A kind of positive electrode material of lithium ion battery and its preparation method and application

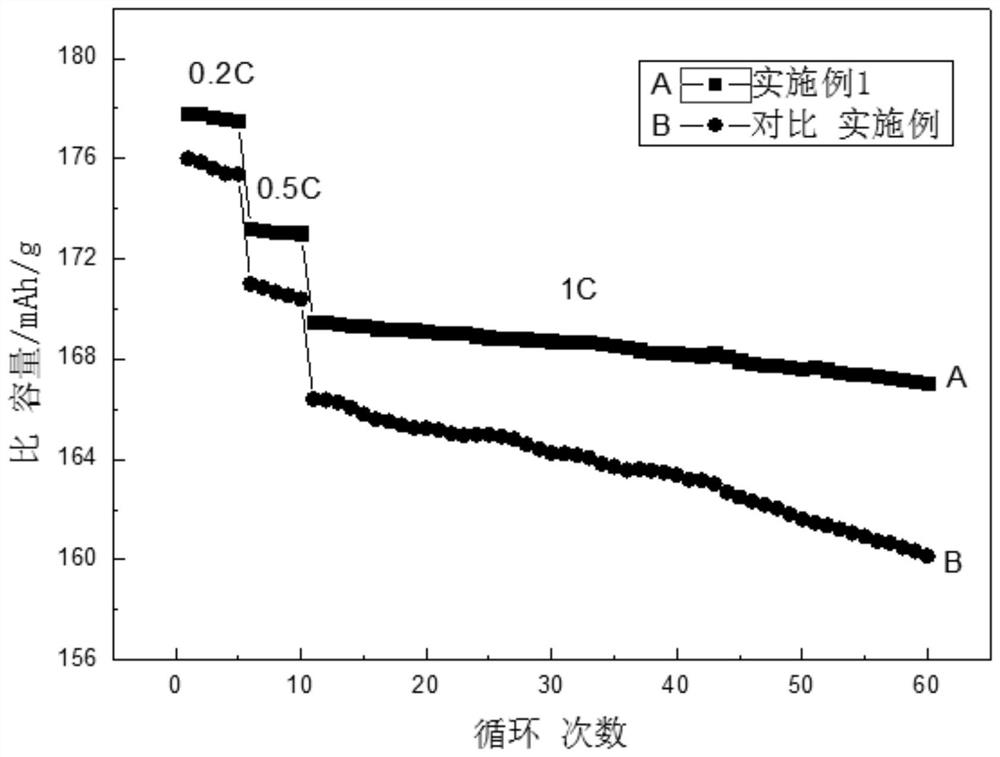

A technology for lithium ion batteries and positive electrode materials, which is applied in the field of positive electrode materials for lithium ion batteries and their preparation, can solve the problems affecting material processing performance and electrochemical performance, reducing structural stability, increasing interface impedance, etc., so as to increase processing performance and Electrochemical performance, improve stress concentration problem, reduce the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, the preparation of lithium-ion battery cathode material-modified LNCM622 comprises the following steps:

[0032] S1. Preparation of LNCM622 precursor: Weigh lithium carbonate, nickel sulfate, cobalt acetate, and manganese sulfate according to the molar ratio of Li:Ni:Co:Mn elements of 10.1:6:2:2, and then add it to isopropanol for ball milling dispersion 2h to prepare the first slurry, the solid content of the first slurry is 20%, the obtained first slurry is ground after vacuum drying at 80°C, and then pre-fired under an air atmosphere of 450°C for 2h, Finally, natural cooling was used to obtain the pure-phase LNCM622 precursor;

[0033] S2, PbO, NiNb 2 o 6 and TiO 2 Add polyvinyl alcohol in a molar ratio of 1:0.2:0.4 and mix to form a mixture, then mix the mixture with LNCM622 precursor and isopropanol to obtain a second slurry, the solid content of the second slurry is 10%, and then Perform ball mill dispersion for 2 hours, and then vacuum dry...

Embodiment 2

[0037] In this embodiment, the preparation of lithium-ion battery cathode material-modified LNCM622 comprises the following steps:

[0038] S1. Preparation of LNCM622 precursor: Weigh lithium nitrate, nickel chloride, cobalt nitrate, and manganese nitrate according to the molar ratio of Li:Ni:Co:Mn elements of 10.2:6:2:2, and add them to absolute ethanol for ball milling Disperse for 2 hours to prepare the first slurry. The solid content of the first slurry is 50%. The obtained slurry is vacuum-dried at 90°C and then ground, then pre-fired in an oxygen atmosphere at 500°C for 3 hours, and finally cooled naturally Obtain a pure phase LNCM622 precursor;

[0039] S2, PbO, NiNb 2 o 6 and TiO 2 Add polyvinyl alcohol in a molar ratio of 1:0.2:0.4 and mix to form a mixture, then mix the mixture with LNCM622 precursor and isopropanol to obtain a second slurry, the solid content of the second slurry is 50%, and then Perform ball mill dispersion for 4 hours, and then vacuum dry at 1...

Embodiment 3

[0043] In this embodiment, the preparation of lithium-ion battery cathode material-modified LNCM622 comprises the following steps:

[0044] S1. Preparation of LNCM622 precursor: Weigh lithium hydroxide, nickel chloride, cobalt chloride, and manganese sulfate according to the molar ratio of Li:Ni:Co:Mn elements of 10.3:6:2:2, then add acetone for ball mill dispersion The first slurry was prepared in 2 hours, the solid content of the first slurry was 40%, the obtained slurry was vacuum-dried at 95°C and then ground, then pre-fired in an oxygen atmosphere at 550°C for 4 hours, and finally cooled naturally to obtain Pure phase LNCM622 precursor;

[0045] S2, PbO, NiNb 2 o 6 and TiO 2 Add polyvinyl alcohol in a molar ratio of 1:0.2:0.4 and mix to form a mixture, then mix the mixture with LNCM622 precursor and acetone to obtain a second slurry, the solid content of the second slurry is 30%, and then ball mill Disperse for 5 hours, then vacuum dry at 110°C to obtain a dry materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com