Patents

Literature

53results about How to "Simple removal process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for treating wasterwater containing copper by utilizing Spartina alterniflora Loisel-based biochar

InactiveCN102600799AAbundant resourcesEasy to prepareOther chemical processesWater/sewage treatment by sorptionBiomassEnvironmental chemistry

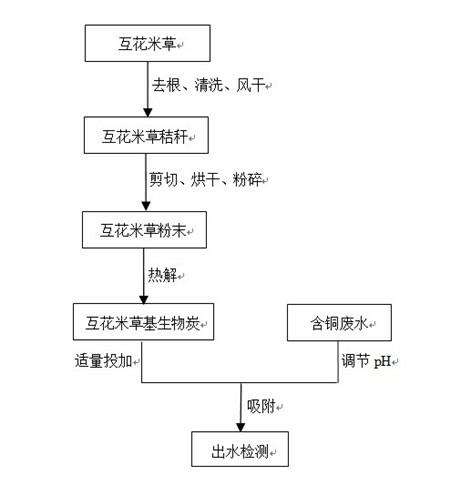

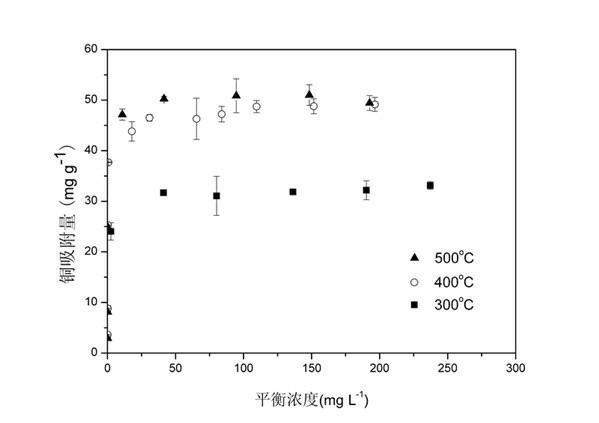

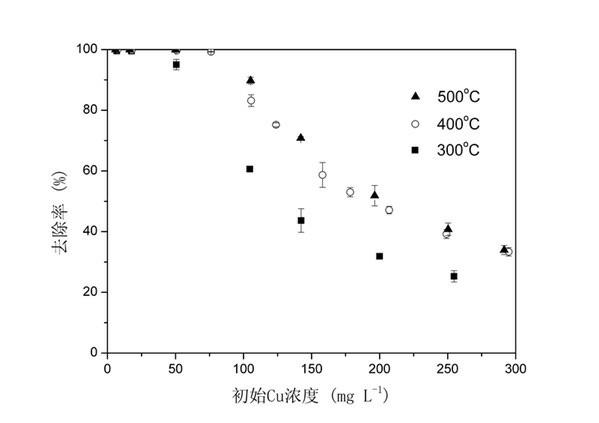

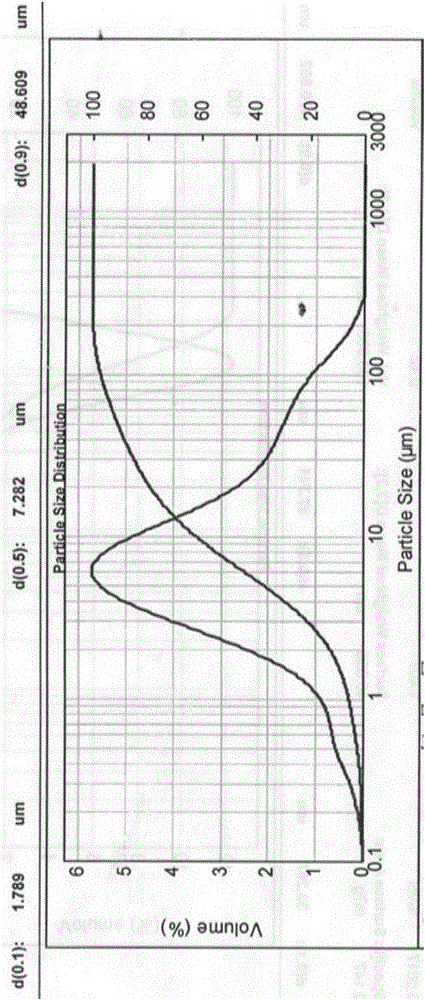

The invention discloses a method for treating wasterwater containing copper by utilizing Spartina alterniflora Loisel-based biochar, belonging to the field of resource utilization of biomass. The method comprises the following steps: 1) removing roots of Spartina alterniflora Loisel, cleaning, airing, then completely stoving and smashing; 2) pyrolyzing Spartina alterniflora Loisel power at a temperature of 300-550 DEG C for 1-4 hours under the protection of N2, cooling to room temperature, and grinding and screening, wherein the productivity is 39-43%; and 3) adding the prepared biochar into the wastewater containing copper according to a proper proportion, and treating for 6-48 hours, wherein the adsorption quantity of copper is 33.12-50.99%. The biochar prepared by the method is low in cost, simple in operation and high in adsorption quantity, so that good environment, social benefit and considerable economic benefit can be created.

Owner:SHANGHAI UNIV

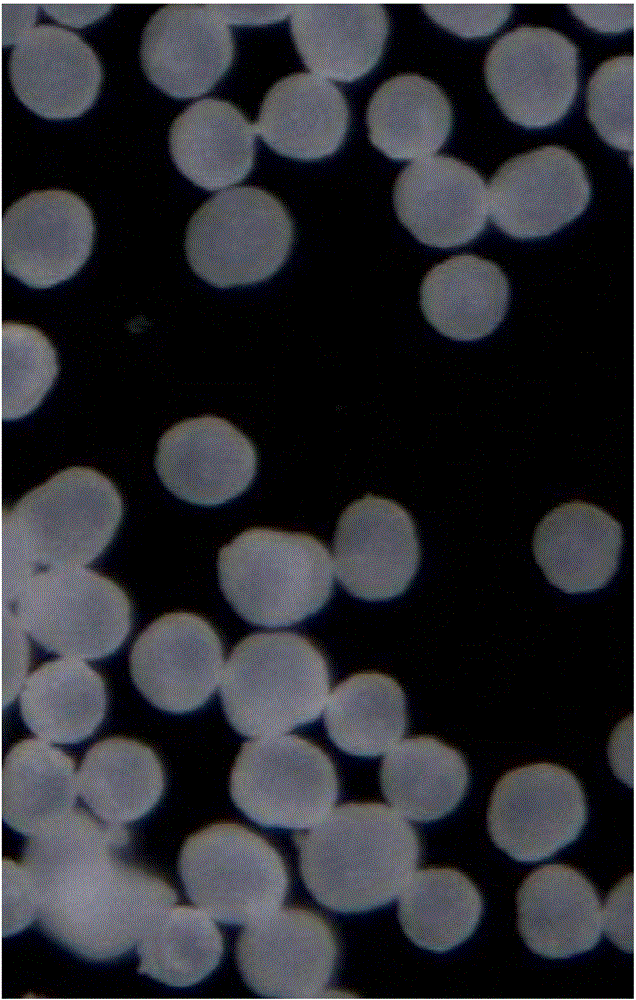

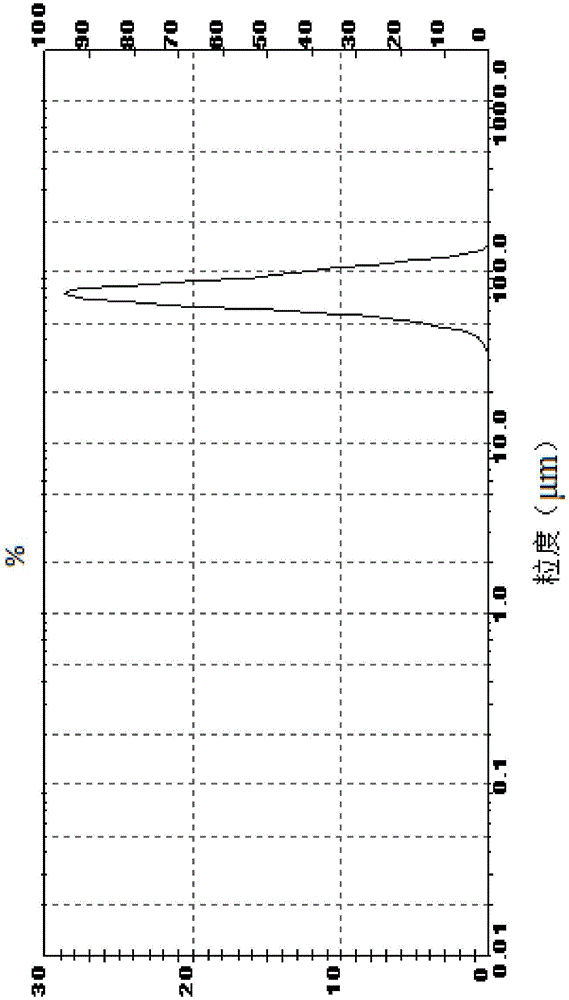

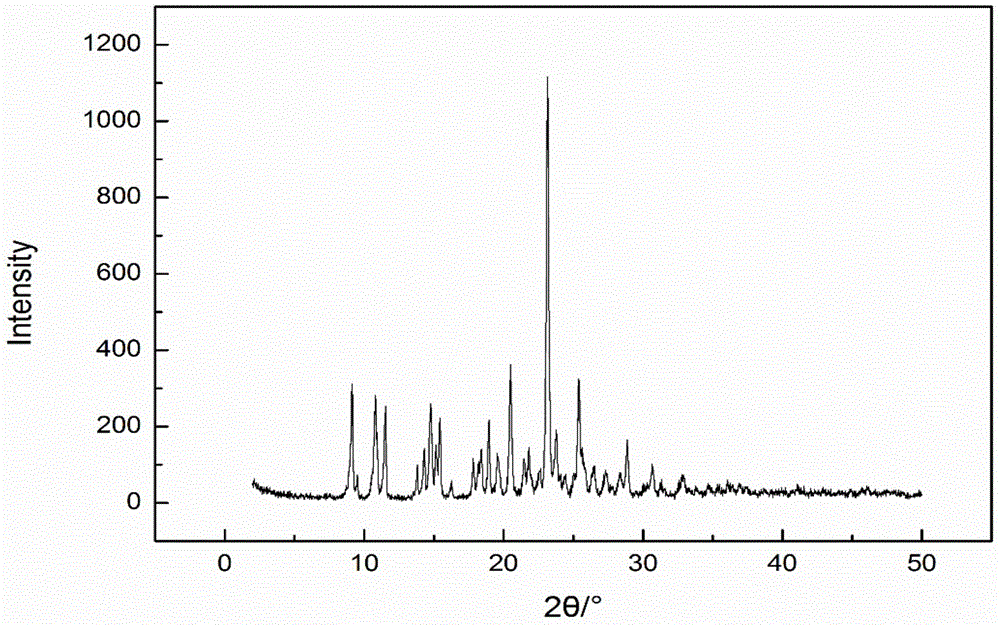

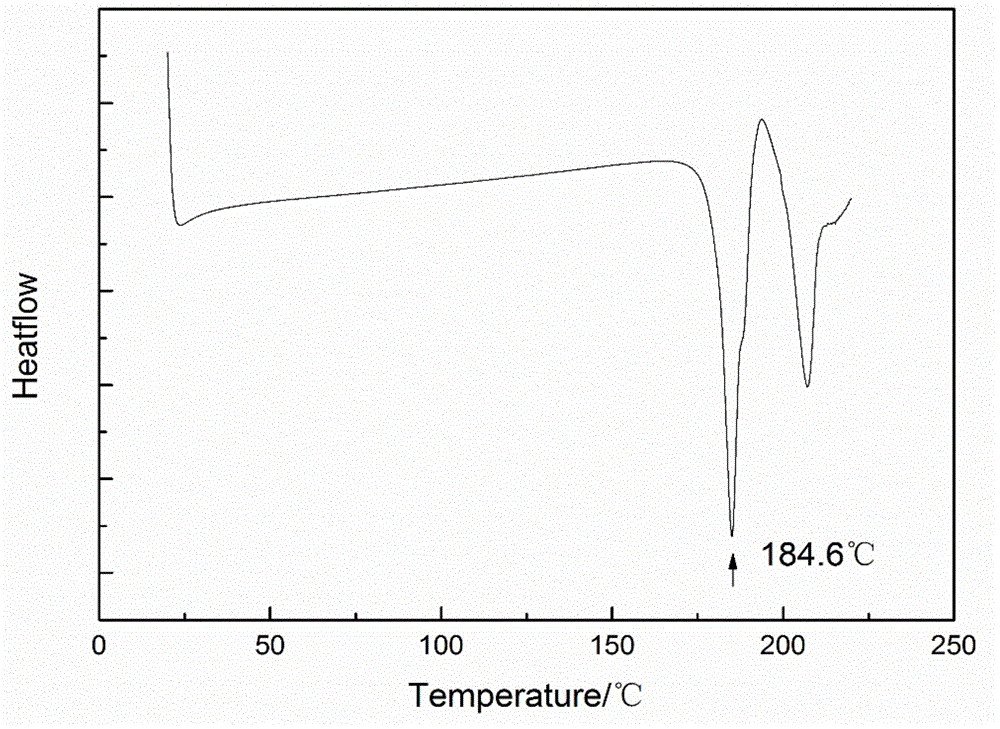

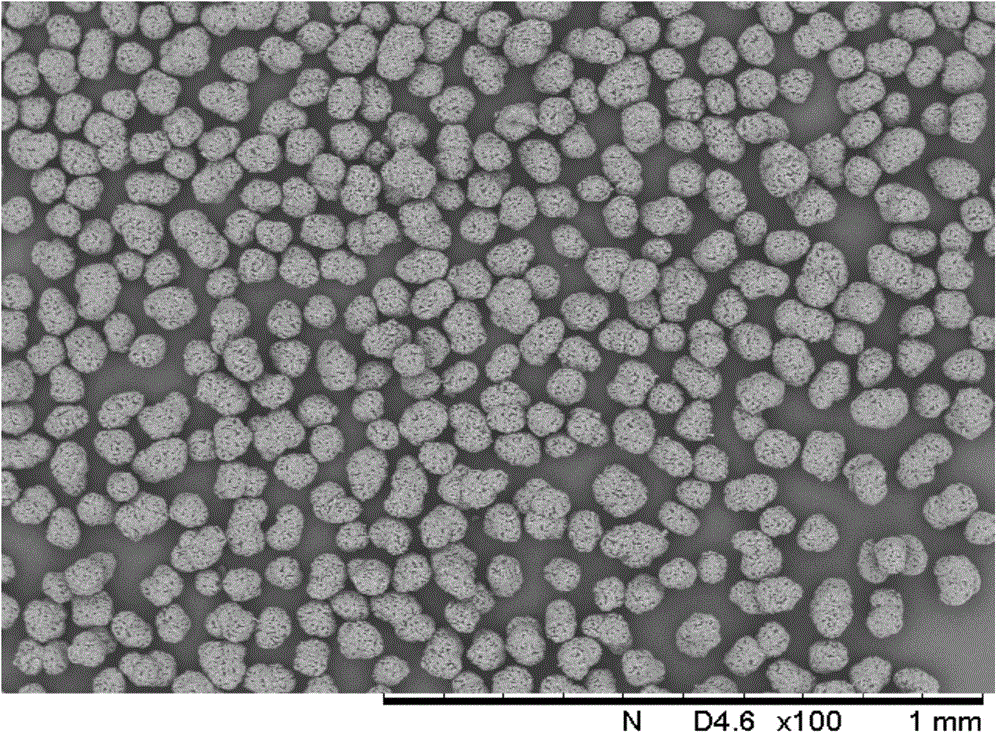

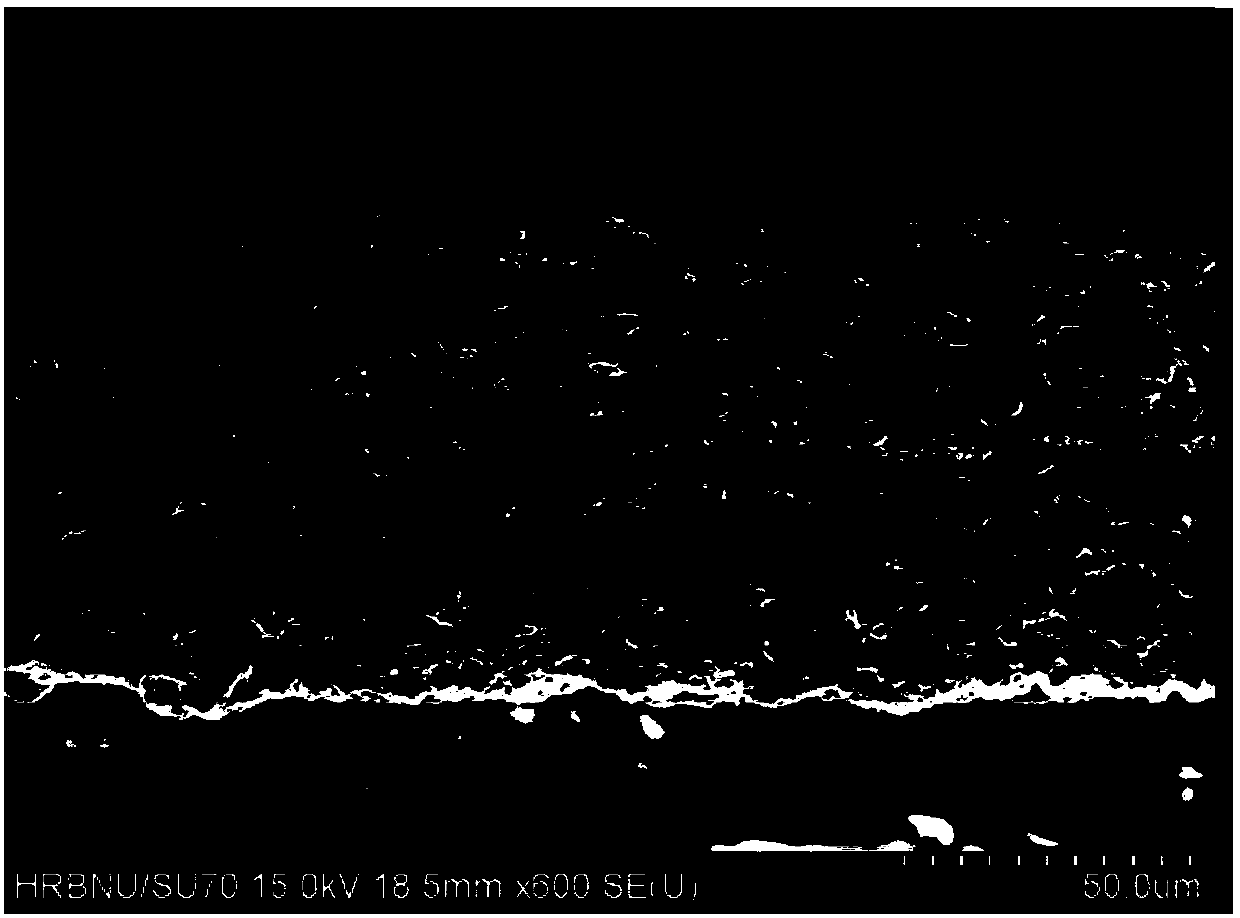

Preparation method of clopidogrel hydrogen sulfate I crystal form spherical crystal

InactiveCN105061459AReduce claddingSimple removal processOrganic active ingredientsOrganic chemistry methodsSolvent2-Butanol

The invention overcomes the technological difficulty that a single solvent is different to prepare a spherical crystal. The single solvent 2-butanol is adopted, and the amount and grain diameters of added clopidogrel hydrogen sulfate I crystal form spherical crystal are controlled, so that clopidogrel hydrogen sulfate is stably separated out from a solution system in a spherical crystal form in a specific powder form range, the obtained clopidogrel hydrogen sulfate spherical crystal has the characteristics of specific powder and has superior state in the aspects of solvent residue, bulk density and mobility, and the preparation method is beneficial for the realization of powder vertical compression preparation technology. The invention also further discloses a medicine composition containing the clopidogrel hydrogen sulfate I crystal form spherical crystal prepared and obtained through the technology.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD +2

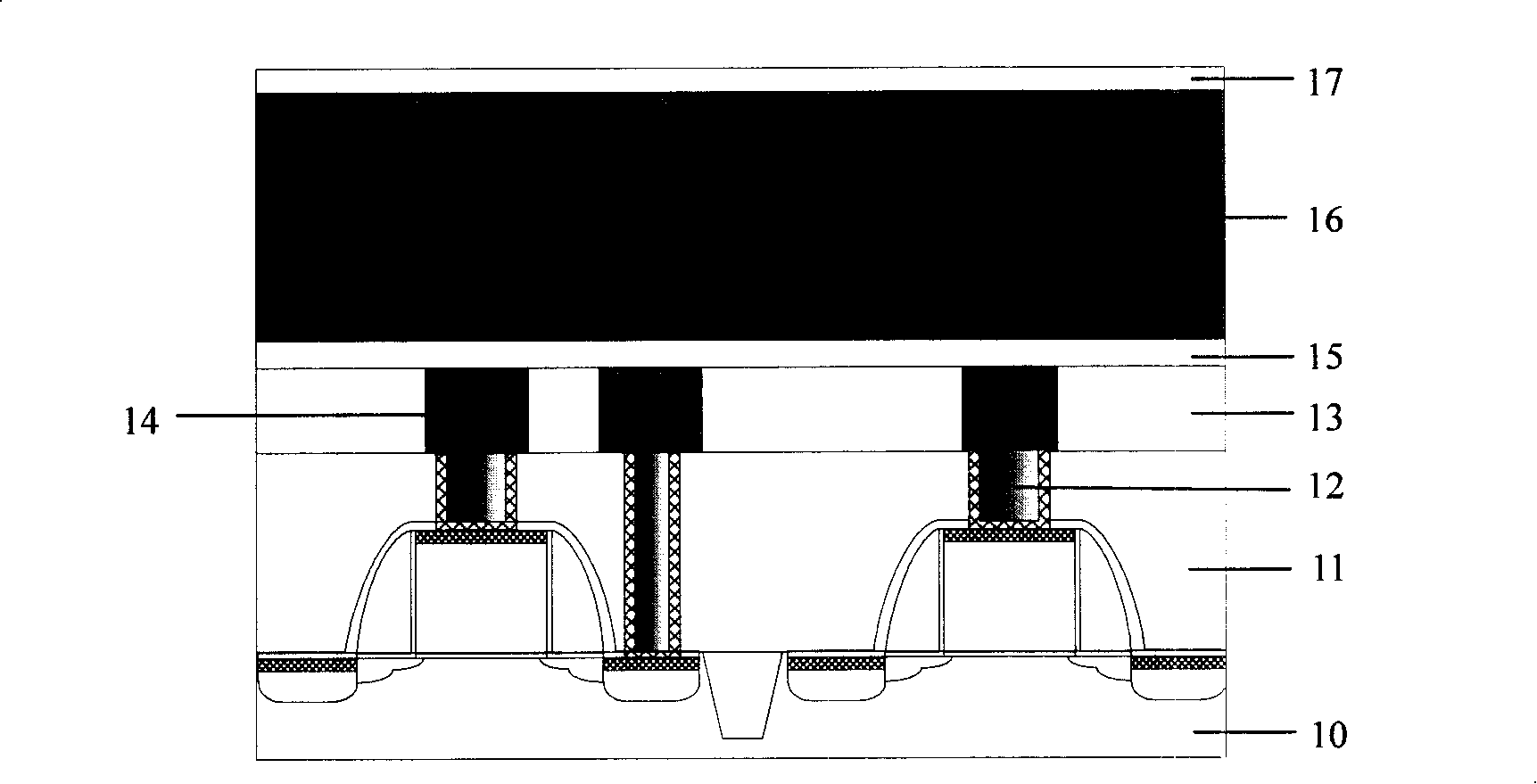

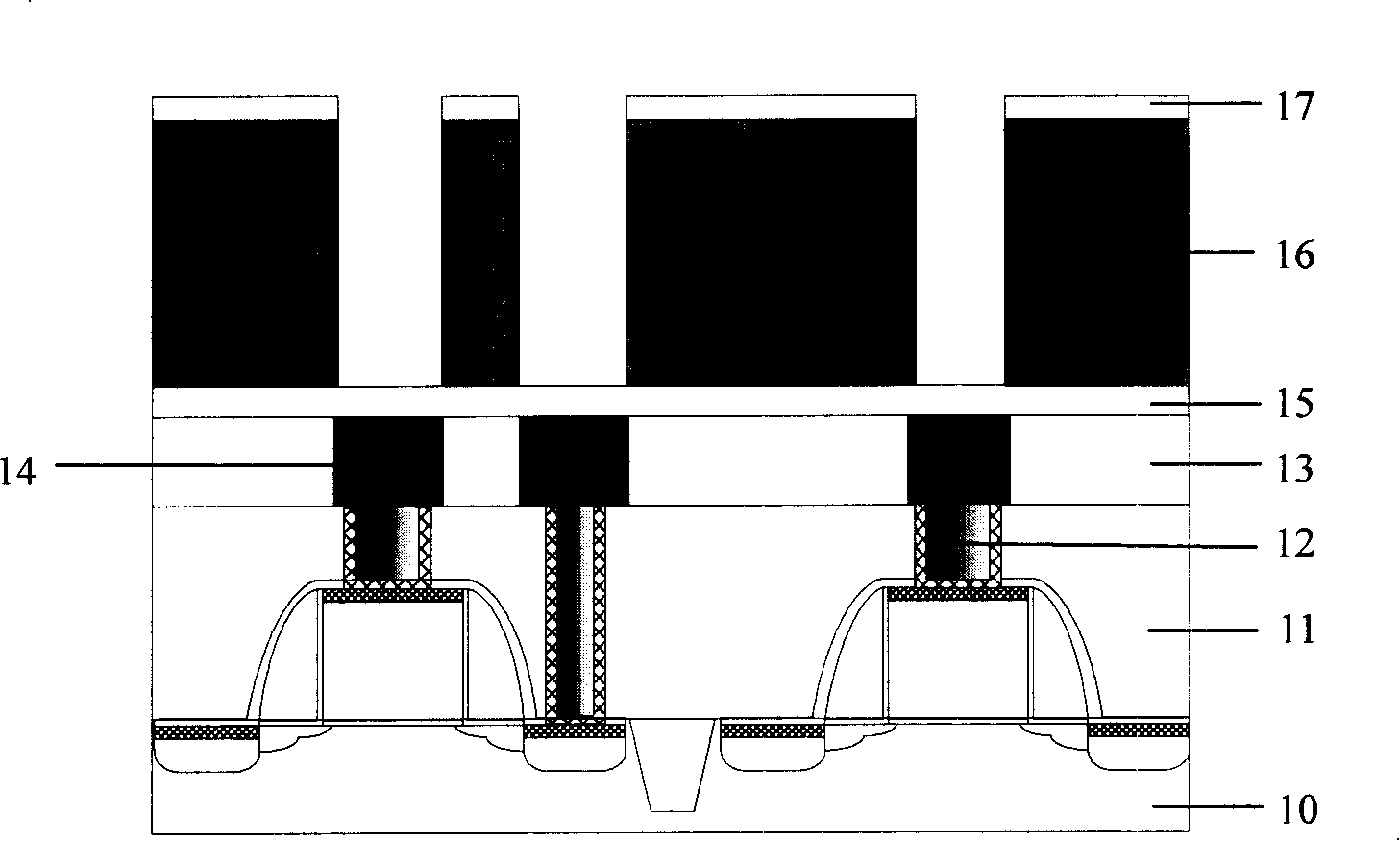

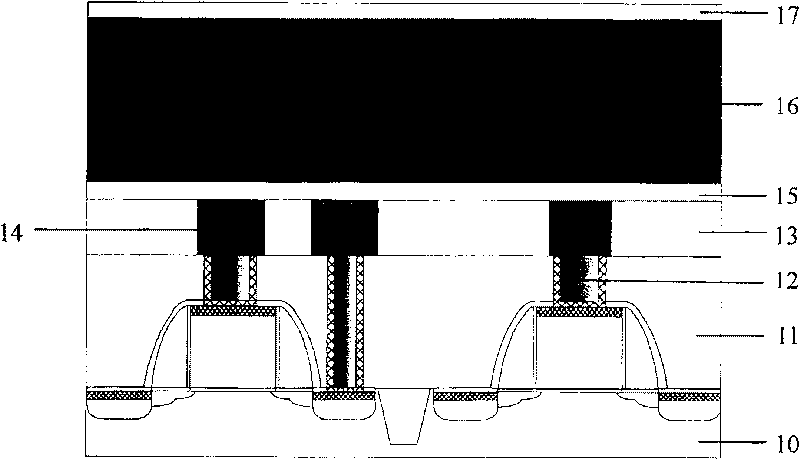

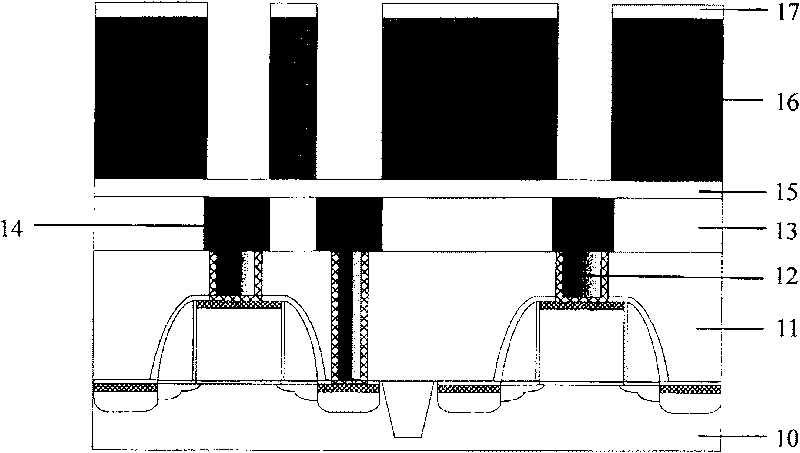

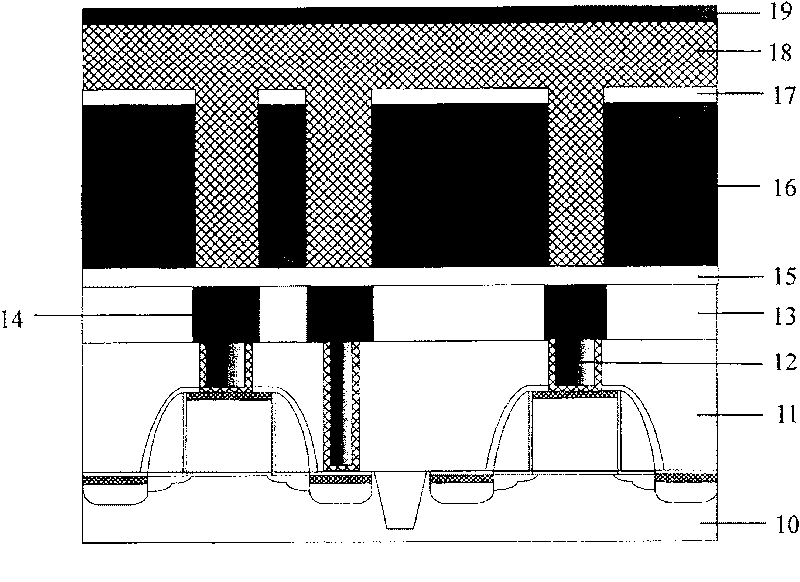

Method for removing photoresist graphical in forming process of dual embedded structure

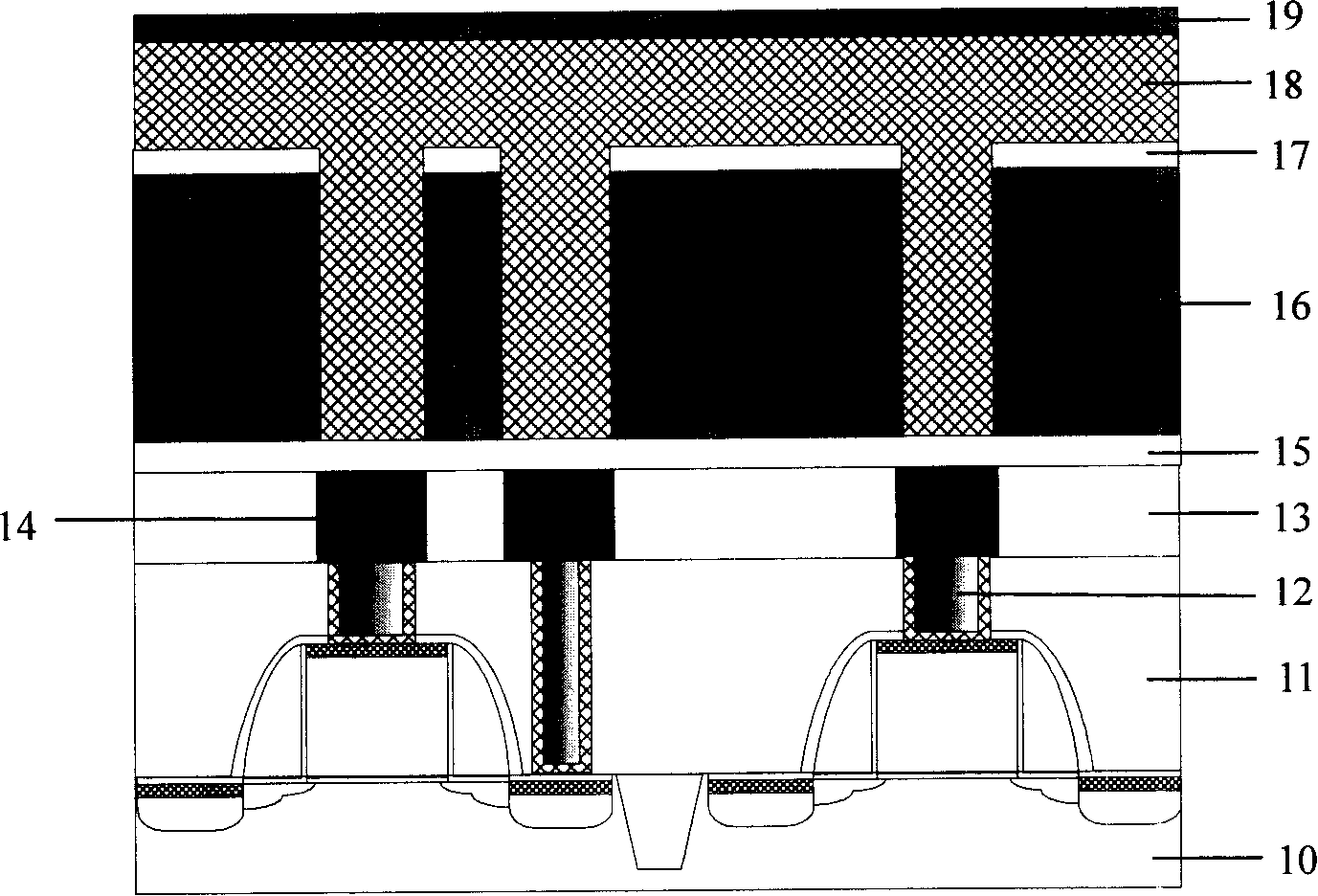

ActiveCN101202244AShorten the timeReduced strengthSemiconductor/solid-state device manufacturingPhotosensitive material processingResistElectrical conductor

The invention provides a removing method for a photo resist image in the forming process of a double inlaying structure; the forming process of the double inlaying structure comprises the following steps: a semiconductor substrate with a preformed semiconductor device is provided; a metal interconnecting line layer with a surface which is provided with a dielectric layer is formed on the substrate; connecting holes are etched in the dielectric layer; a sacrificial layer and a hard mask layer are deposited; a bottom anti-reflecting layer and a photo-resist layer are coated and patterned to form the photo resist image; oxy plasma incinerates and removes the bottom anti-reflecting layer and the photo-resist layer. The removing method of the invention can simplify the removing process and prevent the dielectric layer with a low dielectric constant from being damaged.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

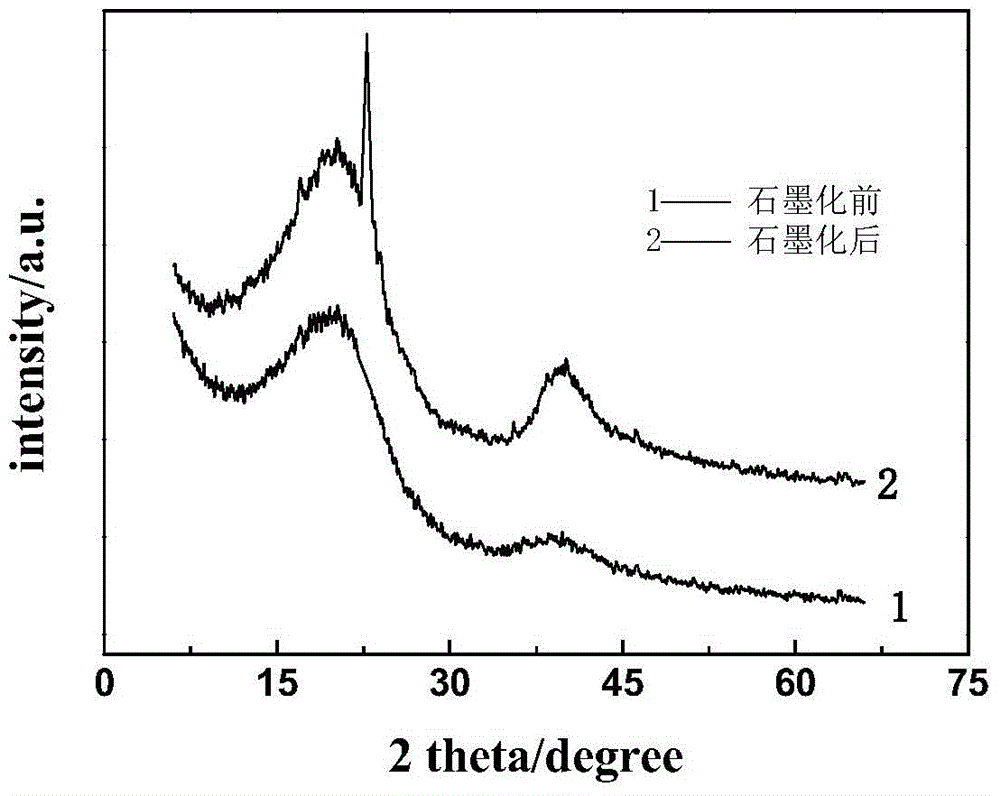

Preparation method for activated carbon with medium pore radii

The invention relates to a preparation method for activated carbon with medium pore radii, and solves the technical problem that the conventional preparation method is complex in technology and high in manufacturing cost. According to the preparation method, the activated carbon is prepared by processing one or more of the following raw materials: wood-based activated carbon, coconut shell-based activated carbon and coal-based activated carbon. The preparation method comprises the following specific steps: soaking one or more of the raw materials in an ethanol-water mixed solution; under the condition that a hydroxide is taken as a pore-enlarging agent, carrying out ultrasonic oscillation, and then carrying out washing and drying; under the protection of inert gas, carrying out calcination to obtain a product, namely the activated carbon. The pore radii (r) of the prepared activated carbon are larger than 2 nm and smaller than 50 nm. The preparation method provided by the invention can be widely applied to the field of preparation of the activated carbon with medium pore radii.

Owner:WEIHAI WENLONG BATTERY

Method for preparing I crystal form of spherical clopidogrel hydrogen sulfate

ActiveCN104817571AReduce claddingSimple removal processOrganic chemistry methodsSolution systemSolvent

The invention provides a novel method for preparing an I crystal form of spherical clopidogrel hydrogen sulfate. The method comprises the following steps: using single 2-butanol as a solvent, controlling the concentration, the adding mode and the adding speed of a sulphuric acid for forming salt, shortening processing time, meanwhile separating the globular clopidogrel hydrogen sulfate stably out of a solution system. The obtained clopidogrel hydrogen sulfate conforms to the needs of a subsequent preparation technology in the respects of solvent residue, bulk density, fluidity and the like.

Owner:TIANJIN UNIV +1

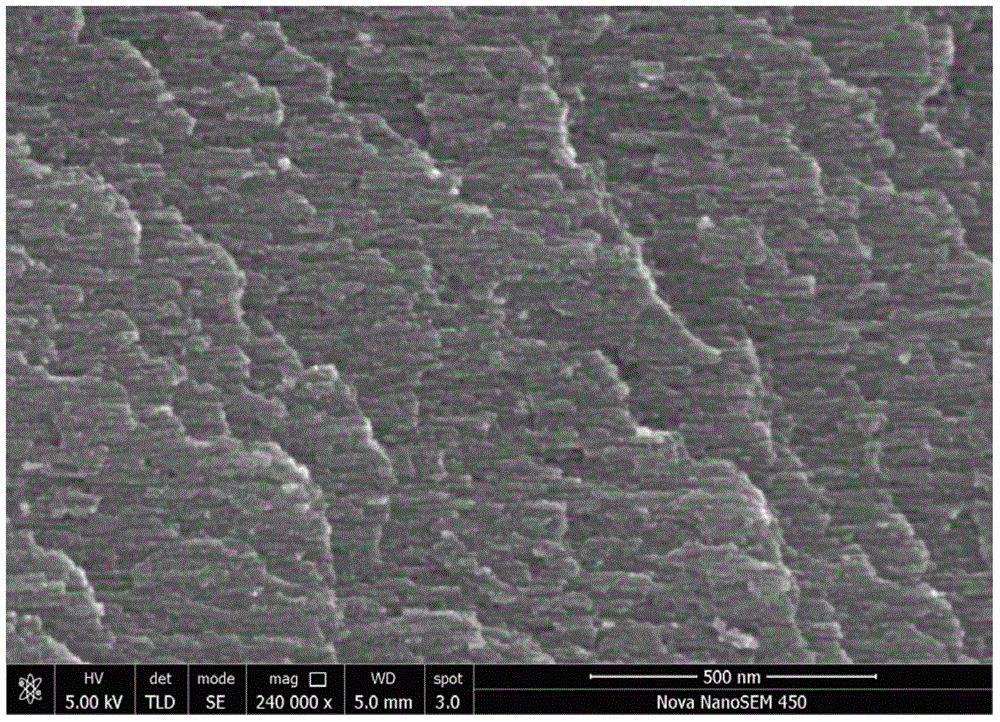

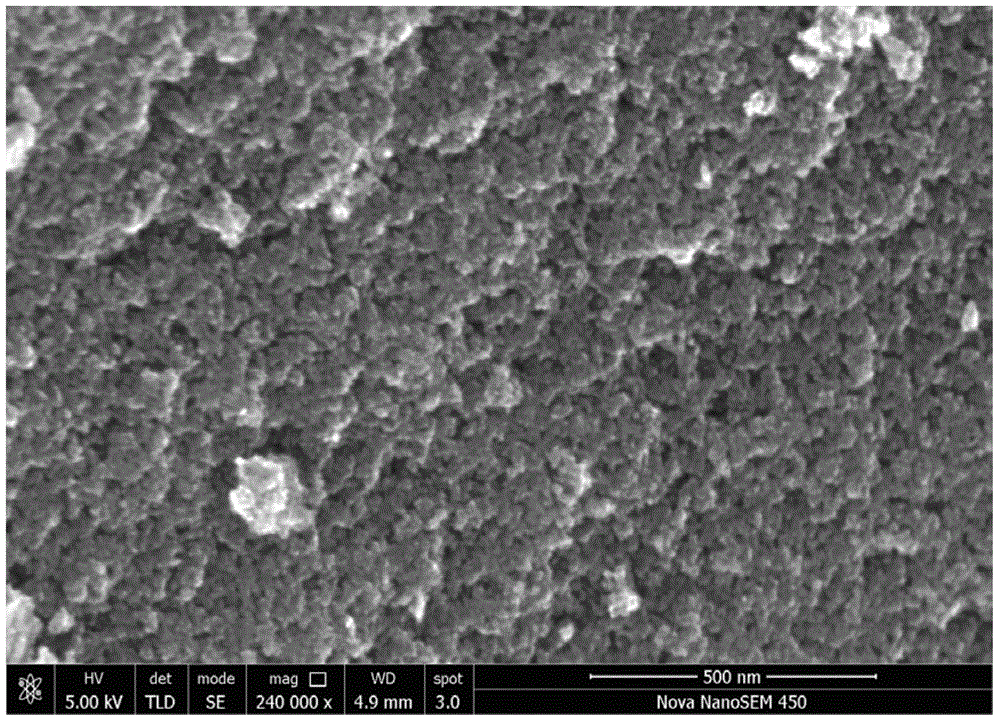

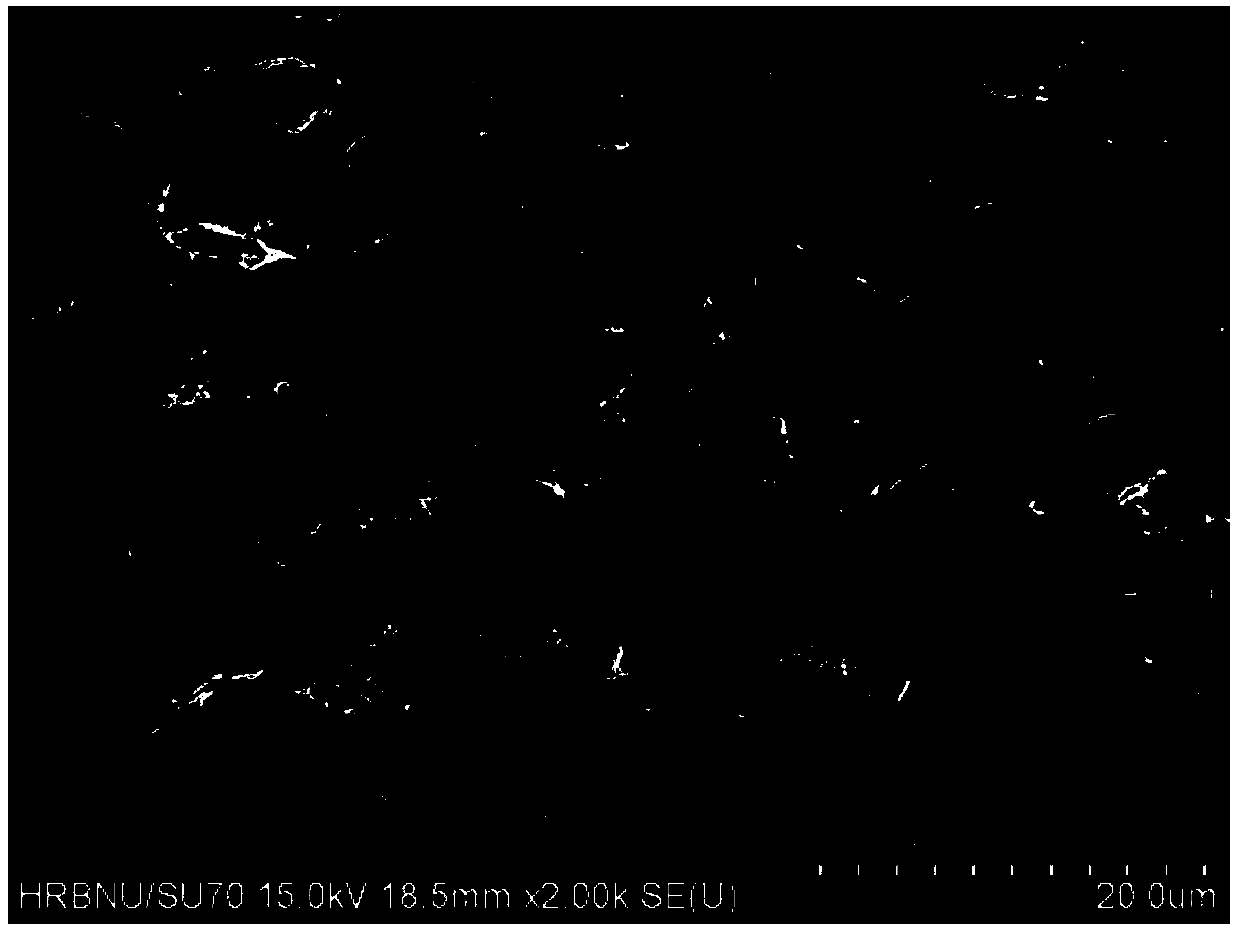

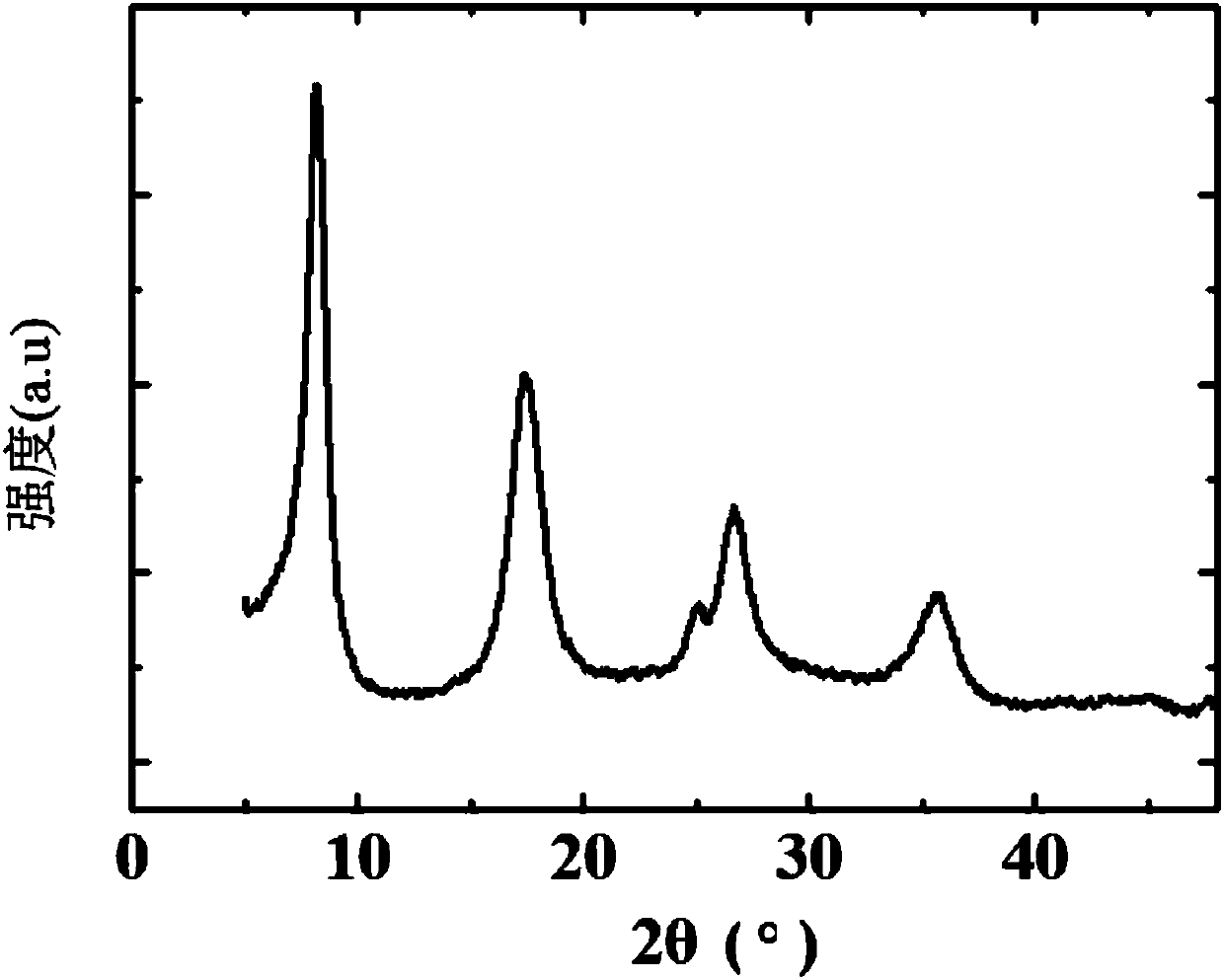

Preparation method and application of three-dimensional multi-dimension porous crystal titanium carbide

ActiveCN107640772AHighly corrosiveImprove uniformityHybrid capacitor electrodesCell electrodesCapacitanceTwo dimensional crystal

The invention discloses a preparation method and application of three-dimensional multi-dimension porous crystal titanium carbide, relates to a preparation method and application of crystal titanium carbide, and aims to solve the problem that existing two-dimensional crystal titanium carbide is liable to stack, and especially has low mass specific capacitance when the mass is relatively large. Themethod comprises the following steps: I, preparing a two-dimensional layered titanium carbide nanosheet; II, calcining to obtain the three-dimensional multi-dimension porous crystal titanium carbide.The mass specific capacitance of the three-dimensional multi-dimension porous crystal titanium carbide prepared by the method is about 129F / g when the mass is 10mg. By adopting the preparation method, the three-dimensional multi-dimension porous crystal titanium carbide can be obtained.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

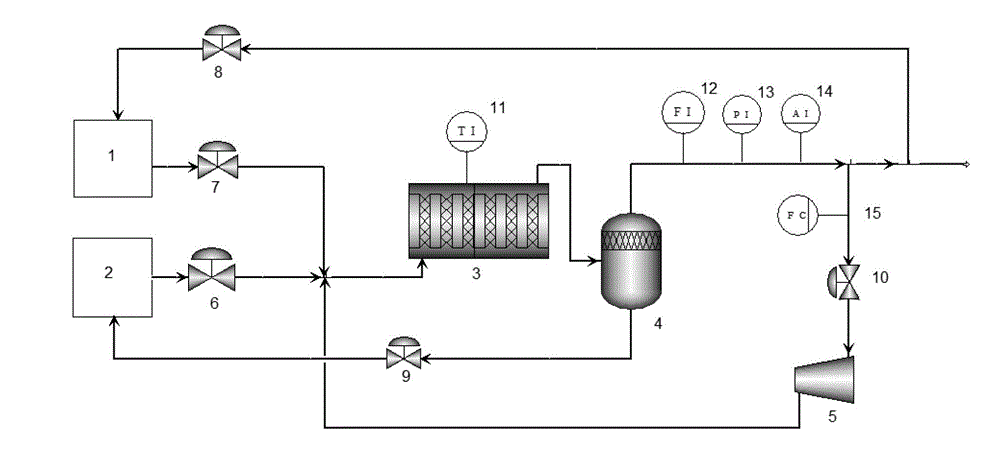

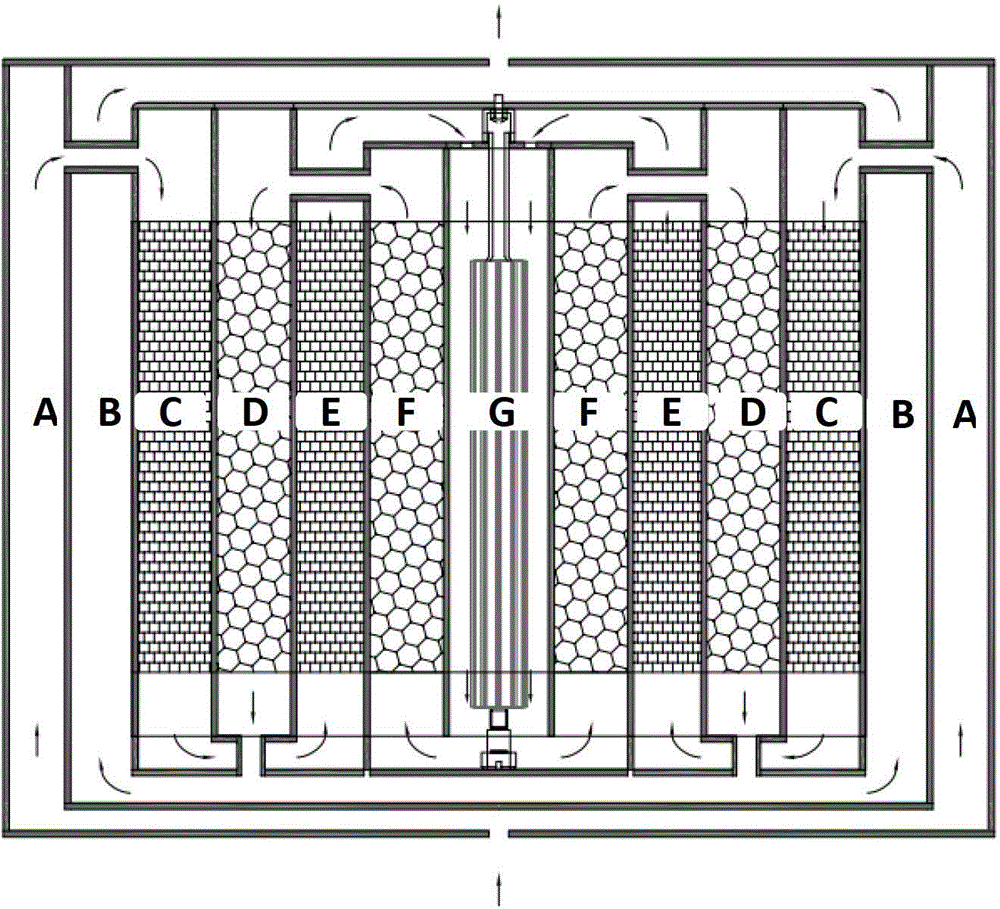

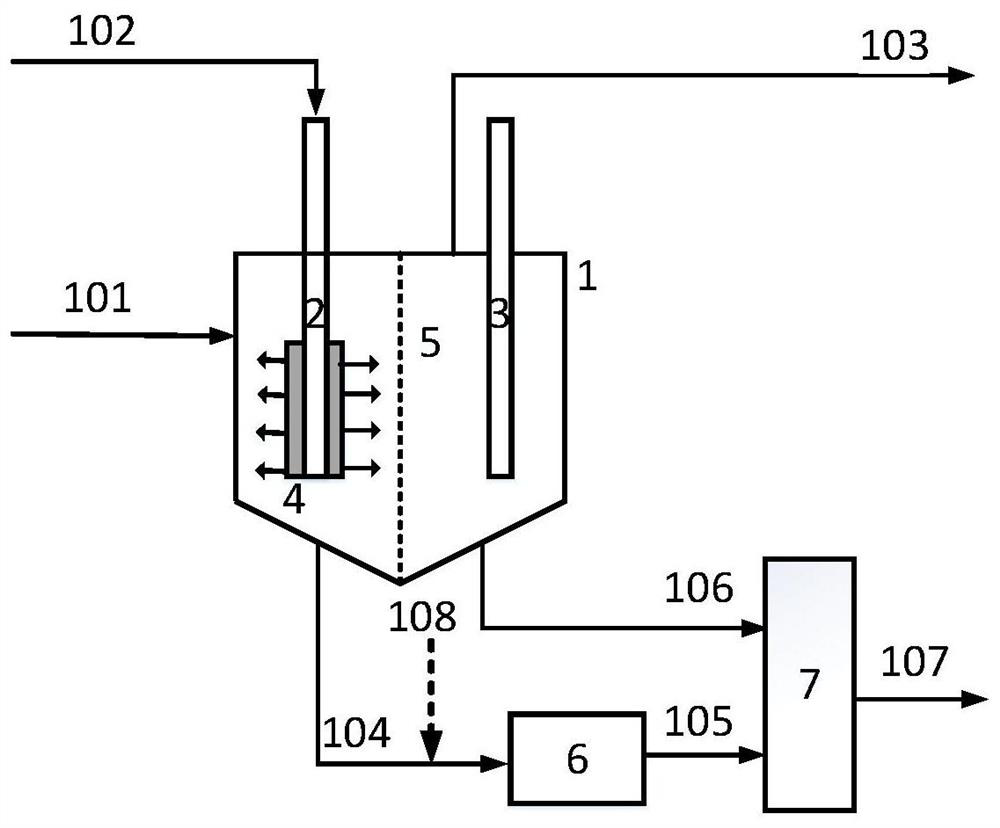

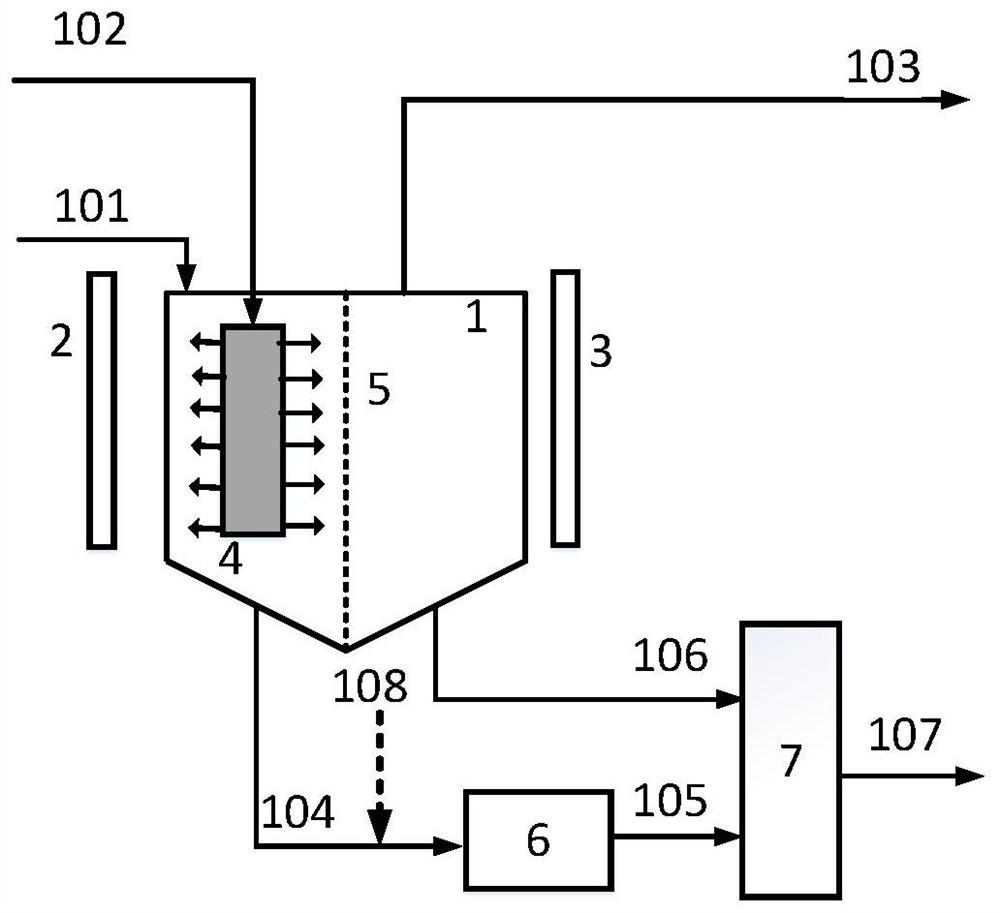

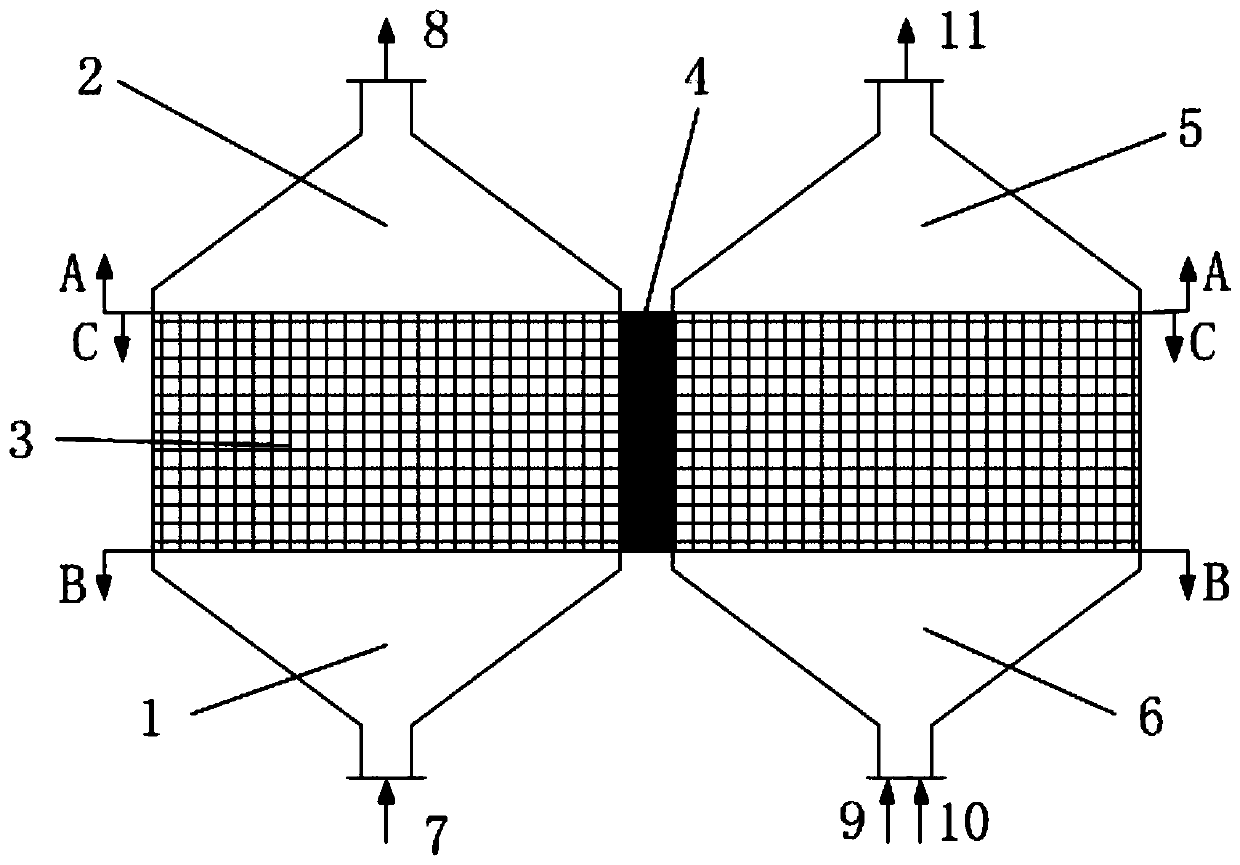

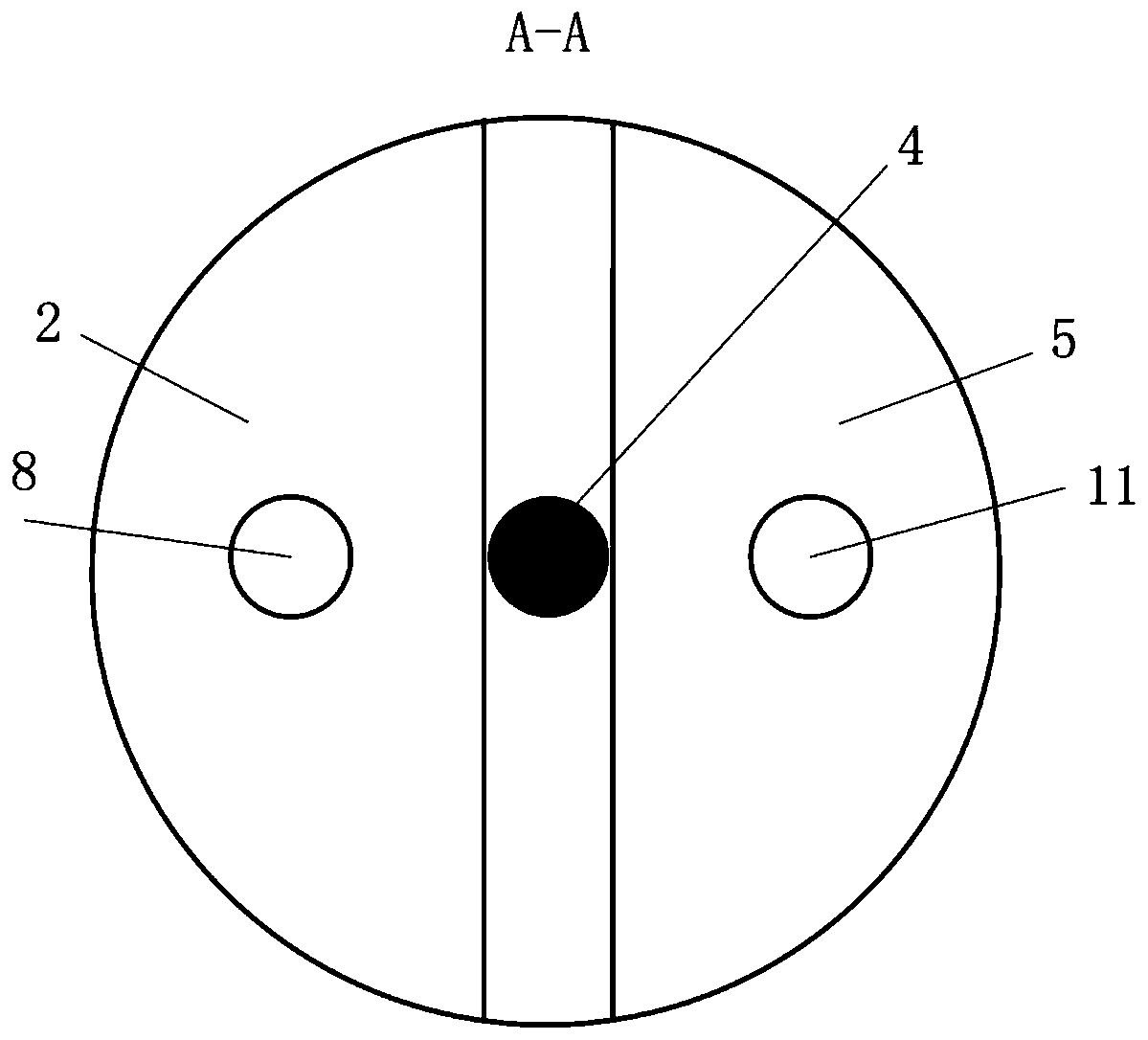

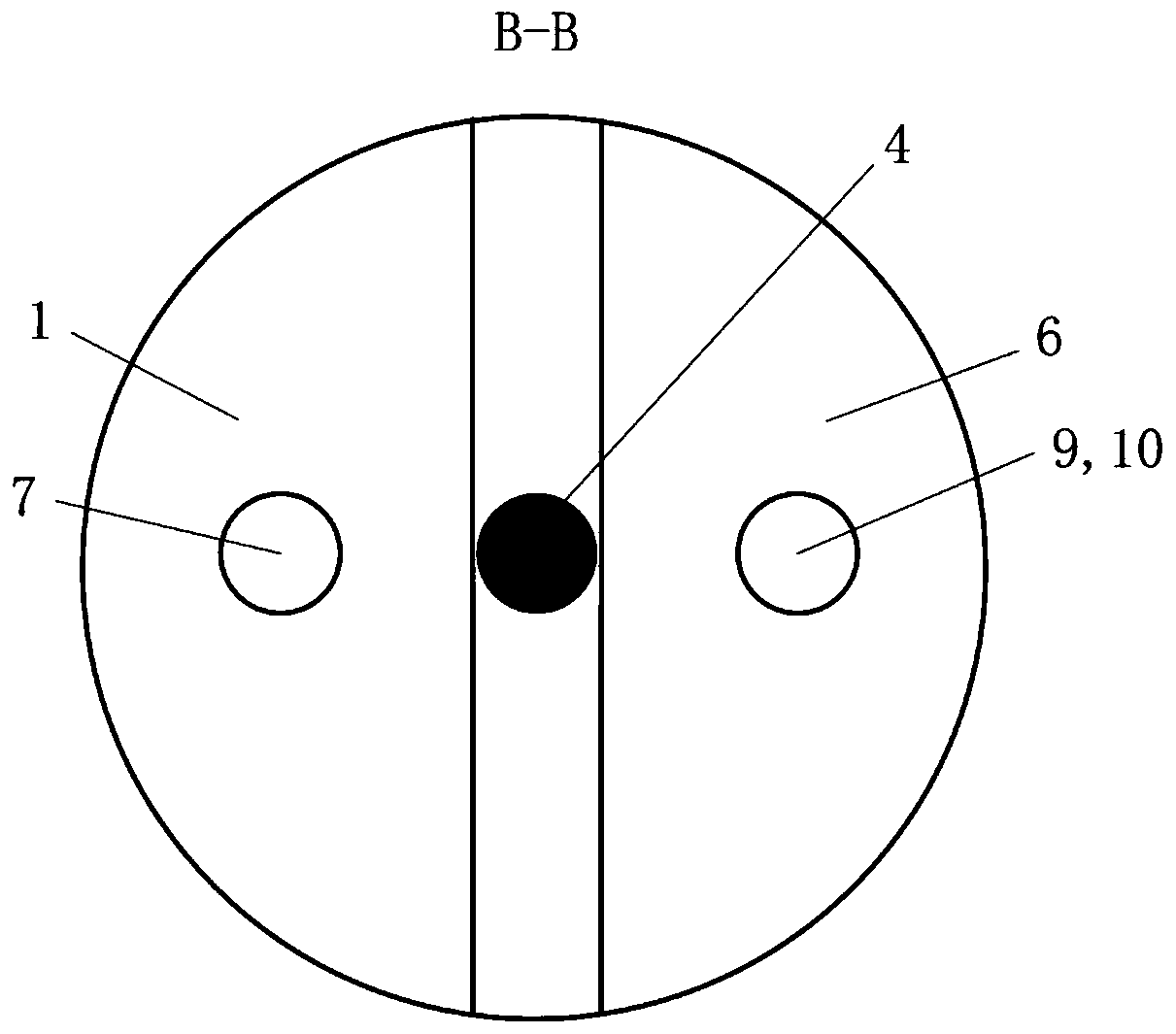

CO2 enrichment and methanation process in sealed space and reactor

ActiveCN104152197AImprove balance limitsLower balance limitHydrocarbon from carbon oxidesGaseous fuelsChemistrySubmarine

The invention relates to a CO2 enrichment and methanation process in a sealed space and a CO2 enrichment and methanation reactor. The CO2 enrichment and methanation process is mainly technically characterized in that the content of CO2 inside the sealed space can be effectively controlled and oxygen essential for survival can be provided. The CO2 enrichment and methanation reactor is compact in structure, CO2 enrichment and methanation reaction are integrated, and thus a CO2 desorption process used inside the sealed space is greatly simplified. By adopting the CO2 enrichment and methanation process and the CO2 enrichment and methanation reactor, CO2 inside the sealed space (in an underwater submarine and a space station) can be efficiently desorbed, and oxygen essential for survival is provided, so that the life and property security of human beings in working in space capsules or submarines is ensured.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

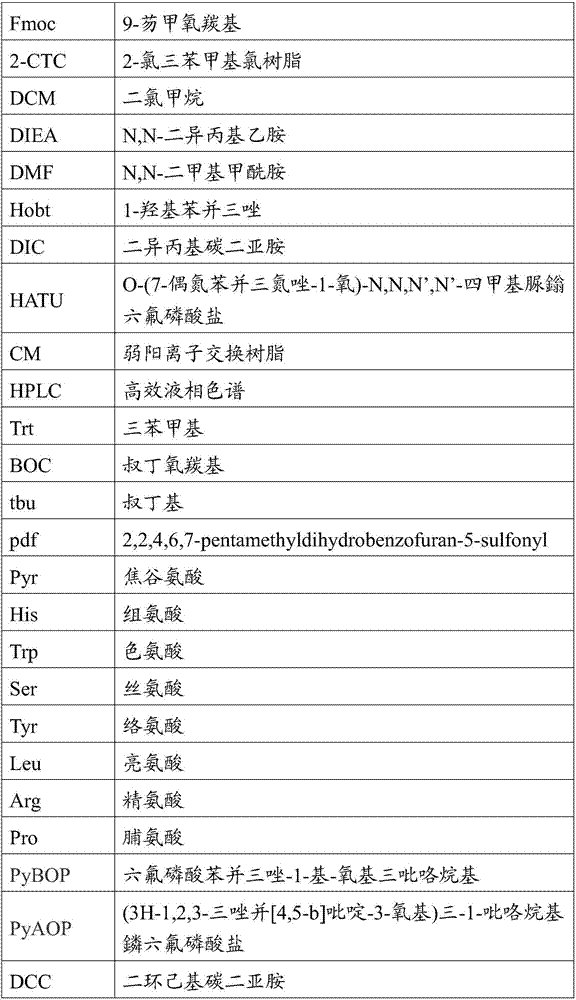

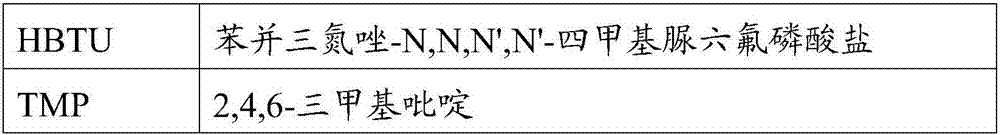

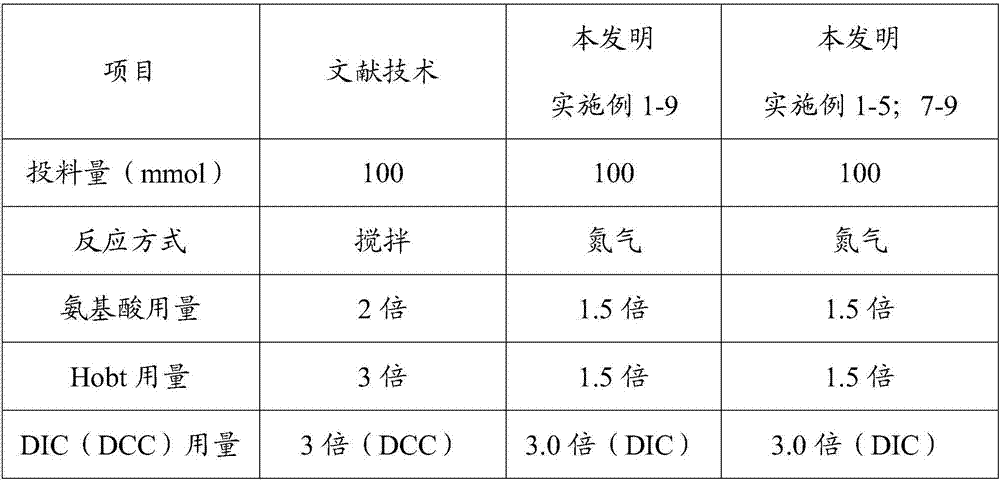

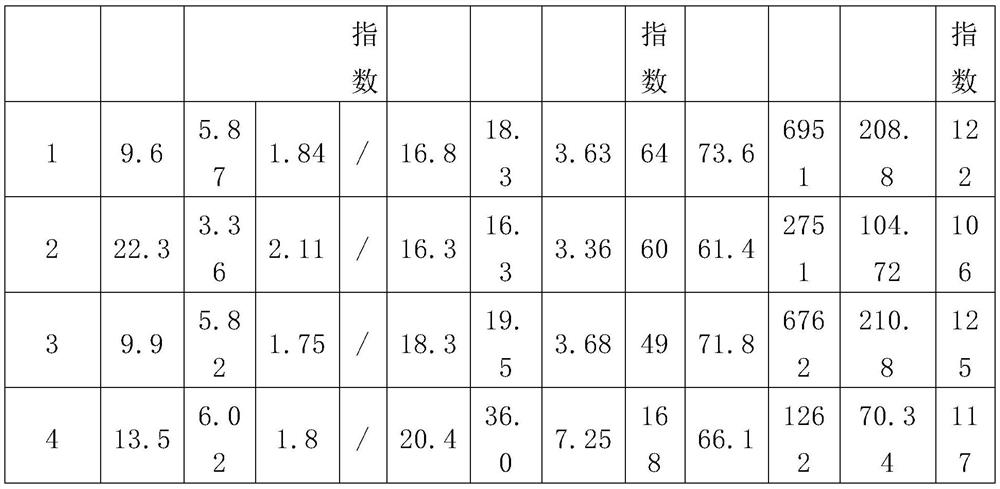

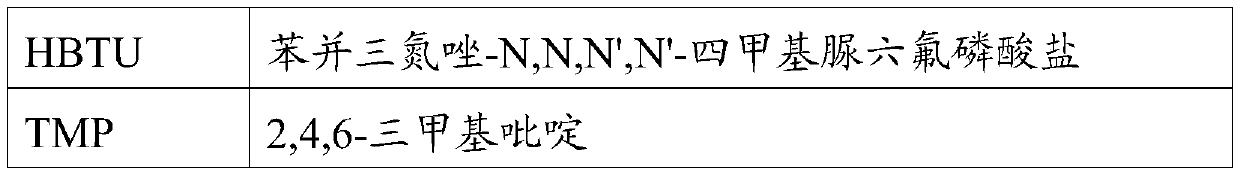

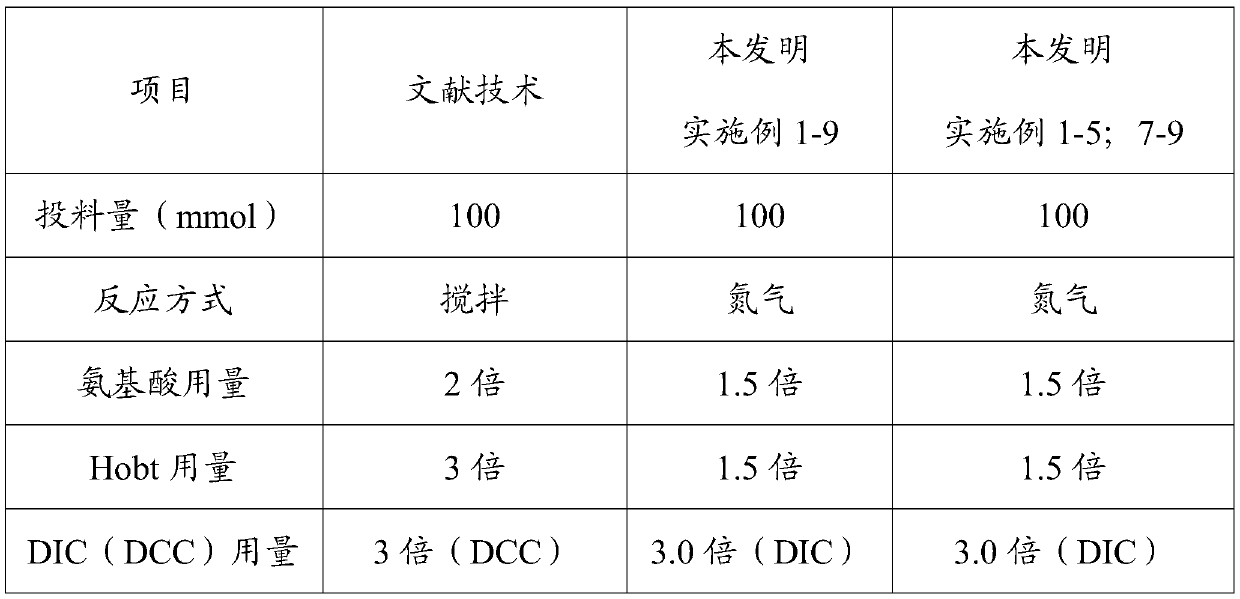

Synthesis method of high-purity leuprorelin

ActiveCN107573408AAvoid overly reactiveMild responseLuteinising hormone-releasing hormonePeptide preparation methodsSolid phasesSide chain

The invention provides a method for preparing leuprorelin. The method comprises the following steps: (1) taking Fmoc-Pro-CTC-OH and CTC (Carbon Tetrachloride) resin as starting raw materials and treating to obtain Fmoc-Pro-CTC-OH resin; (2) sequentially connecting the Fmoc-Pro-CTC-OH resin with an amino acid with a protecting group by adopting a gradual coupling manner of a Fmoc / tBu solid-phase method to synthesize side chain wholly-protected leuprorelin precursor peptide-resin; (3) taking a 20 percent trifluoroethanol / DCM (Dichloromethane) solution as a cutting reagent and cutting the side chain wholly-protected leuprorelin precursor peptide-resin, so as to obtain a side chain wholly-protected leuprorelin precursor peptide; (4) carrying out ethyl amination on the side chain wholly-protected leuprorelin precursor peptide to obtain side chain wholly-protected leuprorelin; (5) carrying out side chain cutting on the side chain wholly-protected leuprorelin to obtain a leuprorelin crude peptide; (6) carrying out CM purification and HPLC (High Performance Liquid Chromatography) purification, concentration, dissolving and freeze-drying on the leuprorelin crude peptide to obtain a high-purity leuprorelin crude drug. The method provided by the invention has the advantages of simplicity in operation, short period, low cost, high product yield and small environment pollution and is very suitable for industrial production.

Owner:上海丽珠制药有限公司

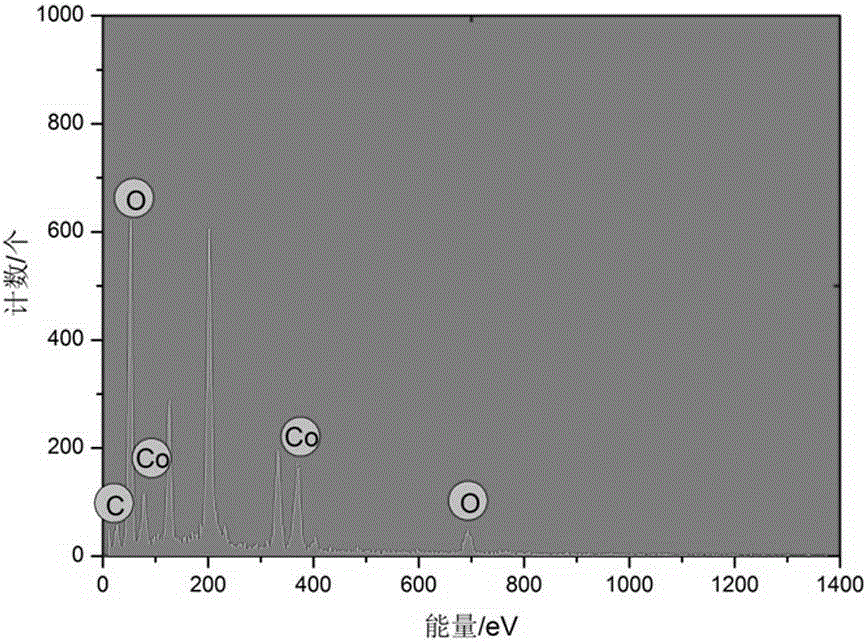

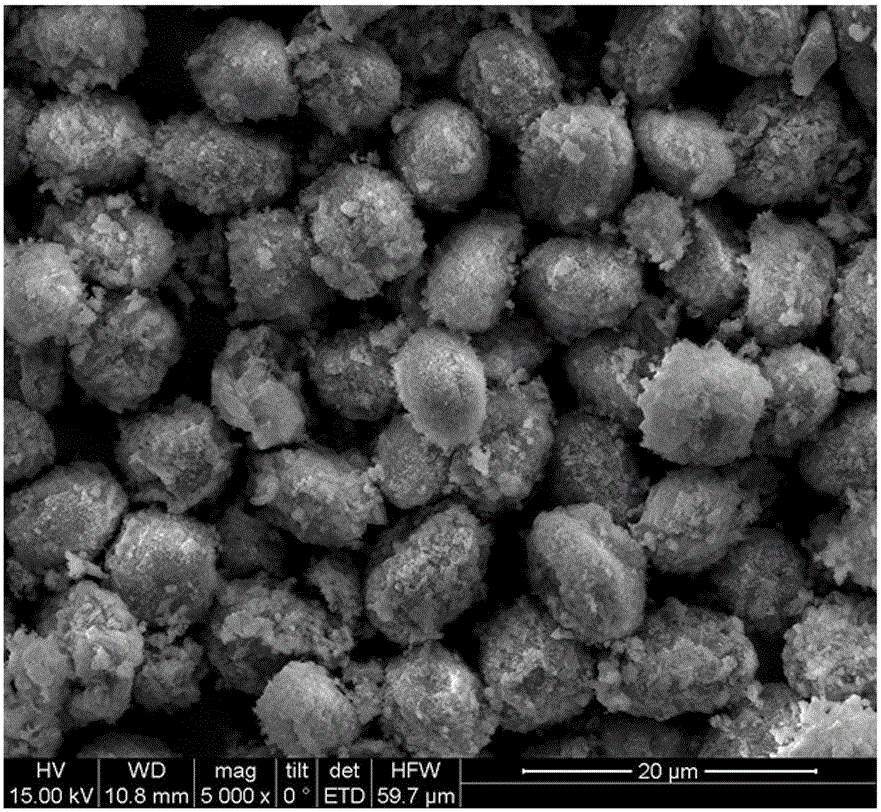

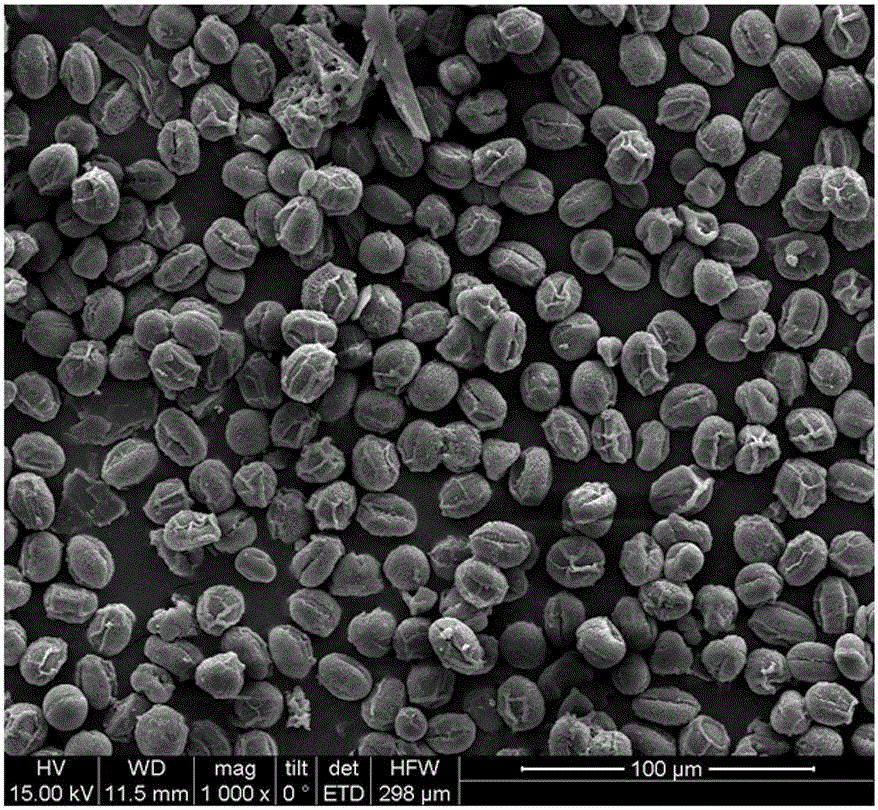

Application of porous cobaltosic oxide

ActiveCN105198006AReduce manufacturing costLow costCobalt oxides/hydroxidesSupercapacitorMaterials science

The invention discloses an application of porous cobaltosic oxide. The porous cobaltosic oxide is in a porous hollow elliptic shape, relatively high in specific surface area, rich in pores, adjustable in pore size, capable of being used as a high-performance super capacitor electrode material, an automobile tail gas treatment material and an adsorption material.

Owner:SUZHOU UNIV OF SCI & TECH

Method and system for electrochemically reducing hardness of wastewater

PendingCN113200615AReduce addTake advantage ofWater contaminantsScale removal and water softeningElectrolysisHard water

The invention discloses a method and system for electrochemically reducing hardness of wastewater. The method comprises the following steps: introducing pretreated wastewater into an electrochemical hardness removal device for electrolysis, then carrying out a reaction with dispersed carbon dioxide to obtain hardness-removed wastewater, and then carrying out solid-liquid separation to obtain hardness-removed water. The electrochemical hardness removal device comprises a closed electrolytic tank, and a cathode and an anode are arranged inside or outside the electrolytic tank. According to the method for electrochemically reducing the hardness of the wastewater, provided by the invention, metal cations such as Ca<2+> and Mg<2+> in the wastewater can be effectively removed by adding nothing or adding a small amount of chemical reagents in the treatment process; and the hardness removal method has little influence on the whole sewage treatment system, the burden of the downstream sewage treatment system can be effectively reduced, and the treated water can be further treated or directly utilized according to requirements.

Owner:SYNFUELS CHINA INNER MONGOLIA CO LTD +1

Rapid removing method for protium in gas-containing tritium hydrogen isotope

ActiveCN104147928AShorten removal cycleSimple removal processIsotope separationHydrogen isotopesPre treatmentGenus Protium

The invention provides a rapid removing method for protium in gas-containing a tritium hydrogen isotope. The rapid removing method sequentially comprises the following steps: a. carrying out leakage rate checking on a palladium retention method protium removing device, inflating He to realize the pressure being 1.5MPa and keeping the pressure for 60min; b. carrying out pre-treatment before purification; c. carrying out purification treatment; and d. carrying out post-treatment. By adopting the rapid removing method for the protium in the gas-containing the tritium hydrogen isotope, the low-protium gas-containing the tritium hydrogen isotope can be obtained.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Mould cleaning cake for removing residual aluminum in to-be-repaired mould as well as preparation method and using method of mould cleaning cake

ActiveCN104194645AEfficient removalSimple removal processPolishing compositions with abrasivesAluminum canWater soluble

The invention provides a mould cleaning cake for removing residual aluminum in a to-be-repaired mould as well as a preparation method and a using method of the mould cleaning cake. The mould cleaning cake comprises the following raw materials in parts by weight: 5-15 parts of filler, 5-15 parts of a solid lubricant, 40-70 parts of water-soluble materials and 1-5 parts of a reinforcing agent. The preparation method of the mould cleaning cake comprises the following steps: drying and crushing the raw materials respectively; then, pressing and molding after mixing according to a proportion; and finally, roasting to prepare the mould cleaning cake. While being adopted to remove the residual aluminum in the mould, the mould cleaning cake is firstly placed above to-be-removed residual aluminum in the mould and then the mould is heated and pressurized to control the temperature to 450-500 DEG C and the pressure to 1000-1200MPa, so that the residual aluminum is replaced by virtue of the mould cleaning cake; and then, the mould is soaked or cleaned by virtue of hot water, so that the mould cleaning cake left in the mould can be removed. The mould cleaning cake provided by the invention can be adopted to effectively remove the residual aluminum in the mould; moreover, the removed residual aluminum can be recycled, and the mould cleaning cake also can be conveniently removed and recycled.

Owner:湖北豪展铝业有限公司

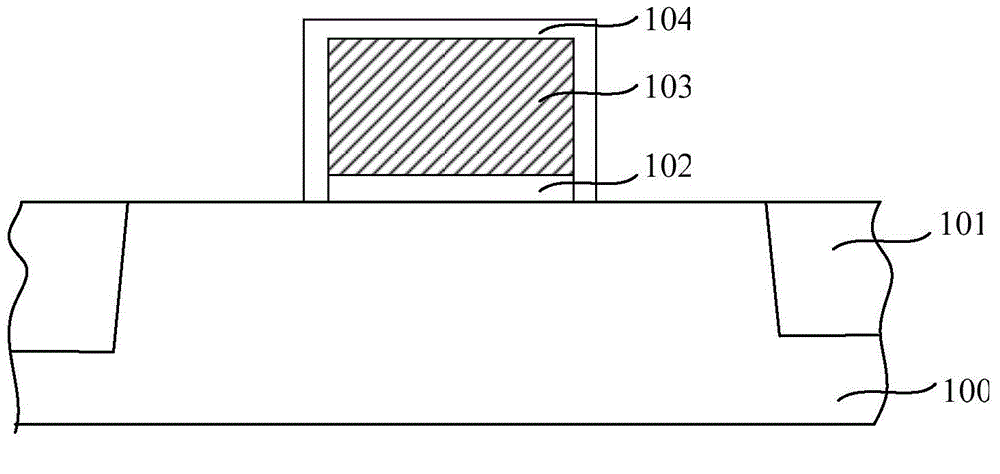

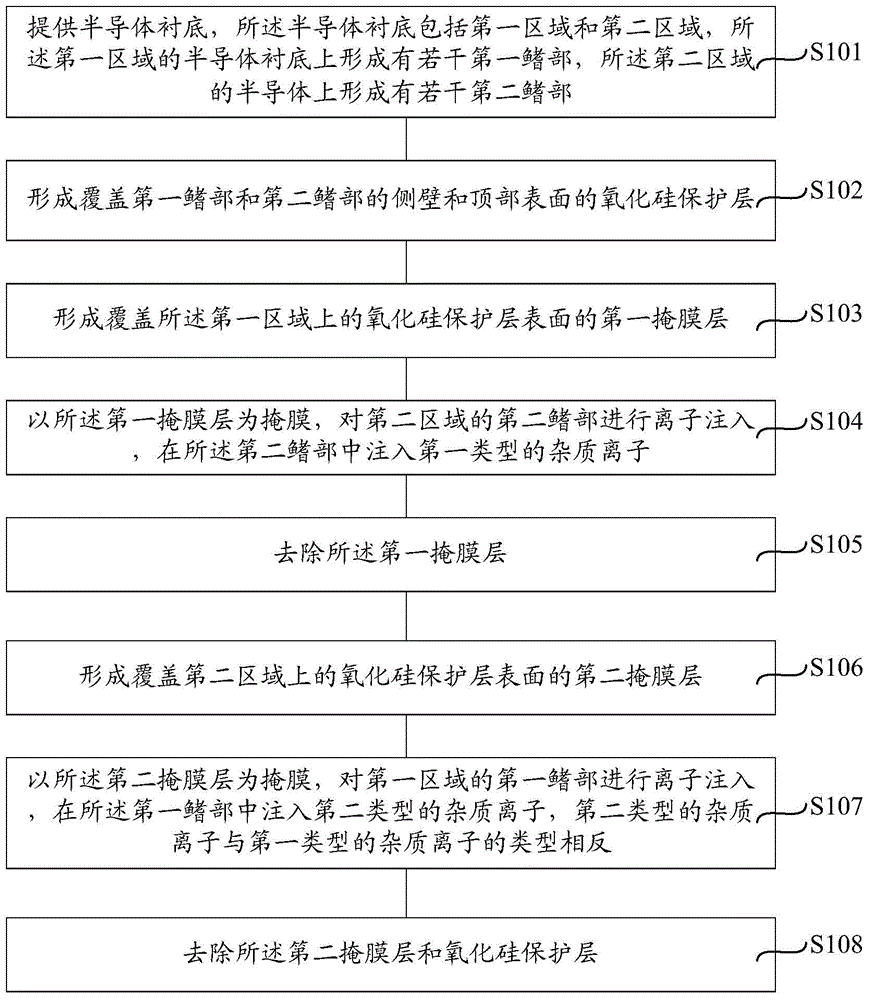

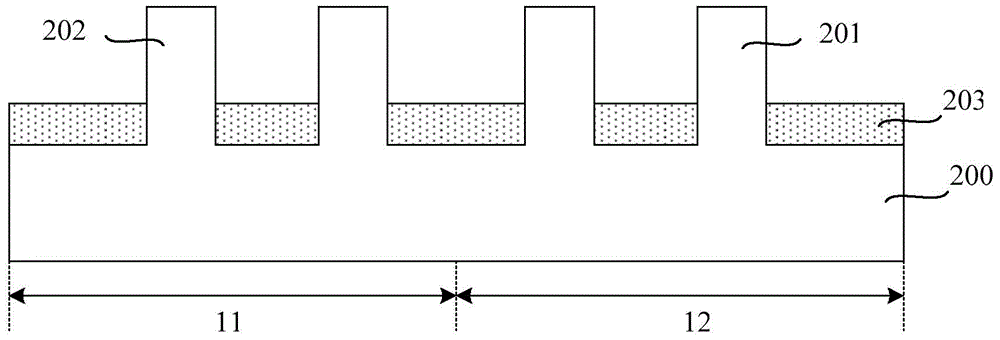

Formation method of semiconductor structure

ActiveCN106328505AReduce dependenceLow costSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structurePhotoresist

The invention discloses a formation method of a semiconductor structure. The method comprises the steps of providing a semiconductor substrate which comprises a first region and a second region, forming a first gate structure on the semiconductor substrate in the first region, forming a second gate structure on the semiconductor substrate in the second region, forming a first photoresist layer covering the semiconductor substrate in the second region and the second gate structure, forming a second photoresist layer covering the semiconductor substrate in the first region and the first photoresist layer, performing shallow doping ion implantation on the semiconductor substrate on the two sides of the first gate structure in the first region by taking the second photoresist layer as a barrier layer, and forming a first shallow doping region in the semiconductor substrate on the two sides of the first gate structure. The method is suitable for forming a shallow doping region.

Owner:SEMICON MFG INT (SHANGHAI) CORP

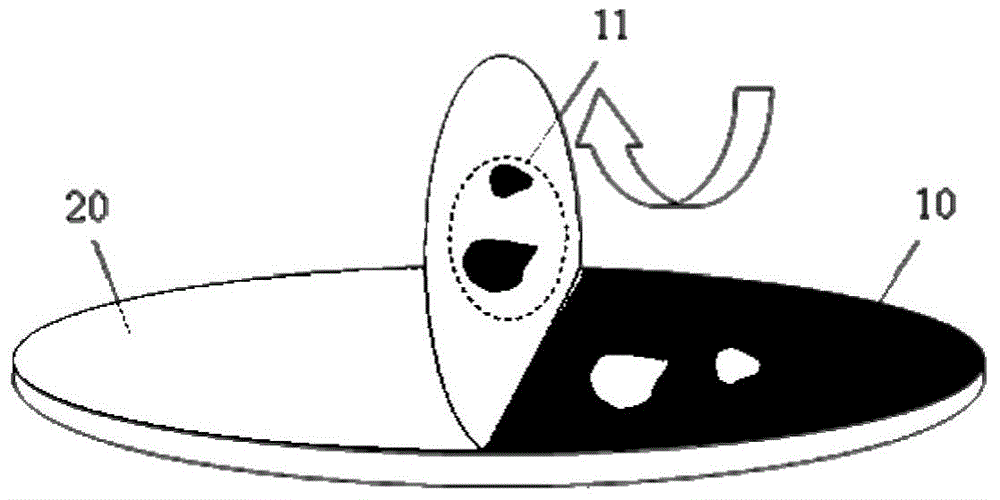

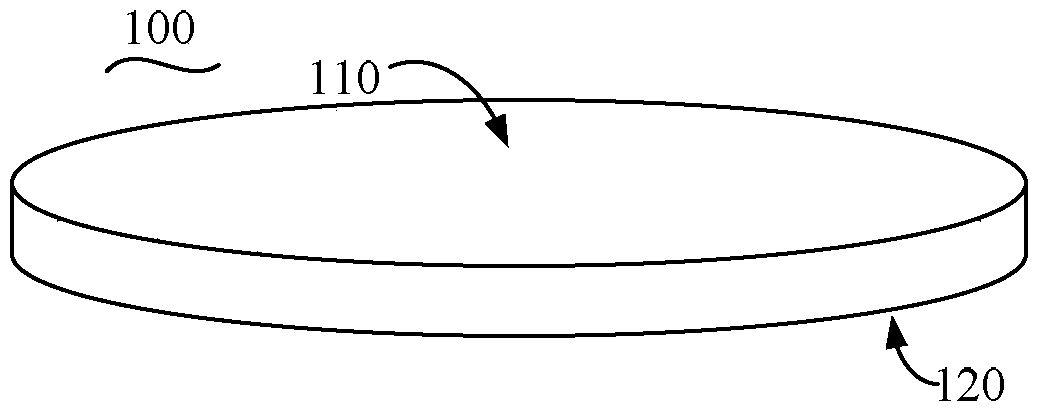

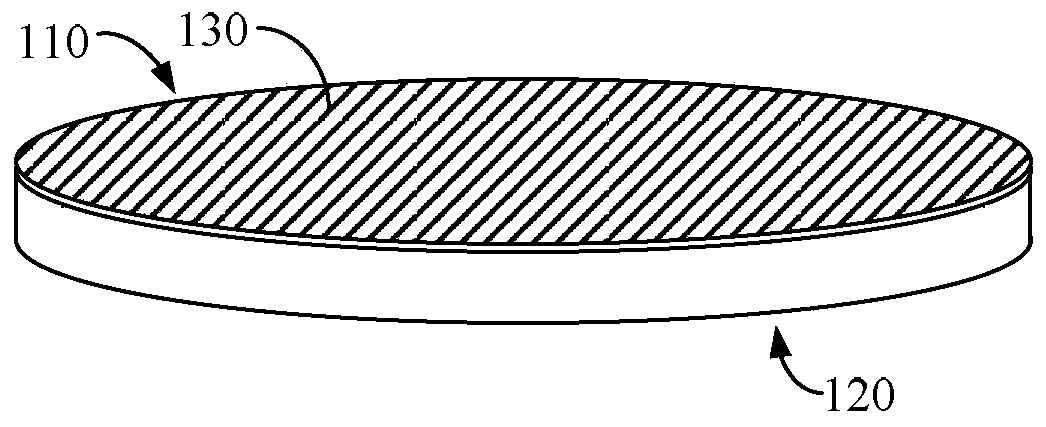

Wafer grinding method

ActiveCN105643431AAvoid contactStructural damage is smallSemiconductor/solid-state device manufacturingLapping machinesEngineeringPartial thickness

The invention provides a wafer grinding method. The wafer grinding method includes the steps that a wafer is provided and comprises a functional face and a back face opposite to the functional face; after a protective layer is formed on the functional face of the wafer, the protective layer is covered with a layer of protective adhesive tape; then, the wafer is placed on a grinding device, the back face of the wafer is ground so that the portion, with the partial thickness, of the wafer can be removed; and the protective adhesive tape is removed, and then the protective layer is removed. Before grinding, the protective layer is formed on the functional face of the wafer, and then the protective layer is covered with one layer of protective adhesive tape. In the grinding process of the protective adhesive tape, the structure on the functional face of the wafer can be effectively protected against damage in the grinding process, the protective adhesive tape is pasted on the protective layer, the situation that the protective adhesive tape makes contact with the functional face of the wafer can be effectively avoided, and therefore in the process of tearing off the adhesive tape after the grinding technology, the protective adhesive tape can remove defects of parts on the surface of the functional face of the part of the wafer, and structural damage on the functional face of the wafer is reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

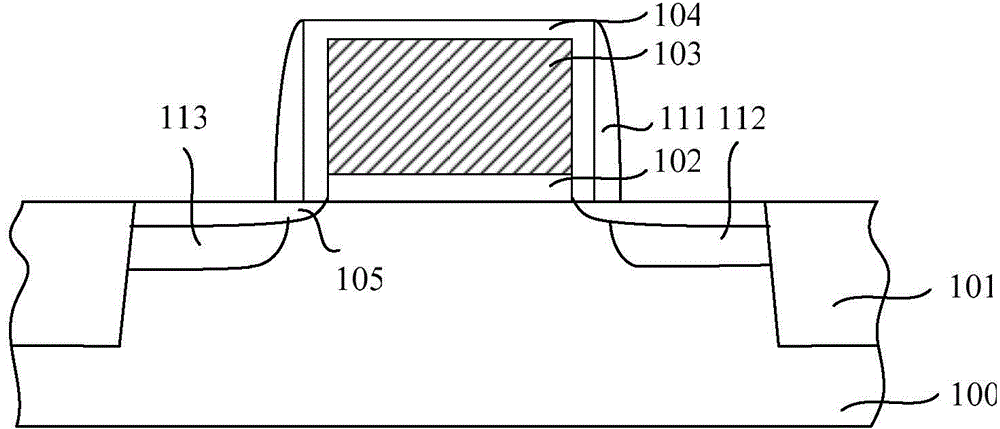

Formation method of semiconductor structure

ActiveCN105632923AAvoid injection damageLittle etching damageSemiconductor/solid-state device manufacturingSemiconductor structureAmorphous silicon

The present invention provides a formation method of a semiconductor structure. The formation method of the semiconductor structure comprises: providing a semiconductor substrate which has a protruded fin; forming sacrificial layers which are configured to cover the side wall and the top surface of the fin, wherein the sacrificial layers include first silicon oxide layers located at the side wall and the top surface of the fin, an amorphous silicon layers located at the surfaces of the first silicon oxide layers and second silicon oxide layers located at the surface of the amorphous silicon layers; performing ion implantation of the fin, and injecting foreign ions in the fin to form a well region; and removing the sacrificial layers. The formation method of a semiconductor structure is able to prevent a fin from etching and damaging when sacrificial layers are removed while preventing the fin from ion implantation damaging.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for using ethanol two-aqueous-phase method for extracting seaweed phycobiliprotein

InactiveCN102532256AImprove broken rateHigh extraction ratePeptide preparation methodsClaviceps purpureaDistilled water

The invention discloses a method for using an ethanol two-aqueous-phase method for extracting seaweed phycobiliprotein, which sequentially comprises the following steps of (1) smashing dry seaweed and then adding distilled water for soaking; (2) using a colloid mill for processing pulpiness seaweed suspension liquid, separating, and respectively obtaining liquid supernatant I and sediment; (3) conducing extraction separation on obtained sediment by adding water to obtain liquid supernatant II; (4) combining the liquid supernatant I and the liquid supernatant II, adding ammonium sulfate, and centrifuging after stewing; and (5) adding ammonium sulfate and ethanol in obtained liquid supernatant III, stewing, obtaining the intermediate phase, enabling the seaweed phycobiliprotein obtained in the step (5) to be subsided, washing, drying, smashing, and obtaining the seaweed phycobiliprotein. The method is used for extracting the seaweed phycobiliprotein, and has the advantages of being concise in process, high in obtaining rate and the like.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Pulping technology of cotton linter

The invention discloses a pulping technology of cotton linters, comprising the following pulping steps by linters: taking the cotton linters as a raw material; at the normal pressure and the temperature below 85DEG C, adding 2.5-3.5% of alkali, boiling for 25-35 minutes to obtain cotton pulp; or directly bleaching without dipping in alkali or boiling, and processing for 30-50 minutes under the condition of 3.5-5.2% of chlorine and pH of 3.2-4.4 to obtain the cotton pulp; and black liquor silicon precipitation: carrying out neutralization reaction for dilute black liquor from a pulp washer by taking flue gas as a neutralizer for precipitating the silicon, wherein the use level of the flue gas for the neutralization reaction is 1250-1450m3 / m<3> dilute black liquor by counting via containing 3.3-3.7% of CO2. According to the pulping technology, the strength and the utilization rate of the cotton pulp can be improved, consumption and cost are lowered, and pollution is reduced or eliminated.

Owner:黄武彬

Method for preparing temperature-control hydrogenation catalyst and application in chemigum hydrogenation

ActiveCN101733159ASimple removal processImprove removal effectOrganic-compounds/hydrides/coordination-complexes catalystsTemperature controlHydrogen

The invention provides a method for preparing temperature-control hydrogenation catalyst and an application in chemigum hydrogenation. The method of the invention uses a metal catalyst having a formula of MaXmLb to realize the hydrogenation of butyronitrile latex and recycle noble metal by the following technical scheme, wherein M is rhodium, X is Cl and L is phosphine compound. The technical scheme comprises the steps of: adding chemigum, solvent, catalyst and trivalence phosphine compound into a reaction device, using a hydrogen substitution system, pressurizing to 0.5 to 5 Mpa, heating to 100 to 175 DEG C, keeping temperature for 3 to 24 hours, adding polyethylene glycol and n-heptane into the resultant of reaction after finishing reaction, stirring 30 min, standing, layering, and then taking out the chemigum solution on upper layer, wherein the solution on lower layer contains the separated catalyst. The method of the invention ensures the chemigum hydrogenation catalyst having a fine temperature-control separating effect and improves the hydrogenation effect of the catalyst so the hydrogenation degree of the prepared chemigum is higher.

Owner:BEIJING UNIV OF CHEM TECH

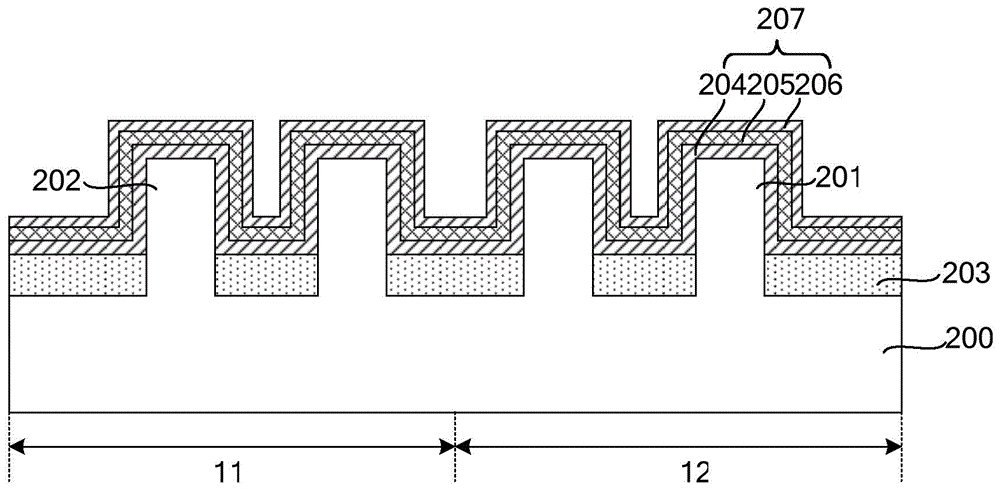

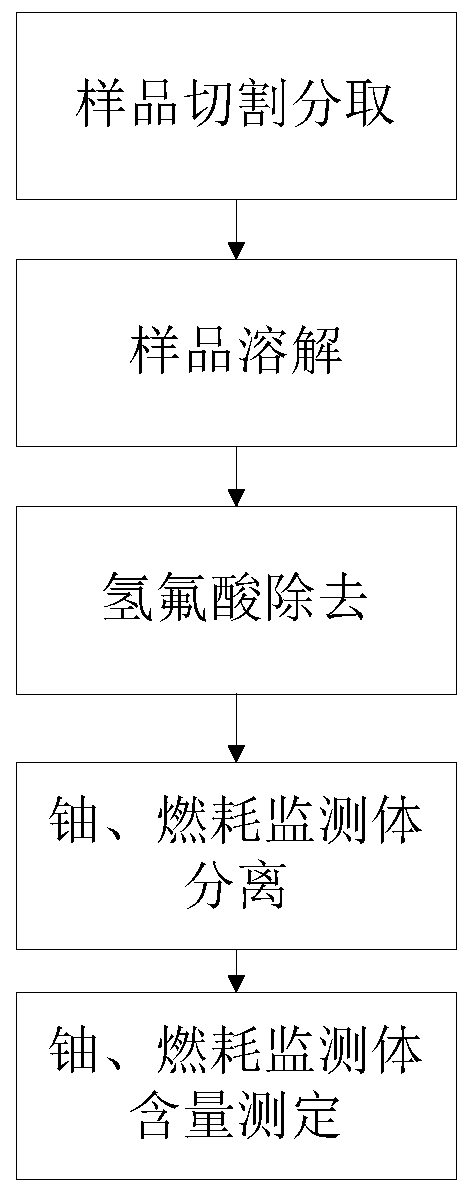

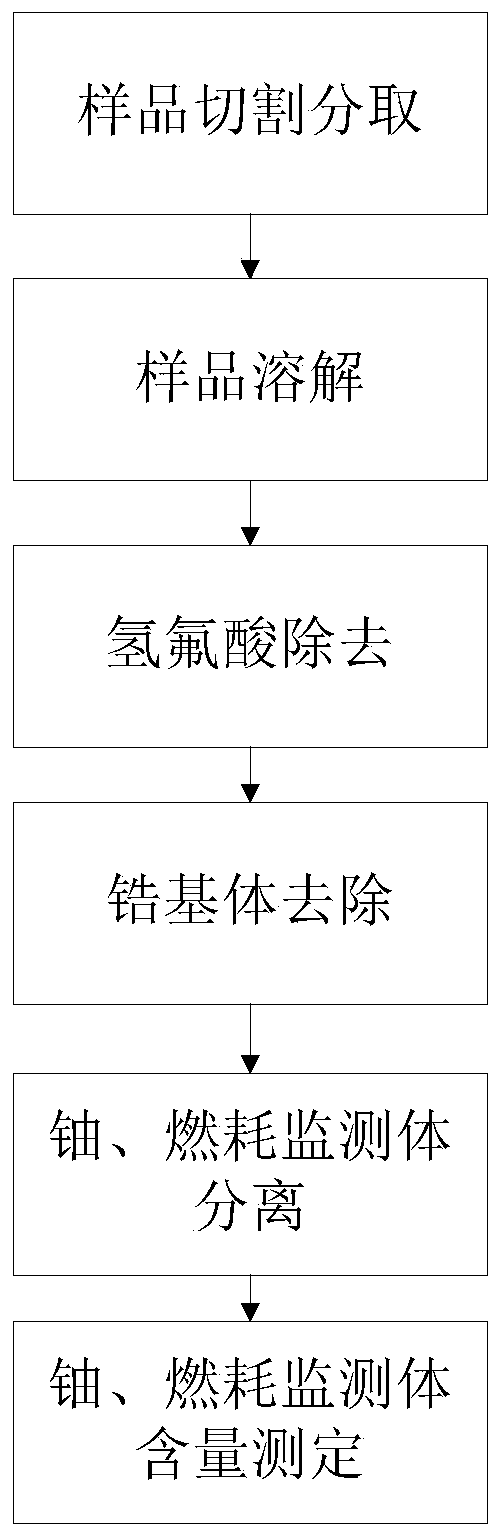

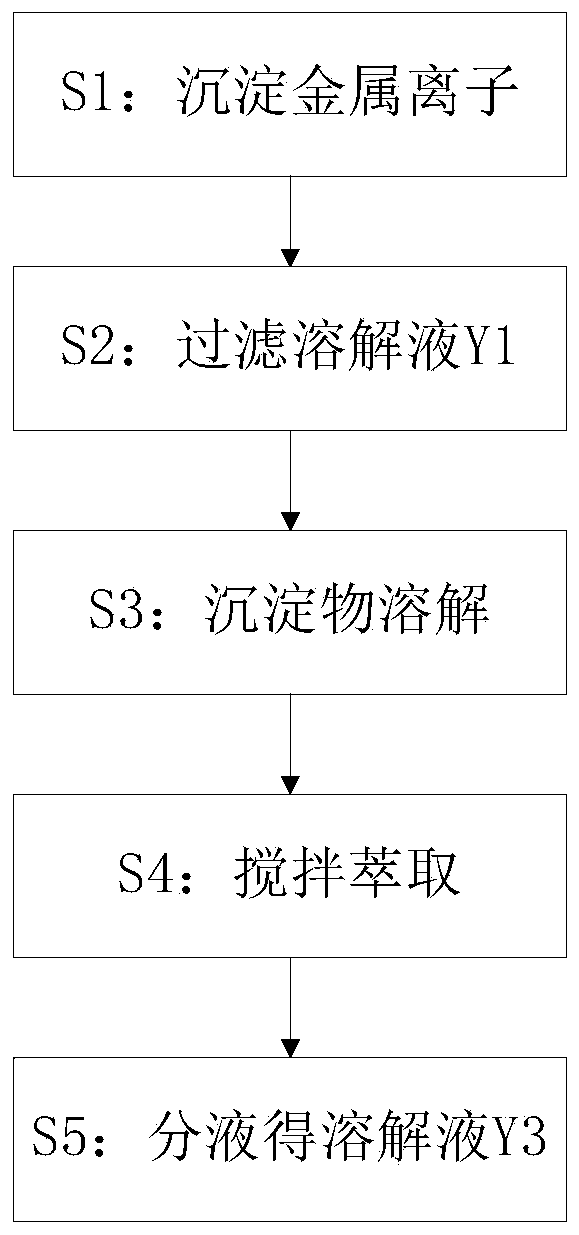

Zirconium matrix removing process and burnup measuring method adopting same

ActiveCN110491531ALow zirconium contentAccurate measurementNuclear energy generationNuclear monitoringHydrofluoric acidBurnup

The invention discloses a zirconium matrix removal process and a burnup measurement method adopting the process. The burnup measurement method comprises a sample cutting and separating step, a sampledissolving step, a hydrofluoric acid removal step, a uranium and burnup monitoring body separation step and a uranium and burnup monitoring body content measurement step. The method further comprisesa zirconium matrix removing step, and the zirconium matrix removing step is located between the hydrofluoric acid removing step and the uranium and fuel consumption monitoring body separating step. Asolution obtained by the zirconium matrix removing step can be directly used in the uranium and burnup monitoring body separation step. Through the zirconium matrix removal process, in the burnup measuring method, a large number of zirconium matrixes in the dissolving solution can be removed after the hydrofluoric acid removal step; and the content of zirconium in the dissolving solution is lowerthan the requirement of the subsequent uranium and burnup monitoring body separation step, so that the burnup measurement process can accurately measure the burnup value of a special system, namely azirconium-based dispersive nuclear fuel element, and has wide application and popularization values.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

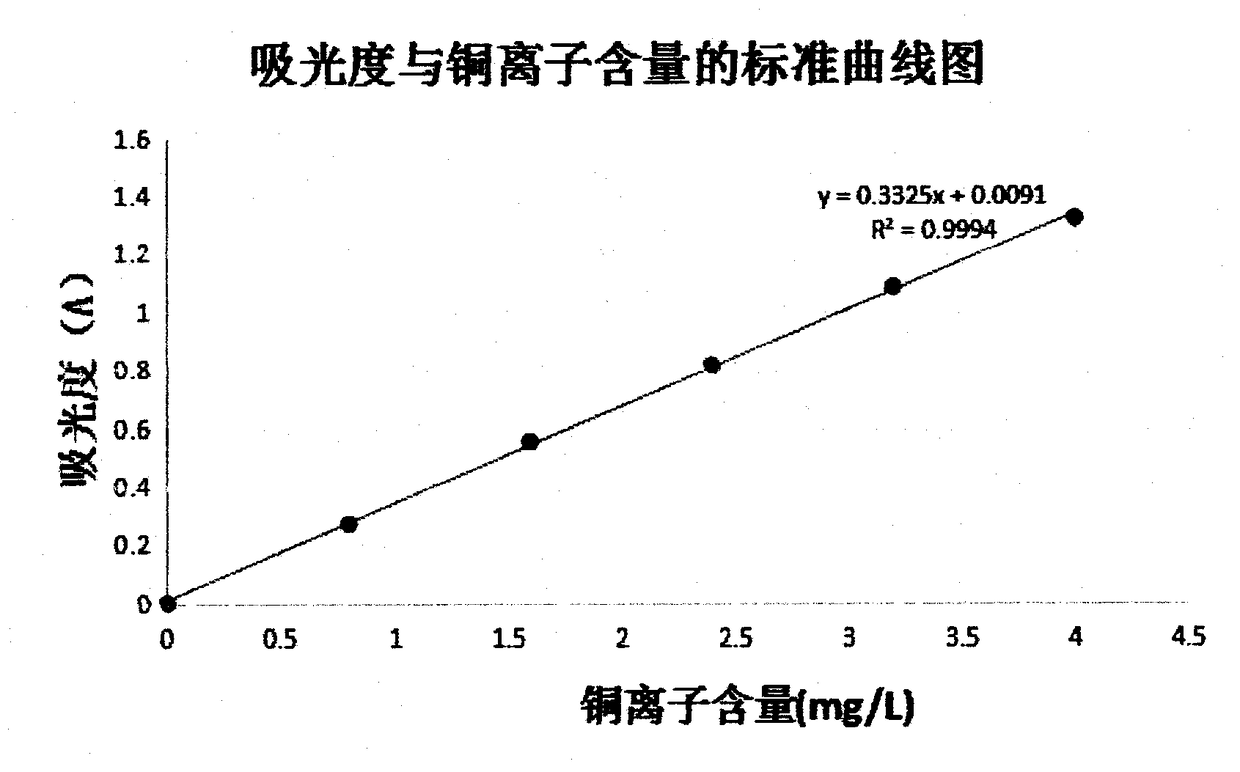

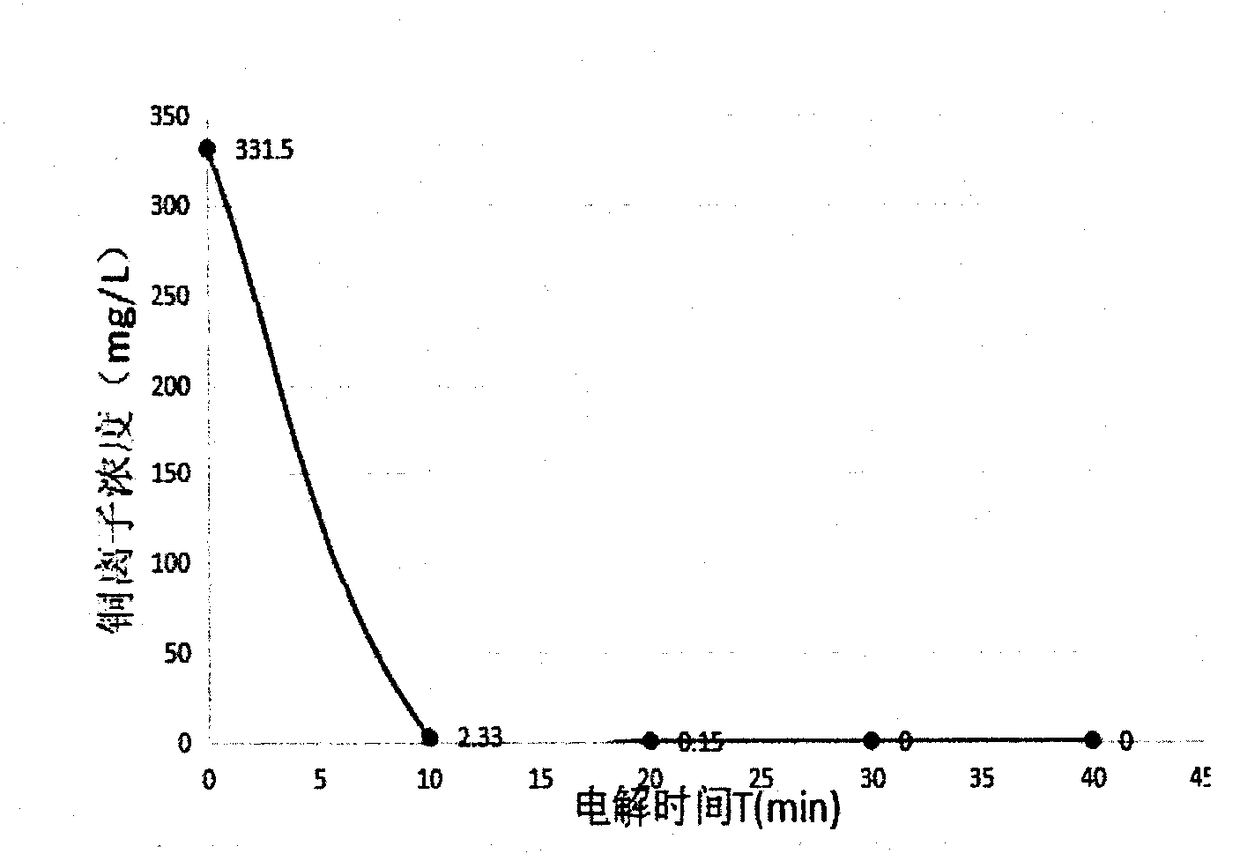

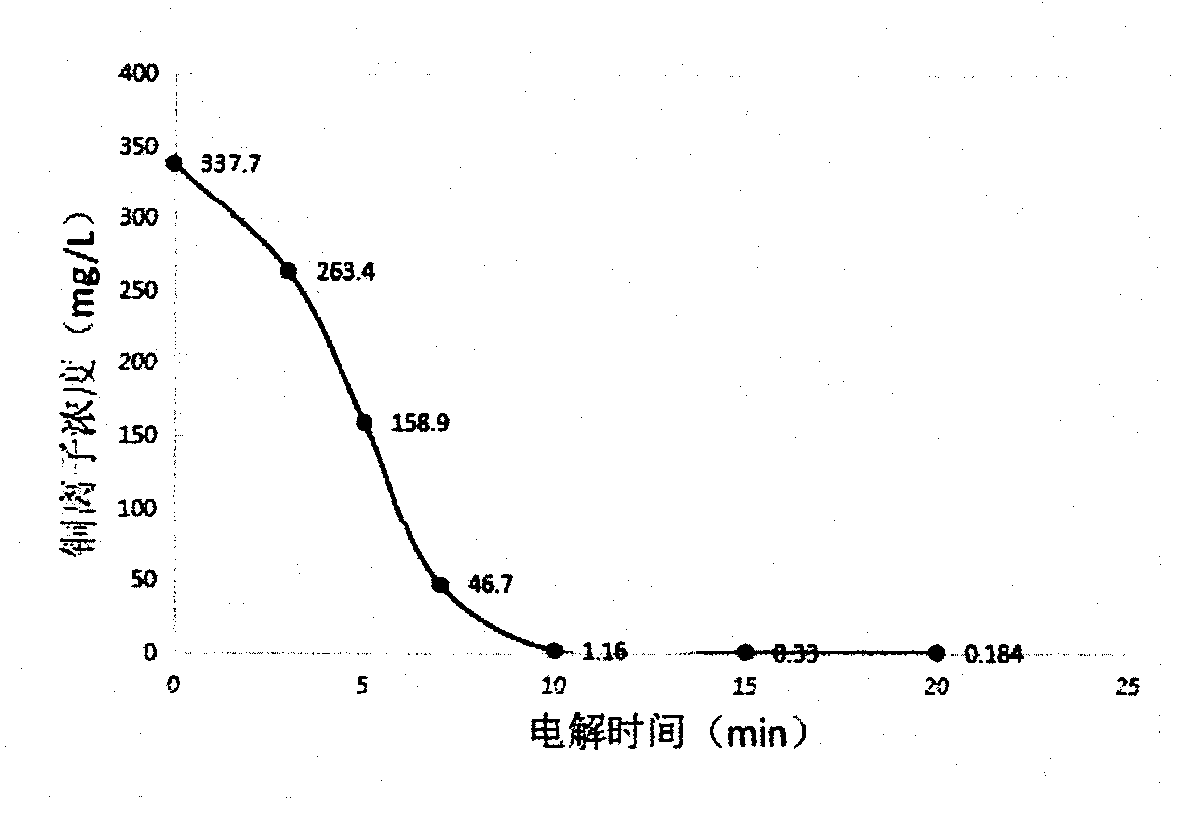

Electrochemical treatment and reclamation of electroplating acid copper wastewater

InactiveCN109467227AGood removal effectEmission complianceWater treatment parameter controlWater treatment compoundsElectrolysisCopper chloride

The invention discloses electrochemical treatment and reclamation of electroplating acid copper wastewater. The electrochemical treatment and reclamation of the electroplating acid copper wastewater comprises the following steps: selecting an experiment instrument and a chemical agent; preparing an experiment agent; performing chemical experiment; and summarizing the experiment result and optimizing the technology. According to the electrochemical treatment and reclamation of the electroplating acid copper wastewater, an electrolysis mode is carried out to remove the electroplating acid copperwastewater, and the effect is obvious, and the removing rate is 99% or more; the treated solution can reach the standard for drainage; in addition, the product of the electroplating acid copper wastewater is copper chloride hydroxide, and the copper recovery rate is 90% or more, and thus the effect of electrolysis in treating the electroplating acid copper wastewater is good; and moreover, the process of removing copper ions in wastewater is simple, convenient, and easy to carry out; the cost is low; and a valid technical technology is supplied to treat the copper containing wastewater in theelectroplating industry.

Owner:JIMEI UNIV

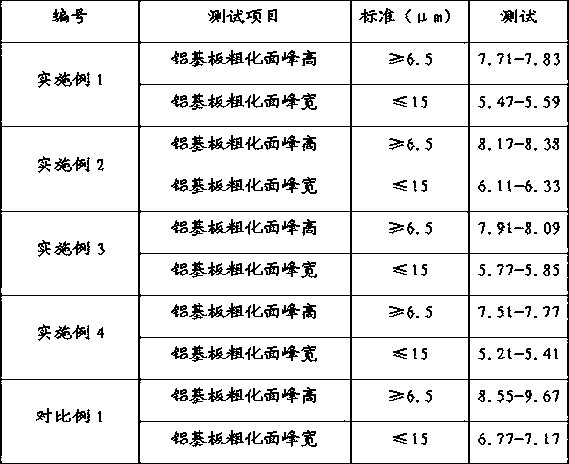

Etching medicinal liquid and surface roughening treatment method of aluminum substrate

InactiveCN110983337AGood coarsening effectPromote environmental protectionOrganic acidPhysical chemistry

The invention discloses etching medicinal liquid which comprises the following raw materials in parts by weight: 10-20 parts of organic acid and 70-90 parts of deionized water. The etching medicine liquid is used for etching an aluminum substrate, the aluminum substrate is good in roughening effect, oil can be removed at the same time, and the oil removal process is simplified; and the etching medicine liquid can be removed only by heating, has no toxic or harmful effect on the periphery in a high-temperature state, and is good in environmental protection. According to a roughening treatment method of the aluminum substrate, the etching medicine liquid is used for etching and roughening, the process is simple, the roughening effect is good, the excessive etching medicine liquid can be volatilized and removed by heating, the removal process is simple, and an alkaline washing neutralization process is not needed.

Owner:广东省华锐高新材料股份有限公司

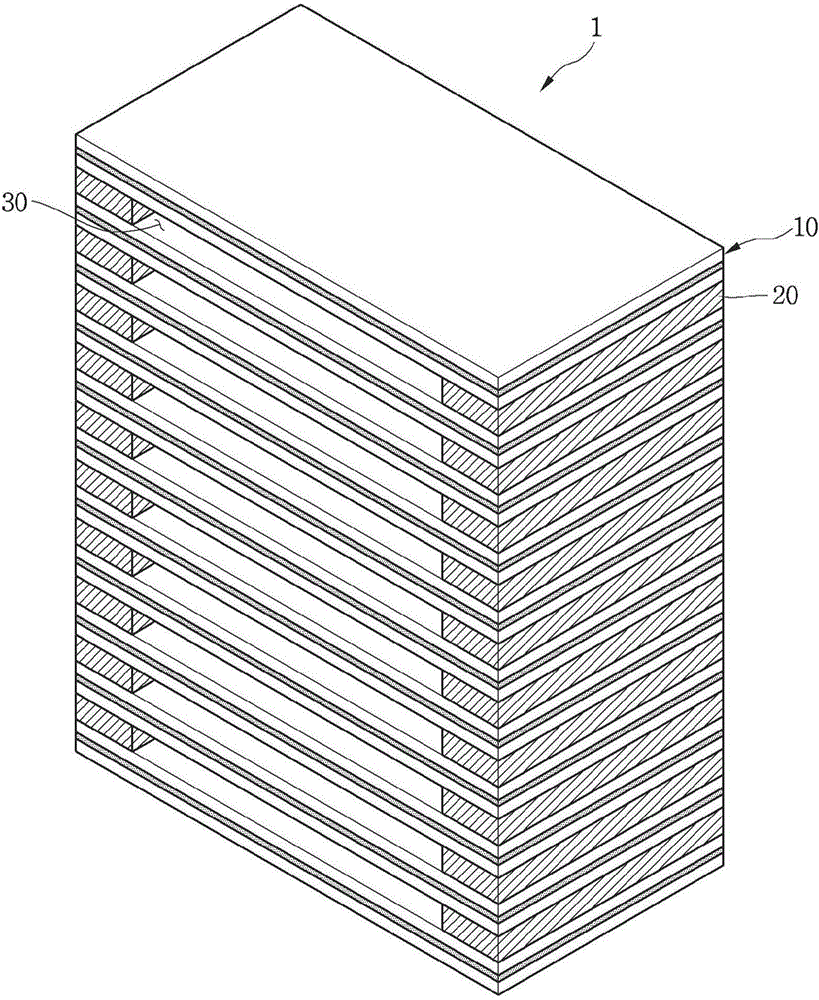

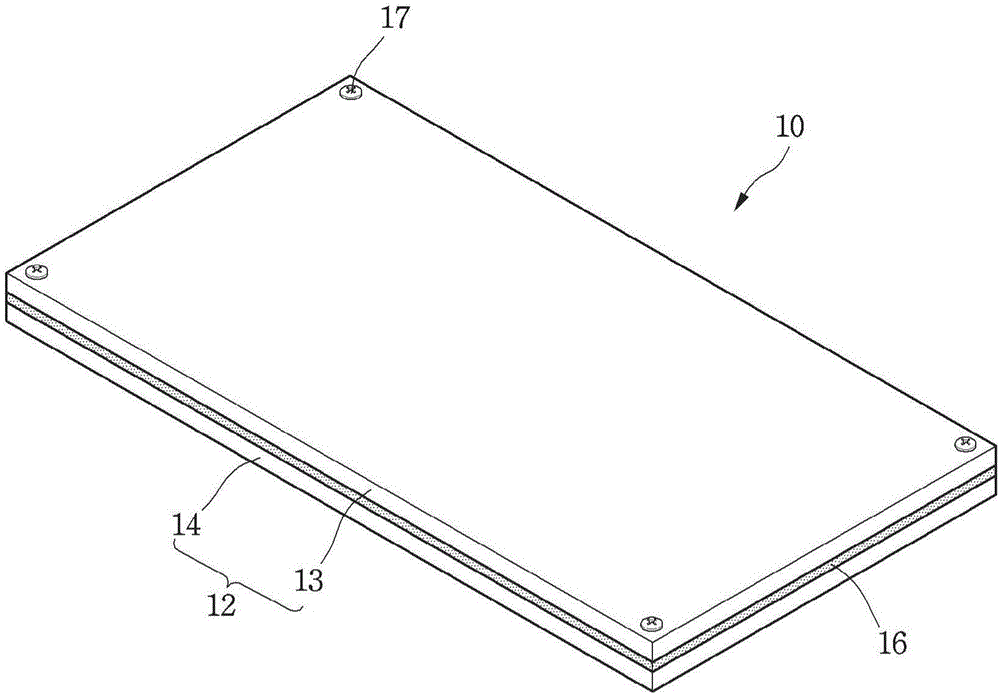

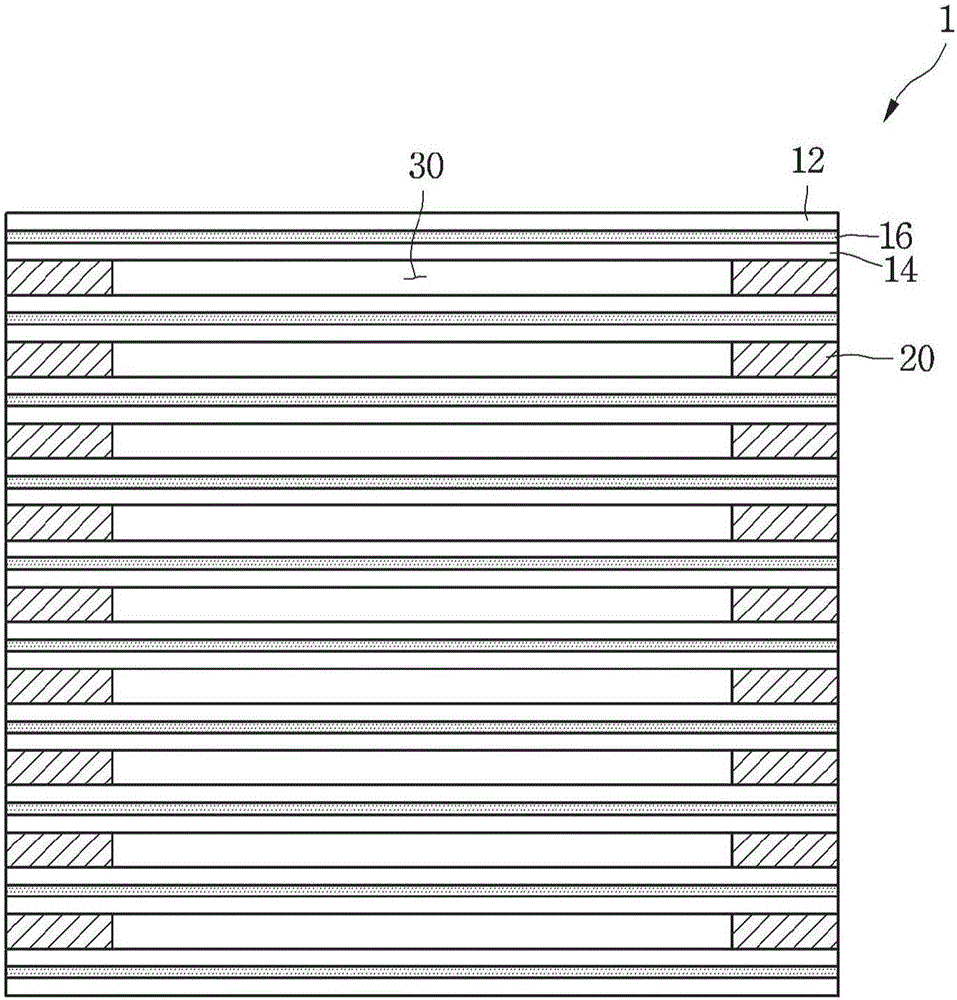

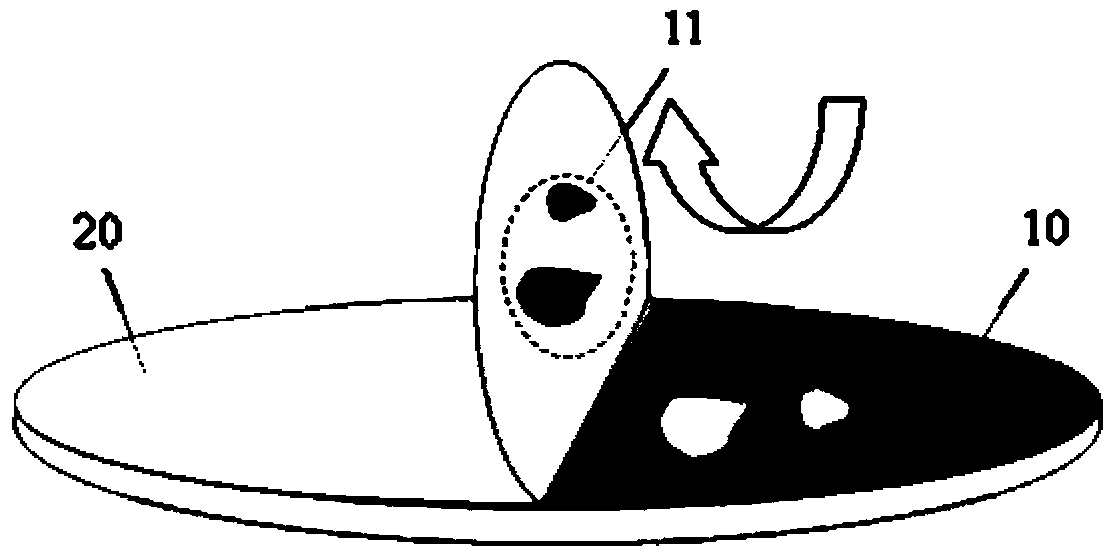

Air purification device

ActiveCN106794472ASimple removal processGuaranteed stabilityDispersed particle separationElectrode constructionsVoltageEngineering

The present invention relates to an air purification device. An air purification device, according to an embodiment, comprises: a plurality of electrode modules which are provided on an air flow path; and a support portion which forms a space portion between the plurality of electrode modules by having the plurality of electrode modules positioned away from each other, wherein the electrode modules have electrode portions, to which a voltage is applied and which form a plasma region, and a dielectric body which is placed on one or more sides of the electrode portions and collects contaminant in the air.

Owner:LG ELECTRONICS INC +1

Wafer Grinding Method

ActiveCN105643431BAvoid contactStructural damage is smallSemiconductor/solid-state device manufacturingLapping machinesAdhesive beltWafer

The invention provides a wafer grinding method. The wafer grinding method includes the steps that a wafer is provided and comprises a functional face and a back face opposite to the functional face; after a protective layer is formed on the functional face of the wafer, the protective layer is covered with a layer of protective adhesive tape; then, the wafer is placed on a grinding device, the back face of the wafer is ground so that the portion, with the partial thickness, of the wafer can be removed; and the protective adhesive tape is removed, and then the protective layer is removed. Before grinding, the protective layer is formed on the functional face of the wafer, and then the protective layer is covered with one layer of protective adhesive tape. In the grinding process of the protective adhesive tape, the structure on the functional face of the wafer can be effectively protected against damage in the grinding process, the protective adhesive tape is pasted on the protective layer, the situation that the protective adhesive tape makes contact with the functional face of the wafer can be effectively avoided, and therefore in the process of tearing off the adhesive tape after the grinding technology, the protective adhesive tape can remove defects of parts on the surface of the functional face of the part of the wafer, and structural damage on the functional face of the wafer is reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for removing photoresist graph in forming process of dual embedded structure

ActiveCN101202244BShorten the timeReduced strengthSemiconductor/solid-state device manufacturingPhotosensitive material processingResistElectrical conductor

The invention provides a removing method for a photo resist image in the forming process of a double inlaying structure; the forming process of the double inlaying structure comprises the following steps: a semiconductor substrate with a preformed semiconductor device is provided; a metal interconnecting line layer with a surface which is provided with a dielectric layer is formed on the substrate; connecting holes are etched in the dielectric layer; a sacrificial layer and a hard mask layer are deposited; a bottom anti-reflecting layer and a photo-resist layer are coated and patterned to formthe photo resist image; oxy plasma incinerates and removes the bottom anti-reflecting layer and the photo-resist layer. The removing method of the invention can simplify the removing process and prevent the dielectric layer with a low dielectric constant from being damaged.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

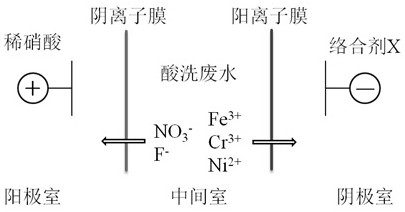

A method for removing heavy metals in stainless steel pickling wastewater

ActiveCN109467167BInhibit electrolysisThe electrodialysis process continues normallyWater contaminantsDispersed particle separationDC - Direct currentSS - Stainless steel

Owner:SHANGHAI UNIV

Method for preparing seaweed nutrition powder rich in fucoidin

ActiveCN103005533BReduce churnGuaranteed NutrientsFood preparationMANNITOL/SORBITOLAdditive ingredient

The invention provides a method for preparing seaweed nutrition powder rich in fucoidin. The method comprises the steps that clean seaweed is chosen and washed with water repeatedly, washing water and the seaweed are collected, the washing water is colated and adsorbed, then the washing water and the clean seaweed are subjected to defibrination, degradation and solvent extraction, and seaweed components from which heavy metals are removed are homogenated, neutralized, concentrated and dried to obtain the seaweed nutrition powder rich in the fucoidin. According to the method, functional components such as the fucoidin, iodine and mannitol in kelp, which can be dissolved in water and can runoff easily during washing, are reserved fully; and different suitable heavy metal-removing methods are adopted respectively based on characteristics of different components, so that the heavy metal-removing effects are guaranteed, and nutrient loss caused by unsuitable removing methods is also avoided.

Owner:QINGDAO BRIGHT MOON SEAWEED GROUP

A rapid removal method for protium in tritiated hydrogen isotope gas

ActiveCN104147928BShorten removal cycleSimple removal processIsotope separationHydrogen isotopesProduct gasPalladium

The present invention provides a method for quickly removing protium in tritiated hydrogen isotope gas, which comprises the following steps in turn: a. Leak rate inspection of the palladium retention method for reducing the protium, charging to 1.5 MPa, and keeping the pressure for 60 minutes; b. Purifying pretreatment before; c, purification treatment; d, post-treatment. By adopting the rapid removal method for protium in tritium-containing hydrogen isotope gas of the present invention, it is possible to obtain tritium-containing hydrogen isotope gas with low content of protium.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

A high-temperature cycle removal method for carbon dioxide based on a rotary fixed bed

ActiveCN108006684BSimple removal processReduce the difficulty of operationEmission preventionDispersed particle separationHigh concentrationFlue gas

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

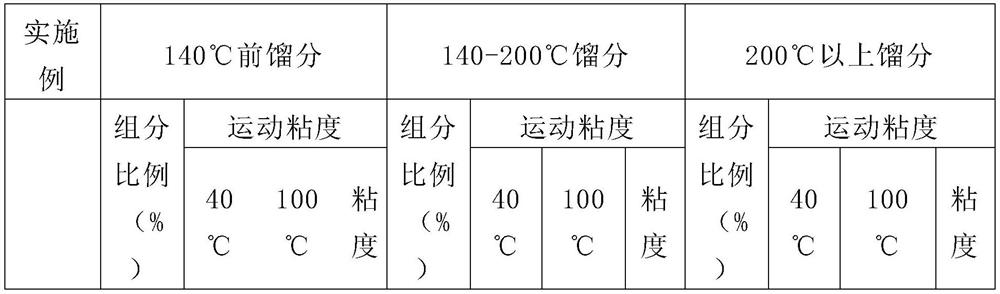

Production method of polybutylene and product application thereof

The invention relates to a method for preparing an olefin polymer for polybutene with different viscosities, such as lubricant base oil and metal processing oil, by polymerizing C4 liquefied petroleum gas. The method provided by the invention has the advantages of few procedures, low requirements on raw materials, low production cost and wide product application field.

Owner:NANJING CHEMRUN CO LTD

A kind of synthetic method of high-purity leuprolide

ActiveCN107573408BAvoid interferenceProtect and extend service lifeLuteinising hormone-releasing hormonePeptide preparation methodsAmino acid synthesisLeuprorelin

The invention provides a method for preparing leuprorelin. The method comprises the following steps: (1) taking Fmoc-Pro-CTC-OH and CTC (Carbon Tetrachloride) resin as starting raw materials and treating to obtain Fmoc-Pro-CTC-OH resin; (2) sequentially connecting the Fmoc-Pro-CTC-OH resin with an amino acid with a protecting group by adopting a gradual coupling manner of a Fmoc / tBu solid-phase method to synthesize side chain wholly-protected leuprorelin precursor peptide-resin; (3) taking a 20 percent trifluoroethanol / DCM (Dichloromethane) solution as a cutting reagent and cutting the side chain wholly-protected leuprorelin precursor peptide-resin, so as to obtain a side chain wholly-protected leuprorelin precursor peptide; (4) carrying out ethyl amination on the side chain wholly-protected leuprorelin precursor peptide to obtain side chain wholly-protected leuprorelin; (5) carrying out side chain cutting on the side chain wholly-protected leuprorelin to obtain a leuprorelin crude peptide; (6) carrying out CM purification and HPLC (High Performance Liquid Chromatography) purification, concentration, dissolving and freeze-drying on the leuprorelin crude peptide to obtain a high-purity leuprorelin crude drug. The method provided by the invention has the advantages of simplicity in operation, short period, low cost, high product yield and small environment pollution and is very suitable for industrial production.

Owner:上海丽珠制药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com