A structure and method for reducing the steel-carbon pressure drop of an aluminum electrolytic anode

A technology of aluminum electrolytic anode and anode steel claws, applied in the field of aluminum electrolytic metallurgy, can solve the problems such as poor contact between carbon block and metal interface at the micro level, so as to achieve a sufficiently tight connection, reduce power consumption per ton of aluminum, and reduce anode The effect of pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

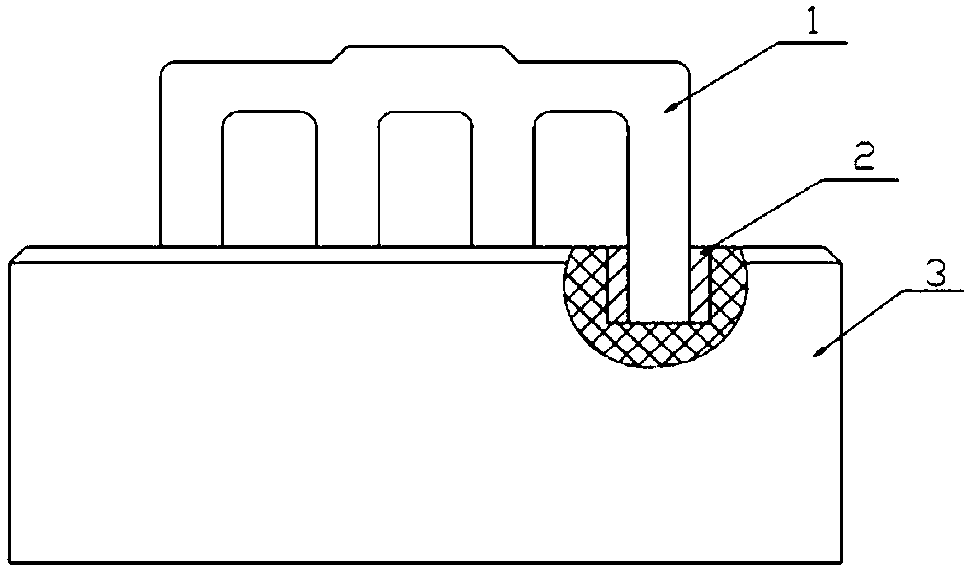

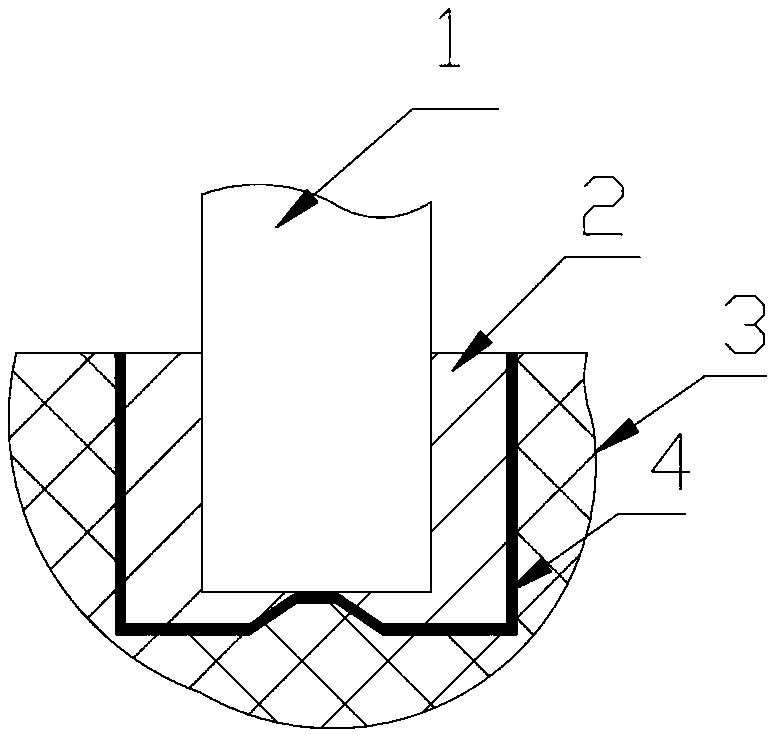

[0021] A structure for reducing the steel-carbon pressure drop of aluminum electrolytic anodes, including steel claws 1, phosphorus pig iron rings 2, and anode carbon blocks 3. There is a cylindrical carbon bowl on the carbon block, and the claw head of steel claw 1 is inserted in the carbon bowl. Between the head and the ring seam of the charcoal bowl is a cast phosphorus pig iron ring 2. It is characterized in that the carbon bowl surface of the carbon block 3 in contact with the steel claw 1 and the phosphorus pig iron 2 has a copper coating 4, and the thickness of the copper coating is 0.02mm, see figure 1 , 2 .

[0022] The structure is realized by the following method, a method of reducing the steel-carbon pressure drop of the aluminum electrolysis anode, during the assembly process of the aluminum electrolysis anode, the surface of the carbon bowl of the anode carbon block 3 is first activated, sensitized, etc. pre-plated For treatment, the conventional electroless co...

Embodiment 2

[0025] A structure for reducing the steel-carbon pressure drop of aluminum electrolytic anodes, including steel claws 1, phosphorus pig iron rings 2, and anode carbon blocks 3. There is a cylindrical carbon bowl on the carbon block, and the claw head of steel claw 1 is inserted in the carbon bowl. Between the head and the ring seam of the charcoal bowl is a cast phosphorus pig iron ring 2. It is characterized in that the carbon bowl surface of the carbon block 3 in contact with the steel claw 1 and the phosphorus pig iron 2 has a copper coating 4, and the thickness of the copper coating is 4.5mm, see figure 1 , 2 .

[0026] The structure is realized by the following method, a method of reducing the steel-carbon pressure drop of the aluminum electrolysis anode, during the assembly process of the aluminum electrolysis anode, the surface of the carbon bowl of the anode carbon block 3 is first activated, sensitized, etc. pre-plated For processing, the conventional electroless co...

Embodiment 3

[0029] A structure for reducing the steel-carbon pressure drop of aluminum electrolytic anodes, including steel claws 1, phosphorus pig iron rings 2, and anode carbon blocks 3. There is a cylindrical carbon bowl on the carbon block, and the claw head of steel claw 1 is inserted in the carbon bowl. Between the head and the ring seam of the charcoal bowl is a cast phosphorus pig iron ring 2. It is characterized in that the carbon bowl surface of the carbon block 3 in contact with the steel claw 1 and the phosphorus pig iron 2 has a copper coating 4, and the thickness of the copper coating is 1mm, see figure 1 , 2 .

[0030] The structure is realized by the following method, a method of reducing the steel-carbon pressure drop of the aluminum electrolysis anode, during the assembly process of the aluminum electrolysis anode, the surface of the carbon bowl of the anode carbon block 3 is first activated, sensitized, etc. pre-plated For processing, the conventional electroless copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com