Double-row ball thin-walled flexible bearing and harmonic gear reducer

A gear reducer and flexible bearing technology, applied in the field of harmonic transmission, can solve the problems of low radial and axial bending stiffness, low working reliability, short service life, etc., and achieve improved contact conditions, axial and circumferential Effects of increased stiffness and load-carrying capacity and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

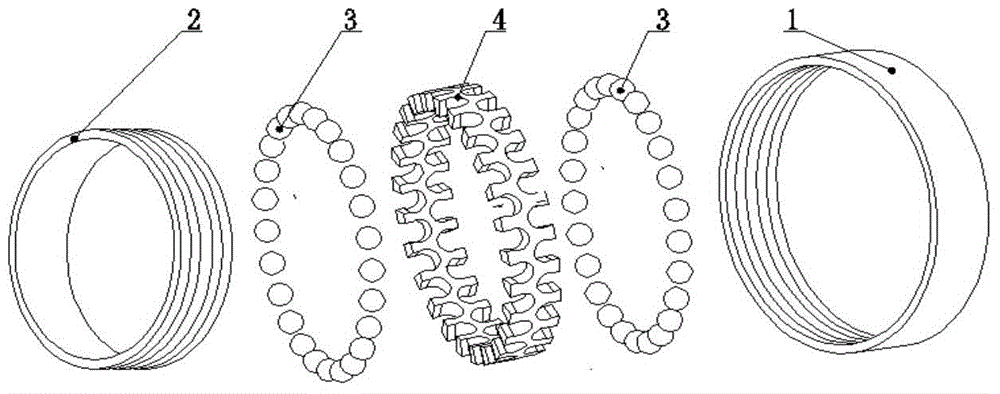

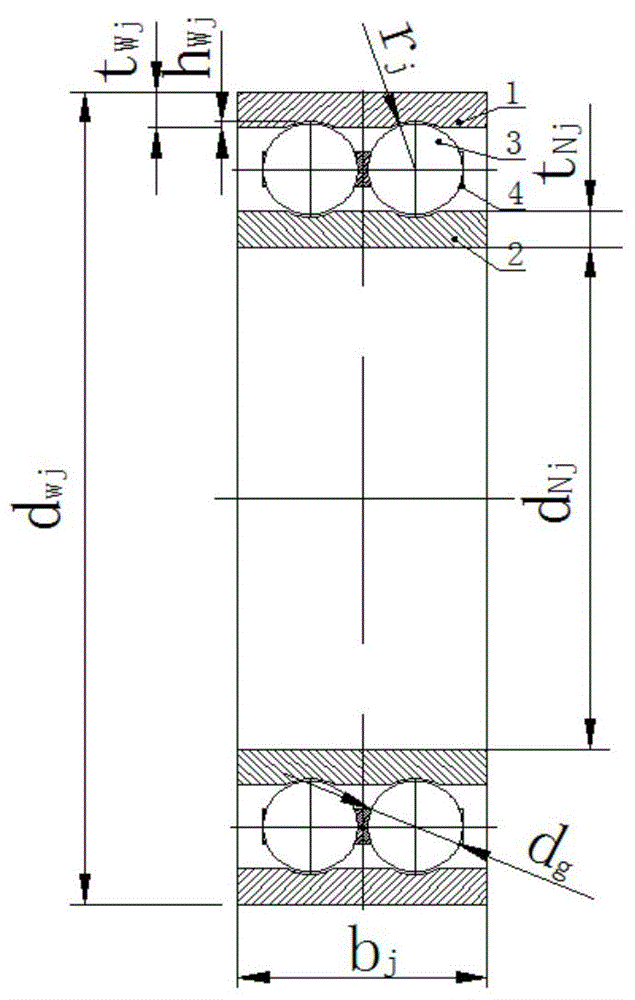

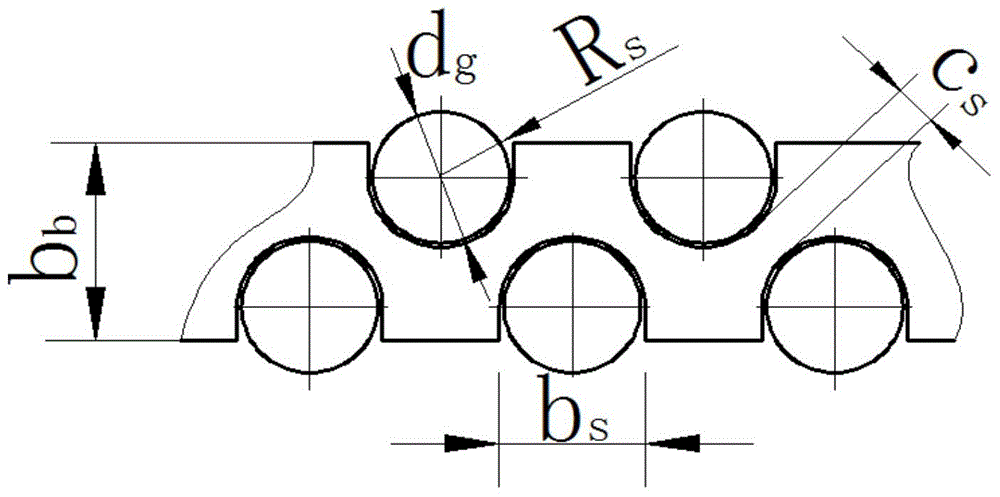

[0020]A double-row ball thin-wall flexible bearing, comprising an outer ring 1, an inner ring 2, rolling elements 3 and a cage 4, characterized in that the outer ring 1 and the inner ring 2 are coaxially arranged, and the inner ring 2 is arranged inside the outer ring 1 The width of the outer ring 1 is equal to the width of the inner ring 2. The inner wall of the outer ring 1 is provided with two parallel, symmetrical and equal-width grooves along the circumferential direction as raceways. The outer wall of the inner ring 2 has a Corresponding raceways; there is a cage 4 between the outer ring 1 and the inner ring 2, the cage 4 is an annular cage, and there are two rows of semicircular open ball socket holes along its outer circumference, and the same row of semicircular open balls The opening direction of the socket holes is the same and arranged at equal in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com