Catalytic reactor for preparing propylene from methanol and method for preparing propylene from methanol

A methanol-to-propylene, catalytic reactor technology, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problems of high methanol consumption per ton of propylene, decreased catalyst activity, and increased average unit consumption, etc. The effect of reducing the unit consumption of propylene and methanol, increasing the production time, and reducing the content of alkane and ethylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

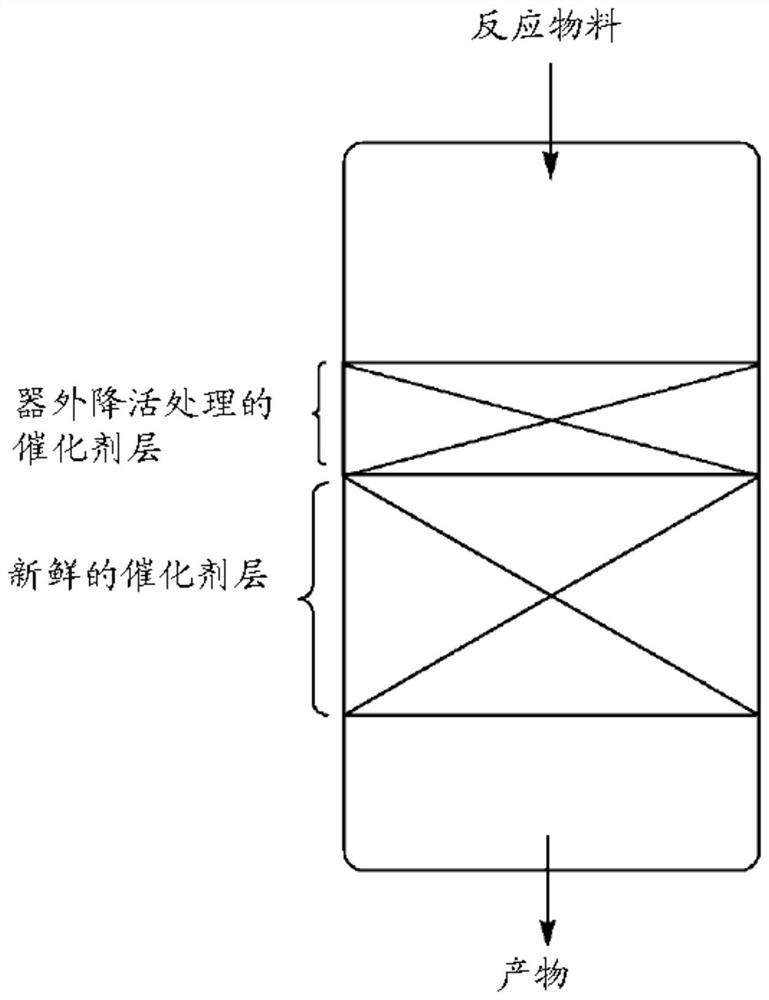

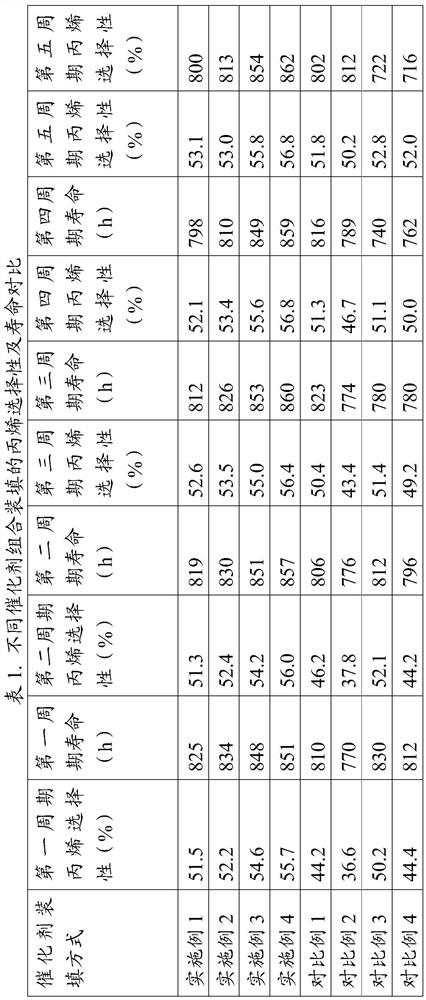

[0028] The catalyst packed in combination in this example is used for producing propylene from methanol. Specifically, the following steps are included:

[0029] (1) Extra-device deactivation treatment

[0030] Weigh 1000g of commercial MTP catalyst HZSM-5 (produced by Shanghai Zhuoyue Environmental Protection New Material Co., Ltd., φ3.2×3.3mm, bulk density is 0.79g / mL), and put it into a quartz tube reactor. At 480°C, using 100% water vapor, at a space velocity of 2h -1 Under the condition of 48 hours, stop feeding water vapor, cool down to room temperature naturally, and obtain the precursor of water vapor treatment.

[0031] Put the above precursor into a U-shaped reaction tube, put it into a water bath at 80°C, pass through HCl solution with a concentration of 2mol / L, treat it for 6 hours, then wash it with deionized water three times, and then dry it at 120°C for 8 hours , and calcined at 550° C. for 6 hours to obtain an ex-situ deactivation-treated catalyst.

[0032...

Embodiment 2

[0035] In the external deactivation treatment, the water vapor treatment conditions are: temperature 500°C, 100% water vapor, space velocity 1h -1 , processing time is 36 hours. The acid treatment conditions are: the concentration of HCl is 5 mol / L, and the treatment is at 100° C. for 4 hours. The other steps are the same as in Example 1, the ratio of the height of the deactivated catalyst to the fresh catalyst is 1:1, and the total loading amount of the catalyst is 200g, which is ready for evaluation.

Embodiment 3

[0037] The external deactivation treatment of the catalyst is the same as that in Example 1. When combined loading, the lower layer is fresh catalyst, and the upper layer is the catalyst with external deactivation treatment. The height ratio of the upper and lower catalyst layers is 1:2. It is 200g, and it is ready for evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com