Fresh-keeping material capable of efficiently removing ethylene and preparation method of fresh-keeping material

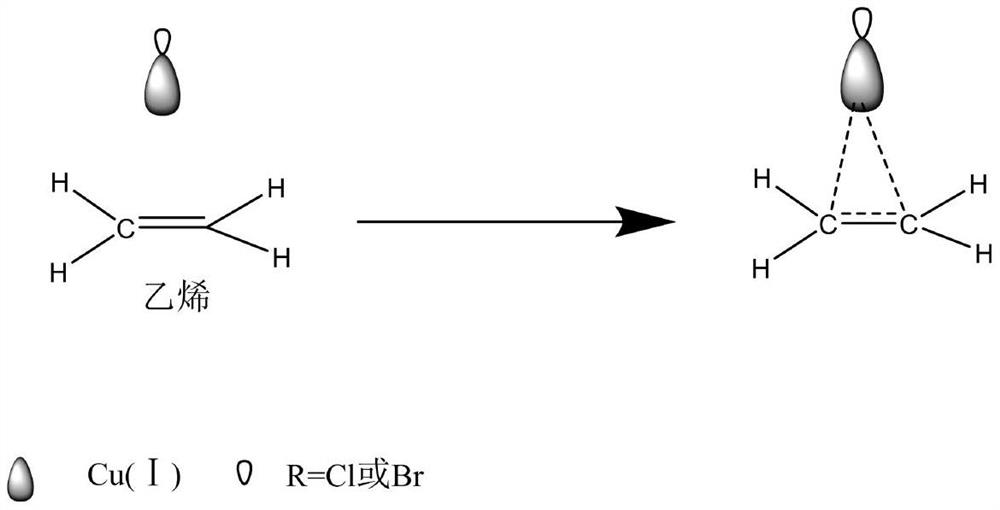

A fresh-keeping material, ethylene technology, applied in botany equipment and methods, plant preservation, fruit and vegetable preservation, etc., can solve the problems of easy contamination of fruit and vegetable surfaces, limited adsorption capacity, unstable ethylene, etc., to reduce ethylene content, prepare The method is simple and the effect of prolonging freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) prepare the hydrochloric acid solution of 0.5mol / L;

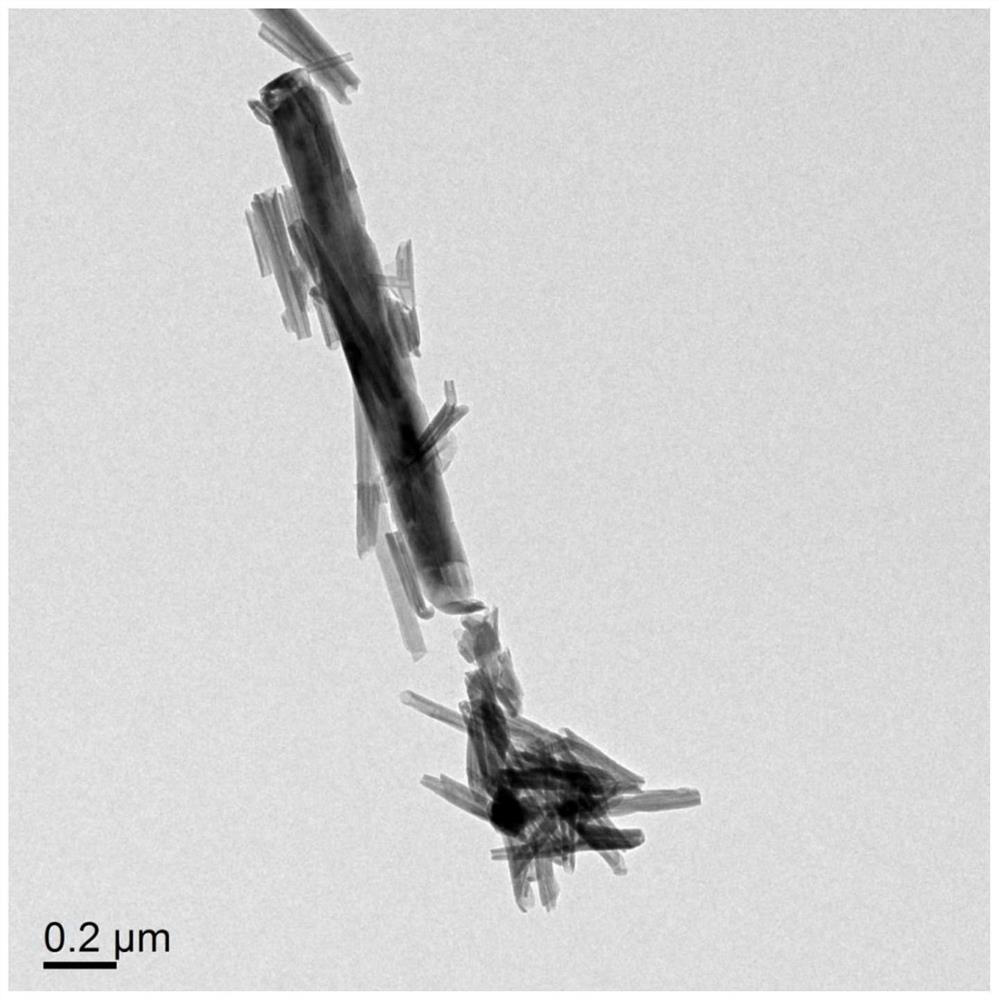

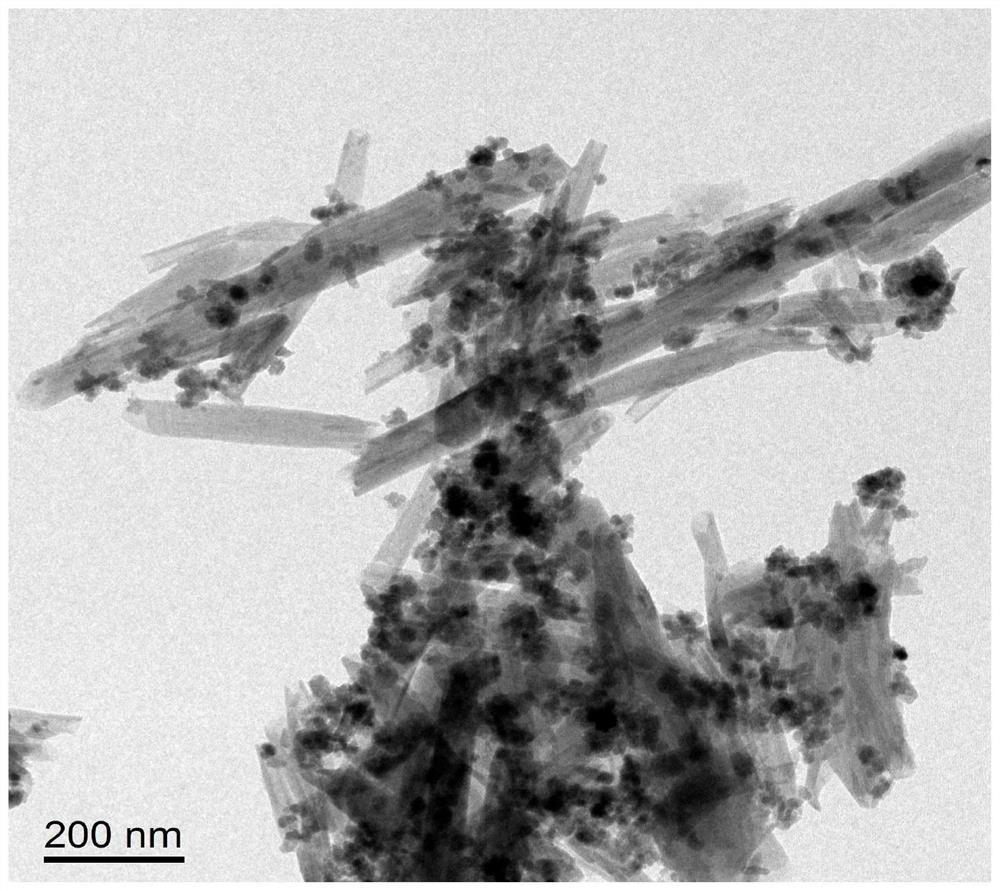

[0043](2) Acidification treatment of the carrier material: 10 g of halloysite nanotubes were weighed, added to 250 mL of hydrochloric acid solution, heated to 50° C., and acidified for 2 hours. The acidified halloysite nanotubes were washed with deionized water to pH=7. Then, put it into an oven at 100° C. and dry for 2 hours to obtain acidified halloysite nanotubes;

[0044] (3) Weigh 5.0 g of acidified halloysite nanotubes, weigh 2.5 g of CuCl, put the two into an agate mortar and grind them fully at the same time, and drop 1 mL (2 drops) of hydrochloric acid solution prepared to make the two well mixed;

[0045] (4) Put the uniformly mixed sample into a tube furnace and heat it up to 400°C for calcination. The heating rate is set at 5°C / min, and it is roasted for 4 hours. Before calcination, the tube furnace is filled with nitrogen for protection. Finally, it is naturally cooled to room temperature to obtai...

Embodiment 2

[0048] (1) prepare the sulfuric acid solution of 0.5mol / L;

[0049] (2) Acidification treatment of the carrier material: 10 g of halloysite nanotubes were weighed, added to 250 mL of sulfuric acid solution, heated to 50° C., and acidified for 2 hours. The acidified halloysite nanotubes were washed with deionized water to pH=7. Then, put it into an oven at 100° C. and dry for 2 hours to obtain acidified halloysite nanotubes;

[0050] (3) Weigh 5.0 g of acidified halloysite nanotubes, weigh 5.0 g of CuCl, put the two into an agate mortar and grind them fully at the same time, and drop 1 mL (2 drops) of acidic solution to make the two well mixed;

[0051] (4) Put the uniformly mixed sample into a tube furnace and heat it up to 500°C for calcination. The heating rate is set at 5°C / min, and it is roasted for 4 hours. Before calcination, the tube furnace is filled with nitrogen for protection. Finally, it is naturally cooled to room temperature to obtain a fresh-keeping material ...

Embodiment 3

[0053] (1) prepare the hydrochloric acid solution of 1.0mol / L;

[0054] (2) Acidification treatment of carrier material: 10 g of halloysite nanotubes were weighed, added to 250 mL of hydrochloric acid solution, heated to 50° C., and acidified for 2.5 hours. The acidified halloysite nanotubes were washed with deionized water to pH=7. Then, put it into an oven at 100° C. and dry for 2 hours to obtain acidified halloysite nanotubes;

[0055] (3) Weigh 5.0 g of acidified halloysite nanotubes, weigh 5.0 g of CuCl, put the two into an agate mortar and grind them fully at the same time, and drop 1 mL (2 drops) of acidic solution to make the two well mixed;

[0056] (4) Put the uniformly mixed sample into a tube furnace and heat it up to 400°C for calcination. The heating rate is set at 5°C / min, and it is roasted for 4 hours. Before calcination, the tube furnace is filled with nitrogen for protection. Finally, it is naturally cooled to room temperature to obtain a fresh-keeping mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com