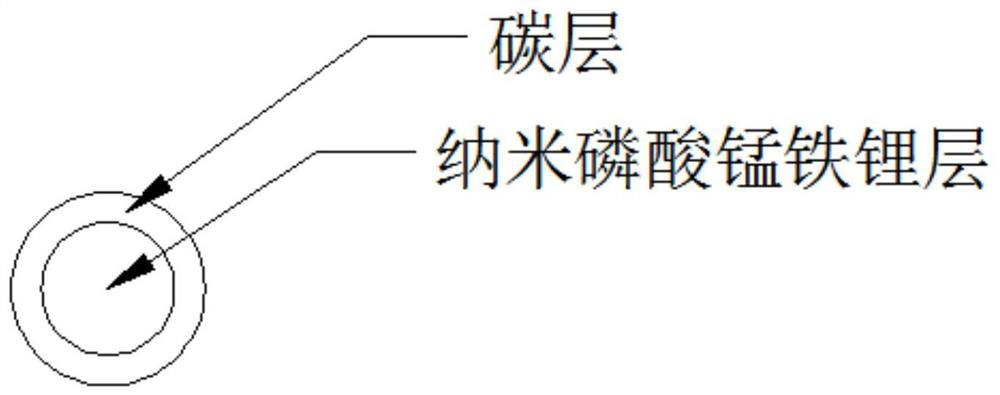

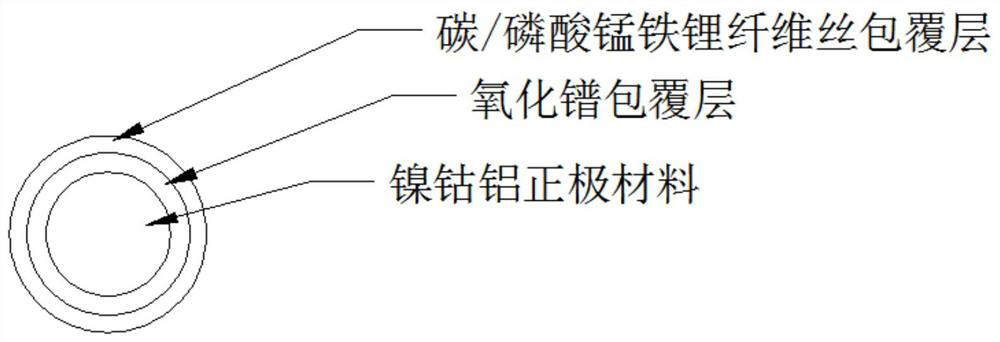

A kind of nickel-cobalt-aluminum positive electrode material coated with carbon/lithium manganese iron phosphate fiber wire and praseodymium oxide double layer and preparation method thereof

A technology of lithium iron manganese phosphate and positive electrode material, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems of reduced electrical performance, reduced electrical performance of products, increase of residual lithium, etc., to improve electrical performance and cycle performance. , Improve conductivity, reduce the effect of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

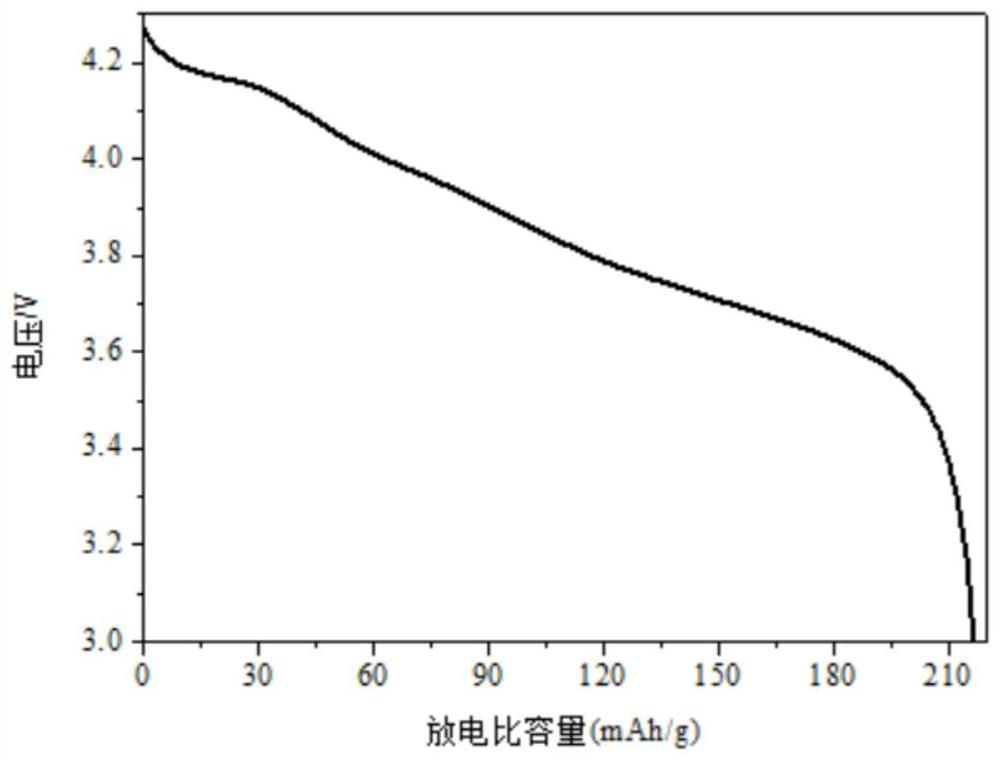

Embodiment 1

[0049] This embodiment provides a nickel-cobalt-aluminum positive electrode material coated with carbon / lithium manganese iron phosphate fiber filaments and praseodymium oxide. Prepared by the following preparation method.

[0050] (1) 100.00kg of nickel cobalt aluminum hydroxide Ni 0.88 co 0.09 Al 0.03 (OH) 2 and 48.02kg of lithium hydroxide monohydrate were put into a high-mixer and mixed at a high speed of 400rpm for 20min to obtain 148.02kg of mixed nickel-cobalt-aluminum raw powder;

[0051] (2) Put 0.23kg of praseodymium oxide and 10kg of ethanol into a high-speed disperser at 3000rpm and disperse for 25 minutes to obtain 10.23kg of praseodymium oxide-ethanol dispersion; then put it into emulsification with 148.02kg of nickel-cobalt-aluminum raw powder In the homogenizer, emulsify at 500rpm for 20min to form a nickel-cobalt-aluminum mixed slurry with a rheological phase system viscosity of 5000mPa.s; then, transfer the nickel-cobalt-aluminum slurry to a closed rotary...

Embodiment 2

[0054] This embodiment provides a nickel-cobalt-aluminum positive electrode material coated with carbon / lithium manganese iron phosphate fiber filaments and praseodymium oxide. Prepared by the following preparation method.

[0055] (1) nickel cobalt aluminum hydroxide Ni 0.88 co 0.08 Al 0.04 (OH) 2 and lithium hydroxide monohydrate into the high mixer to control nickel cobalt aluminum hydroxide Ni 0.88 co 0.08 Al 0.04 (OH) 2 The molar ratio with lithium hydroxide is 1:1, and mixed at 300 rpm for 30 minutes at high speed to obtain mixed nickel-cobalt-aluminum raw powder;

[0056] (2) Put praseodymium oxide and ethanol into a high-speed disperser, control the mass ratio of praseodymium oxide and ethanol to 0.005:1, and disperse at 1000rpm for 30min to obtain a praseodymium oxide-ethanol dispersion; then mix it with nickel-cobalt-aluminum raw powder Put the materials together into the emulsification homogenizer, control the mass ratio of praseodymium oxide and nickel-coba...

Embodiment 3

[0059] This embodiment provides a nickel-cobalt-aluminum positive electrode material coated with carbon / lithium manganese iron phosphate fiber filaments and praseodymium oxide. Prepared by the following preparation method.

[0060] (1) nickel cobalt aluminum hydroxide Ni 0.88 co 0.07 Al 0.05 (OH) 2 and lithium hydroxide monohydrate into the high mixer to control nickel cobalt aluminum hydroxide Ni 0.88 co 0.07 Al 0.05 (OH) 2 The molar ratio of lithium hydroxide to lithium hydroxide is 1:1.1, and mixed at a high speed of 500rpm for 10 minutes to obtain mixed nickel-cobalt-aluminum raw powder;

[0061] (2) Put praseodymium oxide and ethanol into a high-speed disperser, control the mass ratio of praseodymium oxide and ethanol to 0.03:1, and disperse at 5000 rpm for 20 minutes to obtain a praseodymium oxide-ethanol dispersion; then mix it with nickel-cobalt-aluminum raw powder Put the materials into the emulsification homogenizer together, control the mass ratio of praseod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com