A method for removing heavy metals in stainless steel pickling wastewater

A technology for pickling wastewater and stainless steel, applied in separation methods, chemical instruments and methods, water pollutants, etc., can solve the problems of environmental safety still to be evaluated, low market recognition, large land occupation, etc., to avoid secondary Pollution, environmental friendliness, avoids the effect of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Table 1 Composition of stainless steel pickling wastewater

[0030]

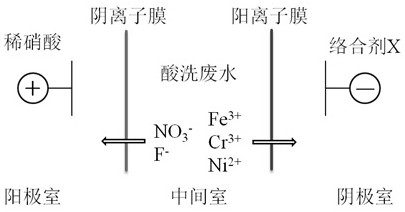

[0031] The electrodialysis cell is divided into an anode chamber, an intermediate chamber and a cathode chamber by an anion exchange membrane and a cation exchange membrane. The stainless steel pickling wastewater is added to the middle chamber of the double-membrane three-chamber electrodialysis cell, and 0.1 mol / L dilute nitric acid solution is added to the anode chamber. The solution of the complexing agent sodium sulfosalicylate with a concentration of 0.12 mol / L and a pH of 7.2 was added to the cathode chamber, and electrodialysis was carried out by direct current. The anode is a graphite plate, the cathode is a stainless steel plate, and the cathode current density is 278 A / m 2 . After 10 hours of electrodialysis, the total chromium concentration in the wastewater dropped to 0.872 mg / L, and the total nickel concentration dropped to 0.747 mg / L, which met the requirements of the "discharge sta...

Embodiment 2

[0033] Add stainless steel pickling wastewater to the middle chamber of the double-membrane three-chamber electrodialysis cell, add 0.1 mol / L dilute nitric acid solution to the anode chamber, and add complexing agent X sodium citrate solution with a concentration of 0.24 mol / L and a pH of 8.8 to the cathode chamber. Electrodialysis was performed using direct current. The anode is a graphite plate, the cathode is a stainless steel plate, and the cathode current density is 253 A / m 2 . After 12 hours of electrodialysis, the total chromium concentration in the wastewater dropped to 0.910 mg / L, and the total nickel concentration dropped to 0.326 mg / L, which met the requirements of the "discharge standard" and achieved the standard discharge of stainless steel pickling wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com