A surface selective coating method for high-nickel ternary materials for lithium-ion batteries

A high-nickel ternary material, lithium-ion battery technology, applied in electrical components, battery electrodes, secondary batteries, etc., can solve the problems of reduced material gram capacity, increased material cost, cumbersome operating procedures, etc., to improve storage performance, The effect of reducing environmental humidity requirements and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A surface selective coating method of high-nickel ternary materials for lithium-ion batteries, such as Figure 4 Shown:

[0029] (1) Place the high-nickel ternary material of the lithium-ion battery in a humid environment with an air humidity of 10%-80% for 0.05-10h to generate residual alkali on the corners or edges of the surface;

[0030] (2) Add the high-nickel ternary material treated in step (1) into the ethanol solution of the metal salt, and stir to make the metal ions fully react with the residual alkali on the surface of the high-nickel ternary material. After the reaction is completed, within 60-80 Stir the solution until dry at ℃ to obtain a sample;

[0031] (3) The sample is sintered in a muffle furnace with oxygen or air atmosphere, the sintering temperature is 300-900°C, and the time is 1-10h; lithium metal oxide is formed on the residual alkali part of the high-nickel ternary material to obtain High nickel ternary material coated with lithium metal oxi...

Embodiment 2

[0032] Example 2: Preparation of LiAlO 2 Coated LiNi 0.85 co 0.1 mn 0.05 o 2

[0033] First, the lithium-ion battery high-nickel ternary material (LiNi 0.85 co 0.1 mn 0.05 o 2 ) placed in an environment with a humidity of 30% for 1 hour to generate residual alkali on the corners or edges of the surface;

[0034] Then add it to the ethanol solution of aluminum nitrate, wherein the mass of the Al element accounts for 0.1% of the total mass of the high-nickel ternary material, after stirring at high speed for 2 hours, stir the solution at 60°C until dry;

[0035] Finally, the dried sample was placed in a muffle furnace with an oxygen atmosphere, sintered at 600 °C for 2 h, and then cooled down to room temperature naturally, and lithium metal oxide was formed on the residual alkali part of the high-nickel ternary material for coating.

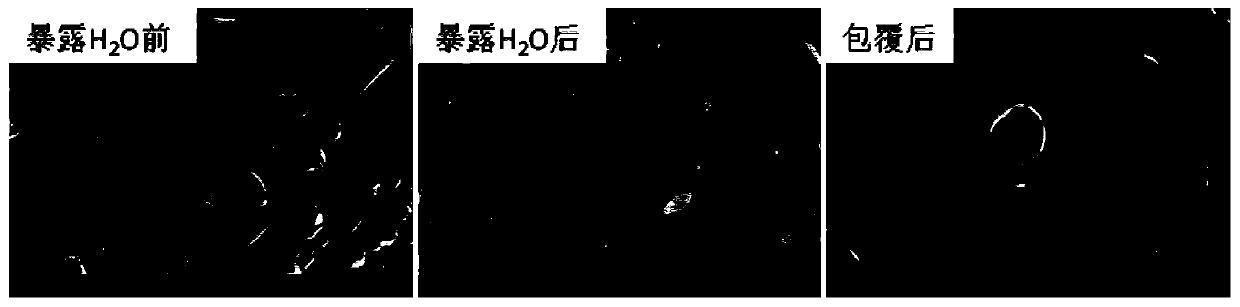

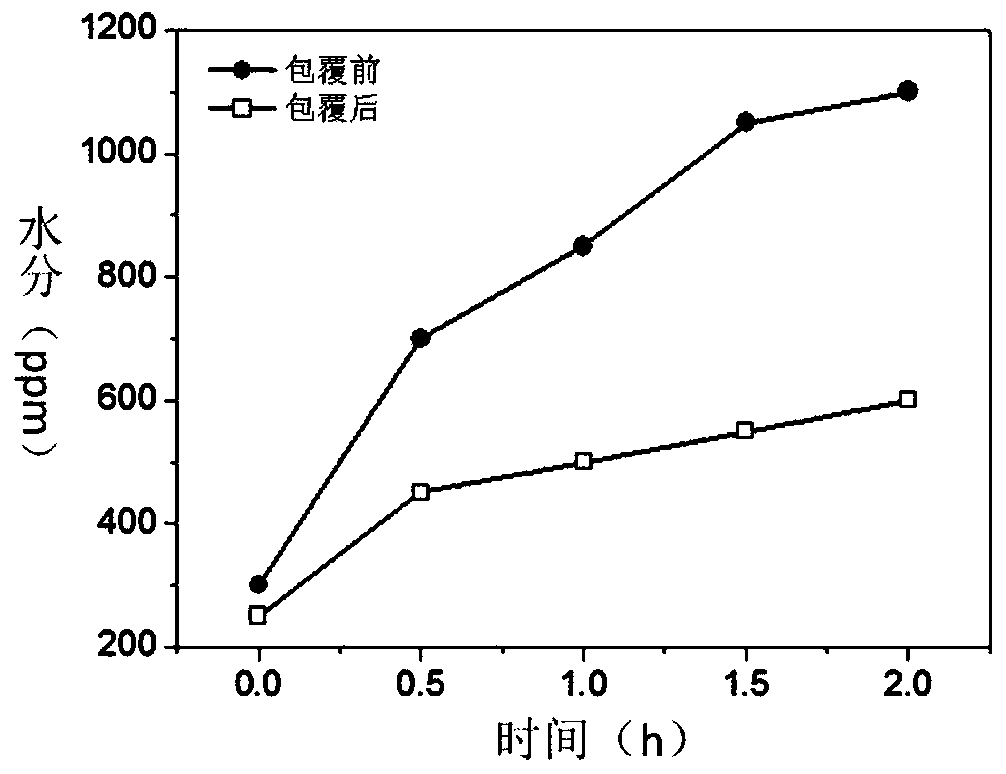

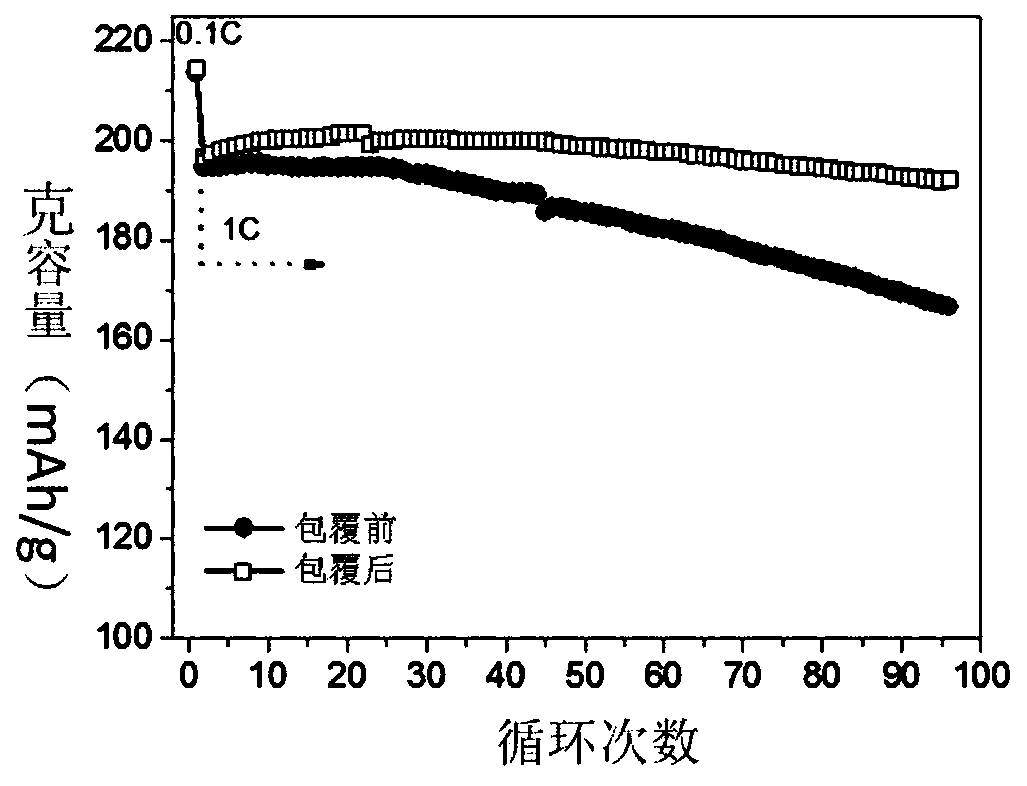

[0036] Such as figure 1 As shown, the high-nickel ternary material (LiNi 0.85 co 0.1 mn 0.05 o 2 ) placed in an environment with a h...

Embodiment 3

[0039] Example 3: Preparation of LiAlO 2 Coated LiNi 0.85co 0.1 mn 0.05 o 2

[0040] First, the lithium-ion battery high-nickel ternary material (LiNi 0.85 co 0.1 mn 0.05 o 2 ) into N with a humidity of 30% 2 Treat for 0.5 hours to generate residual alkali on the corners or edges of the surface;

[0041] Then add it to the ethanol solution of aluminum nitrate, wherein the mass of the Al element accounts for 0.1% of the total mass of the high-nickel ternary material, after stirring at high speed for 2 hours, stir the solution at 60°C until dry;

[0042] Finally, the dried sample was placed in a muffle furnace with an oxygen atmosphere, sintered at 600 °C for 2 h, and then cooled down to room temperature naturally, and lithium metal oxide was formed on the residual alkali part of the high-nickel ternary material for coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com