Application of porous cobaltosic oxide

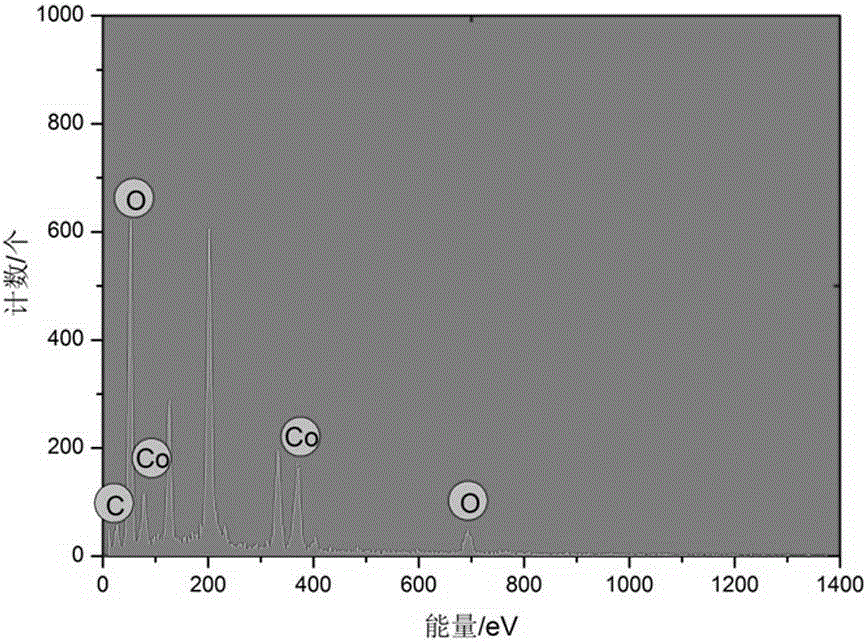

A technology of cobalt tetroxide and cobalt salts, applied in cobalt oxide/cobalt hydroxide and other directions, can solve the problems that the physical and chemical properties of cobalt tetroxide are greatly affected by morphology, size and structure, which is unfavorable to large-scale production and affects application performance, etc. Achieving the effect of abundant pores, reducing preparation cost, and being beneficial to enterprise production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

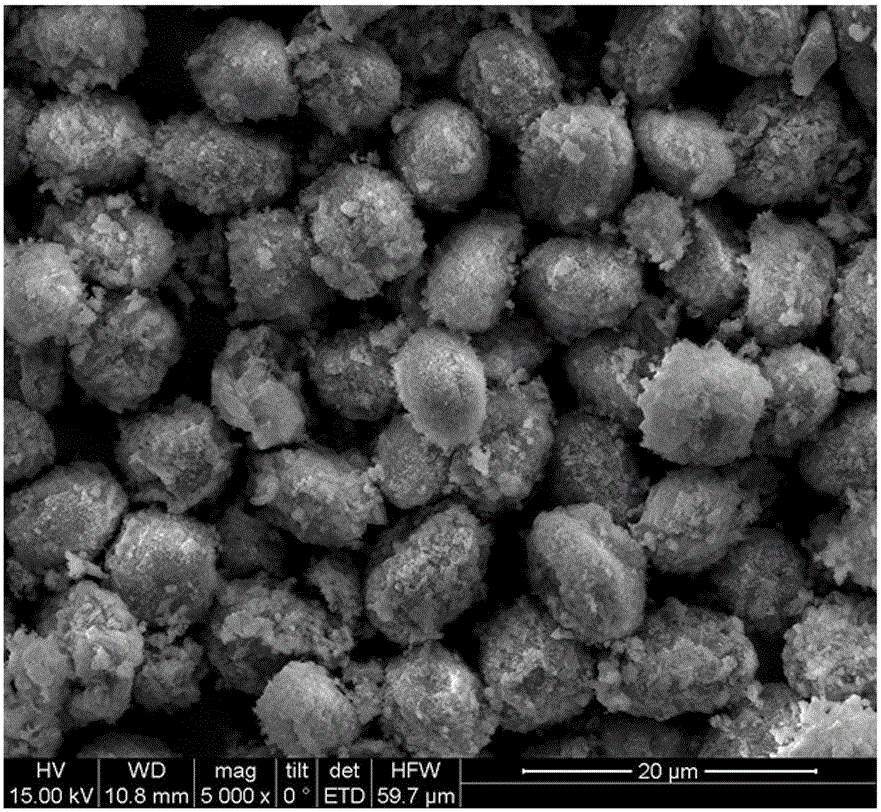

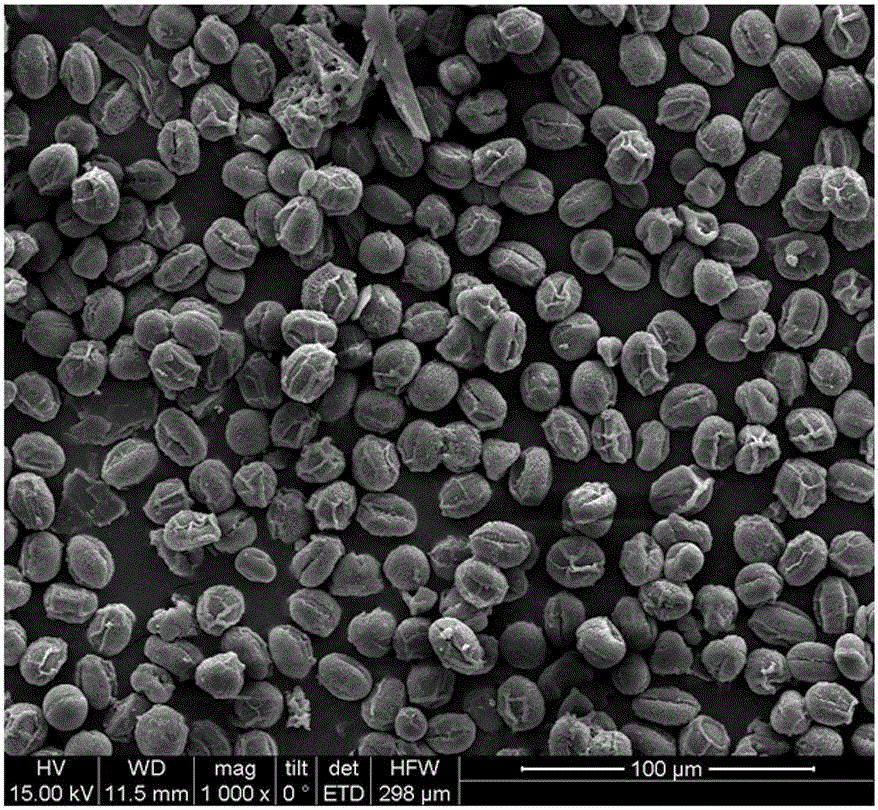

[0035]At room temperature, 5 g of porous rapeseed pollen was added to 50 mL of distilled water, stirred for 30 min, and ultrasonically dispersed for 5 to 30 min. After the above mixture was centrifuged, 50 mL of absolute ethanol was added, and the above steps were repeated three times to fully remove impurities on the surface. Then, the centrifuged product was dried in an oven at 30°C. At room temperature, take 1 g of pretreated pollen and add it to 10 mL of distilled water, then add 1 mmol of cobalt acetate, stir for 10 min, then ultrasonically shake for 3 min, then add 0.5 g of ethylenediamine, and mechanically stir for 10 min to obtain a mixed solution. At room temperature, 0.2 g of PVP was added to 20 mL of 2 mol / L NaOH aqueous solution, and stirred for 6 min. The stirred solution was slowly dropped into the mixed solution, and mechanically stirred for 10 min. The above mixed solution was heated to 65°C, then slowly dropped into 20 mL of hydrazine hydrate, and stirred fo...

Embodiment 2

[0039] At room temperature, 10 g of rapeseed pollen was added into 80 mL, stirred for 40 min, and ultrasonically dispersed for 20 min. After the above mixture was centrifuged, 40 mL of absolute ethanol was added, and the above steps were repeated 4 times to fully remove impurities on the surface. Then, the centrifuged product was dried in an oven at 45°C. At room temperature, take 2 g of pretreated pollen and add it to 30 mL of distilled water, then add 1.5 mmol of cobalt chloride hydrate, stir for 65 min, then ultrasonically shake for 3 min, then add 4 g of ethylenediamine, and mechanically stir for 18 min to obtain a mixed solution. At room temperature, 0.3 g of polyethylene glycol 400 was added to 30 mL of NaOH solution with a concentration of 3 mol / L, and stirred for 7 min. The stirred solution was slowly added dropwise to the mixed solution, and mechanically stirred for 40 min. The above mixed solution was heated to 70°C, then 25 mL of hydrazine hydrate was slowly added...

Embodiment 3

[0042] At room temperature, 15 g of rapeseed pollen was added to 80 mL of distilled water, stirred for 45 min, and ultrasonically dispersed for 25 min. After the above mixture was centrifuged, 100 mL of absolute ethanol was added, and the above steps were repeated 5 times to fully remove impurities on the surface. Then, the centrifuged product was dried in an oven at 60°C. At room temperature, 10 g of pretreated pollen was added to 65 mL of distilled water, then 2 mmol of cobalt sulfate hydrate was added, stirred for 25 min, then ultrasonically oscillated for 5 min, then 4 g of ethylenediamine was added, and mechanically stirred for 15 min to obtain a mixed solution. At room temperature, 0.5 g of PVP was added to 40 mL of NaOH solution with a concentration of 3 mol / L, and stirred for 7 min. The stirred solution was slowly dropped into the mixed solution, and mechanically stirred for 15 min. The above mixed solution was heated to 75°C, and then 35 mL of hydrazine hydrate was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com