more uniform; stimulation on the skin of the human body is avoided; the temperature is monitored and controlled; and no hidden safety dangers in the case of use exist.

Owner:杨配媛

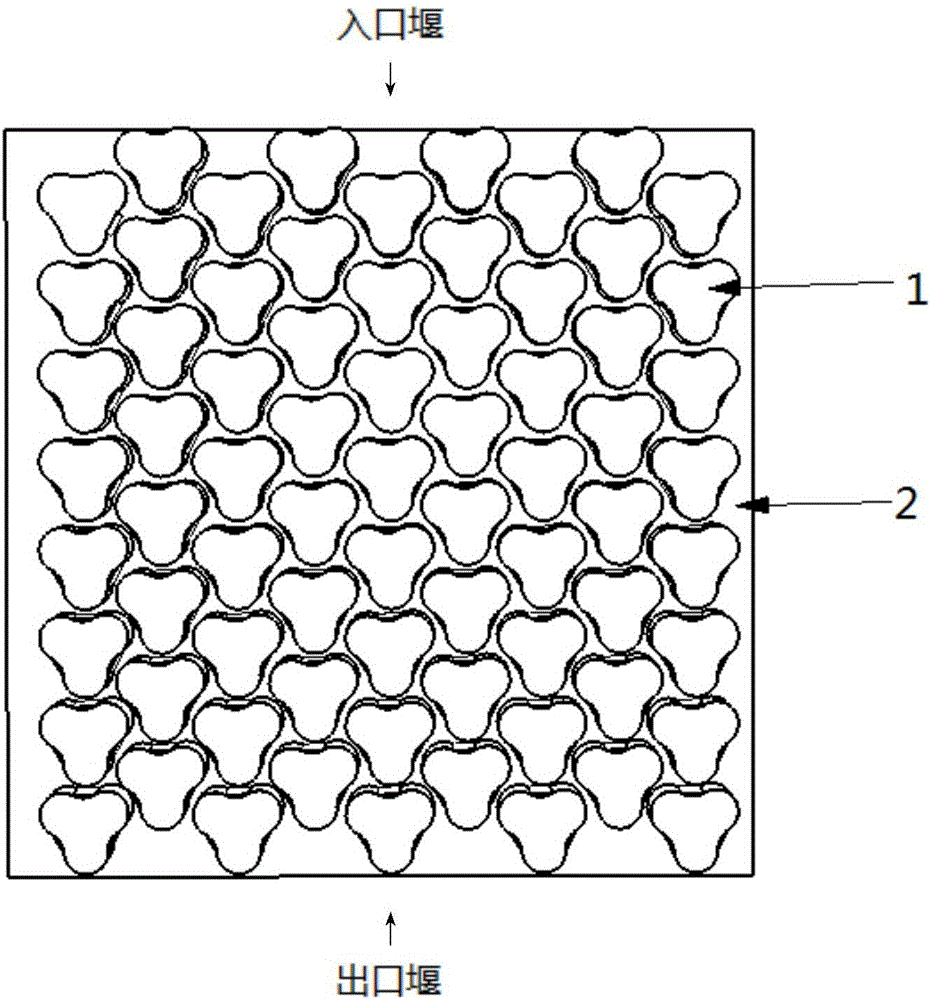

Novel high-flux gas-liquid uniform tower tray

ActiveCN106140075AIncreased wetted perimeterIncrease the gas-liquid contact areaChemical/physical/physico-chemical processesInterval distributionValve opening

The invention provides a novel high-flux gas-liquid uniform tower tray which comprises a tower plate, valve openings and floating valves. The edge of the valve block of each floating valve is arranged in a manner that convex arches and concave arches are arranged in intervened arrangement, the number of convex portions formed by the convex arches and the number of concave portions formed by the concave arches are respectively three, and the curvature radius of the convex portions is smaller than / equal to that of the concave portions; valve legs of each floating valve are perpendicularly fixed on the lower end surface of each convex portion, and the number of the valve legs is three which are in equidistant interval distribution; a spacing strip is arranged at the edge of each valve block. The novel high-flux gas-liquid uniform tower tray is high in operational flexibility, high in mass transfer efficiency, even in airflow dispersion and sufficient in gas-liquid connection.

Owner:TIANJIN AOZHAN XINGDA TECH

A special aluminum paste for partial aluminum back field crystalline silicon solar cells and preparation method thereof

ActiveCN103545013BImprove liquidityAvoid damageFinal product manufactureNon-conductive material with dispersed conductive materialAluminium powderBack surface field

Provided is an aluminium paste dedicated for a local aluminium back surface field crystalline silicon solar cell. The paste is prepared from raw materials matched with the following parts by mass: 70-78 parts of aluminium powder, 0.05-3 parts of inorganic bond, 17-27 parts of organic bond and 1-5 parts of additive. Further provided is a preparation method for the aluminium paste dedicated for a local aluminium back surface field crystalline silicon solar cell. Therefore, compared with the traditional aluminium paste, the aluminium paste is specially applied to a local aluminium back surface field crystalline silicon solar cell, and has the advantages of good flowability, minimal damage to a passive film, good contact with a window, a compact and uniform aluminium film, etc. The average conversion efficiency of volume production for the crystalline silicon solar cell is ≥ 20.0%. After a cell slice is laminated and packaged, and an EVA tear test is performed thereon, the adhering pulling force of the aluminium back surface field is measured as ≥ 10 N.

Owner:GUANGZHOU RUXING TECH DEV +1

Roadway U-shaped support device and method

PendingCN112324478AImprove the support effectImprove self-stabilityProps/chocksStressed stateUltimate tensile strength

The invention relates to a roadway U-shaped support device and method. The roadway U-shaped support device comprises support vault U-shaped steel, support leg U-shaped steel is fixedly connected to the two ends of the support vault U-shaped steel through connecting clamping cables, and a support leg expansion device is arranged at the bottom of the support leg U-shaped steel; the support leg expansion device comprises a lower inner sleeve, an upper outer sleeve, a bundle-shaped composite expansion material cartridge and filling river sand; and the upper outer sleeve sleeves the lower inner sleeve, the bundle-shaped composite expansion material cartridge is arranged in the lower inner sleeve, and the filling river sand is arranged at the top and the bottom of the bundle-shaped composite expansion material cartridge. The overall stress state of the U-shaped support can be effectively improved, load-controllable initial supporting force can be provided for surrounding rock, the function of adapting to surrounding rock deformation is achieved, the column leg structure is good in bending resistance, the column leg strength is high, the structure is simple, the cost is low, the construction process is simple, and the roadway section utilization rate is not affected.

Owner:NORTHEASTERN UNIV +1

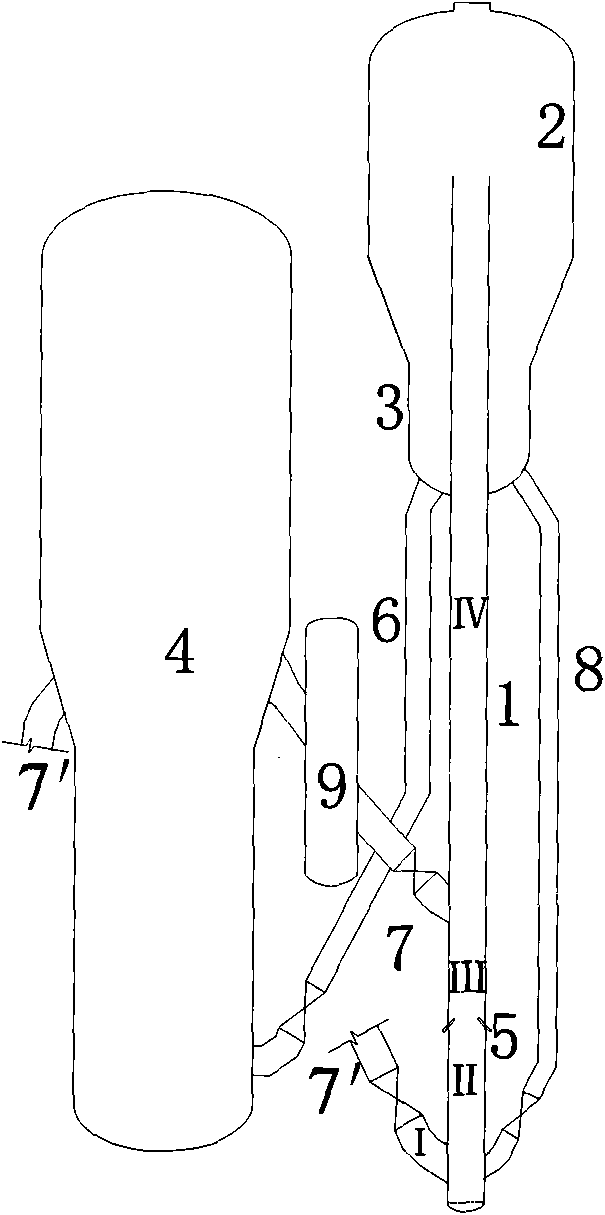

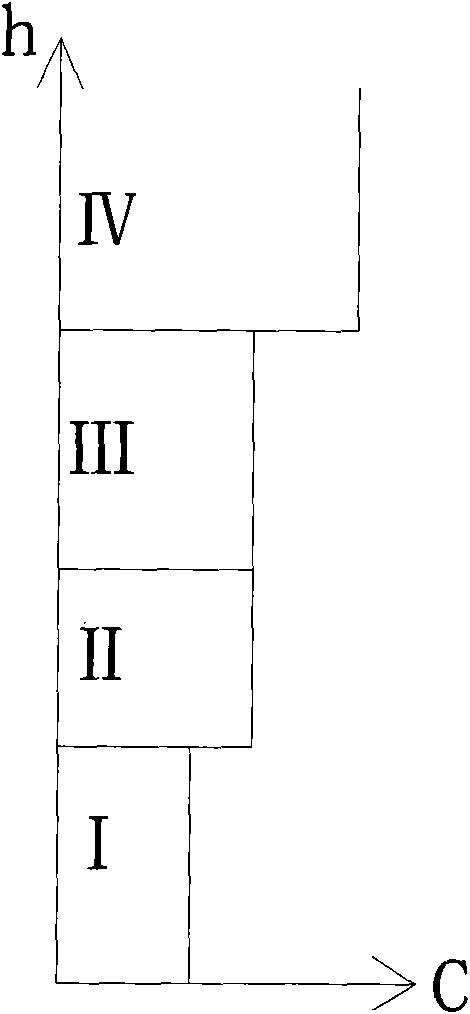

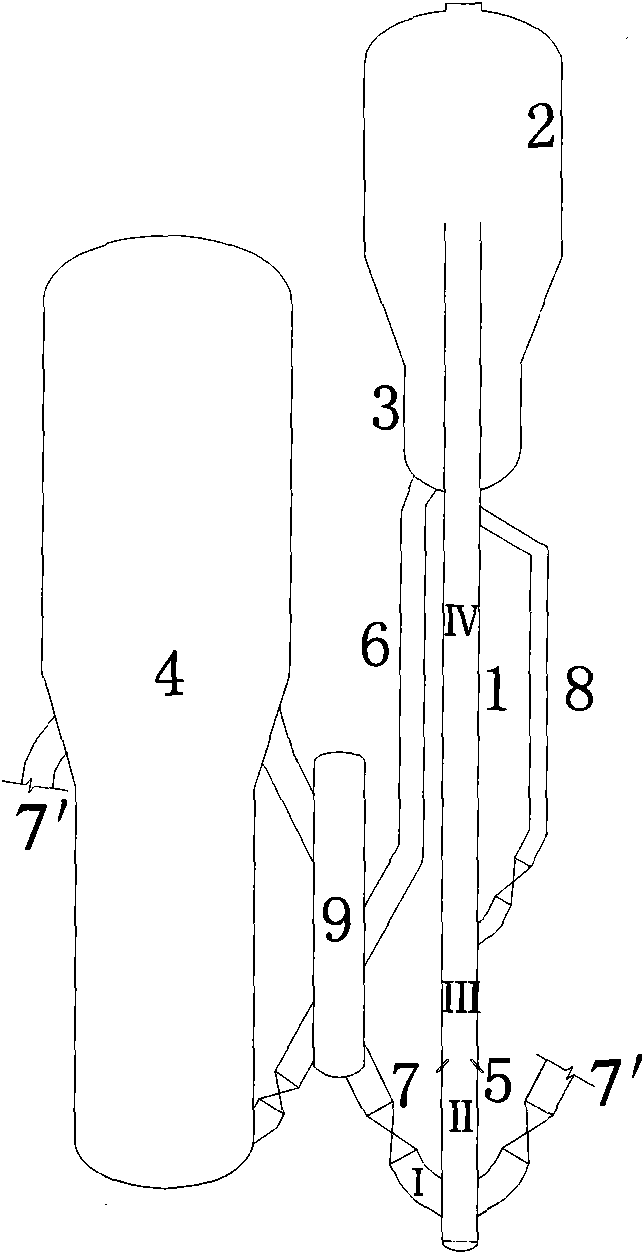

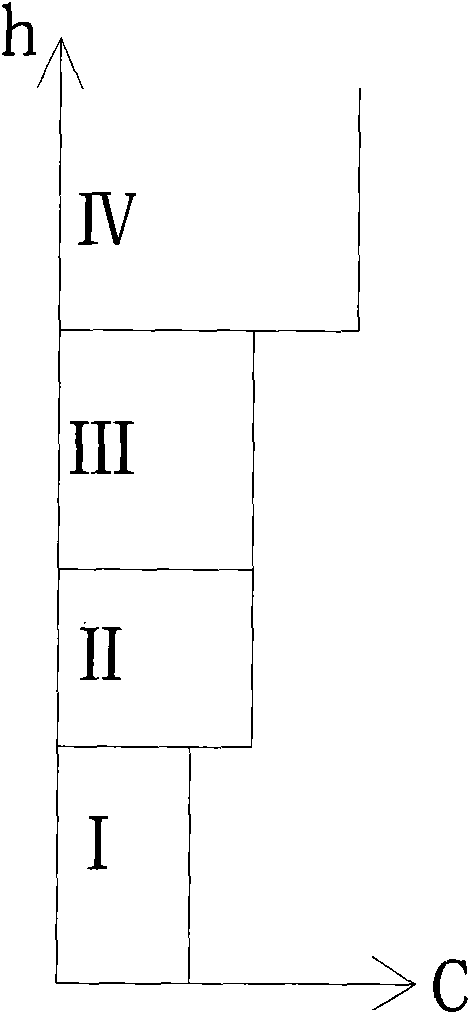

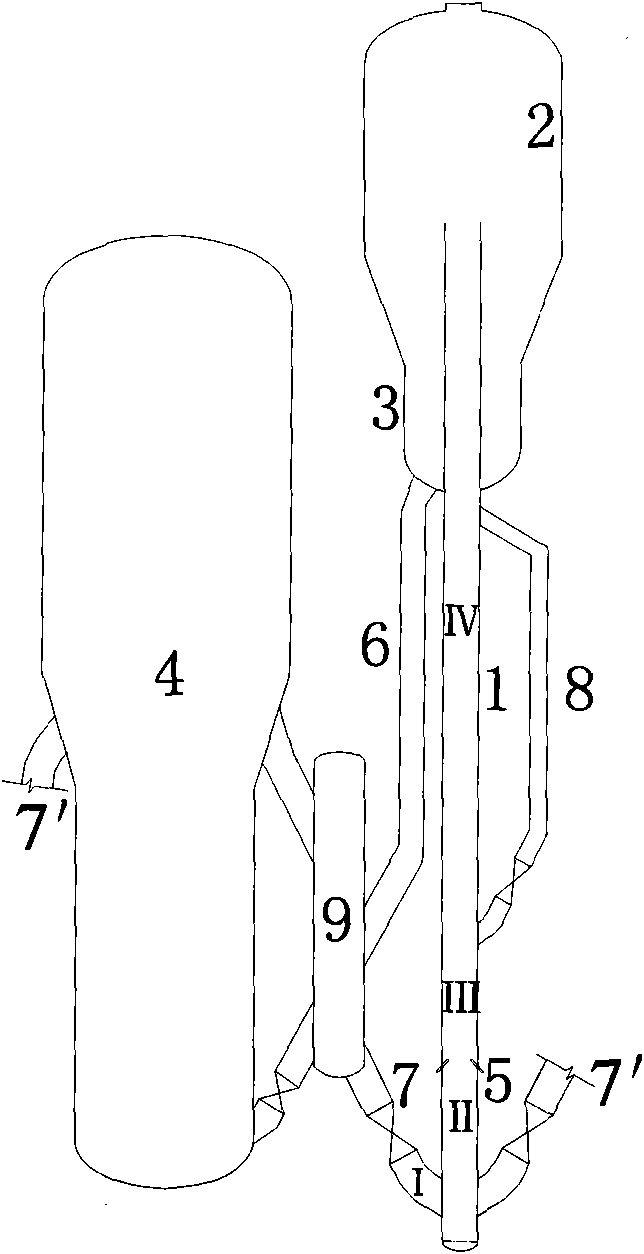

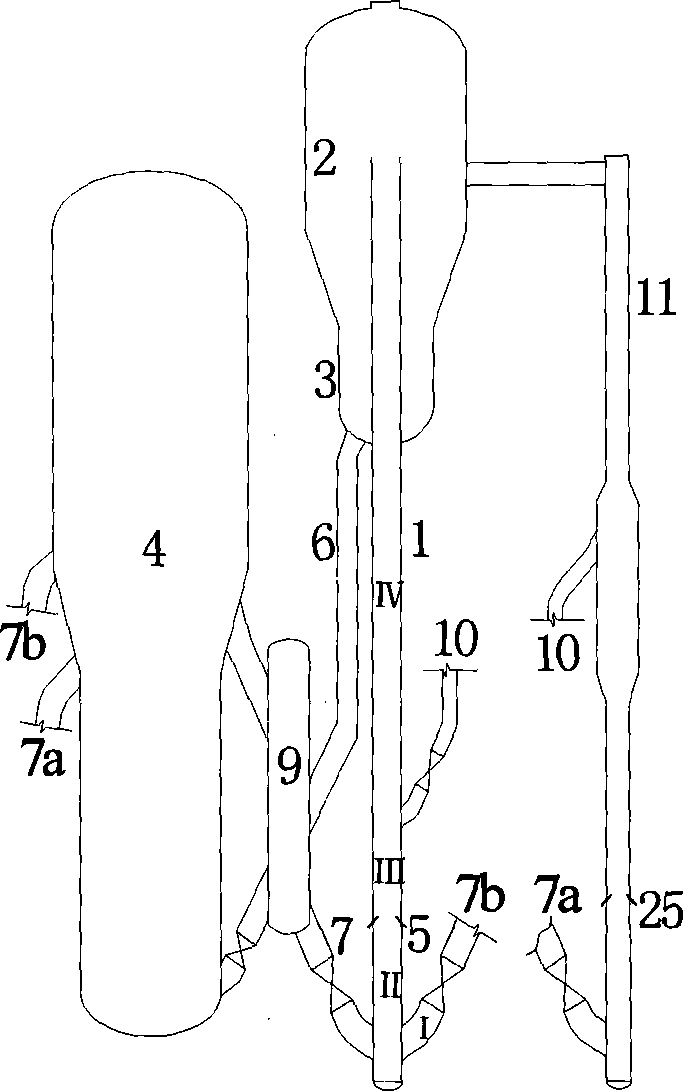

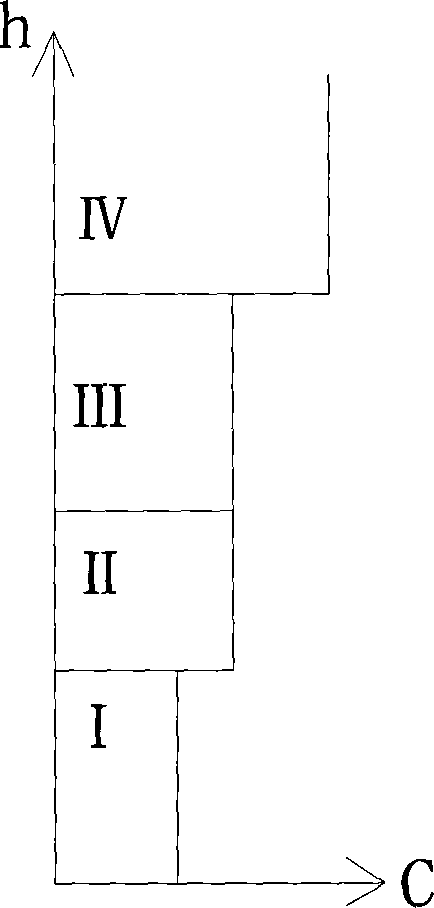

Catalytic conversion method and device for single-riser petroleum hydrocarbon type raw material

InactiveCN102051198AEasy to controlControl responseCatalytic crackingChemical/physical processesPetroleumContact reaction

The invention discloses a catalytic conversion method and a catalytic conversion device for a single-riser petroleum hydrocarbon type raw material. A catalyst which has a temperature lower than that of a regenerated catalyst is fed into a pre-rising section of a riser reactor and is conveyed into an oil-catalyst contact reaction section by pre-risen gas to be contacted with the raw material for catalytic conversion reaction; and a cooled regenerated catalyst or a reflowed spent catalyst is fed into the riser reactor from the space above a raw material nozzle to participate in the catalytic conversion reaction. By the method and the device, reaction dry gas can be reduced, product distribution can be improved, and the temperature or the catalyst-oil ratio of the riser oil-catalyst contact reaction section and a post-reaction section can be adjusted and controlled, so catalytic conversion has sufficient flexibility to adapt to change of quality of raw material oil or the requirement of a market on products.

Owner:QINGDAO JINGRUN PETROCHEM DESIGN INST CO LTD

Catalytic conversion method and device for single-riser petroleum hydrocarbon type raw material

InactiveCN102051198BEasy to controlControl responseCatalytic crackingChemical/physical processesContact reactionsProduct gas

The invention discloses a catalytic conversion method and a catalytic conversion device for a single-riser petroleum hydrocarbon type raw material. A catalyst which has a temperature lower than that of a regenerated catalyst is fed into a pre-rising section of a riser reactor and is conveyed into an oil-catalyst contact reaction section by pre-risen gas to be contacted with the raw material for catalytic conversion reaction; and a cooled regenerated catalyst or a reflowed spent catalyst is fed into the riser reactor from the space above a raw material nozzle to participate in the catalytic conversion reaction. By the method and the device, reaction dry gas can be reduced, product distribution can be improved, and the temperature or the catalyst-oil ratio of the riser oil-catalyst contact reaction section and a post-reaction section can be adjusted and controlled, so catalytic conversion has sufficient flexibility to adapt to change of quality of raw material oil or the requirement of a market on products.

Owner:QINGDAO JINGRUN PETROCHEM DESIGN INST CO LTD

Structure and method for reducing aluminum electrolysis anode steel-carbon voltage drop

The invention discloses a structure and method for reducing aluminum electrolysis anode steel-carbon voltage drop. The structure comprises an anode steel claw, a phosphorous pig iron ring and a carbonblock, wherein the carbon block is provided with a cylindrical carbon bowl; a claw head of the steel claw is inserted into the carbon bowl; and the phosphorous pig iron ring is cast between the clawhead and a circular seam of the carbon bowl. The structure is characterized in that an easily-conductive metal plating layer is plated on the surface, making contact with the steel claw and the phosphorous pig iron, of the carbon bowl. The implementation method includes the steps that in the aluminum electrolysis anode assembling process, the easily-conductive metal plating layer is plated on thesurface of the carbon bowl of the anode carbon block and then connected with the phosphorous pig iron used for the steel claw in a casting mode, and a new anode is assembled and then used for an electrolytic bath. By means of the structure and the method, the situation of poor connection between the carbon block and metal in an aluminum electrolysis anode can be effectively avoided, the steel clawis more fully and compactly connected with the carbon block, the contact resistance is reduced, and the reduction of the anode steel-carbon voltage drop and reduction of power consumption are achieved. By means of the structure and method provided by the invention, the anode steel-carbon voltage drop can be reduced by at least 20 mV on average, and therefore the power consumption per ton aluminumis effectively reduced.

Owner:ANGANG STEEL CO LTD

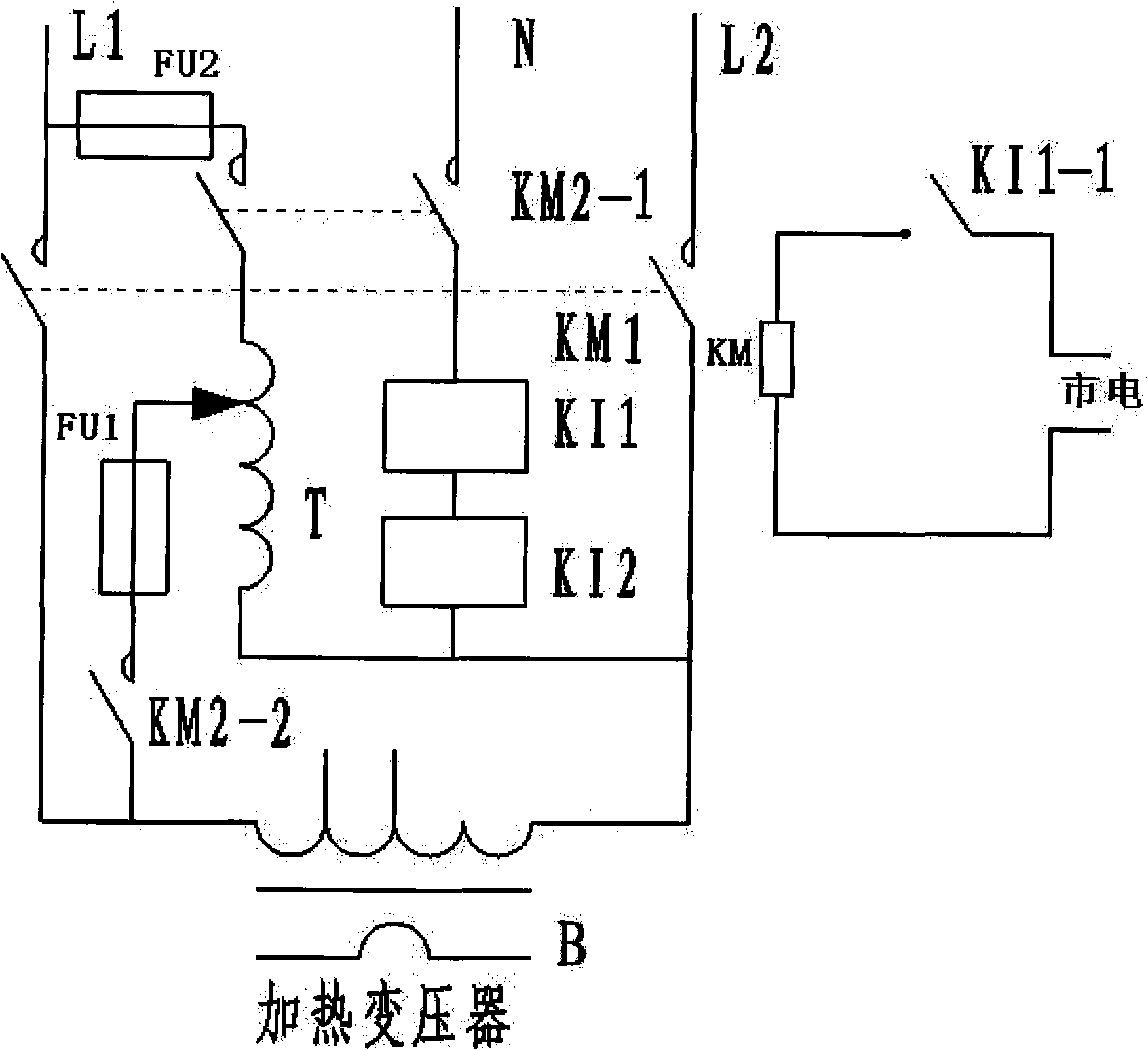

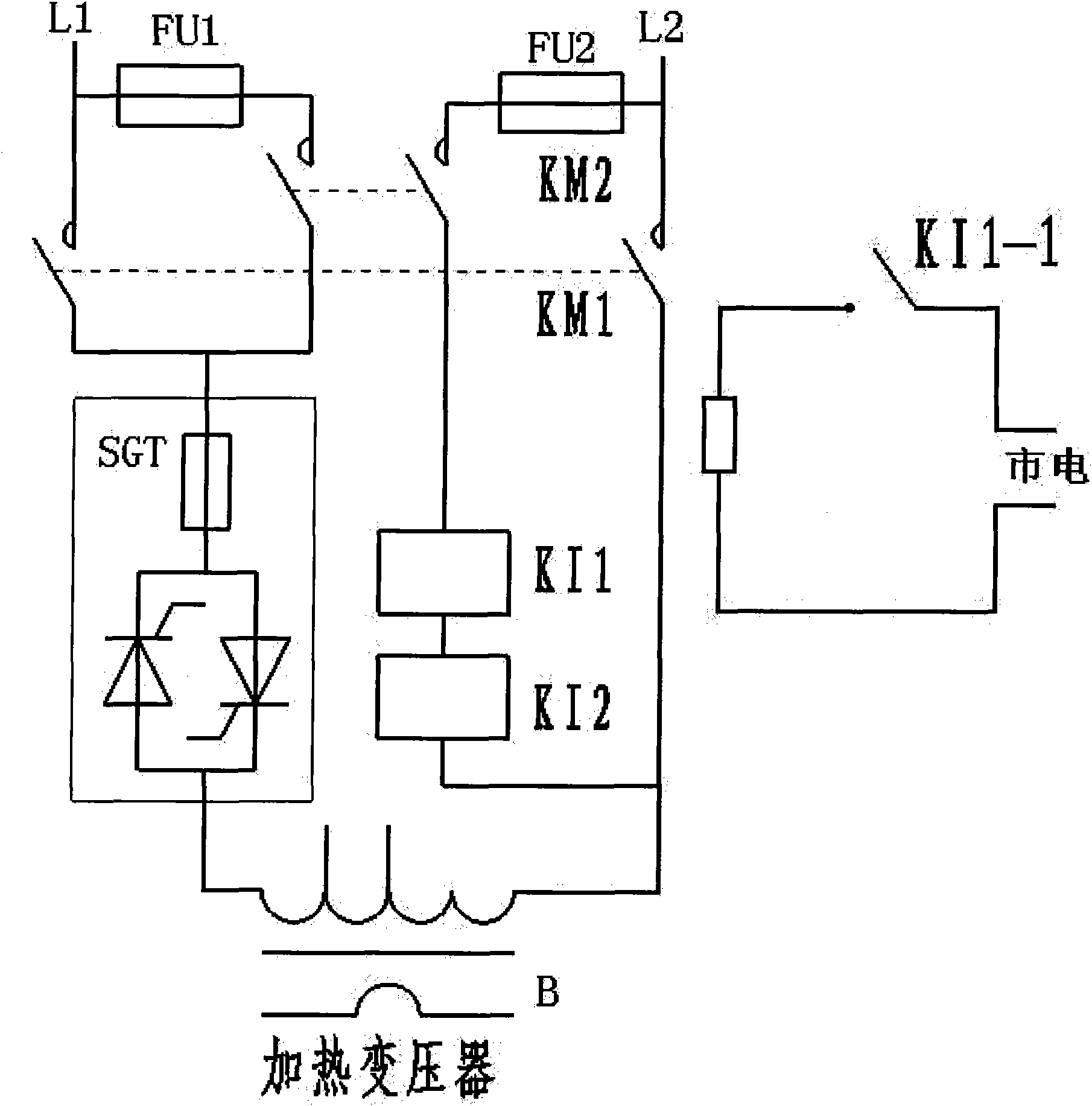

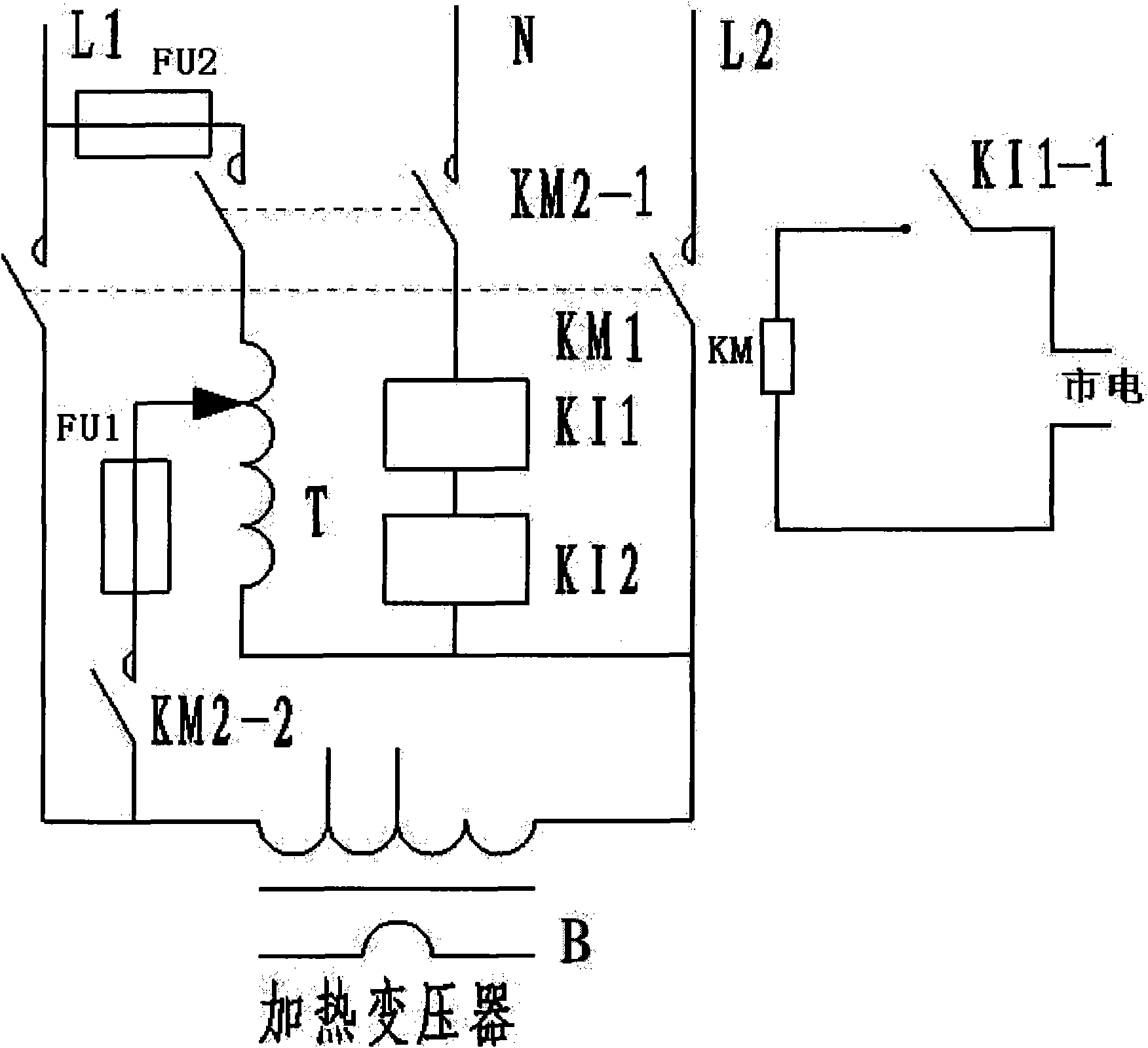

Method and device for determining heating start point of electric upsetting through current detection

The invention discloses a method for determining a heating start point of electric upsetting through current detection. The method comprises the following steps of: previously applying low voltage between a workpiece and an anvil; and judging whether the workpiece is contacted with the anvil or not by detecting current during contact of the workpiece and the anvil so as to determine the heating start point of the electric upsetting. The invention has the advantages that: 1, the method is more convenient to use and has higher reliability compared with a pressure detection method and a time judgment method; 2, since the current cannot be detected and then the operation is stopped once poor contact occurs, whether a contact condition between the anvil and an anvil seat is good can be judged; and 3, the workpiece length from the anvil to a clamping block can be controlled to be proper at the beginning of heating so as to avoid local overheating. The invention also discloses a device for implementing the method.

Owner:HUNAN TYEN MACHINERY

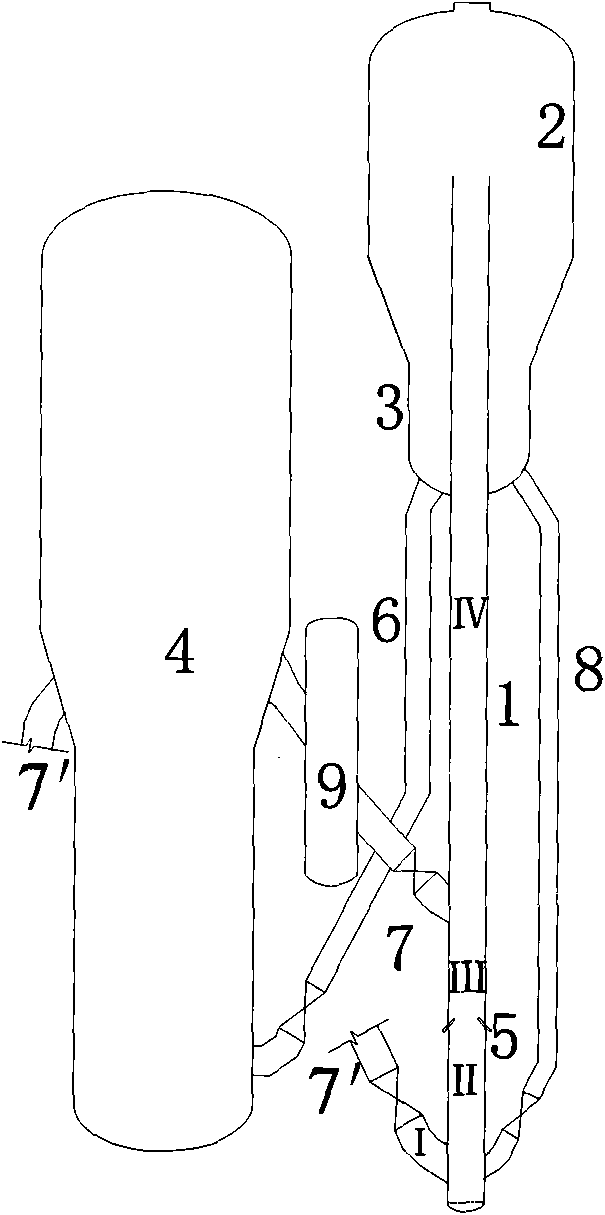

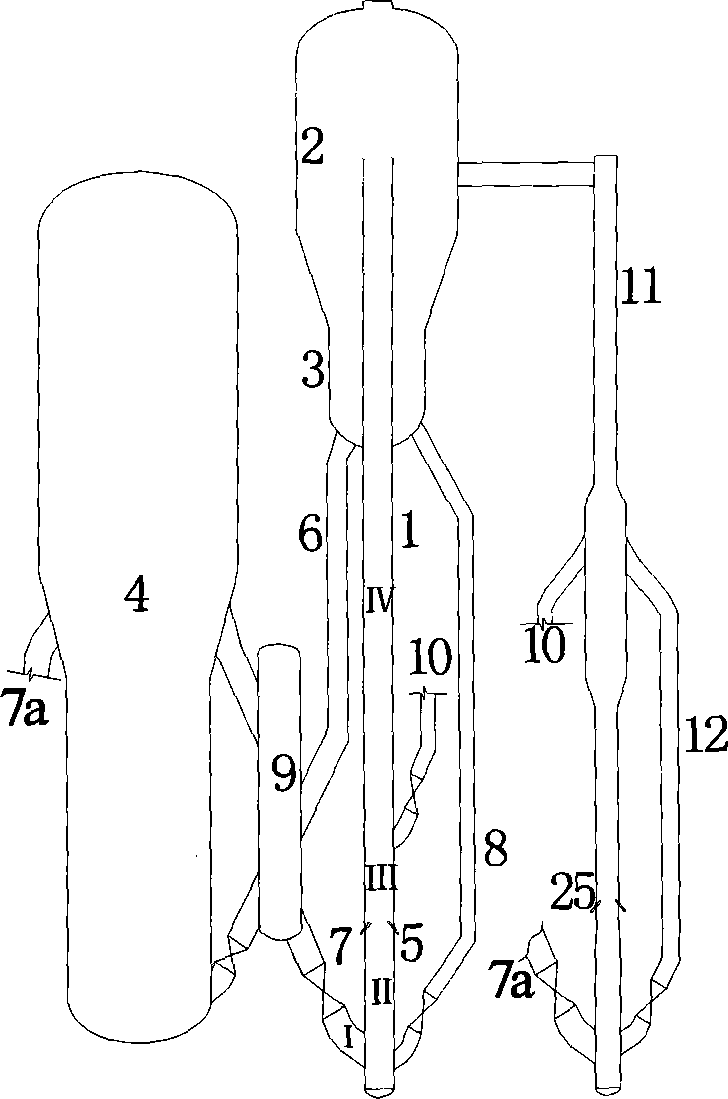

Dual-riser petroleum hydrocarbon feed stock catalytic conversion method and device

InactiveCN102051210BControl responseControlling the overall conversion reactionCatalytic crackingTreatment with plural parallel cracking stages onlyCracking reactionPetroleum

A catalytic conversion process of petroleum hydrocarbons in double reactor, and apparatus thereof are disclosed. The catalytic conversion process takes place in both the main reactor and the secondary reactor where reaction feedstock is lighter than the former. The first low temperature catalyst is introduced into the pre-lift section of the main reactor, and the said catalyst is conveyed to the oil / catalyst contact reaction section by the pre-lift gas and contacts with the feedstock from the feeding nozzle for the catalytic conversion reaction. The reaction mixture goes up and contacts with the second low temperature catalyst fed to the main reactor above the feeding nozzle, and the catalytic conversion reaction continues in the post-reaction section so as to complete the catalytic conversion reaction of the feedstock from the main reactor. Through flexible control over the reaction condition of the contact reaction section and post-reaction section of the reactor,thermal cracking reaction is effectively reduced, the reacting efficiency of the post-reaction section is improved. Accordingly, the reaction byproduct is effectively reduced and the product distribution is flexibly modified.

Owner:QINGDAO JINGRUN PETROCHEM DESIGN INST CO LTD

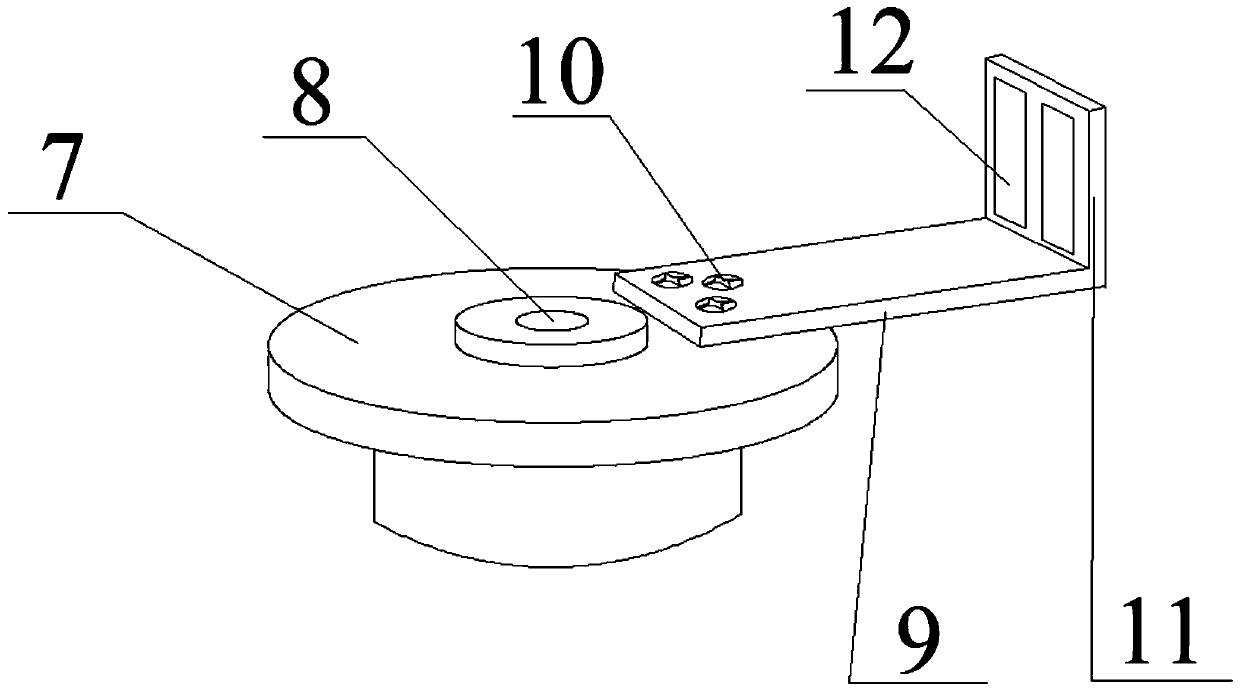

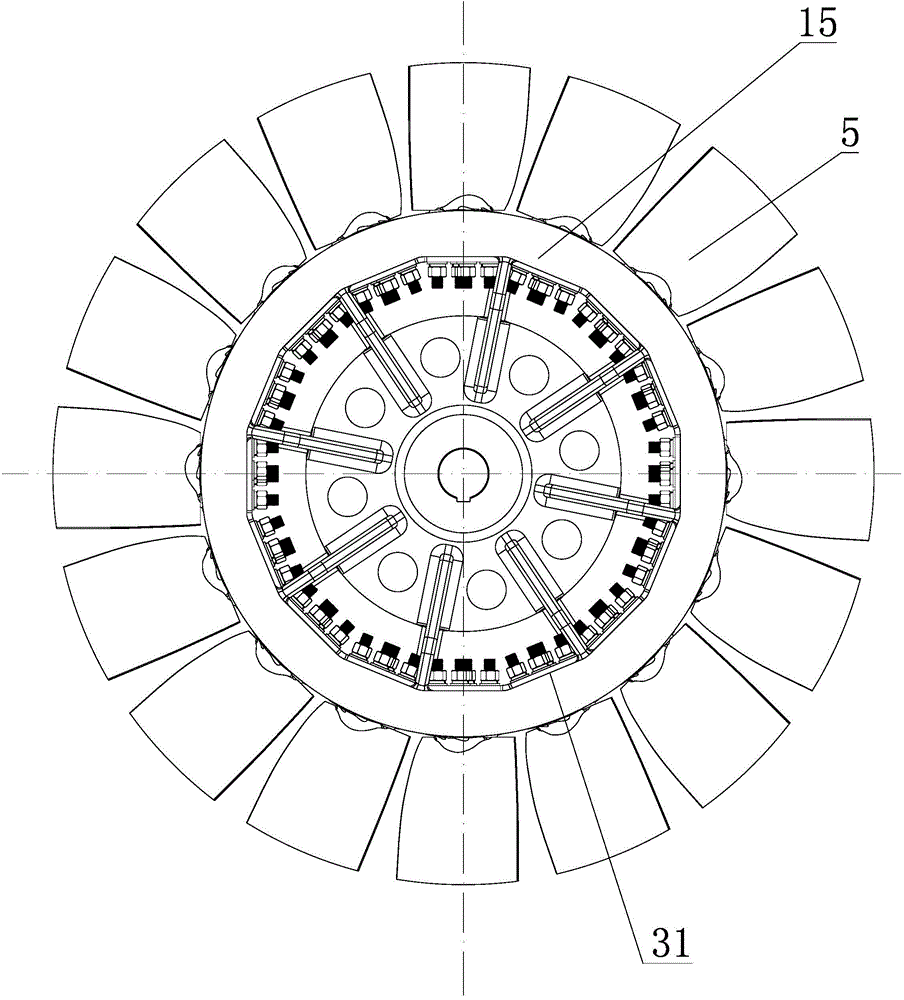

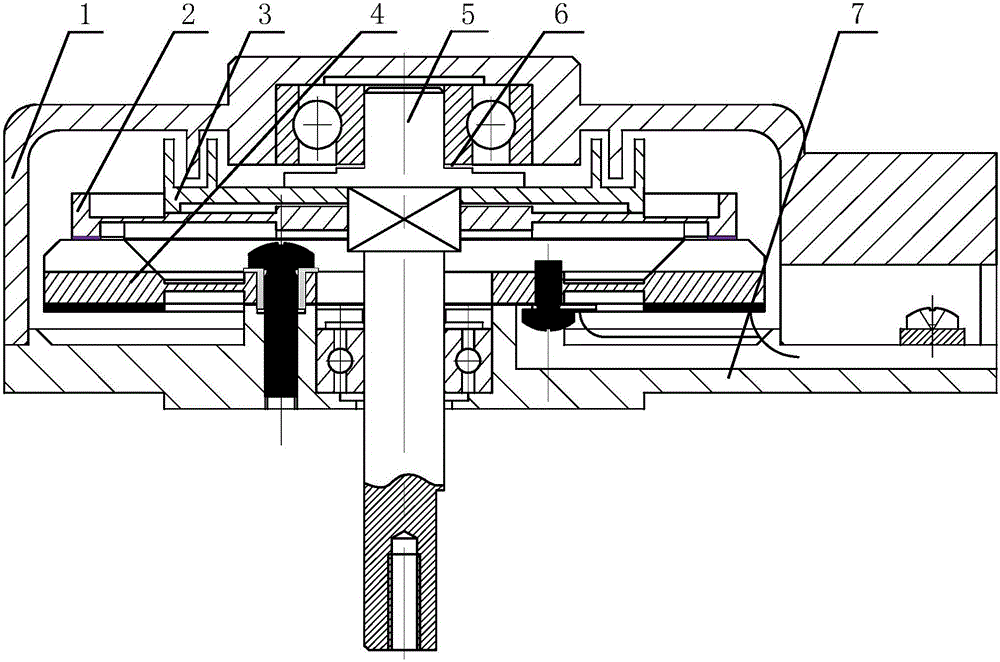

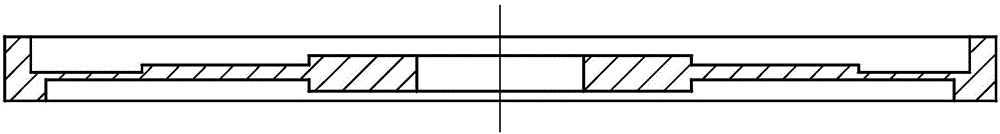

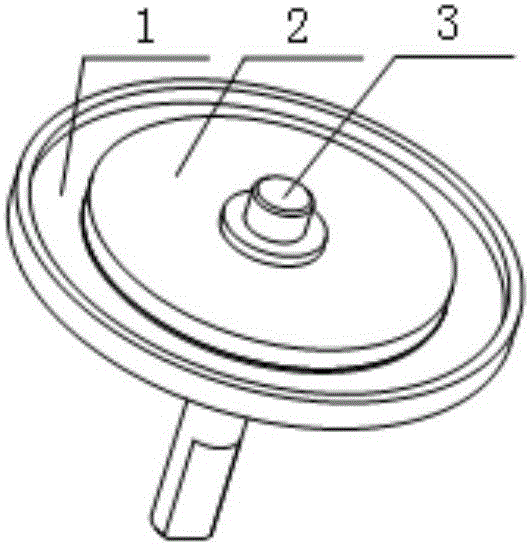

Dust-proof traveling wave type ultrasonic motor pre-loaded rotor system

ActiveCN105827148ASimple processing technologyImprove accessPiezoelectric/electrostriction/magnetostriction machinesUltrasonic motorControl theory

A dust-proof traveling wave type ultrasonic motor pre-loaded rotor system comprises a center shaft, a motor shell, a rotor, and a gland. The motor shell and the rotor sequentially sleeve the center shaft, and the motor shell and the rotor are arranged concentrically. The gland is arranged on the top of the center shaft. The surface of the rotor is provided with a preloading point, and the gland contacts the preloading point. The rotor is gradually thinned from center to outside to generate elastic deformation. By using the pre-loaded rotor system, the output stalling torque and no-load speed of motors are increased by more than 50%, the output performance of traveling wave type ultrasonic motors is improved greatly, and solutions are provided for more applications. Moreover, the pre-loaded rotor system has the advantages of simple processing technology and good contact between a stator drive surface and a rotor friction interface.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

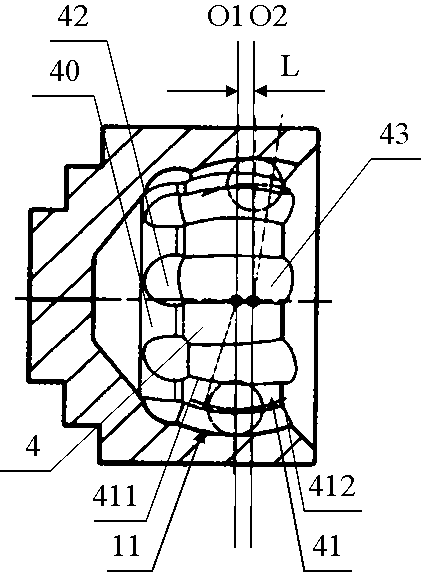

Ball cage type constant velocity universal joint

InactiveCN111365377AImprove carrying capacityExtended service lifeYielding couplingUniversal jointEngineering

The invention relates to a ball cage type constant velocity universal joint which comprises a bell-shaped shell, a retainer, steel balls and a star-shaped sleeve. The ball cage type constant velocityuniversal joint is characterized in that an arc channel is selected as an inner channel of the bell-shaped shell; a double-center arc channel is selected as outer channels of the star-shaped sleeve, and the intersection points of a left arc line and a right arc line of the double-center arc channel meet on a line O1; the positions of the circle centers of the steel balls in the two adjacent outerchannels of the star-shaped sleeve are different, the positions of the circle centers of some of the steel balls meet on the line O1, while the positions of the circle centers of some of the steel balls meet on a line O2; and the linear distance between the line O1 and the line O2 is L. Due to the fact that the inner channel of the bell-shaped shell is the arc channel, the outer channels of the star-shaped sleeve are the double-center arc channel, and the steel balls of the ball cage type constant velocity universal joint are in a three-point contact channel section form, the internal contactcondition of the constant velocity universal joint is improved, the internal contact stress is effectively reduced, accordingly, the bearing capacity of the ball cage type constant velocity universaljoint can be improved, and the service life of the ball cage type constant velocity universal joint is prolonged.

Owner:中科重工设备制造(江苏)有限公司

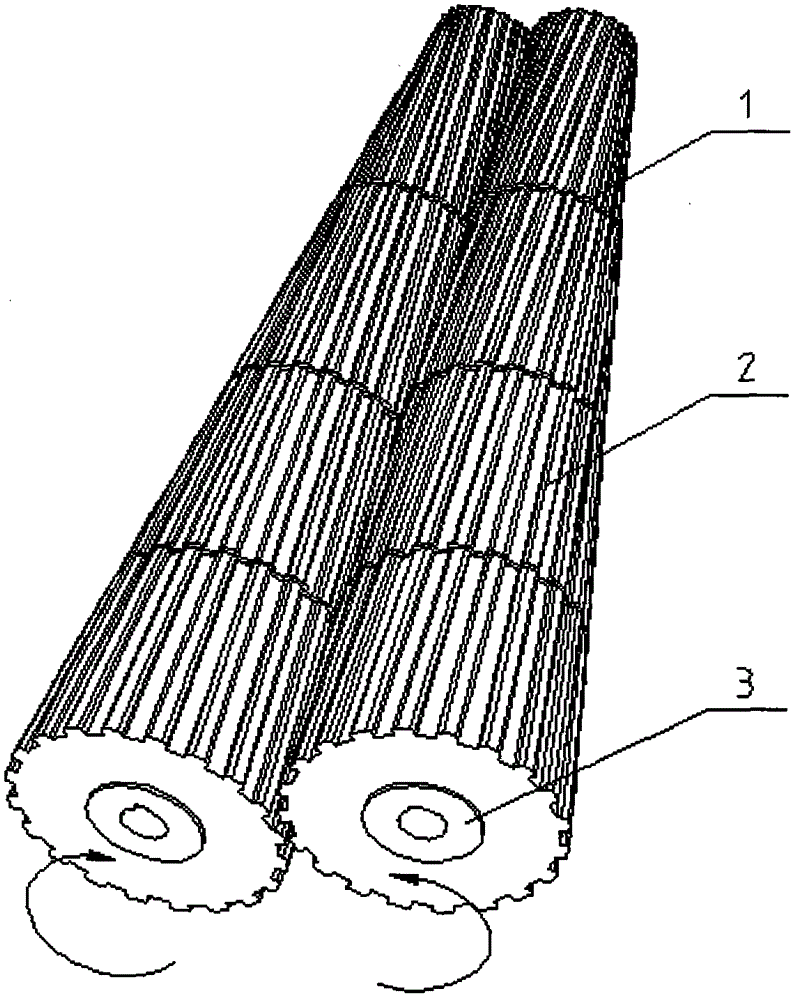

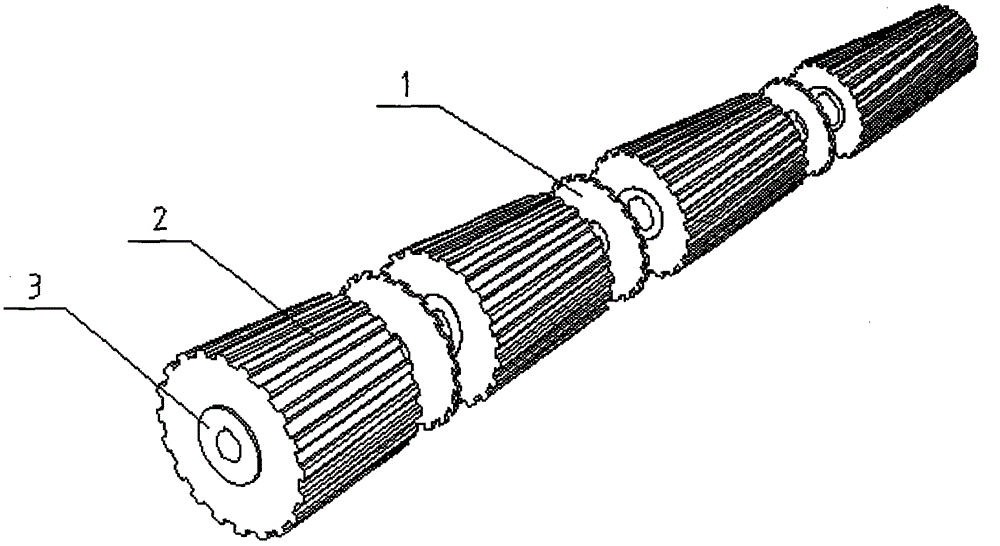

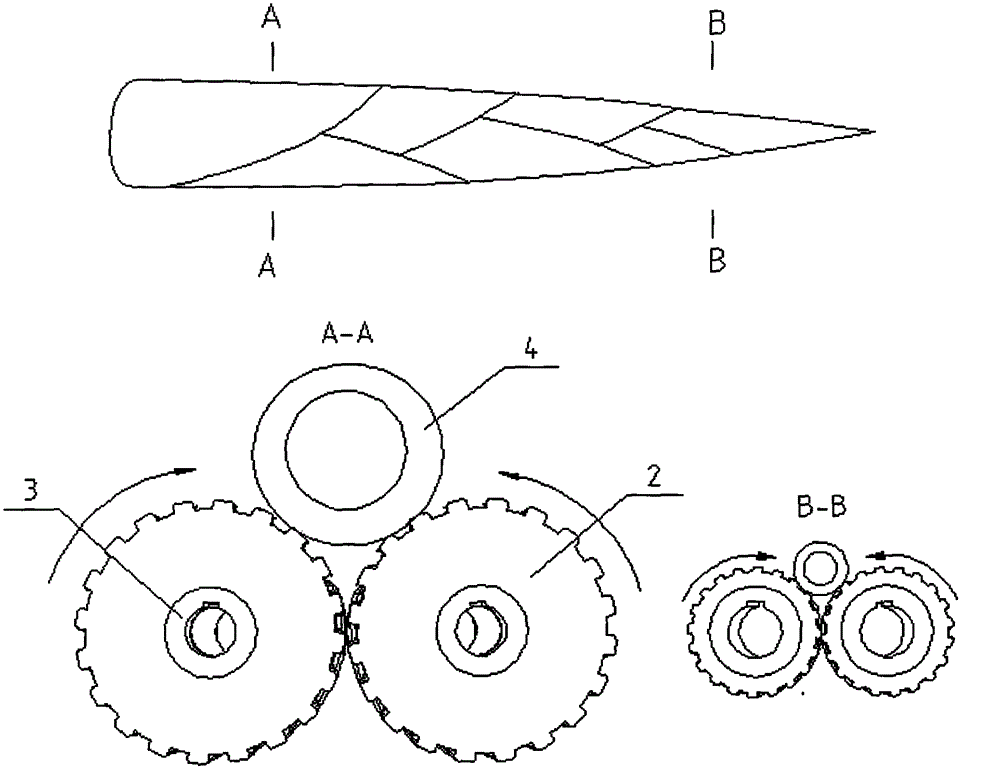

Bamboo shoot peeling roller

InactiveCN104783306AImprove accessGood peeling effectVegetable peelingContact conditionAgricultural engineering

The invention discloses a bamboo shoot peeling roller which comprises blades, rubber covered rollers and installation casing pipes. The bamboo shoot peeling roller is characterized in that the installation casing pipes are coated with the rubber covered rollers which are fixed relative to the installation casing pipes, the rubber covered rollers are made of food grade silica gel, the outer sides of the rubber covered rollers are conic faces, spiral protruding edges extending longitudinally in the direction of the conic surfaces are evenly distributed on the conic faces, each circular blade with teeth is installed between every two adjacent rubber covered rollers, the tooth crest diameter of each blade is changed along with the diameter of the end face of the corresponding rubber covered roller, the tooth crest diameter of each blade is slightly smaller than the outer diameter of the end face of the rubber covered roller to which the blade is tightly adjacent, after the bamboo shoot peeling roller is installed, the protruding edges of the rubber covered rollers are aligned, and the whole bamboo shoot peeling roller is conic. By the utilization of the bamboo shoot peeling roller, the section of the roller is changed from large to small from the root to the top end of a bamboo shoot, the contact condition of the roller and the bamboo shoot is effectively improved, and compared with a cylindrical roller, the bamboo shoot peeling roller can well peel bamboo shoot shell close to the top end of the bamboo shoot and the overall peeling effect is better.

Owner:JINHUA VOCATIONAL TECH COLLEGE

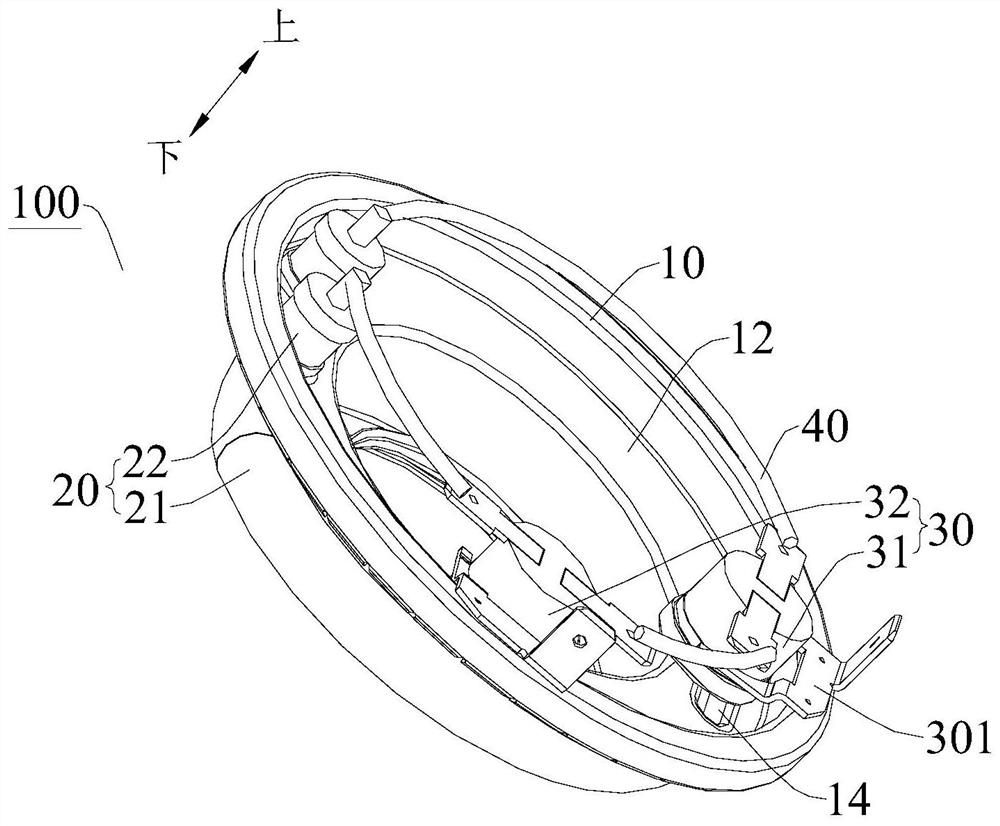

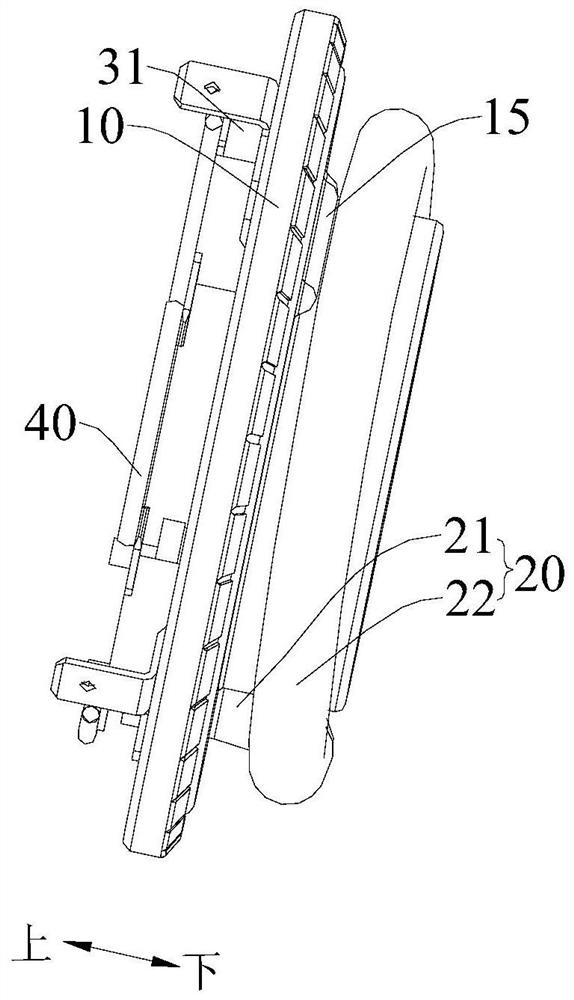

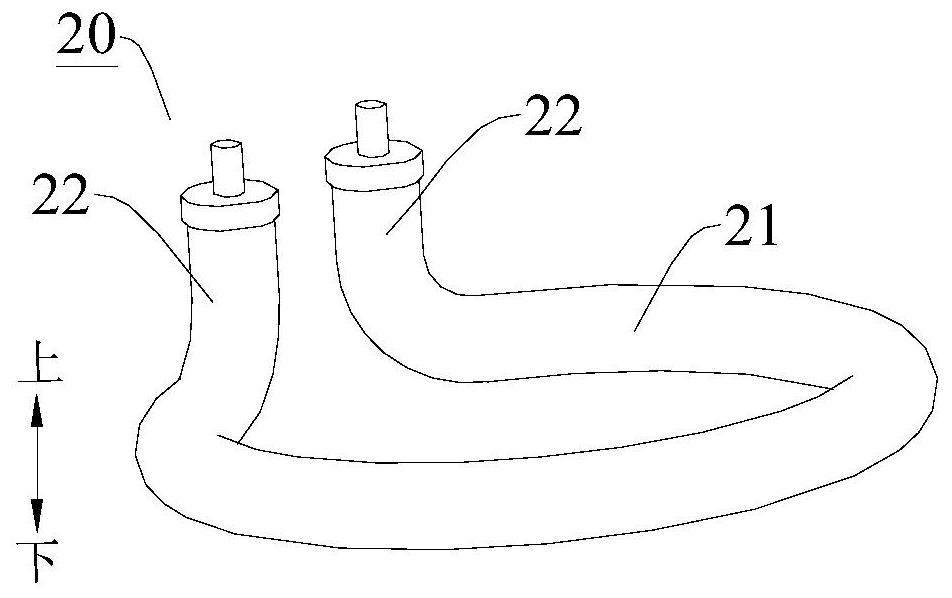

Heating device of heater and integrated heating pump

PendingCN112922901ATimely protectionEffective protectionTableware washing/rinsing machine detailsPump componentsEngineeringThermal contact

The invention discloses a heating device of a heater and an integrated heating pump. The heating device comprises a heat conduction cover plate, an electric heating tube and a protector, wherein two opposite side surfaces of the heat conduction cover plate are an inner side surface and an outer side surface respectively, the inner side surface is used for forming the inner wall of a containing cavity, and the heat conduction cover plate is provided with installation through holes and a thermal contact point which are separated; the electric heating tube comprises a main body heating part and connecting end parts connected with the main body heating part, the main body heating part is arranged at the inner side of the heat conduction cover plate, each connecting end part cooperates with the corresponding installation through hole, and the main body heating part is in contact with the inner side surface only at the thermal contact point; and the protector is arranged at the outer side of the heat conduction cover plate, the protector arranged by at least one, and the temperature sensing face of the at least one protector is attached to the outer side surface right in a manner of being opposite to the thermal contact point. According to the heating device, the electric heating tube is in direct contact with liquid but can be prevented from being in complete contact with the heat conduction cover plate, so that the heating efficiency is high, and the safety is high. While the potential safety hazard can be further reduced by installing the at least one protector.

Owner:FOSHAN WEILING WASHER MOTOR MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com