Construction method for proton exchange membrane with three-dimensional high specific surface area surface, and high performance membrane electrode based on proton exchange membrane

A technology of proton exchange membrane and high specific surface area, which is applied in the direction of circuits, fuel cells, electrical components, etc., can solve the problems of complex preparation methods, the gap between the requirements of the contact interface between the proton exchange membrane and the catalytic layer, and the large thickness of the porous membrane. The preparation method is simple and easy, the performance of the membrane electrode is improved, and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The first step is to take a 4cm×4cm Nafion212 proton exchange membrane, first place it in 15% hydrogen peroxide at 80°C for 1 hour, wash it with distilled water, and put it in 1mol.L -1 treated in a sulfuric acid solution at 80°C for 1 hour, and then washed with distilled water. Place the treated proton exchange membrane on the fixed frame of the prepared porous membrane and fix it, the size of the active area is 6.25cm 2 , to prevent the film from shrinking and deforming during the spraying of the porous layer slurry;

[0038] The second step is to weigh 5mg zinc oxide, 11mg perfluorosulfonic acid resin solution (5wt% Nafion, DuPont) and 0.3g isopropanol respectively according to the mass ratio of 5:11:300, mix and disperse into a porous layer slurry by ultrasonic vibration Material spare.

[0039] In the third step, the porous layer slurry in the second step is sprayed onto one side of the proton exchange membrane by spraying method, and then heat-treated at 50° C. ...

Embodiment 2

[0046]In addition to changing the nafion212 film into a nafion211 film, changing the mass percent concentration of 15% hydrogen peroxide into a mass percent concentration of 5% hydrogen peroxide, and changing the perfluorosulfonic acid resin solution (5wt% Nafion, DuPont) into perfluorosulfonic acid The acid resin solution (0.1wt% Nafion) and the mass ratio of 5:11:300 was changed to 5:200:2000, and the rest of the steps were the same as in Example 1.

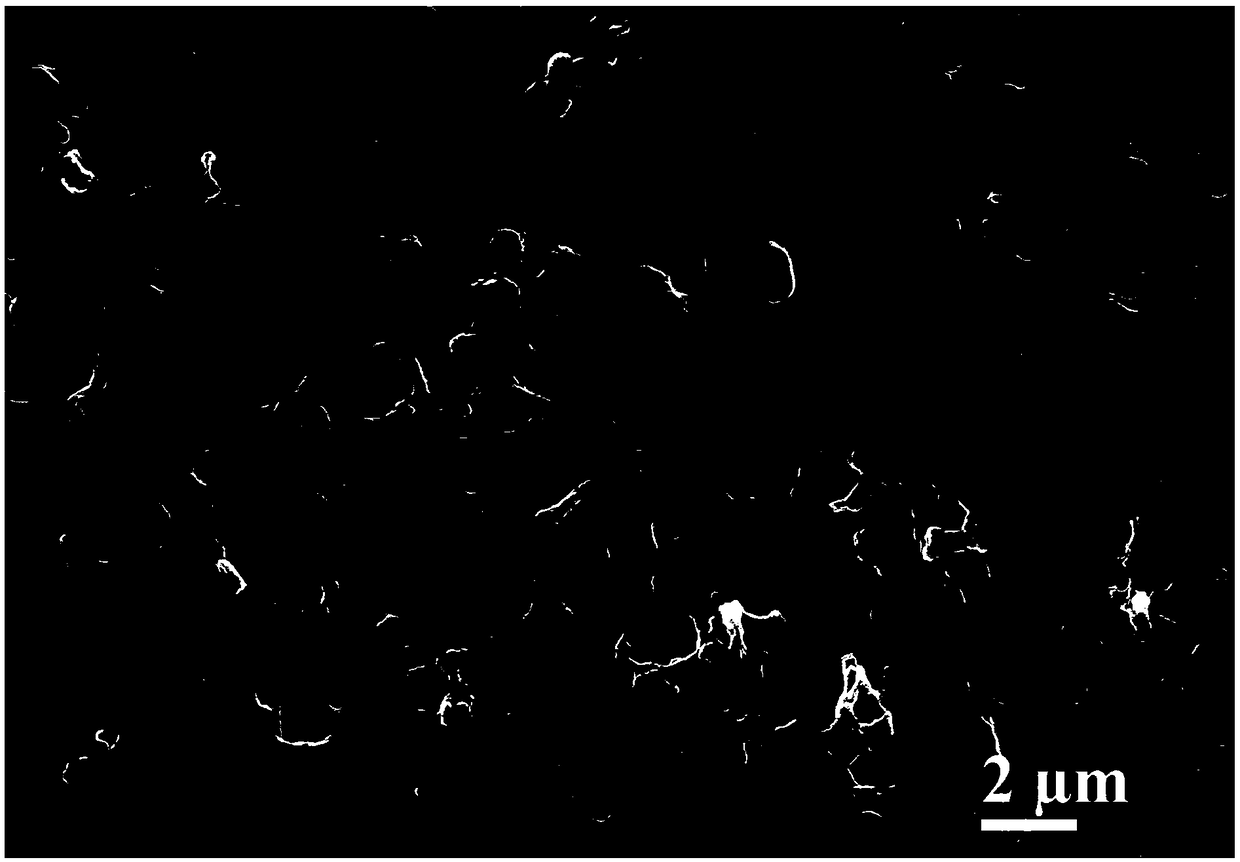

[0047] image 3 It is the scanning electron micrograph of embodiment 2. It can be found in the figure that after the ratio is changed, the distribution form of the pores also changes.

Embodiment 3

[0049] In addition to changing the nafion212 membrane to nafionhp membrane, changing the sulfuric acid solution of 1mol.L-1 to 0.5mol.L-1 sulfuric acid solution, changing zinc oxide to magnesium oxide and changing the mass ratio of Except the mass ratio of 5:20:300, all the other steps are identical with embodiment 1.

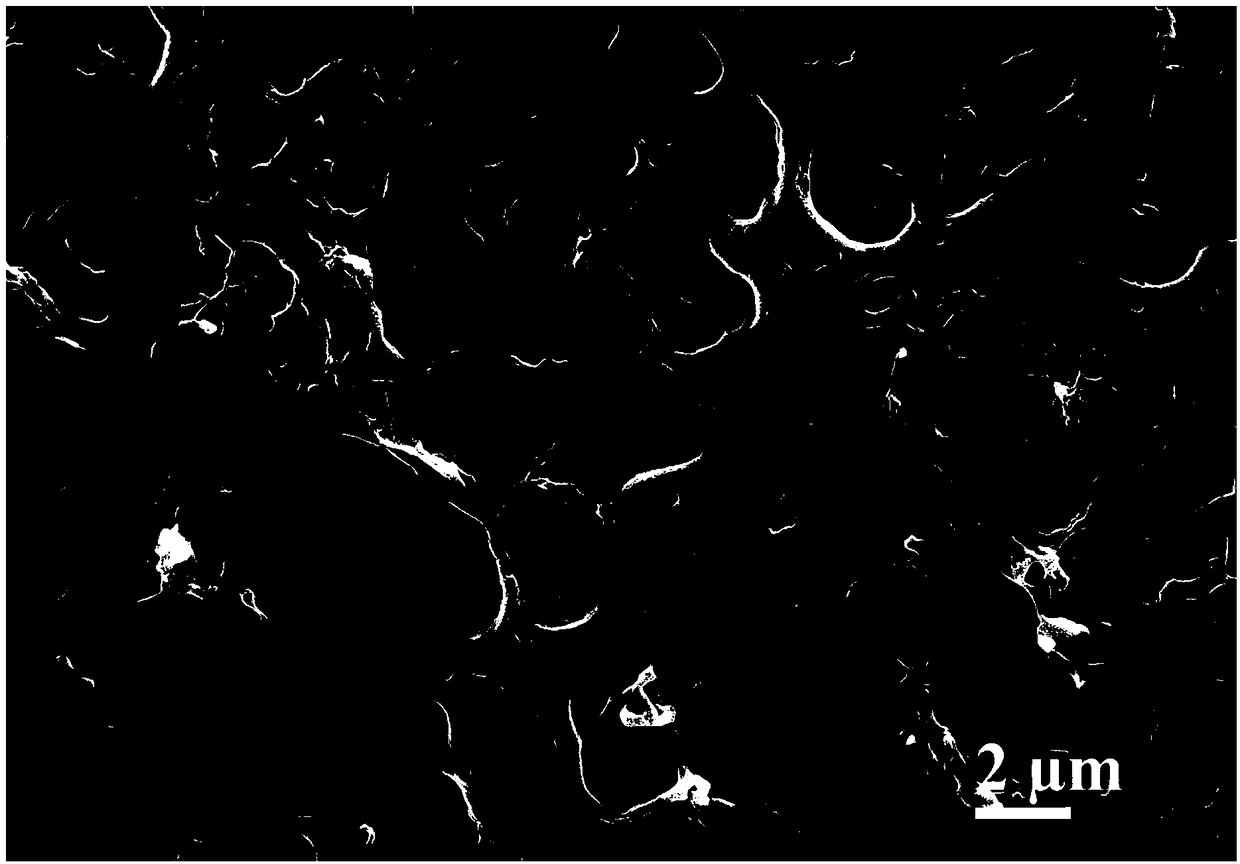

[0050] Figure 4 It is the scanning electron micrograph of embodiment 3. It can be found in the figure that the pore size and distribution are changed by changing the pore-forming agent and the ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com