Lithium-ion battery positive electrode material and preparation method thereof, lithium-ion battery positive electrode, lithium-ion battery and electrical equipment

A technology for lithium ion batteries and positive electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of difficulty in further improving material stability, the coating layer is not stable enough, the coating layer is unstable, etc. Good stability and high temperature stability, low cost, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

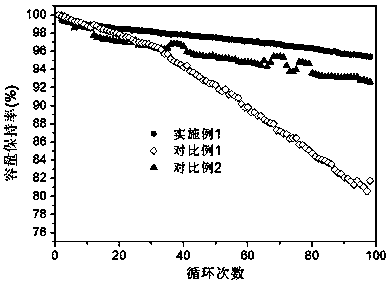

Embodiment 1

[0050] Weigh 75g Te 2 o 3 , 20g Al 2 o 3 and 5g TiO 2 Powder, mixed evenly, sintered at 1000 ℃ for 2h. Then the material was quenched in water and crushed to about D50=0.8 μm to obtain the cladding layer material.

[0051] Weigh LiNi 0.8 co 0.1 mn 0.1 o 2 100 g of material, 0.05 g of the above coating material. The two were placed in a planetary ball mill and mixed evenly, and then 2 Sintered at 400°C for 8h under atmosphere. Finally, after cooling to room temperature with the furnace, the material is taken out, crushed and sieved to obtain the lithium ion cathode material.

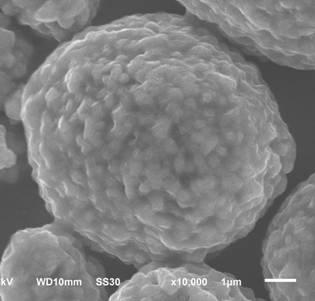

[0052] figure 1 It is the SEM image of the lithium ion cathode material obtained in Example 1. It can be seen from the figure that there is an obvious coating layer on the surface of the material, and the distribution of the coating layer is very uniform, and there is almost no bare or agglomerated area of the coating layer.

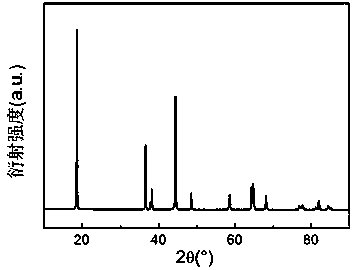

[0053] figure 2 The XRD diffraction pattern of the lithium-io...

Embodiment 2

[0059] Weigh 30g Sb 2 o 3 , 10g Bi 2 o 3 , 35g SnO 2 , 25g ZnO mixed evenly, and sintered at 1200 ℃ for 4h. Then the material is water-quenched and crushed to about D50=0.6 μm to obtain the cladding layer material.

[0060] Weigh LiNi 0.9 co 0.05 Al 0.05 o 2 100g of material, 0.1g of the above coating material. The two were placed in a planetary ball mill and mixed evenly, and then sintered at 250°C for 20h in an air atmosphere. Finally, after cooling to room temperature with the furnace, the material is taken out, crushed and sieved to obtain the lithium ion cathode material.

Embodiment 3

[0064] Weigh 40g LiF, 10g AlF 3 , 16g CaF 2 and 34g ZrF 4 After mixing evenly, sinter at 1100 °C for 1 h. Then the material is water-quenched and crushed to about D50=1 μm to obtain the cladding layer material.

[0065] Weigh LiNi 0.5 co 0.2 mn 0.3 o 2 100g of material, 1g of the above cladding layer material. The two were placed in a planetary ball mill and mixed evenly, and then sintered at 450 ° C for 10 h in an air atmosphere. Finally, after cooling to room temperature with the furnace, the material is taken out, crushed and sieved to obtain the lithium ion cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com