Safe friction material with low noise and preparation method of friction plate

A friction material and safe technology, applied in the direction of friction linings, chemical instruments and methods, mechanical equipment, etc., to achieve the effect of stable friction coefficient, ensuring safety, and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

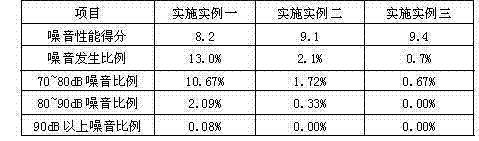

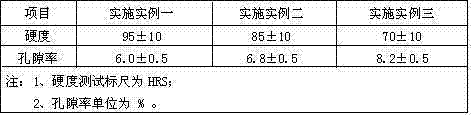

Embodiment 1

[0024] The friction material includes the following components by percentage: resin 10%, coke powder 6.8%, nitrile powder 0.5%, tire powder 1.0%, corundum 1.5%, graphite 9.1%, iron black 2.5%, chromite powder 4.3%, friction powder 2.3%, fiber 22.15%, filler 39.85%. The fibers are formed by mixing metal fibers and organic fibers, and the content of the metal fibers is 21.3% by weight, and the content of the organic fibers is 0.85%. The filler includes 30.0% barite, 6.0% cryolite, 0.85% calcium oxide, and 3.0% sulfide, with a total content of 39.85%. The resin is phenolic resin or linear resin, and the nitrile powder is nitrile rubber powder or styrene-butadiene rubber powder.

[0025] Weigh each raw material according to the above weight ratio, adopt the dry preforming process, and proceed in the following five steps:

[0026] (1) Mixing: Weigh all the raw materials by weight percentage, put all the materials into a high-speed mixer, and stir for 4 minutes to make a friction ...

Embodiment 2

[0032] The friction material includes the following components in terms of percentages: resin 8.0%, coke powder 6.8%, nitrile powder 1.0%, tire powder 1.2%, corundum 1.5%, graphite 10.5%, iron black 2.5%, chromite powder 4.3%, activated carbon 1.5%, friction powder 2.3%, fiber 22.15%, filler 38.25%. The fibers are formed by mixing metal fibers and organic fibers, and the content of the metal fibers is 21.3% by weight, and the content of the organic fibers is 0.85%. The filler includes 28.4% barite, 6.0% cryolite, 0.85% calcium oxide and 3.0% sulfide.

[0033] Various raw materials were weighed according to the above weight ratios, and prepared with the same process steps as described in Example 1.

Embodiment 3

[0035] The friction material includes the following components in terms of percentages: 4.7% resin, 6.8% coke powder, 1.7% nitrile powder, 4.3% tire powder, 1.7% corundum, 12.8% graphite, 1.7% iron black, chromite powder 4.3%, activated carbon 3.0%, friction powder 4.3%, fiber 22.15%, filler 32.55%. The fibers are formed by mixing metal fibers and organic fibers, and the content of the metal fibers is 21.3% by weight, and the content of the organic fibers is 0.85%. In this embodiment, the activated carbon and the friction powder are added as a component of the filler, and the filler also includes 22.98% of barite, 6.0% of cryolite, 0.85% of calcium oxide, sulfide 3.0%.

[0036] Various raw materials were weighed according to the above weight ratios, and prepared with the same process steps as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com