Ball cage type constant velocity universal joint

A technology of constant velocity universal joints and ball cages, which is applied in the field of universal joints, and can solve the problems of difficult processing of ball cage constant velocity universal joints, increased noise and impact of constant velocity universal joints, and high manufacturing precision requirements. problems, to achieve the effect of reducing frictional resistance, improving carrying capacity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

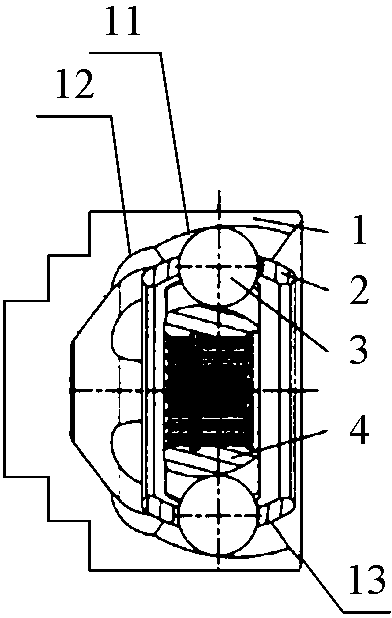

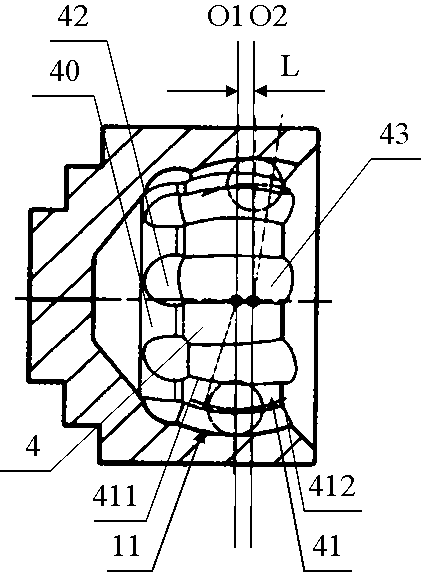

[0020] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0021] like Figure 1-2 As shown, the cage type constant velocity universal joint includes a bell shell 1, a cage 2, steel balls 3 and a star sleeve 4; the bell shell 1 is located outside the cage 2, and the star sleeve 4 is located on the cage 2 Inside, the steel balls 3 pass through the notches of the cage 2 and are evenly distributed along the circumference of the cage 2, and the steel balls 3 are in contact with the corresponding grooves of the bell-shaped shell 1 and the star-shaped sleeve 4; the bell-shaped shell 1 The inner channel 11 is an arc channel, and the outer channel 41 of the star sleeve 4 is a double-center arc channel, thereby providing a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com