Bamboo shoot peeling roller

A technology of roller and bamboo shoot peeling, applied in the field of bamboo shoot peeling rollers, can solve the problems of unsatisfactory peeling effect of bamboo shoot shells, achieve good peeling effect and improve contact conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

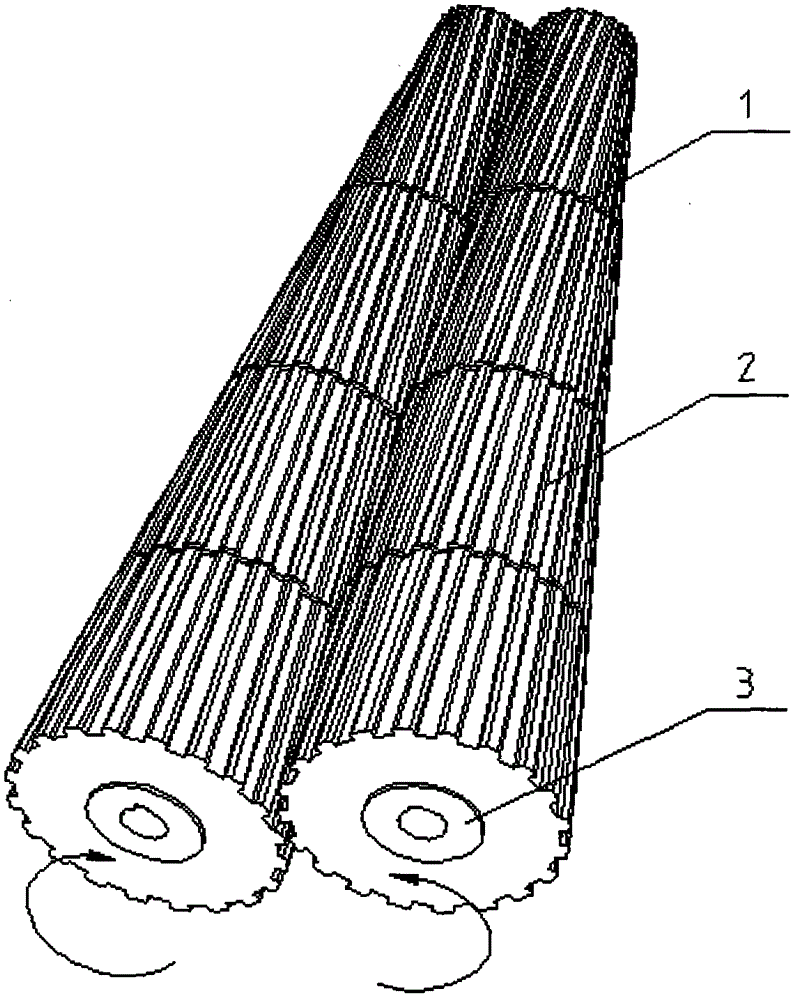

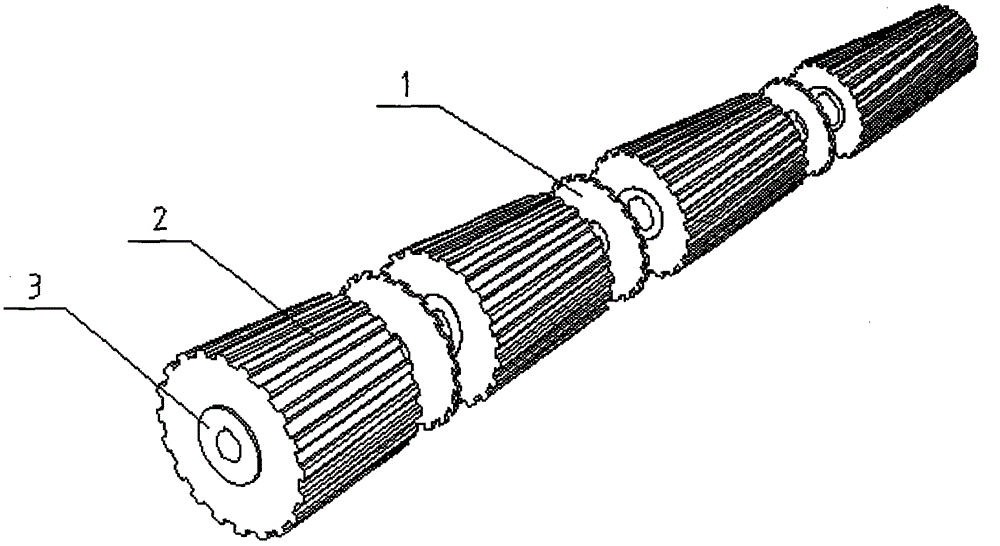

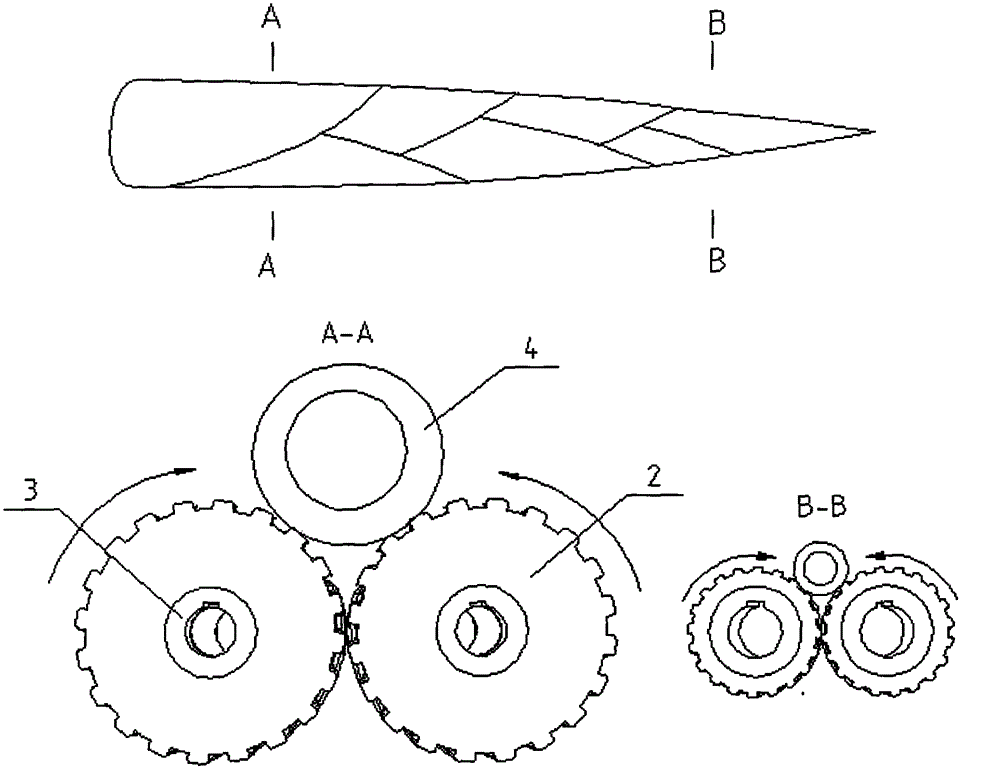

[0012] Such as Figure 1-Figure 3 As shown, a bamboo shoot stripping roller includes a blade 1, a rubber roller 2, and an installation sleeve 3;

[0013] It is characterized in that the installation sleeve 3 is wrapped with a rubber roller 2, which is fixed relative to the installation sleeve 3. The rubber roller 2 is made of food-grade silica gel. There is a circular toothed blade 1 installed between the rubber rollers 2. The diameter of the tooth tip of the blade 1 changes with the diameter of the end surface of the rubber roller 2. The diameter of the tooth top of the blade 1 is slightly smaller than the outer diameter of the end surface of the rubber roller 2 next to it. After the rollers are installed, the convex edges of each rubber roller 2 are aligned, and the whole roller is conical.

[0014] Working process of the present invention is: as image 3 As shown, after the bamboo shoots 4 are transported to the bamboo shoot roller through layout, the rubber roller 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com