Method and device for determining heating start point of electric upsetting through current detection

A current detection and electric upsetting technology, applied in heating/cooling equipment, forging/pressing/hammer devices, metal processing equipment, etc., can solve the problem of unreliability, inconvenient use, and inability to effectively detect whether the workpiece is in contact with the anvil, etc. problem, to achieve the effect of high reliability and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

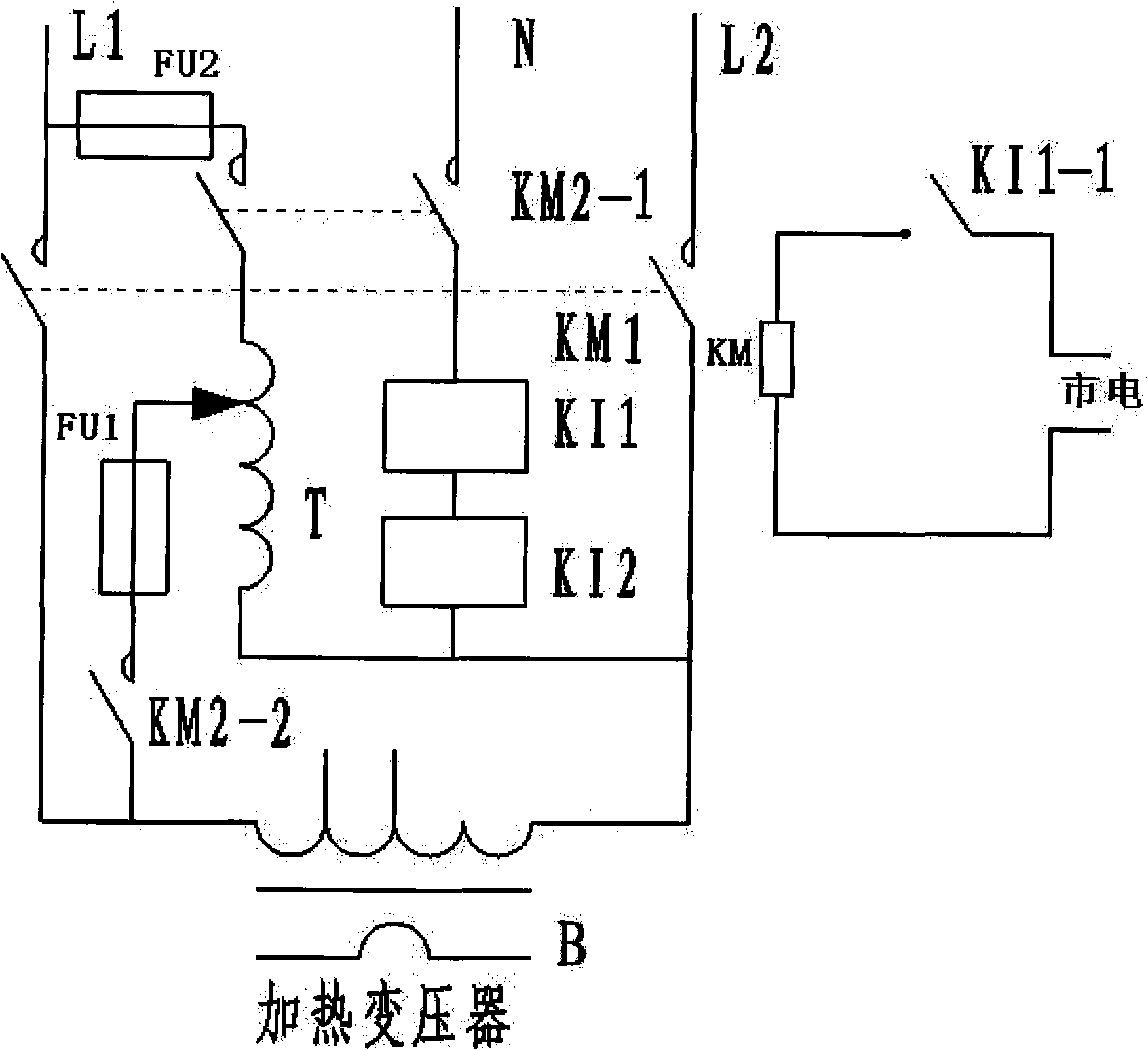

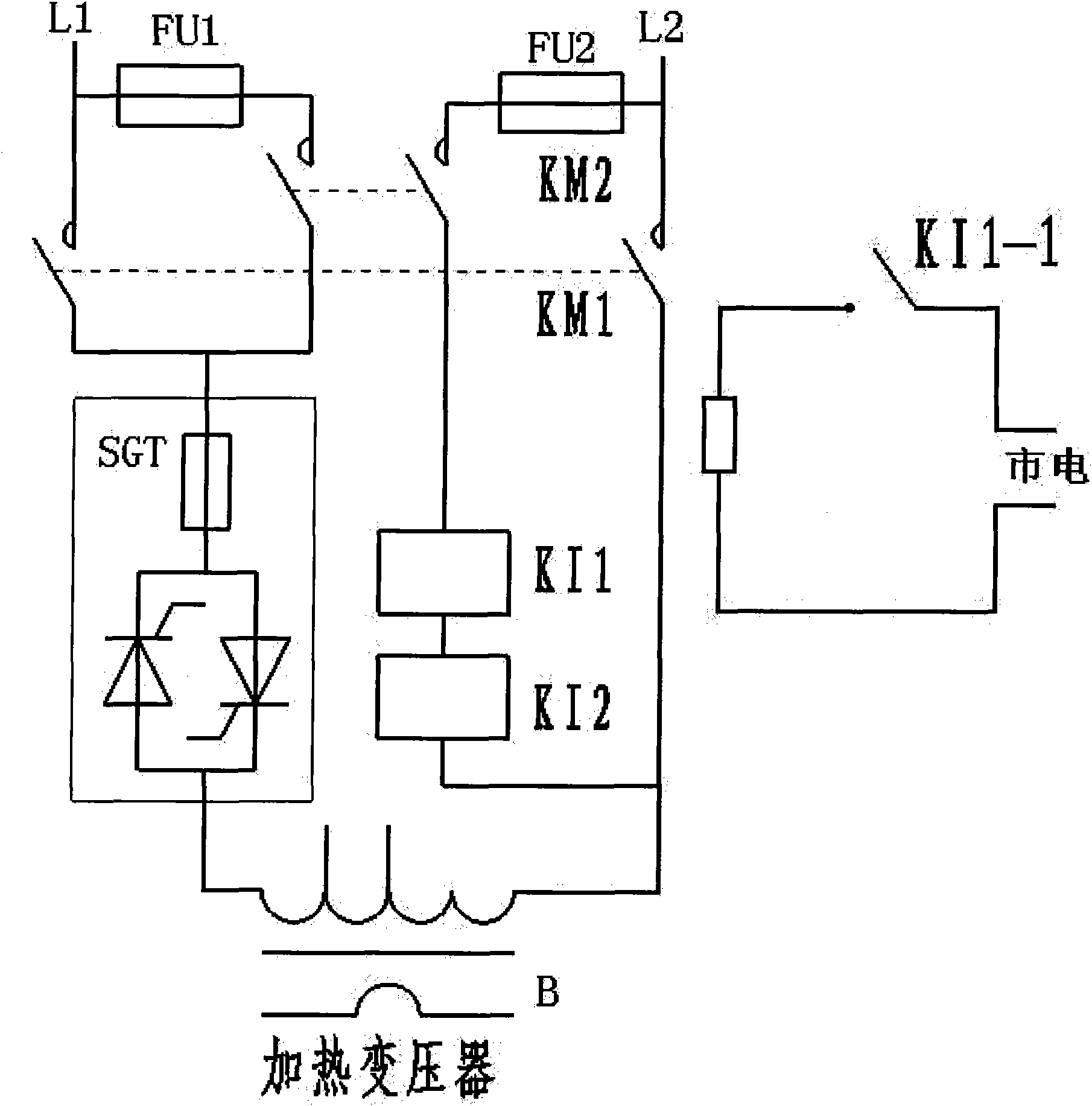

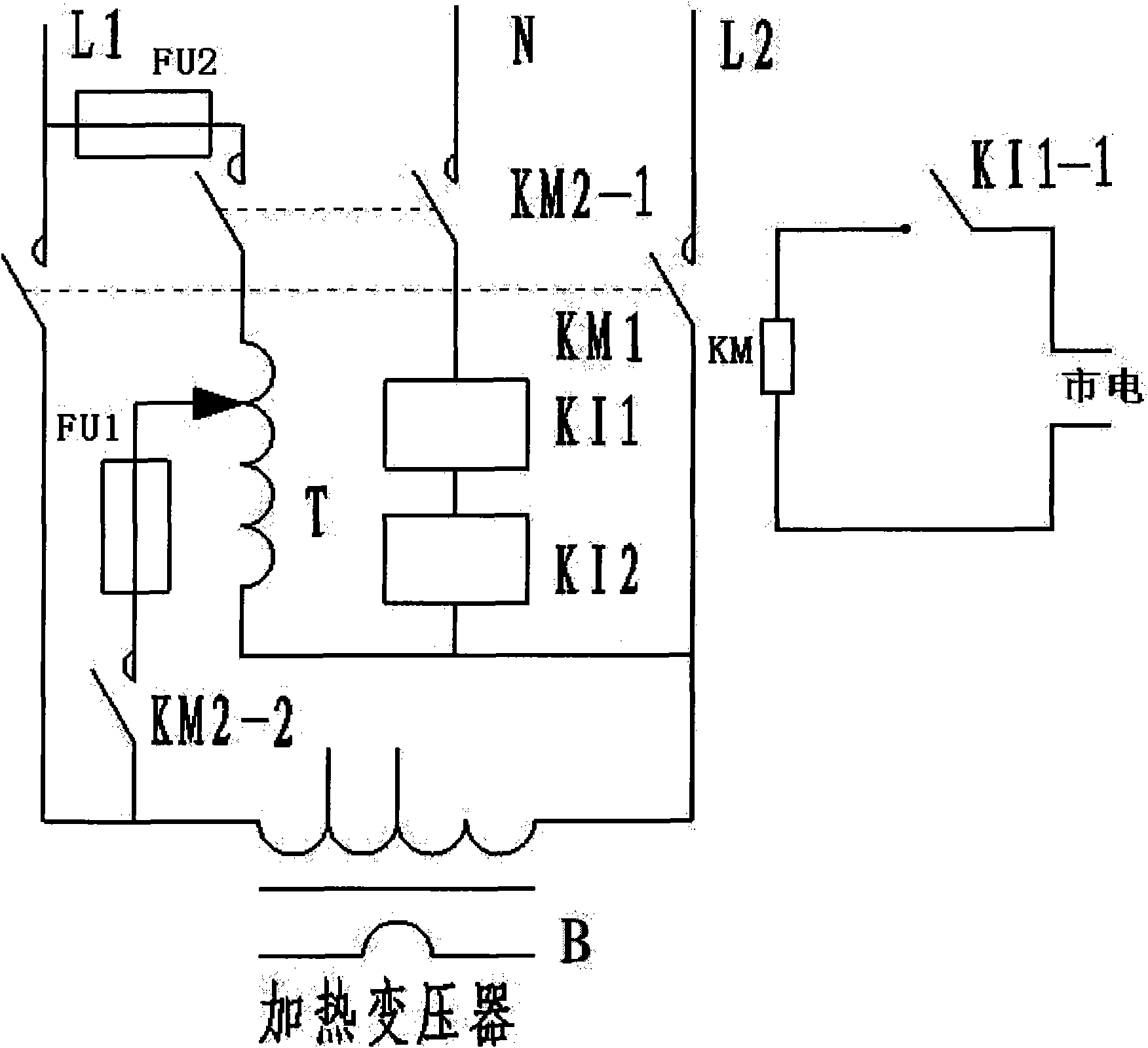

[0025] see figure 2, a device that uses current detection to determine the starting point of electric heating upsetting, including heating transformer B, AC contactors KM1, KM2, thyristor voltage regulator SGT, impedance relays KI1, KI2, fuses FU1, FU2; heating transformer B The input terminal is connected to the mains, and one output terminal of the heating transformer B and the output terminal of the thyristor voltage regulator SGT pass through a pair of normally open contacts KM1-1 connected to the terminal L1 on the anvil and the wiring on the clamping block Column L2, the input end of the thyristor voltage regulator SGT is connected to the other output end of the heating transformer B; one end of the line package of the impedance relay KI1 and KI2 connected in series is connected to an output end of the heating transformer B, and the end of the impedance relay KI1 and KI2 The other end of the wire package connected in series and the output end of the thyristor voltage re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com