Axial flow fan for nuclear power station containment continuous ventilation system

A nuclear power plant containment and ventilation system technology, which is applied to the parts of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve the problem of insufficient strength performance, unimaginable consequences, and axial displacement of blades and hubs To meet the performance requirements, strengthen the connection strength and improve the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

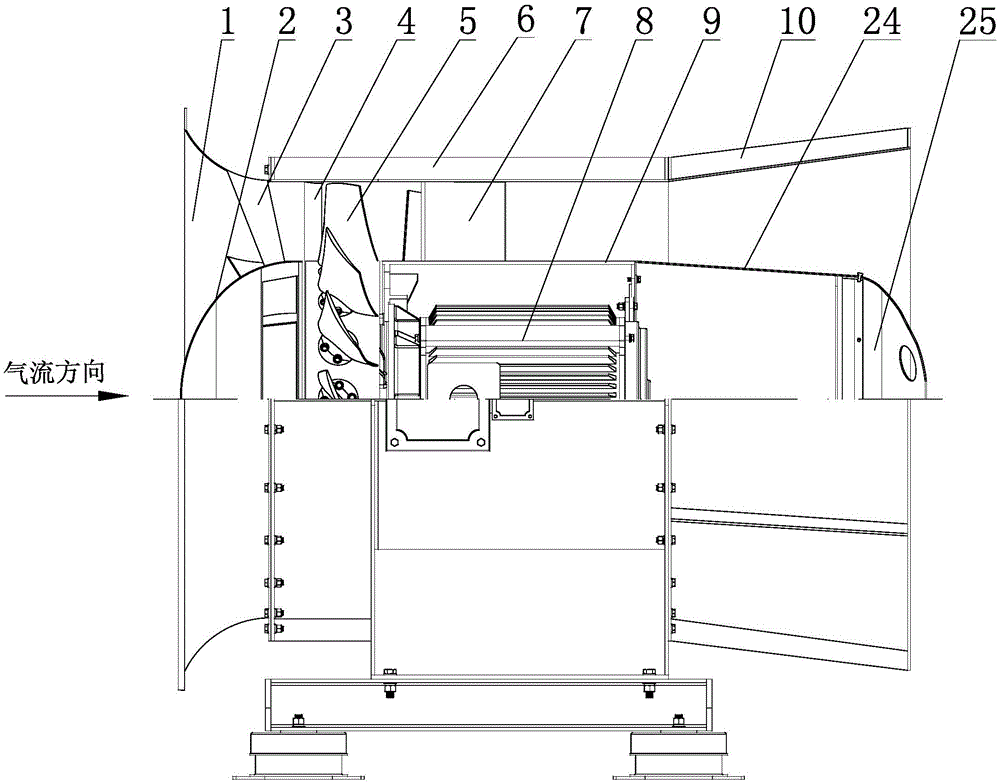

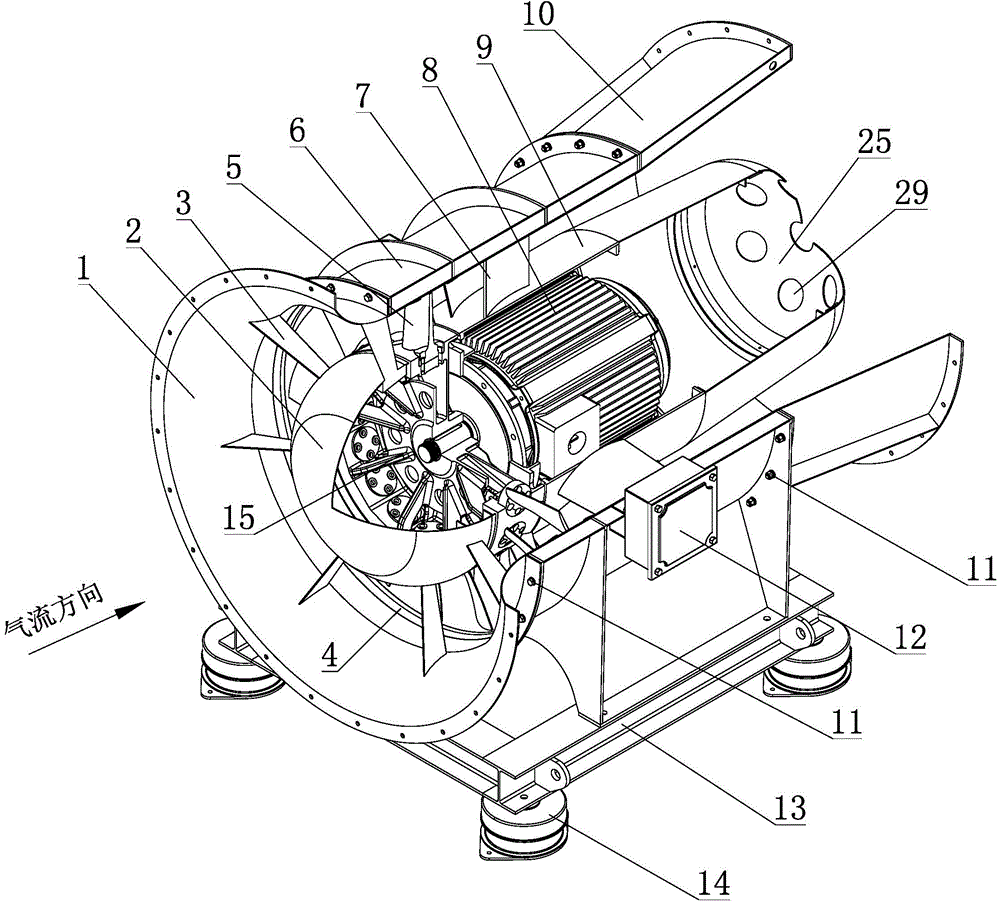

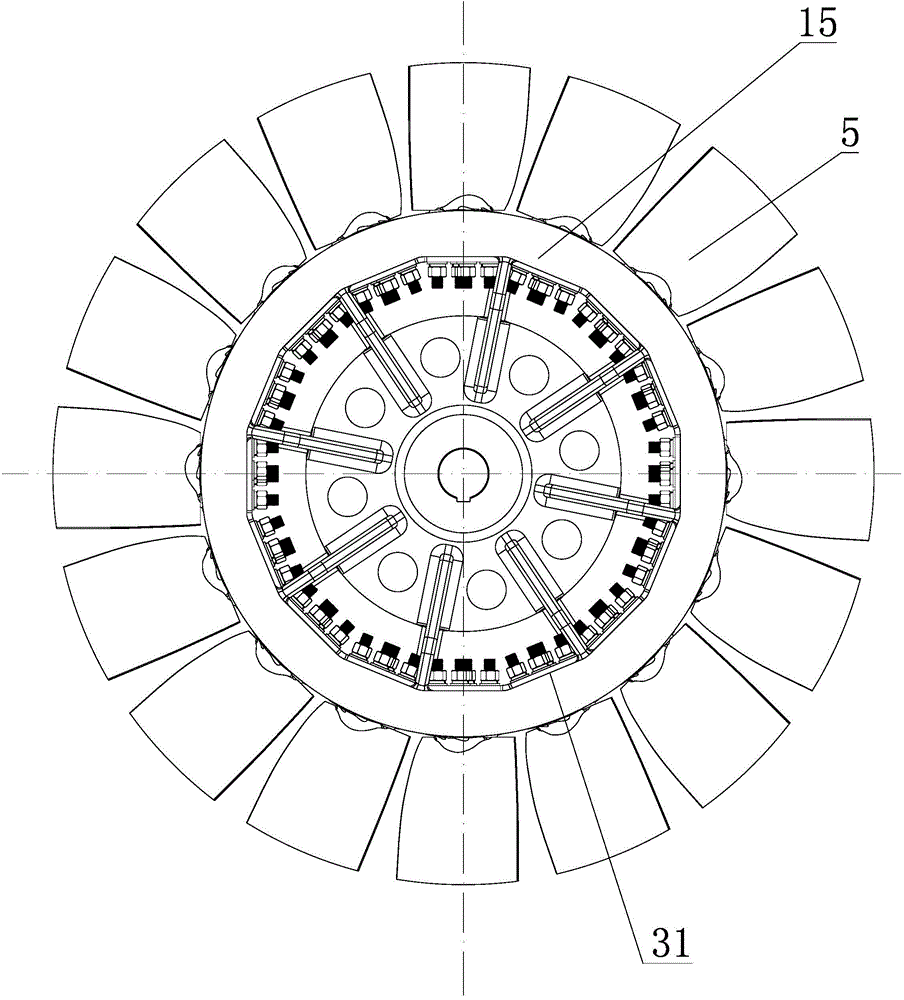

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an axial flow fan for a continuous ventilation system of a nuclear power plant containment according to the present invention includes a fairing 2, an impeller, and an inner cylinder assembly 9 arranged in sequence in the casing according to the airflow direction. The casing is composed of a current collector 1, a fan outer cylinder 6, and a diffuser cylinder 10 arranged in sequence according to the airflow direction. The current collector 1, the fan outer cylinder 6, and the diffuser cylinder 10 are fixedly connected by bolt fasteners. The fairing 2 is welded together with the collector 1 through the front inlet guide vane 3 . The inner cylinder assembly 9 includes a motor 8 installed in the cylinder, the impeller is installed on the output shaft of the motor 8 , and the outer wall of the cylinder is fixedly connected with the fan outer cylinder 6 through guide vanes 7 .

[0028] A further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com