Preparation method and application of three-dimensional multi-dimension porous crystal titanium carbide

A titanium carbide, multi-size technology, applied in the direction of titanium carbide, carbide, electrical components, etc., can solve the problems of easy stacking of two-dimensional crystal titanium carbide, low mass capacitance, etc., and achieve abundant reserves, high safety, and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

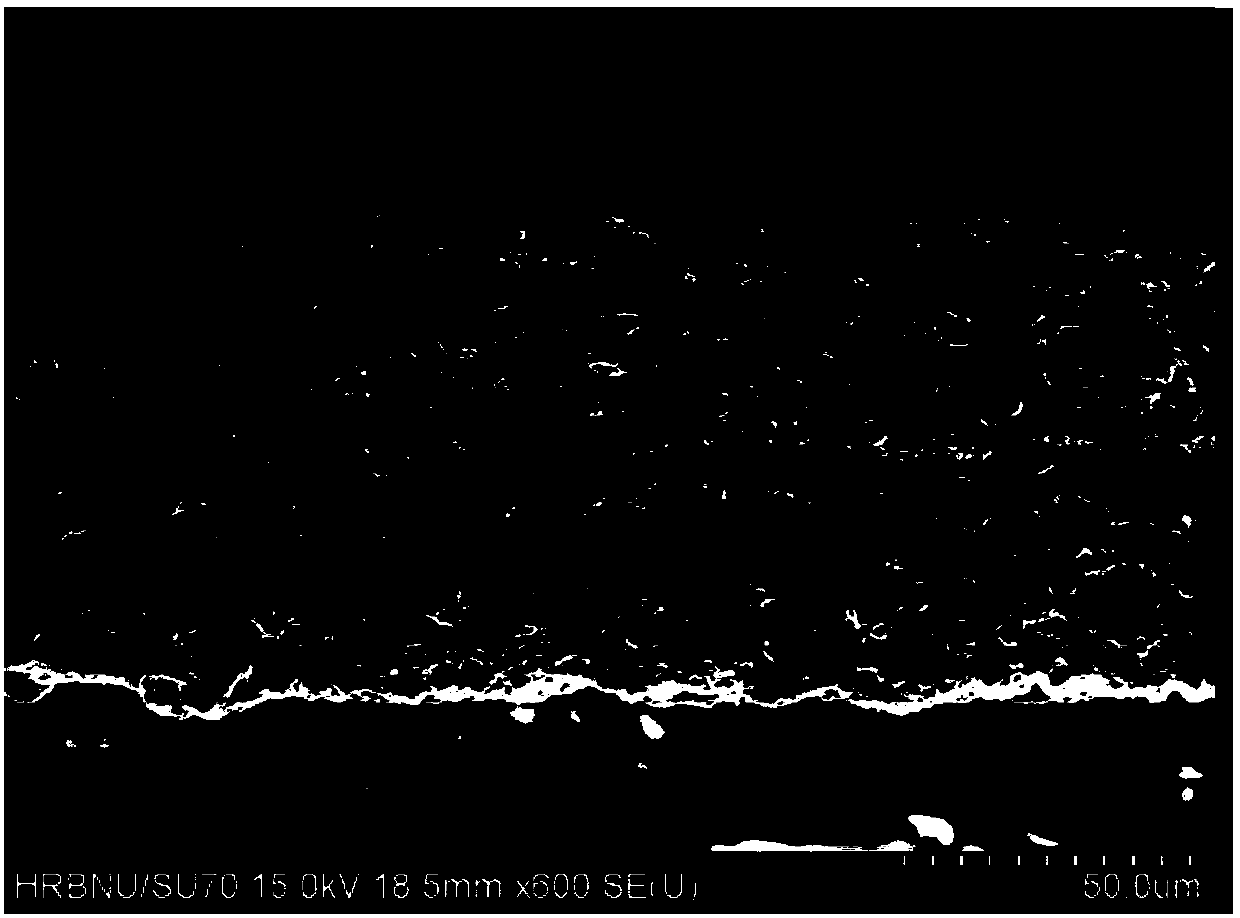

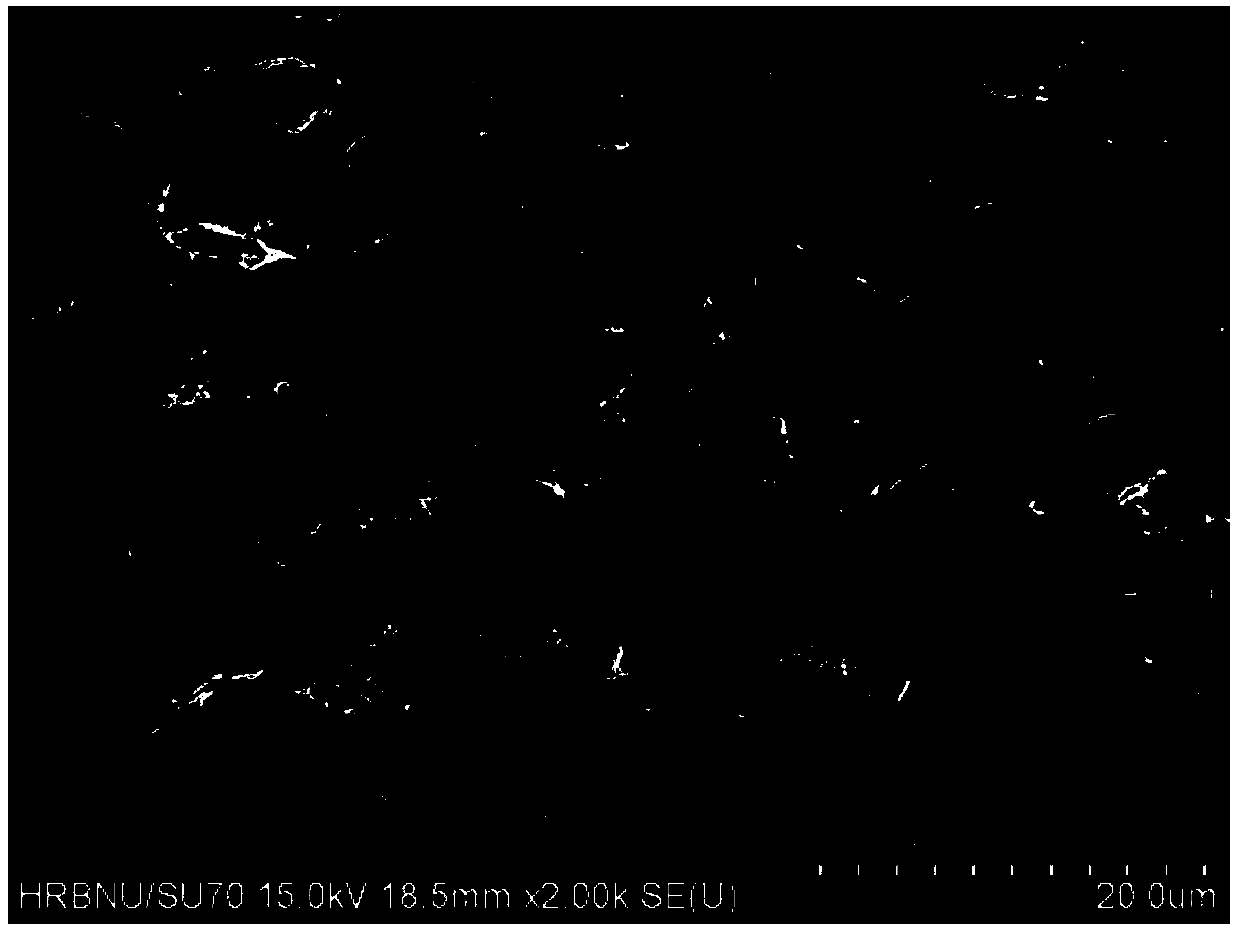

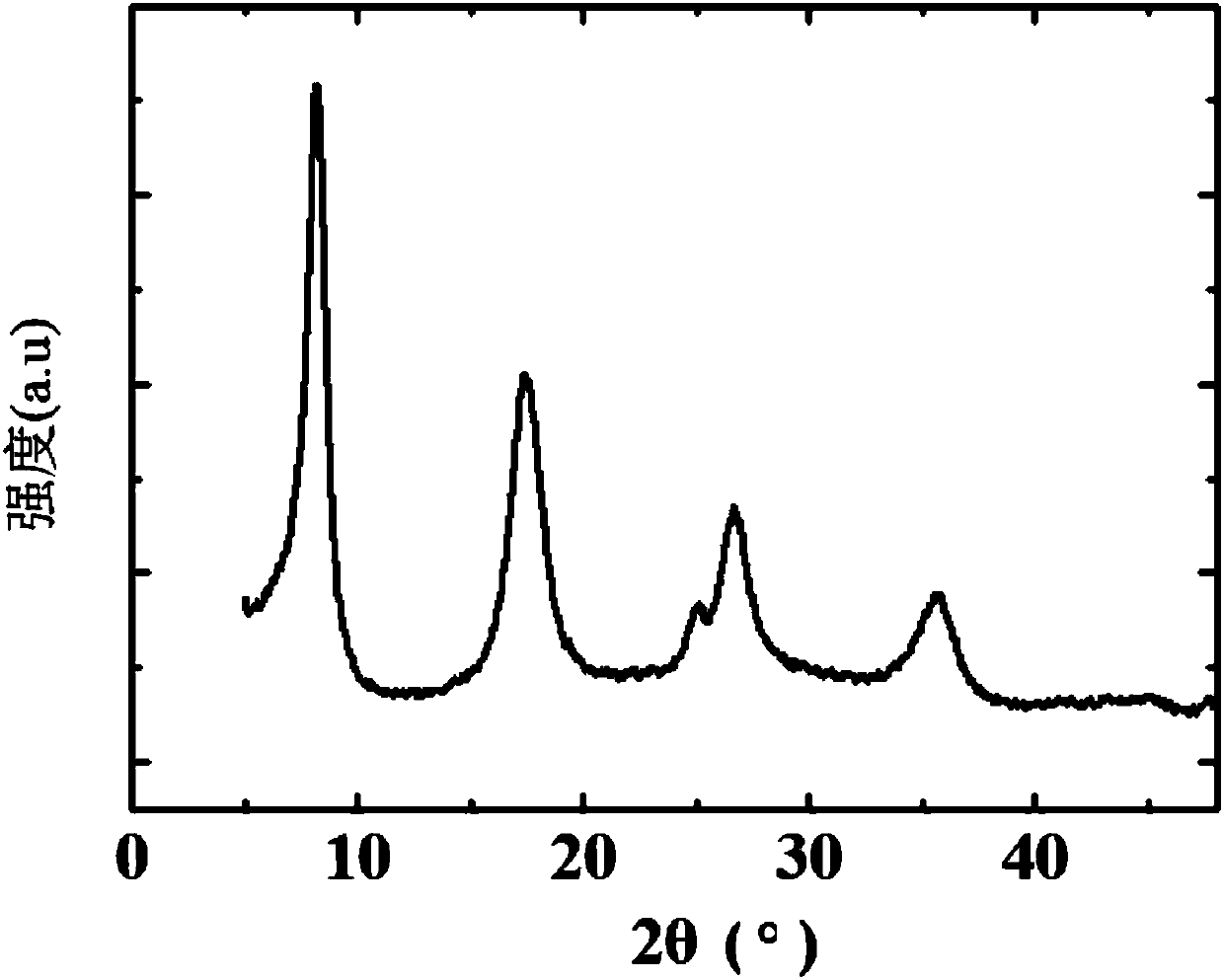

[0039] Specific implementation mode 1: This implementation mode is a preparation method of three-dimensional multi-size pore crystal titanium carbide, which is specifically completed according to the following steps:

[0040] 1. Preparation of two-dimensional layered titanium carbide nanosheets:

[0041] ①. Add lithium fluoride to hydrochloric acid with a concentration of 6mol / L-12mol / L, and then magnetically stir for 5min-10min at a stirring speed of 300r / min-500r / min to obtain solution A;

[0042] The volume ratio of the mass of lithium fluoride described in step 1. to concentration of hydrochloric acid of 6mol / L~12mol / L is (1g~3g):20mL;

[0043] ②. Add Ti to solution A in 3 to 15 times under the conditions of ice water bath and stirring speed of 200r / min to 1000r / min 3 AlC 2 powder, stirred to Ti 3 AlC 2 Disperse the powder evenly in solution A, then magnetically stir for 24h-72h at a temperature of 30°C-50°C and a stirring speed of 100r / min-500r / min to obtain solution ...

specific Embodiment approach 2

[0065] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass of lithium fluoride described in step one ① and the volume ratio of the hydrochloric acid that concentration is 6mol / L~12mol / L are (1g~1.5g ): 20mL. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0066] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass of lithium fluoride described in step 1. and the concentration are 6mol / L~12mol / L The volume ratio of hydrochloric acid is ( 1.5g~3g): 20mL. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com