Wafer Grinding Method

A grinding method and wafer technology, applied in the direction of grinding machine tools, grinding devices, manufacturing tools, etc., can solve problems affecting chip quality, damage, etc., and achieve the effect of reducing structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] As mentioned in the background art, in the back grinding process of existing wafers, even if the functional surface of the wafer is covered with a protective tape (BG tape), after the protective tape is removed, it is found that the functional surface of the wafer is still damaged. Analyze its reasons:

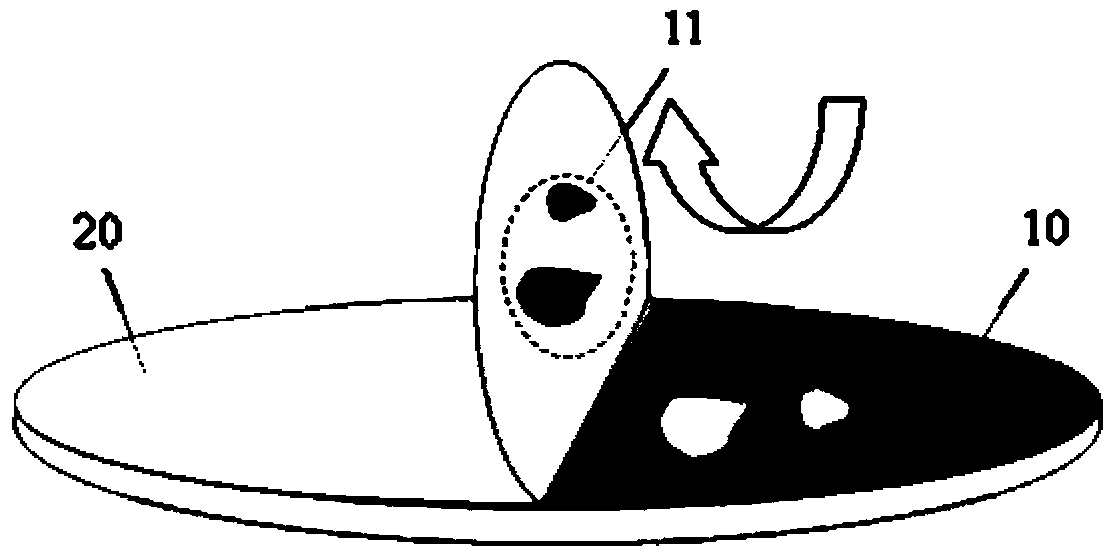

[0029] The existing protective tape is adhered to the functional surface of the wafer, and the protective tape and the wafer have strong adhesion to prevent the protective tape from falling off during the grinding process, thereby better protecting the functional surface of the wafer from contamination. And damage caused by direct contact with grinding equipment. But after the grinding process, refer to figure 1 , due to the strong adhesion between the protective tape 20 and the wafer 10, during the process of tearing off the protective tape 20 from the functional surface of the wafer 10, the protective tape 20 will damage parts 11 on the surface of the functional surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com