Novel high-flux gas-liquid uniform tower tray

A technology with uniform gas-liquid distribution and large flux, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical processes, etc. Small and other problems, to achieve the effect of reducing the amount of entrained mist, increasing the gas-liquid contact area, and increasing the flexibility of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

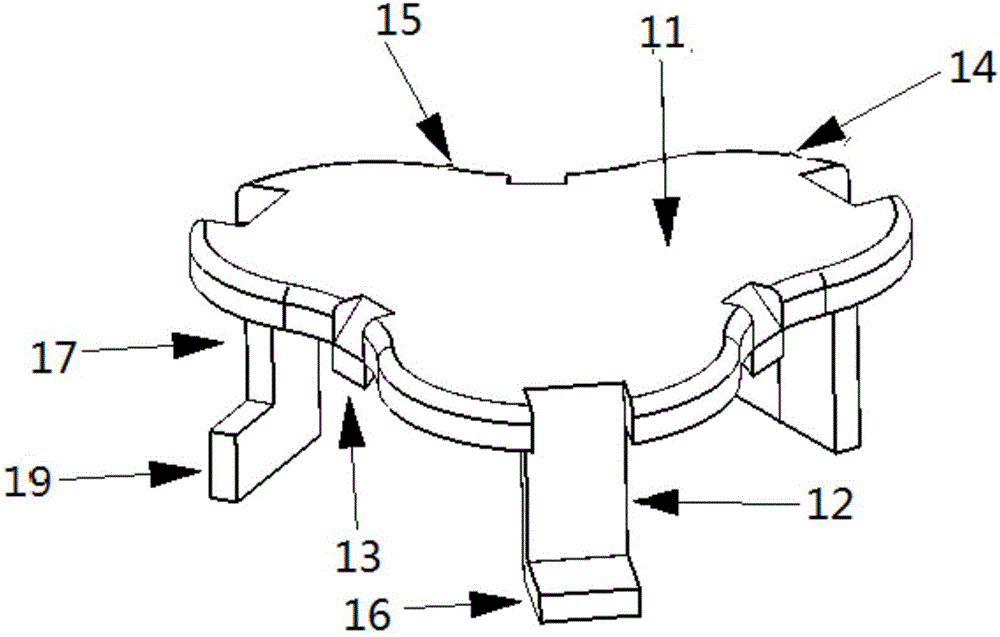

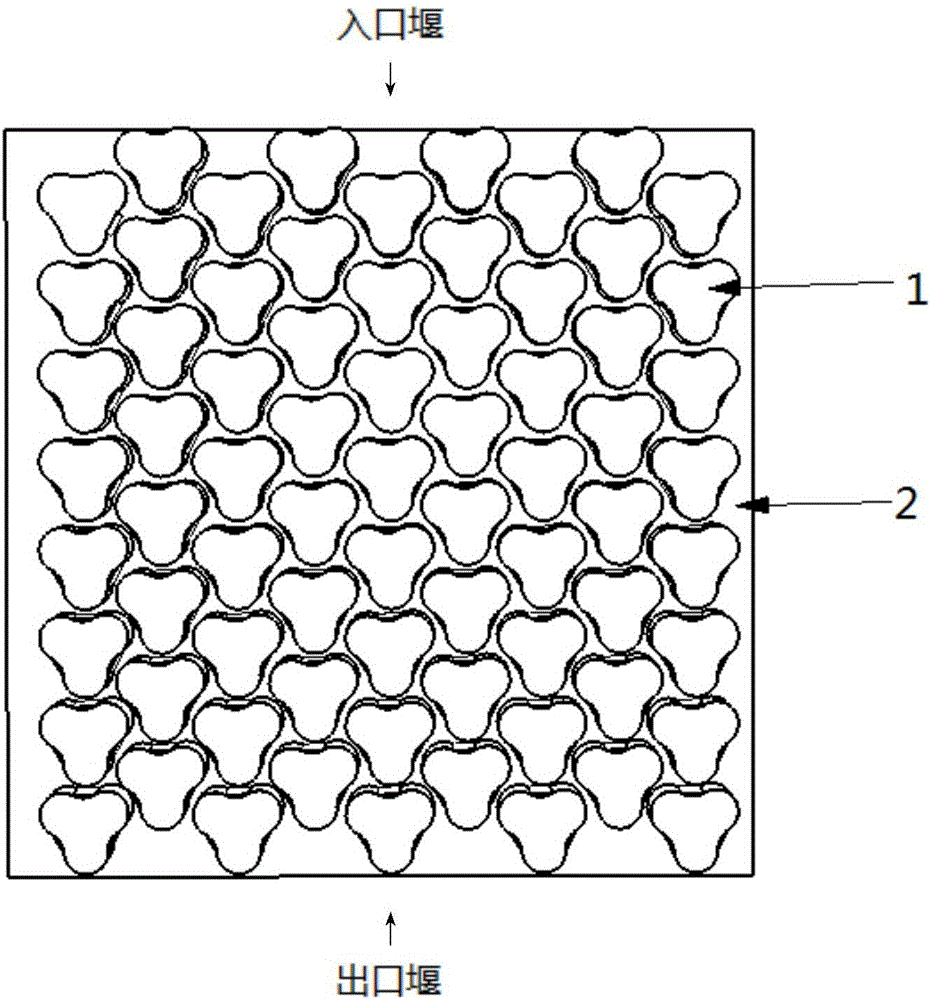

[0033] like figure 1 As shown, a new type of tray with a large flux of gas-liquid evenly distributed, including tray 2, valve hole 3 and float valve 1; float valve 1 includes valve plate 11, valve leg 12 and spacer bar 13; wherein the valve plate 11. The edges are alternately arranged with convex arcs and concave arcs. There are three convex parts 14 formed by convex arcs and three concave parts 15 formed by concave arcs. The three convex parts 14 have the same radius of curvature, and the three concave parts 15 The radii of curvature are the same, and the radii of curvature of the three convex portions 14 are less than or equal to the radii of curvature of the three concave portions 15, (preferably the radius of curvature of the convex portions 14 is equal to the radius of curvature of the concave portion 15); between valve plates 11 of different float valves 1 The concave part 15 and the convex part 14 can cooperate with each other; the edge of the valve plate 11 can be incl...

Embodiment 2

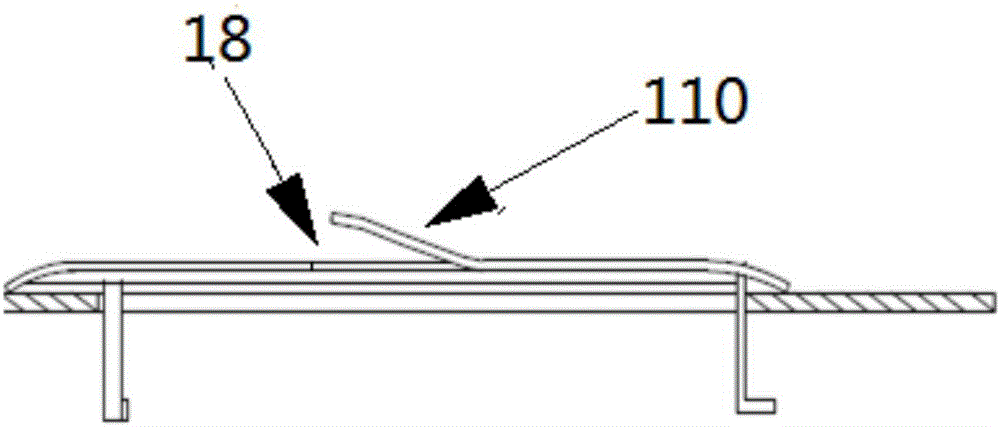

[0040] Different from Example 1, as figure 2 As shown, the valve plate 11 can be provided with one or more guide holes 18, and the guide hole 18 is fixed with a guide valve plate 110 supported obliquely. The edge shape of the guide valve plate 110 corresponds to the edge shape of the guide hole 18. ; The guide hole 18 is tongue-shaped, trapezoidal, rectangular, circular or triangular, and the guide valve plate 110 and the guide hole 18 are made by stamping directly on the valve plate.

Embodiment 3

[0042] In the specific embodiment of the present invention, the fixed valve tray of the same structure can also be used, a kind of fixed valve tray, including tray, valve hole and fixed valve; The convex arcs and concave arcs are arranged alternately, and there are three convex parts formed by the convex arcs and three concave parts formed by the concave arcs. The curvature radii of the three convex parts are the same, and the curvature radii of the three concave parts are the same, and The radius of curvature of the convex part is less than or equal to the radius of curvature of the concave part, preferably the radius of curvature of the convex part is the same as that of the concave part; there are three valve legs, and the valve legs are equidistantly spaced, one end of the valve leg is fixed on the lower end surface of the convex part, and the other end is fixed to the tray connect.

[0043] There are several rows of fixed valves parallel to each other on the tray; the fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com