Method for treating wasterwater containing copper by utilizing Spartina alterniflora Loisel-based biochar

A technology of Spartina alterniflora and biochar, which is applied in the field of biomass resource utilization, can solve the problems of threatening indigenous species in coastal wetlands, affecting tidal flat farming, and the decline of coastal water quality, and achieves low requirements for adsorption and management conditions. The process is simple and easy, and the removal effect is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

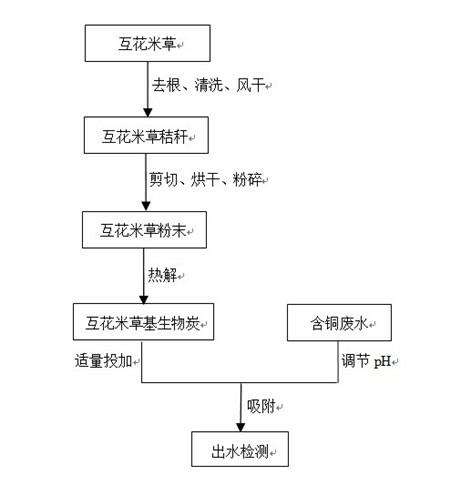

[0032] 1. Remove the roots of Spartina alterniflora, wash with distilled water and air dry. The air-dried Spartina alterniflora stalks were cut into small pieces of about 50 cm, placed in an oven to dry at 105° C., and then pulverized with a pulverizer to obtain a 50-mesh powder.

[0033] 2. The powder is placed in a tube furnace, and heated to 300°C at a rate of 5°C / min in an atmosphere of 100mL / min nitrogen, and pyrolyzed at a constant temperature for 2 hours. Continue to pass through 50mL / min of nitrogen to cool to room temperature, grind, and pass through a 50-mesh sieve to obtain biochar. The yield was 43%.

[0034] 3. The prepared biochar, according to the dosage of 2g / L, can adsorb the copper solution with a pH of 6±0.1, and the reaction time is 36 hours.

[0035] 4. Take part of the adsorbed suspension and filter it, and use ICP to measure its copper content.

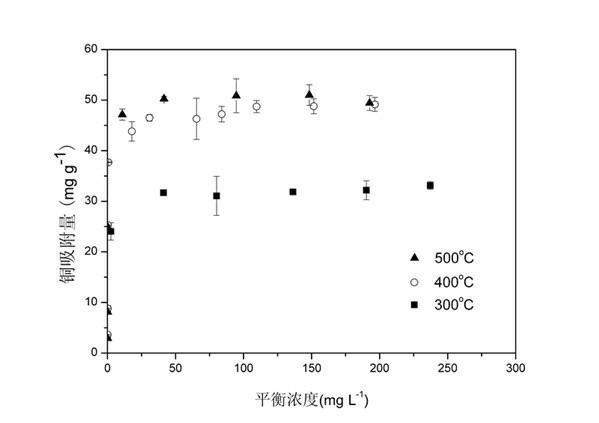

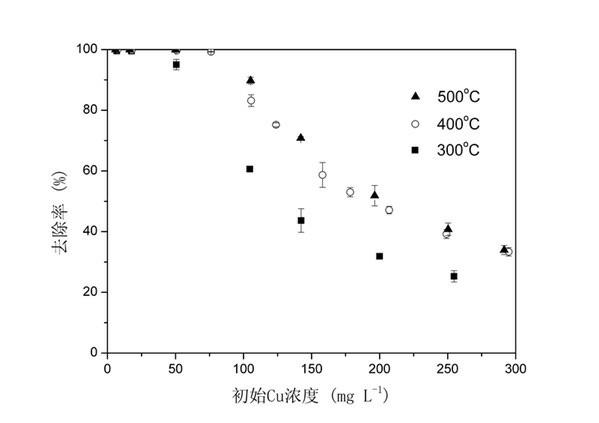

[0036] The adsorption capacity of the biochar obtained in this example to copper is 33.12mg / g, for the cop...

Embodiment 2

[0038] With other conditions unchanged, the pyrolysis temperature in Example 1 was changed to 400°C. The yield was 40%.

[0039] The biochar obtained in this example has an adsorption capacity of 48.49 mg / g of copper at pH 6. When the dosage of biochar is 2g / L, the removal rate of 100mg / L copper solution is 83%, and the removal rate of 50mg / L is more than 99%, reaching the first-level emission standard (<0.5mg / L).

Embodiment 3

[0041] With other conditions unchanged, the pyrolysis temperature in Example 1 was changed to 500°C. The yield was 39%.

[0042] The biochar obtained in this example has an adsorption capacity of 50.99 mg / g of copper, a removal rate of 89% for a 100 mg / L copper solution, and a removal rate of more than 99% for a 50 mg / L copper solution, which is close to complete removal and has reached the first level. Emission Standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com