Synthesis method of high-purity leuprorelin

A technology of leuprolide and solid-phase method, which is applied in the field of high-purity leuprolide synthesis, can solve the problems of large ether consumption, increased production cost, unfavorable industrial production, etc., and achieves reduced racemization side reactions and mild reaction , to avoid the effect of excessive reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of Fmoc-Pro-CTC resin

[0041] 1.1 Weigh 200g of CTC resin, add it to the reaction kettle, add 1500ml of DCM, make the resin fully swell in the DCM solvent, swell for 1h, and drain. If the reagent cannot completely soak the resin during the swelling process, additional reagent should be added as appropriate. Weigh 54.0g of Fmoc-Pro-OH, dissolve it with 700ml DCM, add 28ml DIEA and mix well, then add it into the reaction kettle, blow nitrogen gas from the bottom of the reaction kettle, and react for 120min.

[0042] 1.2 Head, prepare 800ml of methanol: DIEA:DCM (volume ratio 1:1:2) mixed solution; add it to the reaction kettle, and shake it with nitrogen for 20min. The reaction solution was drained and washed 4 times with DMF.

[0043] 1.3 The degree of substitution was measured by a spectrophotometer, and the degree of substitution was detected to be 0.51 mmol / g.

Embodiment 2

[0045] Preparation of Leuprolide Precursor Peptide-CTC Resin with Fully Protected Side Chains

[0046] Pyr-His(trt)-Trp(boc)-Ser(tbu)-Tyr(tbu)-D-Leu-Leu-Arg(pbf)-Pro-CTCResin

[0047] 2.1. Dipeptide connection

[0048] Deprotection: after the DMF washing is completed, add 700ml of 20% piperidine / DMF solution to the reactor (this value can be adjusted, it is advisable to fully mix the resin well, and react for 20min. The deprotection solution is drained, and the DMF is washed 8 times, 700ml each time. After washing, it can be detected by Kaiser reagent. If the value is reddish brown, it indicates that the deprotection is successful.

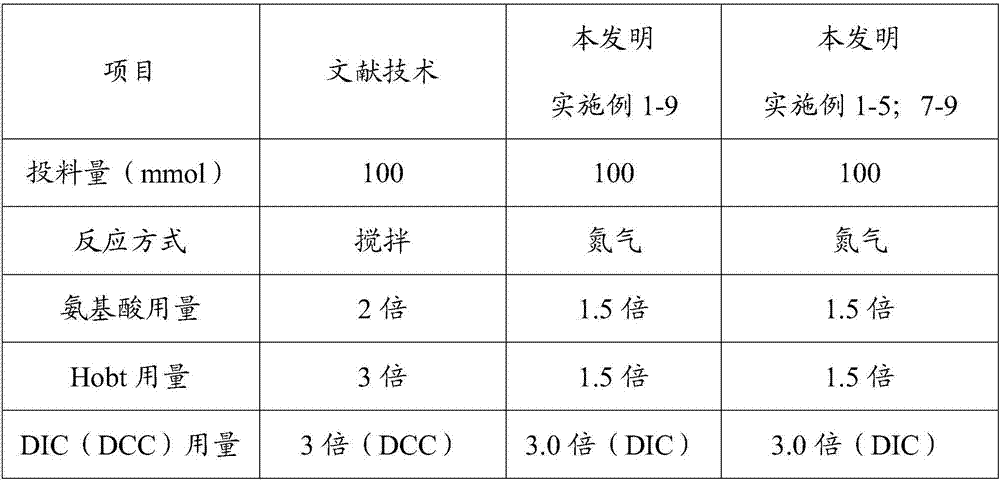

[0049] Peptide: Fmoc-Arg(pbf)-OH 97g(150mmol)

[0050] Hobt 20g (150mmol)

[0051] DIC 54ml (300mmol)

[0052] Put the weighed Fmoc-Arg(pbf)-OH and HOBT in a beaker, add DMF to dissolve them, then add DIC to the beaker for activation for 20 seconds, and mix well. Added to the reaction kettle and reacted for 60min. During the condensation pro...

Embodiment 3

[0097] Preparation of leuprolide precursor peptide with fully protected side chains:

[0098]Pyr-His(trt)-Trp(boc)-Ser(tbu)-Tyr(tbu)-D-Leu-Leu-Arg(pbf)-Pro-OH

[0099] Weigh the leuprolide precursor peptide-resin and add it to two 3L Erlenmeyer flasks. Prepare 20% trifluoroethanol / DCM solution according to 10ml of cutting reagent per gram of dry resin, after cooling in the refrigerator for 1 hour, add it into two reaction flasks respectively, shake at a speed of 100r / min, and react for 120min; Place in a rotary evaporator and evaporate to dryness under reduced pressure at 35°C to obtain 175.2 g of leuprolide precursor peptide, MS: 1889.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com