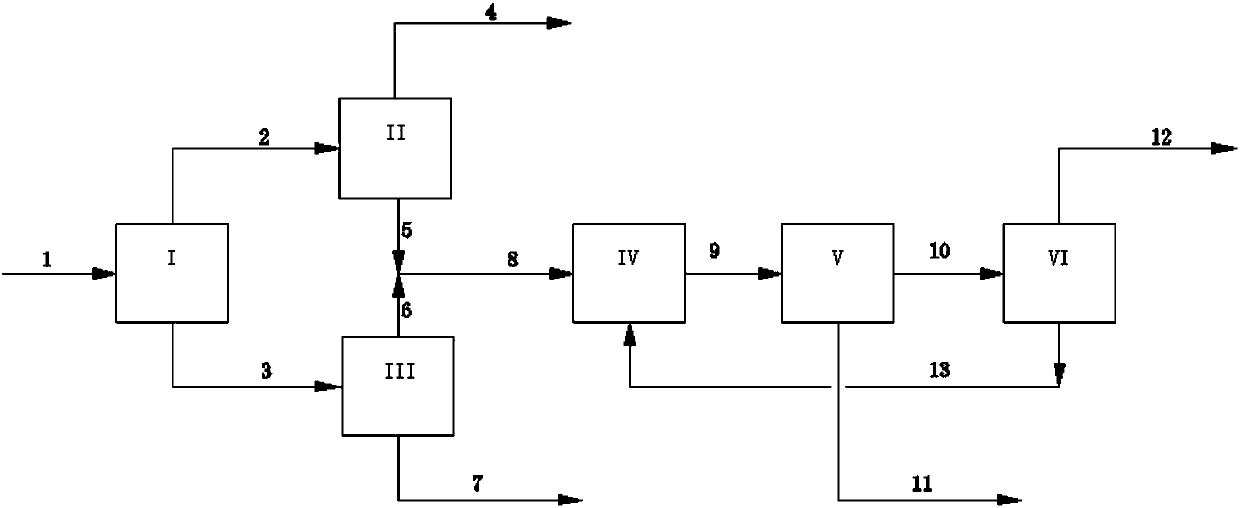

Method for preparing aromatic hydrocarbon from mixed light hydrocarbon

A technology for light hydrocarbons and aromatics, applied in the field of mixing light hydrocarbons to aromatics, can solve the problem of high energy consumption in ethylene recovery and utilization, achieve the effects of reducing investment and energy consumption, ensuring the conversion rate of raw materials, and avoiding separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The temperature of the light hydrocarbon raw material is 40°C, the pressure is 1.5 MPa, and the volume fraction composition is as follows: hydrogen 54%, methane 8%, carbon 2 12%, carbon 3 and above 26%. The mass content of aromatics in the light hydrocarbon raw material is 4.9%. After the light hydrocarbon raw material is cooled to 10°C in the heat exchanger, it is separated into hydrogen-rich gas and hydrogen-poor liquid in the gas-liquid separator. At this time, the content of aromatics in the hydrogen-rich gas is 180PPM (volume content). The hydrogen-rich gas is separated into methane-hydrogen mixed gas and dehydrogenation stream through the PSA pressure swing adsorption separation unit. The dehydrogenation stream is pressurized to 0.3MPa by a compressor. The hydrogen-depleted liquid is separated in the depentanizer into a deheavy stream and a first aromatics stream. The operating pressure of the depentanizer is 0.6MPa, the temperature at the top of the tower is 6...

Embodiment 2

[0030] Using the same light hydrocarbon raw material, process flow and operating conditions as in Example 1, only the temperature of the light hydrocarbon raw material heat exchanger in the cooling and separation unit I was changed to 5°C. The content of aromatics in the hydrogen-rich gas is 120PPM (volume content). The energy consumption of this embodiment is 339kg standard oil / ton of aromatics.

Embodiment 3

[0032] Using the same light hydrocarbon raw material, process flow and operating conditions as in Example 1, only the temperature of the light hydrocarbon raw material heat exchanger in the cooling and separation unit I was changed to 15°C. The content of aromatics in the hydrogen-rich gas is 260PPM (volume content). The energy consumption of this embodiment is 332kg standard oil / ton of aromatics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com