Patents

Literature

61results about How to "Geometrically stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength ultrafine fiber simulation composite lether and its manufacturing method

The present ivnention relates to a high-strength ultrafine fibre imitation leather. It is made up by using sea-island ultrafine fibre base cloth through processes of impregnating with polyurethane, extracting treatment and after-finishing. The described base cloth is a double-layer or more than double-layer composite base cloth formed from sea-island composite fibre woven fabric and non-woven fabric which are combined together by means of needling process or cohesive process, then said invention makes the composite base cloth undergo the processes of impregnating with polyurethane, hardening, extracting 'sea' component in the solvent capable of removing 'sea' component from sea-island fibre to obtain semifinished product, widening forming, mellowing, dyeing, grinding or sticking film so as to obtain the invented product.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

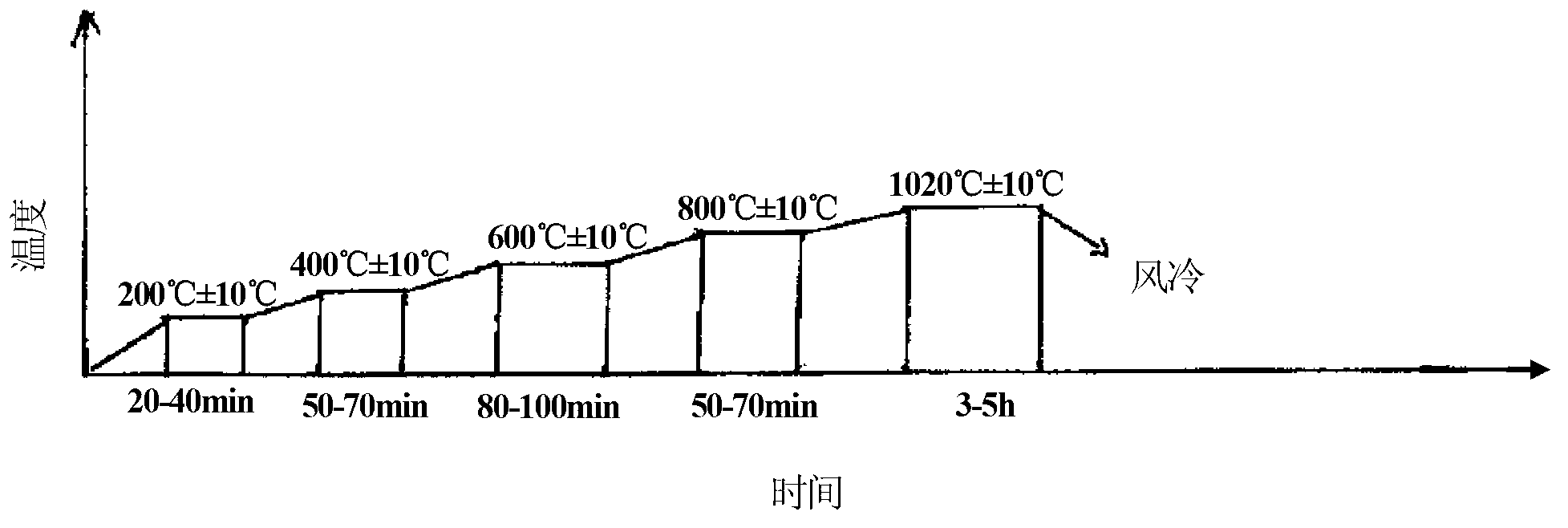

Steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents

ActiveCN102363286AImprove the speed of useExtended service lifeAbrasion apparatusCeramic compositeTissue density

The invention relates to a steel blank grinding abrasion wheel adopting microcrystal ceramic bonding agents, which is in a structure made of polycrystalline solid materials with the coexistence of glass and crystals and adopts the bonding agents of clay, feldspar, boron-containing microcrystal glass, pyrophyllite and soapstone to be made into high-intensity and low-shrinkage engineering ceramic bonding agents, good performance of the glass and the ceramics such as high mechnical intensity, wear resistance, corrosion resistance and the like are integrated, then, the glass and the ceramics are combined with mixed grinding materials, a molding pressing method is adopted for the high-pressure double-side pressing process forming, the low-temperature firing is adopted, the positive pressure reducing atmosphere heat simulation crystallization is adopted at the 800 DEG C heat insulation section, and the mixed grinding material and micro porous glass phase high-intensity microcrystal engineering ceramic composite structure is formed, so the intensity and the bonding degree of the steel blank grinding abrasion wheel are greatly improved, the use linear speed of the abrasion wheel is accelerated, and the safety factor is high. The steel blank grinding abrasion wheel belongs to the novel efficient special steel blank grinding abrasion wheel with the characteristics that the intensity andthe hardness are high, the tissue density is uniform, the grinding ratio is great under the condition of high-speed grinding, workpieces can not be damaged through firing, and the automation of iron and steel industries is easy to realize.

Owner:江苏华东砂轮有限公司

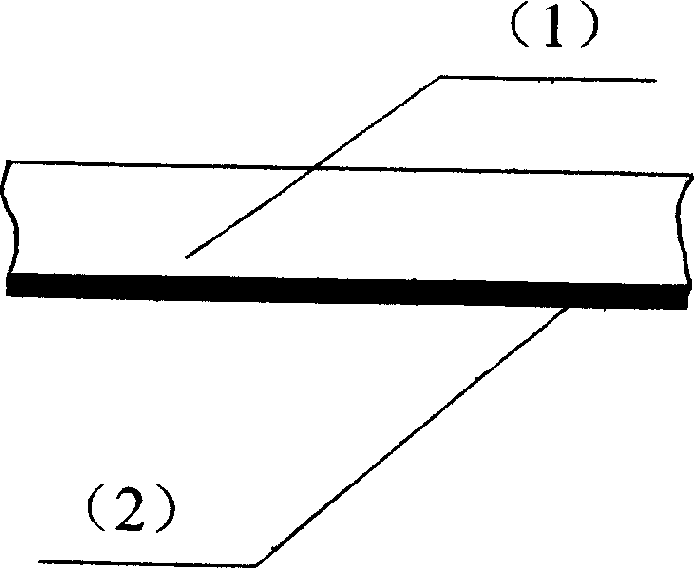

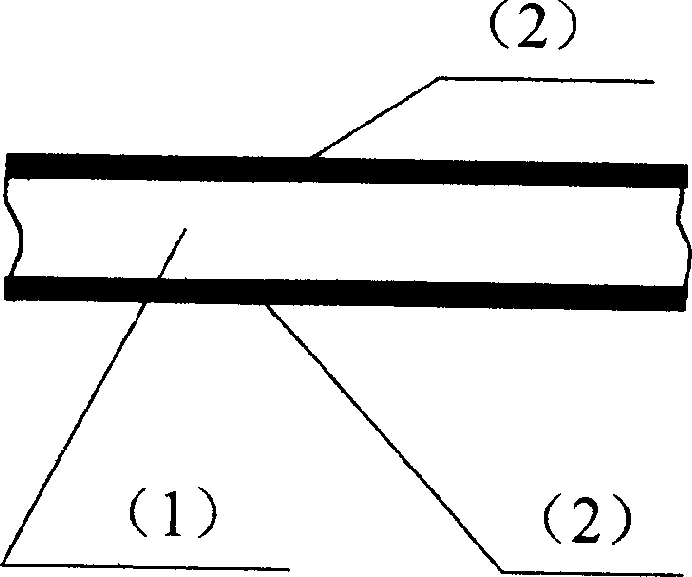

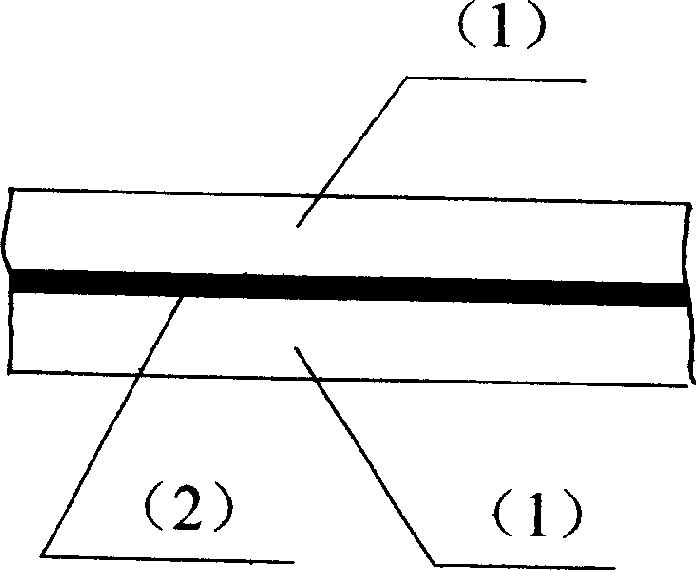

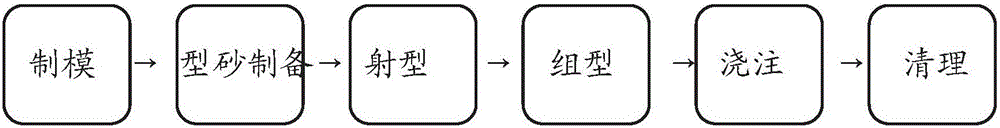

Method for casting large-scale box type castings through precoated sand shell mold

InactiveCN106001453AGood quality instant noodlesSand core surface quality is goodFoundry mouldsMoulding machinesSurface finishSand casting

The invention belongs to the technical field of coated sand casting technology, in particular to a method for casting large-scale box castings with coated sand shell molds. Including mold making, molding sand preparation, core mold making, and core mold combination: After the shell molds and shell cores are combined according to the process card or drawing, the sand box is placed on the outside, the gating system is drawn out, and the gate and the gate are wrapped with plastic film. Riser, then between the shell mold and the sand box, add clay sand layer by layer and solidify, and finally lock the upper and lower boxes; pouring molding and cleaning. The invention has high casting precision, high yield and good surface finish, and is suitable for larger castings.

Owner:东港市永盛铸造有限公司

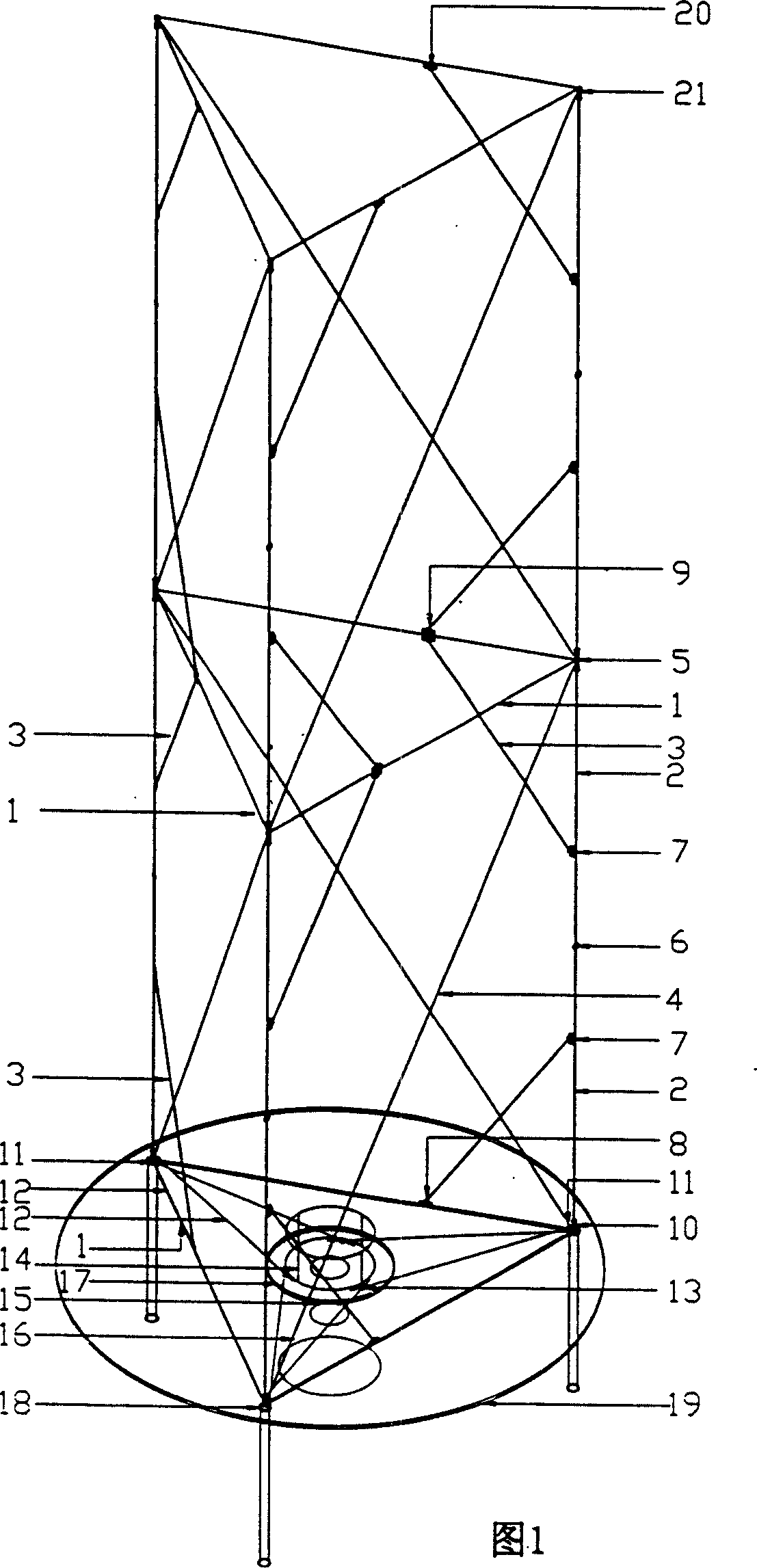

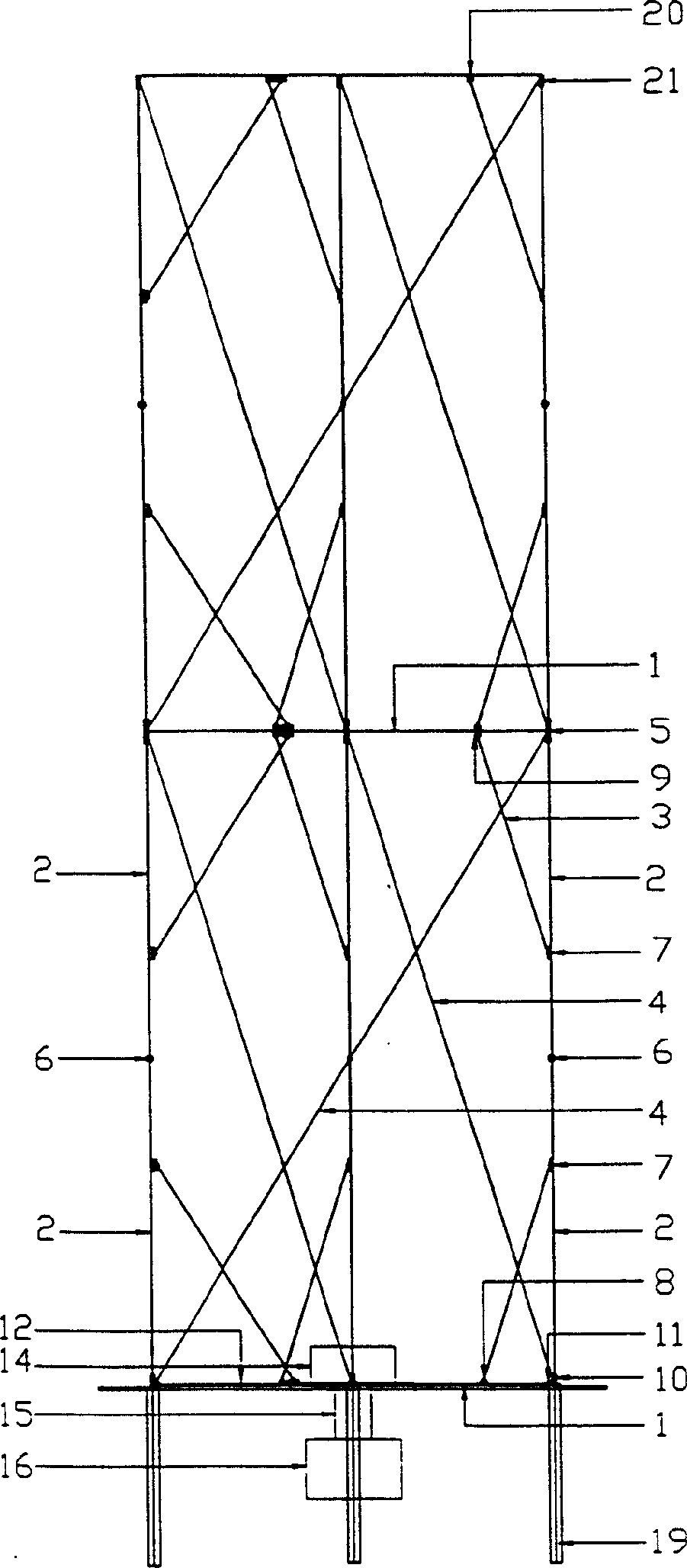

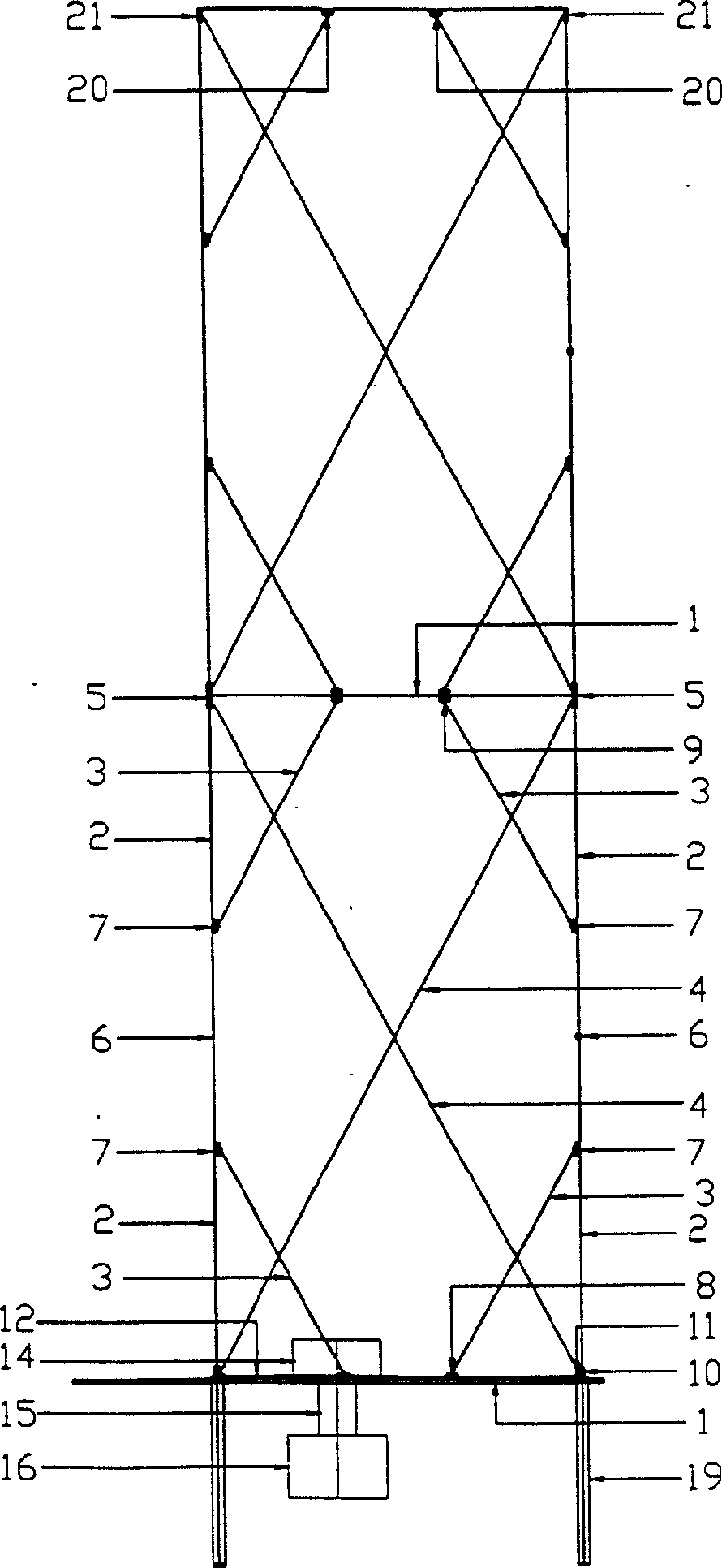

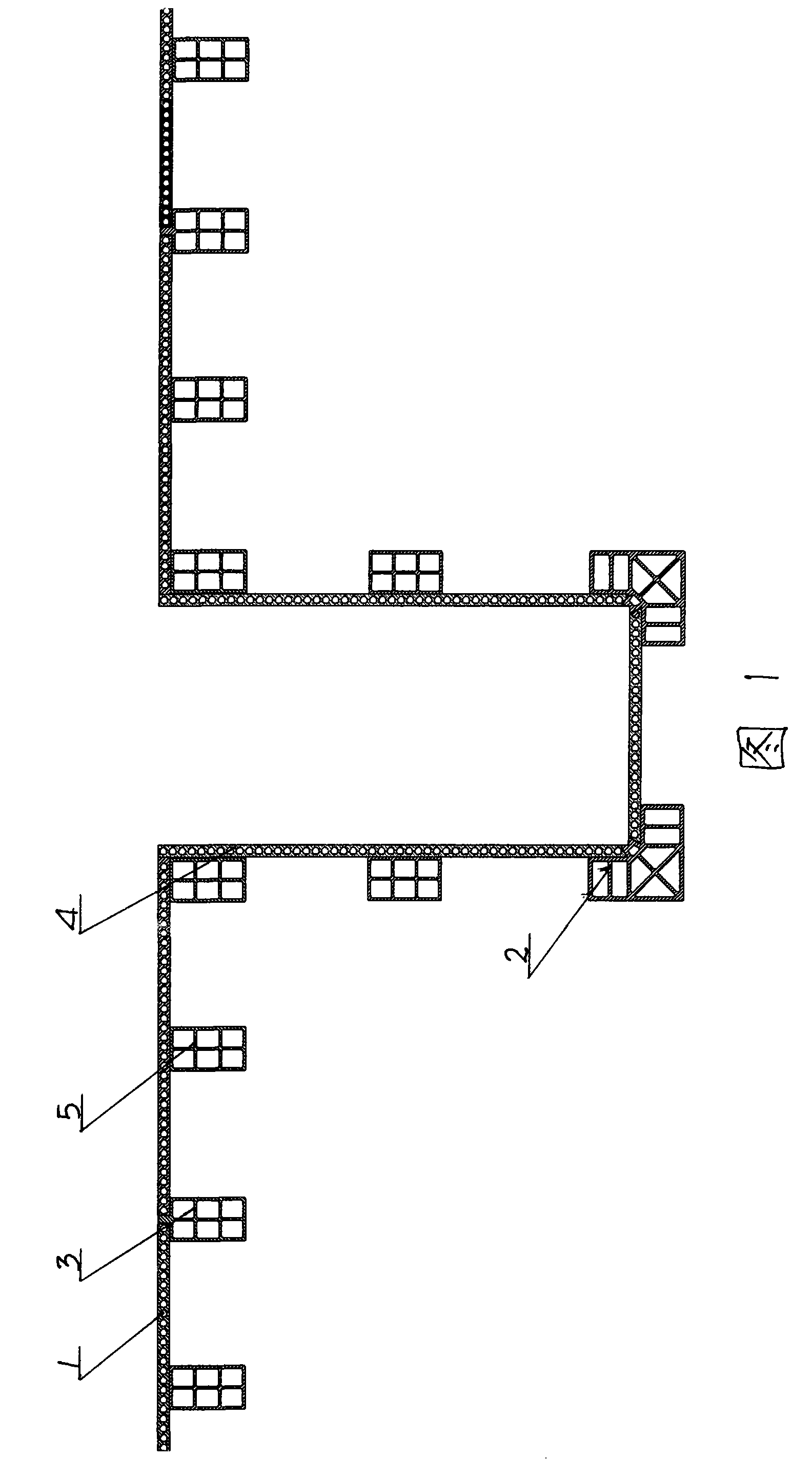

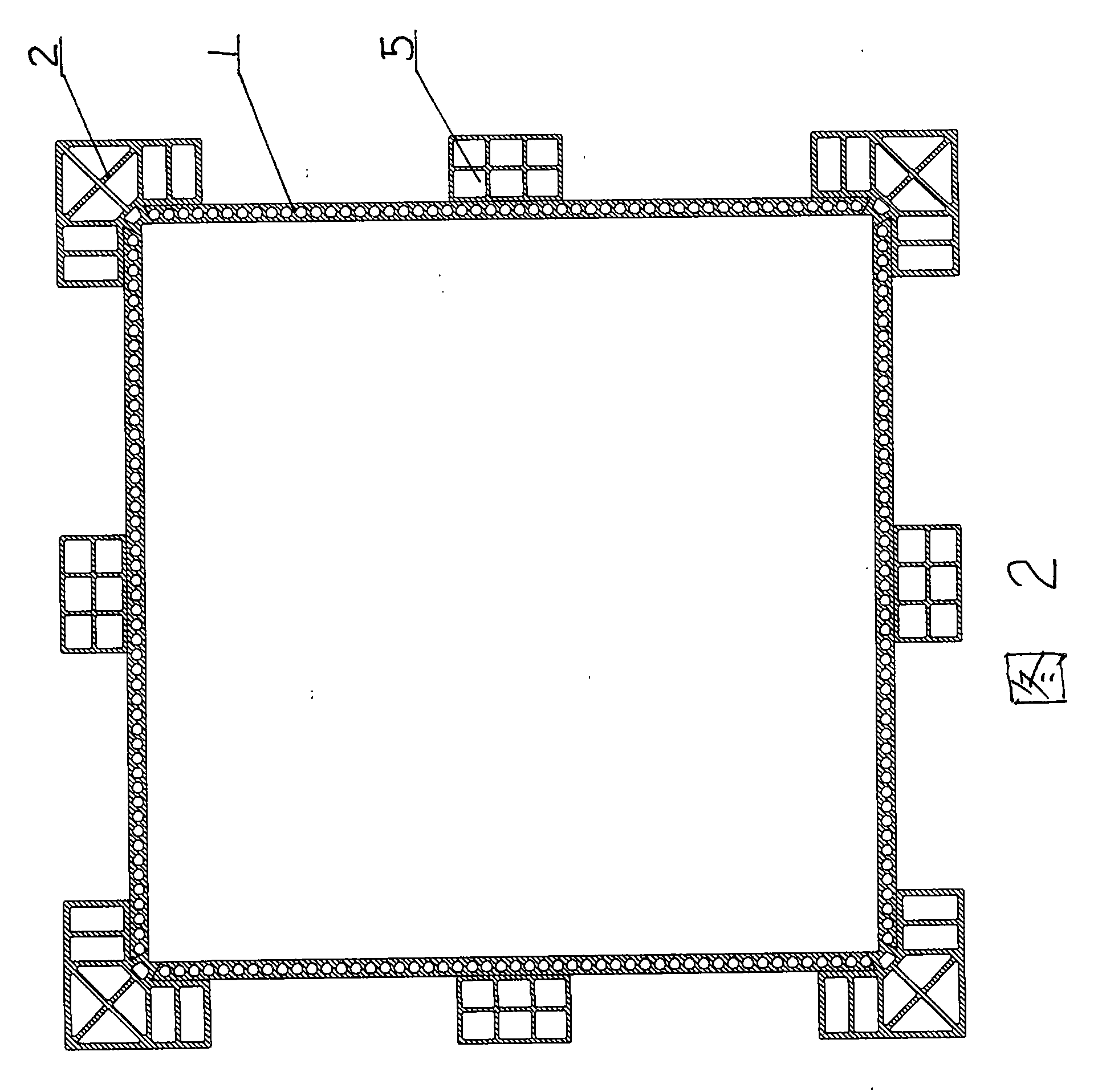

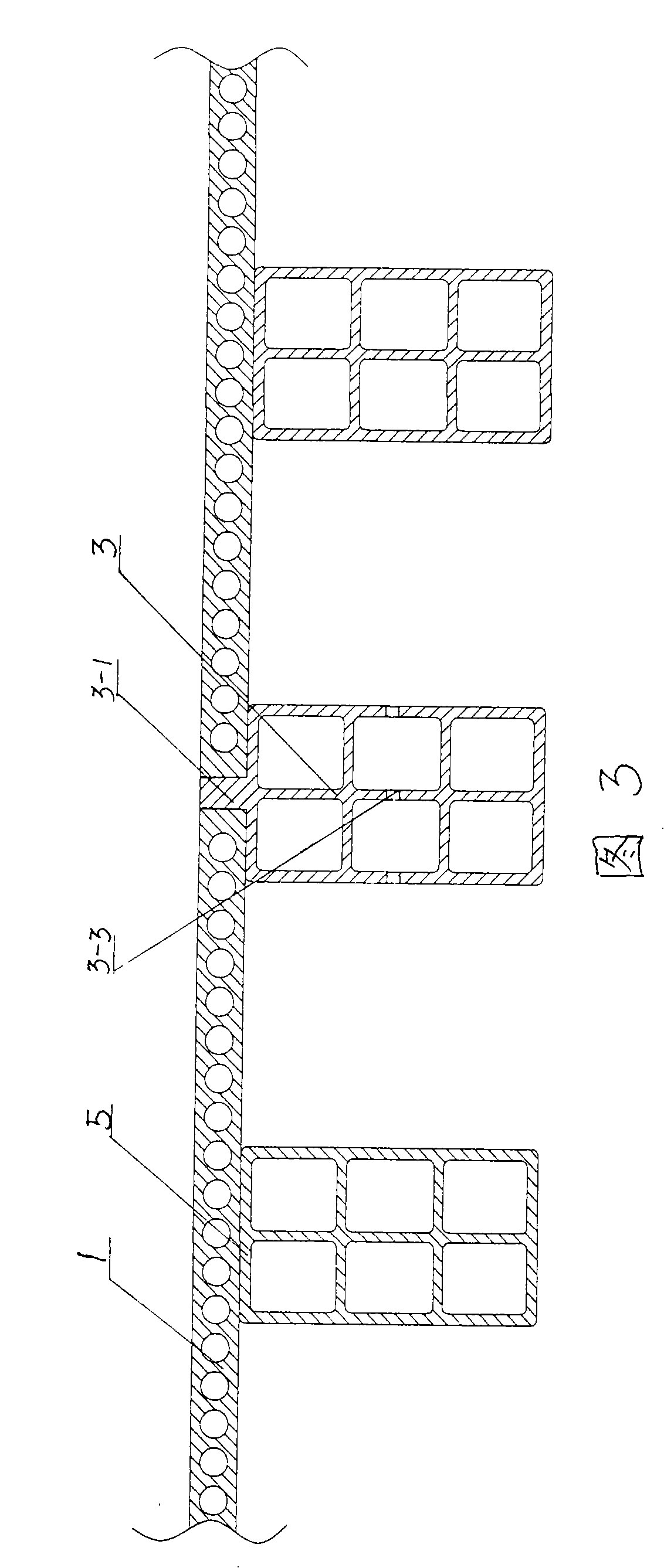

Spherical reticulated shell composed of connected quadrilateral-planed six-rod tetrahedron units

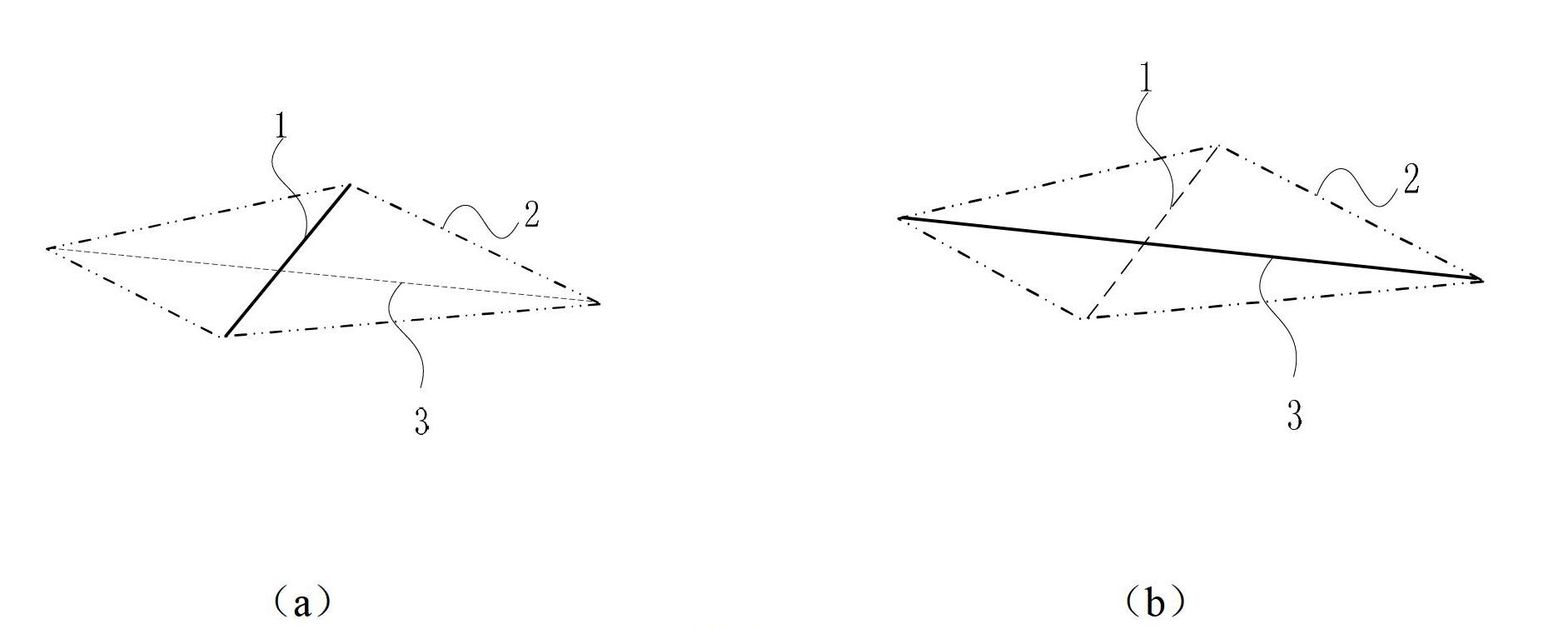

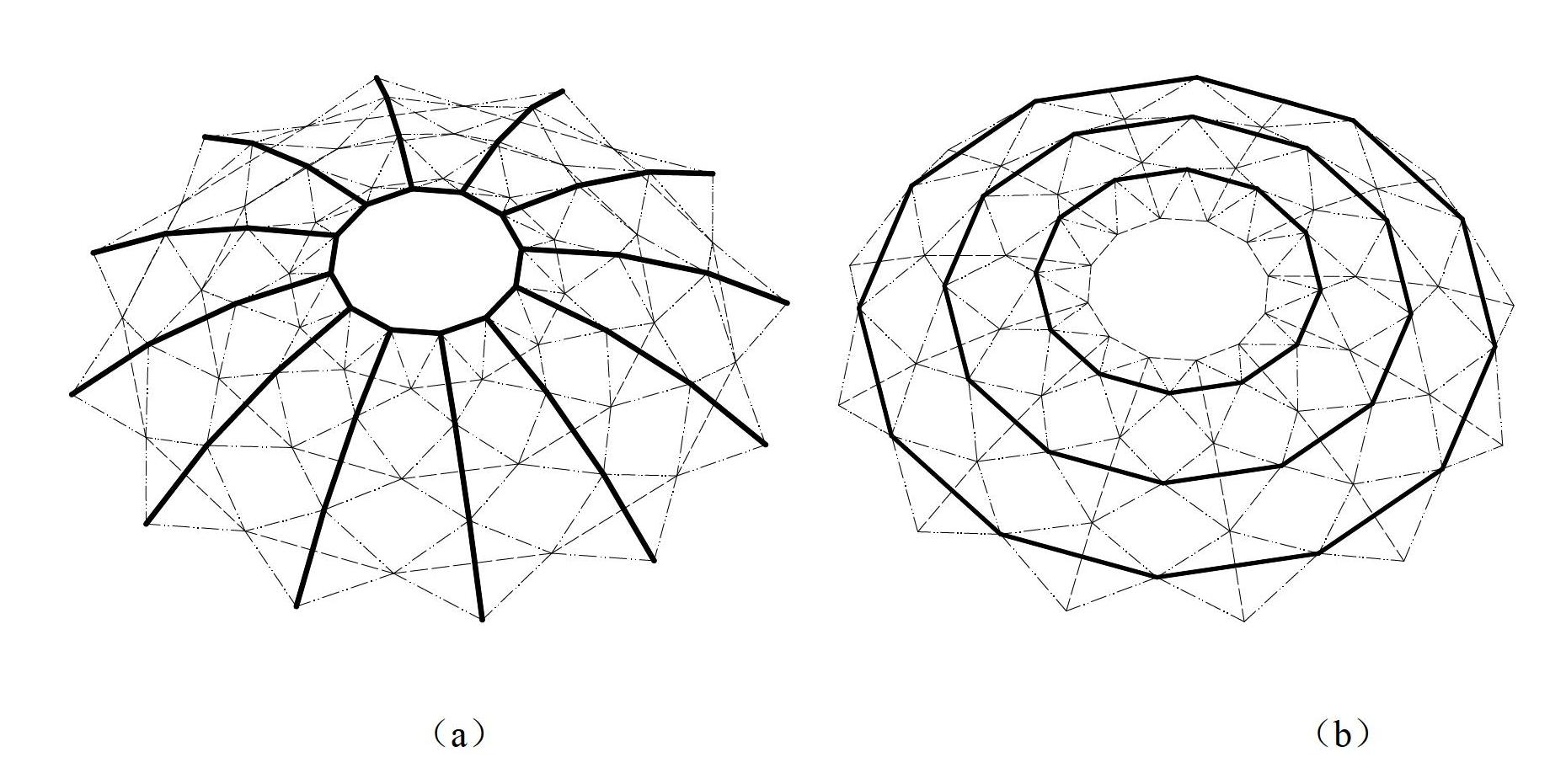

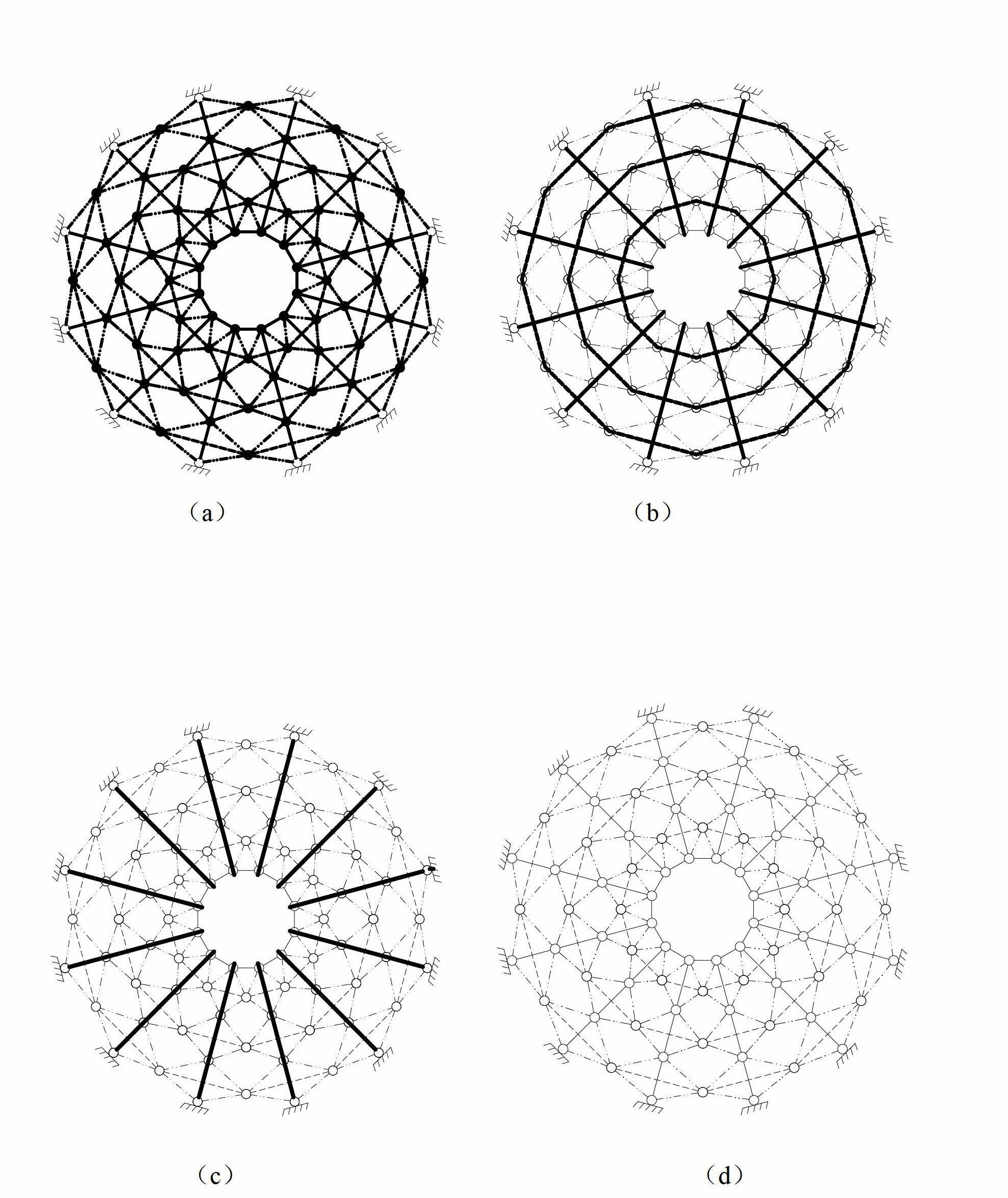

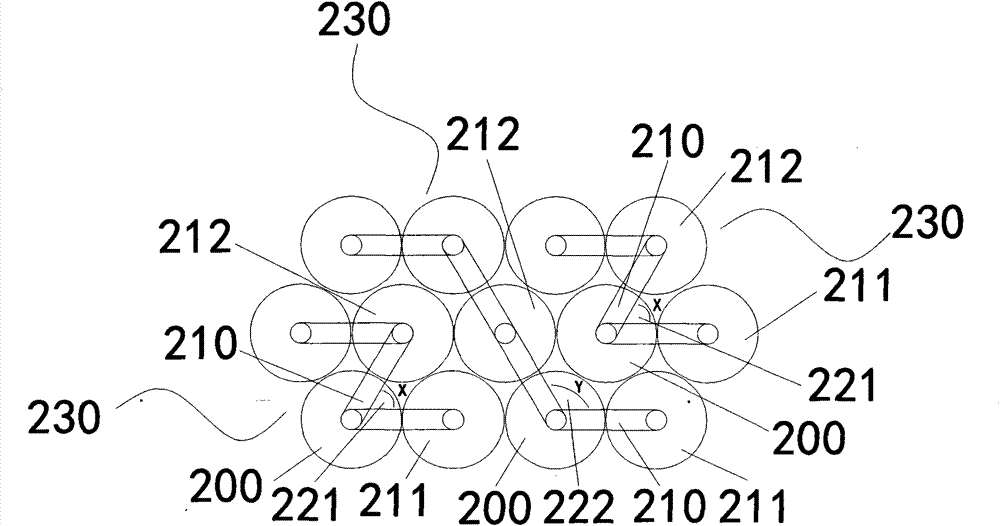

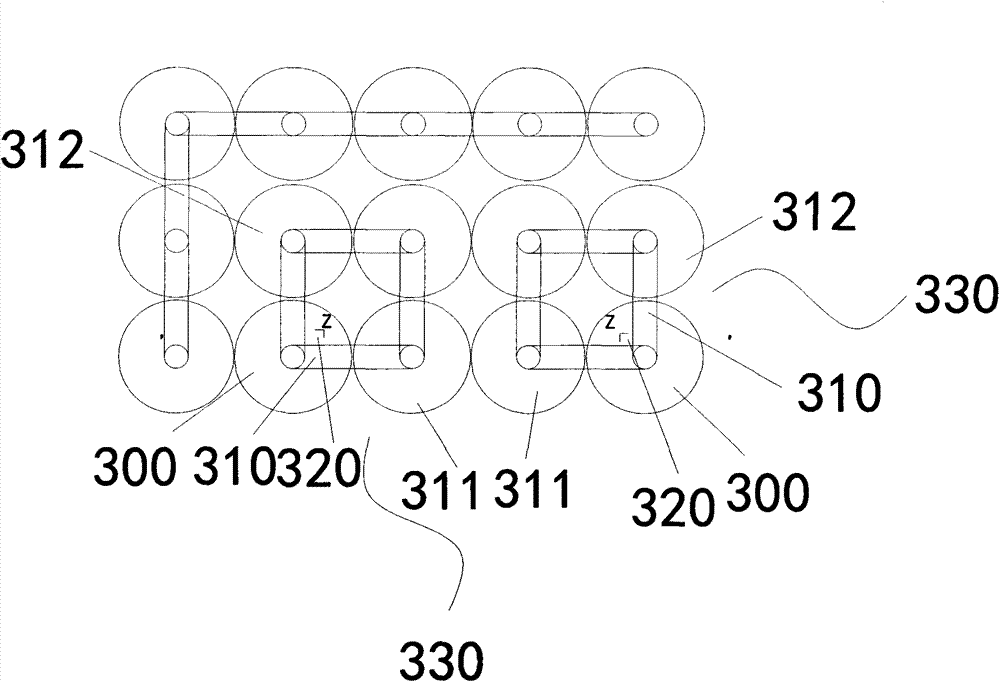

ActiveCN102619281ASimple architectural shapeBeautiful buildingArched structuresVaulted structuresEngineeringTetrahedron

The invention discloses a spherical reticulated shell composed of connected quadrilateral-planed six-rod tetrahedron units. In the structure of the prior art, the number of node concurrent rod pieces is large, which leads the installation and the construction to be difficult. The quadrilateral-planed six-rod tetrahedron unit comprises an upper chord, a lower chord and four web members. The upper chord and the lower chord are in space quadrature arrangement at the center of the rod pieces; the four web members are respectively connected with the upper chord and the lower chord; the spherical reticulated shell is formed by radially and toroidally extending quadrilateral-planed six-rod tetrahedron unit along the open-mouthed spherical shell; among the basic units, the nodes of the upper chords are connected and the nodes of the lower chords are connected; when the quadrilateral-planed six-rod tetrahedron units radially extend, the radial rod pieces of each unit are the same in length, the toroidal rod pieces of each unit have linear variation in length, and a circle of rod pieces are added in the inner ring of the structure from the opening edge to the bottom edge of the shell body. The spherical reticulated shell has stable structure, fewer node concurrent rod pieces and simple and beautiful shape.

Owner:ZHEJIANG UNIV

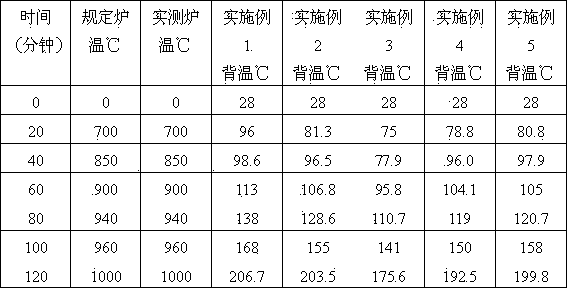

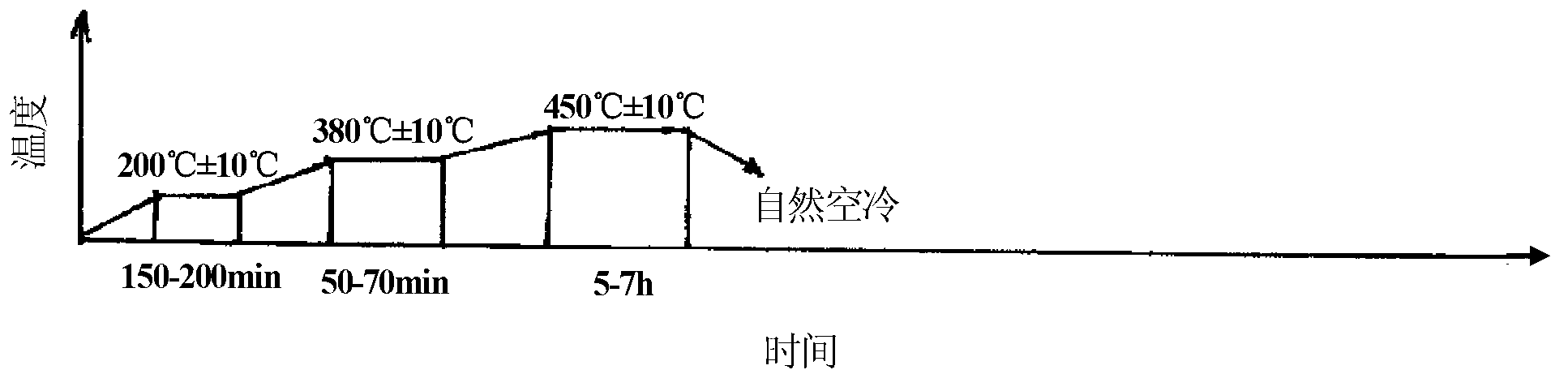

Cast iron material for cylinder sleeve, cylinder sleeve and preparation method thereof

ActiveCN109706381AHigh tensile strengthHigh hardnessFurnace typesProcess efficiency improvementRoom temperatureAlloy

The invention belongs to the technical field of engine cylinder sleeves, and particularly relates to a cast iron material for a cylinder sleeve, the cylinder sleeve and a preparation method thereof. The cast iron material for the cylinder sleeve is prepared the following components in percentage by weight: 2.7-3.2% of C, 1.8-2.3% of Si, 2.0-2.5% of Mn, 0.1-0.3% of Mo, 0.1-0.3% of Nb, smaller thanor equal to 0.1% of P, smaller than or equal to 0.1% of S and the balance of Fe. According to the cast iron material for the cylinder sleeve, only a small amount of noble elements of Mo and Nb are added, the total weight of the Mo and the Nb is no more than 0.5%, the type of alloy is few, and the content of the alloy is low. The strength of extension at room temperature of the cylinder sleeve madeof the cast iron material for the cylinder sleeve reaches up to about 470 MPa, and the strength level is much stronger than the higher level of an existing pearlite-based gray cast iron cylinder sleeve.

Owner:HENAN UNIV OF SCI & TECH

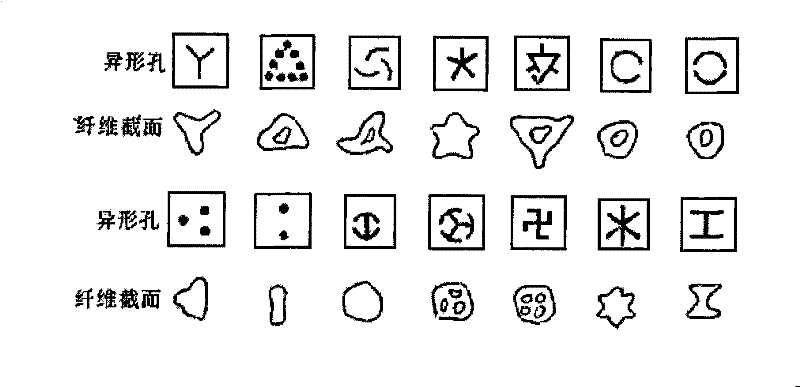

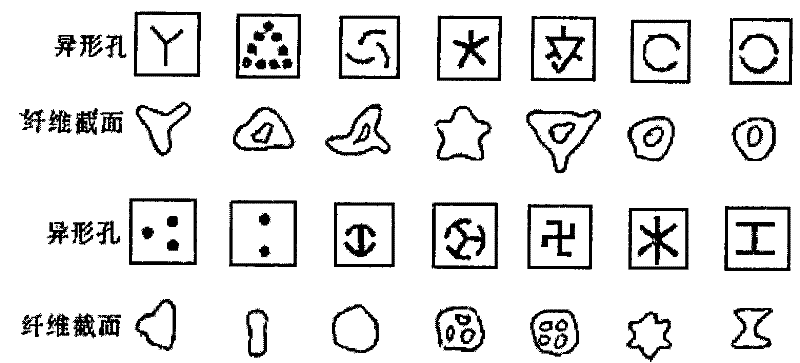

Colored special-shaped size-stabilized type polyester monofilament and preparation method thereof

InactiveCN104532388AImprove heat resistanceGood dimensional stabilityArtificial thread manufacturing machinesFilament/thread formingPolyesterPolyethylene terephthalate glycol

The invention relates to a colored special-shaped size-stabilized type polyester monofilament and a preparation method thereof. The colored special-shaped size-stabilized type polyester monofilament is composed of, by weight, 84.5 parts to 99.75 parts of polyethylene terephthalate (PET), 0.2 part to 5 parts of color master batches, 0.1 part to 10 parts of poly(ethylene 2,6-naphthalate) (PEN) and 0.05 part to 1 part of barium sulfate powder. By adding the PEN, the thermal resistance of fiber is improved, and no roller sticking phenomenon can occur even when the heat setting temperature is above 245 DEG C; nanometer barium sulfate plays a role of plasticizer, the slippage among high polymers is improved, the drawing ratio is increased, the fiber contraction rate is decreased, and meanwhile the colored fiber can be more uniform and brighter in color and luster; the high drawing ratio is achieved in the fiber drawing process, induced crystallization produced in the fiber drawing process is improved, and the boiling water shrinkage is decreased; the fiber preparing process is simple, dry strands are uniform, fiber is uniform in thickness, woven fabric is smooth, grids are exquisite and uniform, and a colored special-shaped filament is softer and richer in color so that stylized reflection can be facilitated.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD +1

Leadless radiation protection barium plate and method for producing the same

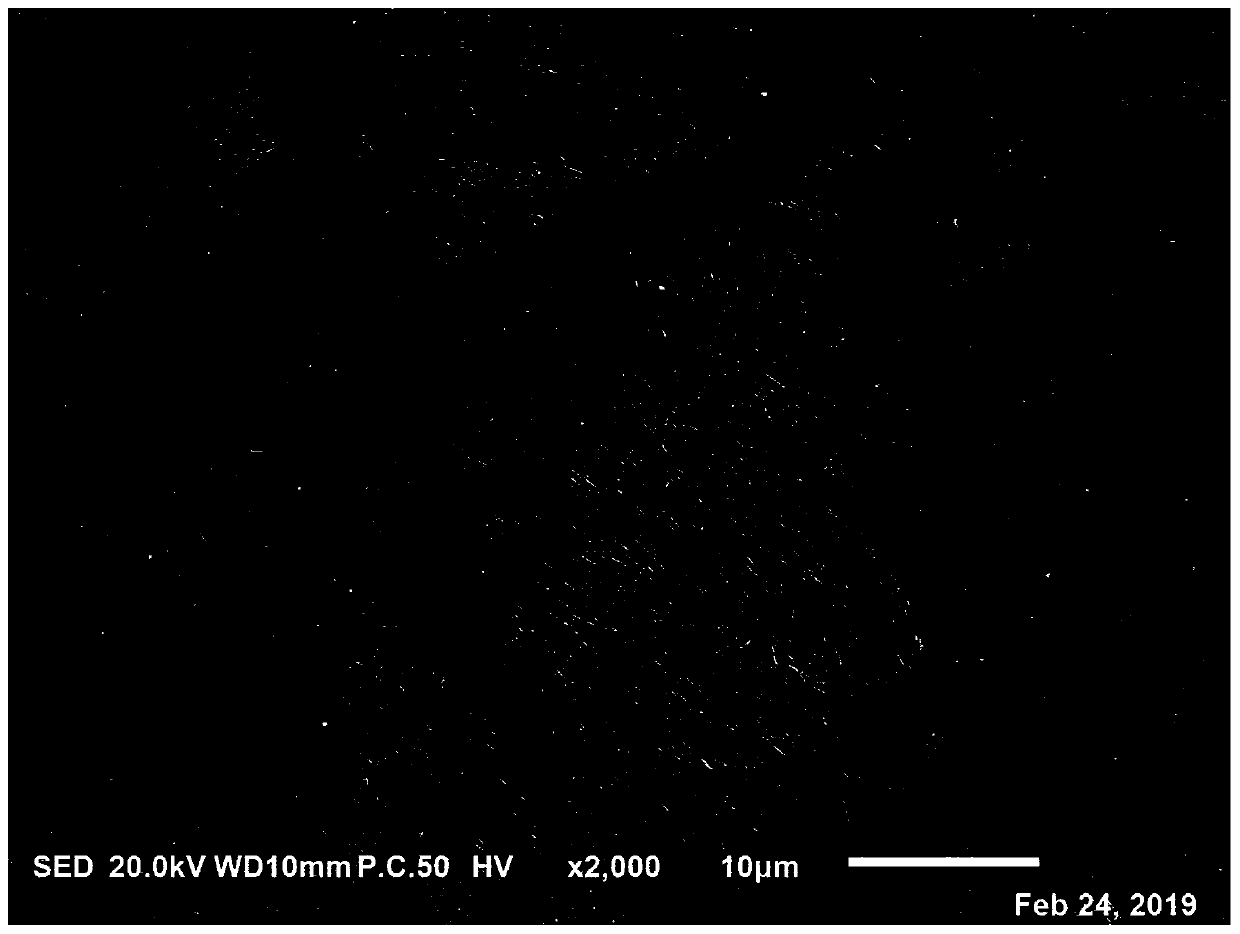

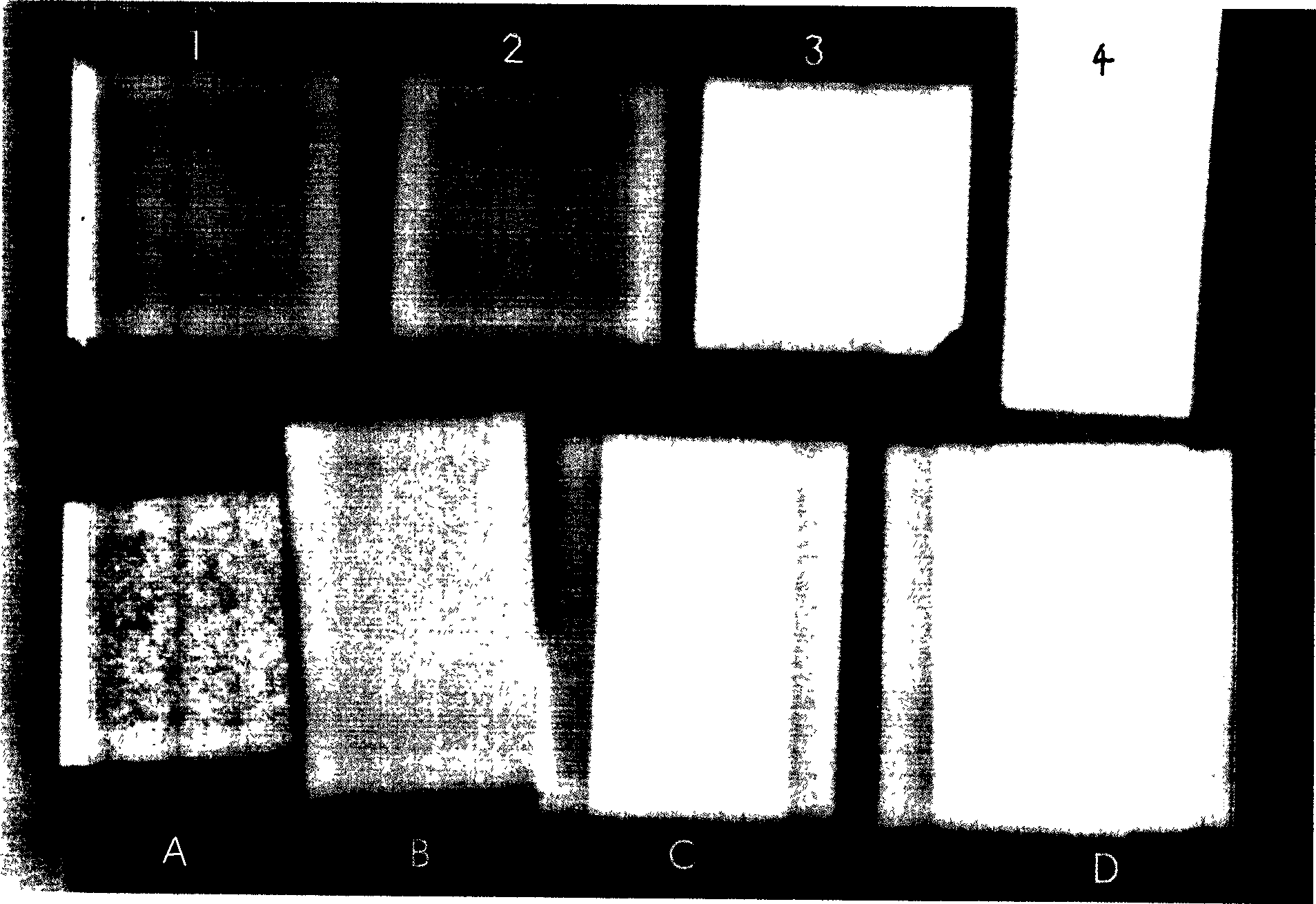

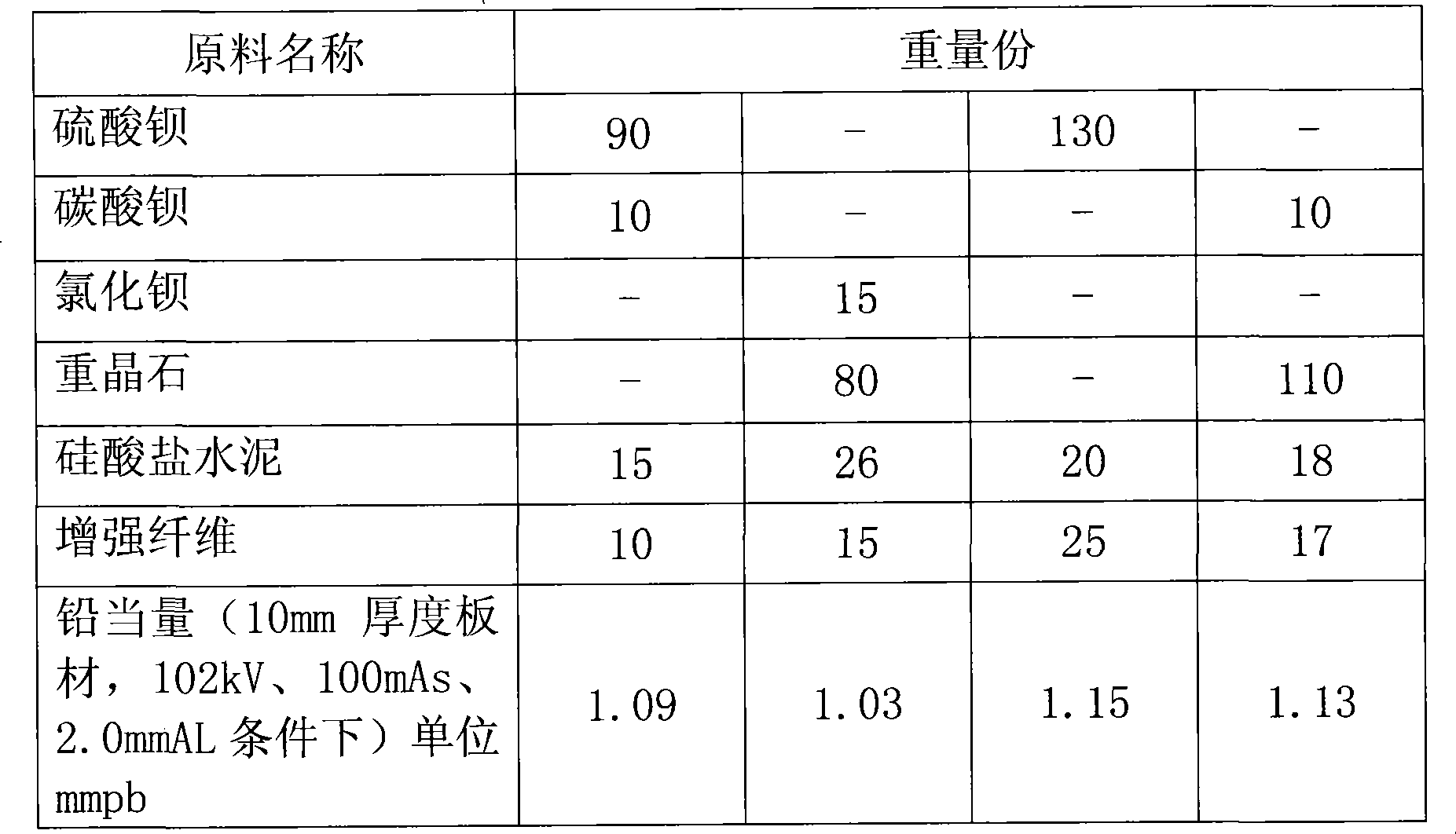

The invention relates to a radiation protection material in the ionizing radiation protection field, and a production method thereof, in particular to a lead-free radiation protection barium board and a production method thereof. The lead-free radiation protection barium board adopts raw materials which are barium salt with the granularity of 300-500 meshes, portland cement and reinforcing fiber, and comprises the following components (part by weight): barium salt: 80-130, portland cement: 15-35 and reinforcing fiber: 5-28. The raw materials are made into mixed slurry and then made into boards with the thickness of 6mm-12mm on a cylinder extrusion machine, and multilayer boards are superposed and pressurized on a punch press of 2500T for 30-70 minutes for molding; the boards are treated with high-temperature steaming for 10-26 hours at 60-120 degrees, and then the lead-free radiation protection barium board is obtained after sanding. The product has stable protection performance, no lead or lead compounds contained in the raw materials, safety and harmlessness, fire prevention, moisture-proof performance, high-temperature resistance, stable geometric dimension, mechanization batch production, low cost with the price of only 1 / 3 of that of the lead plates with the same thickness, and simple production method.

Owner:JINAN DAHUA YITE ENVIRONMENTAL PROTECTION ENG

Modified polyphenyl composite insulation board and production technique thereof

InactiveCN101200919AShape stableGeometrically stableClimate change adaptationSynthetic resin layered productsCalcium silicateGlass fiber

The present invention relates to the technical field of energy-saving, environment-friendly building materials, in particular to a modified polyphenyl composite thermal insulation board and a production technique thereof. The present invention also relates to the fabrication method of the thermal insulation board material, the thermal insulation board material includes six layers: the first layer is polymer mortar, the second layer is fiber glass mesh cloth, the third layer is a modified polyphenyl board, the fourth layer is polymer adhesive emulsion, the fifth layer is a calcium silicate board and the sixth layer is coating, and with a novel production technique, the six layers are compounded together to form the thermal insulation board material. Because the modified polyphenyl board is added with 5 percent to 10 percent of rare earth material, diatomite, and an aluminium plate is embedded in the middle, the properties of the product, such as ageing resistance, crack resistance, etc., are increased, and meanwhile, the service life of the product is prolonged by over one time.

Owner:朱玉华

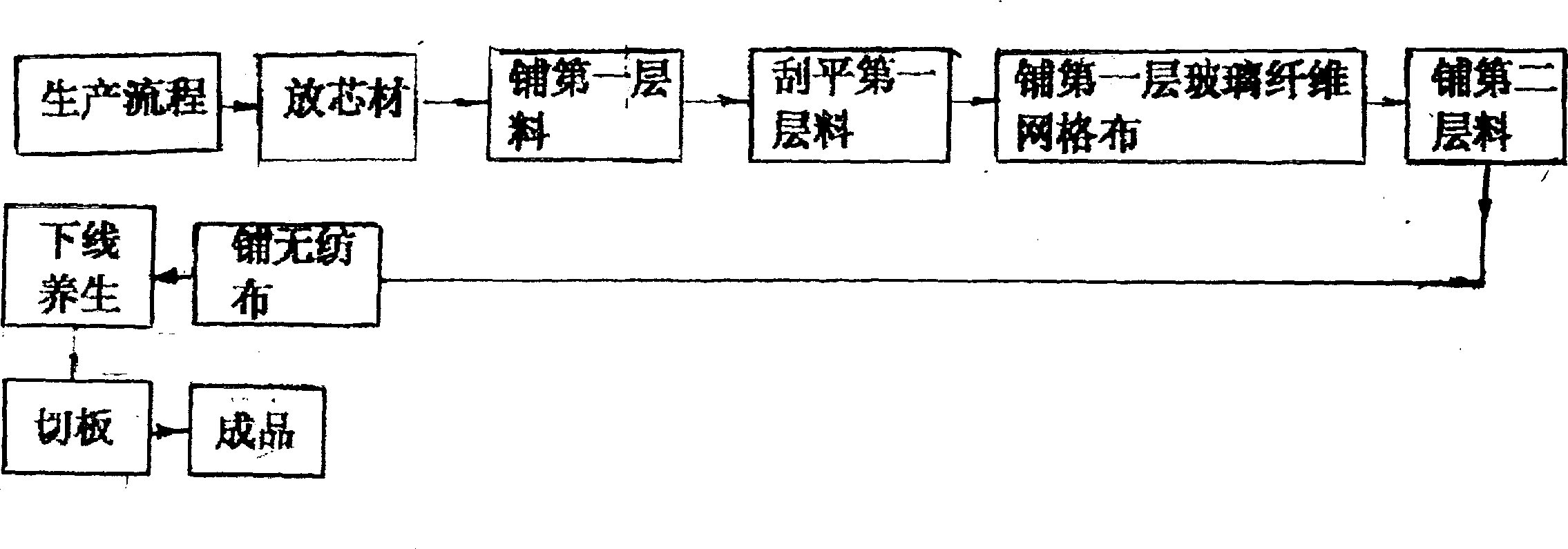

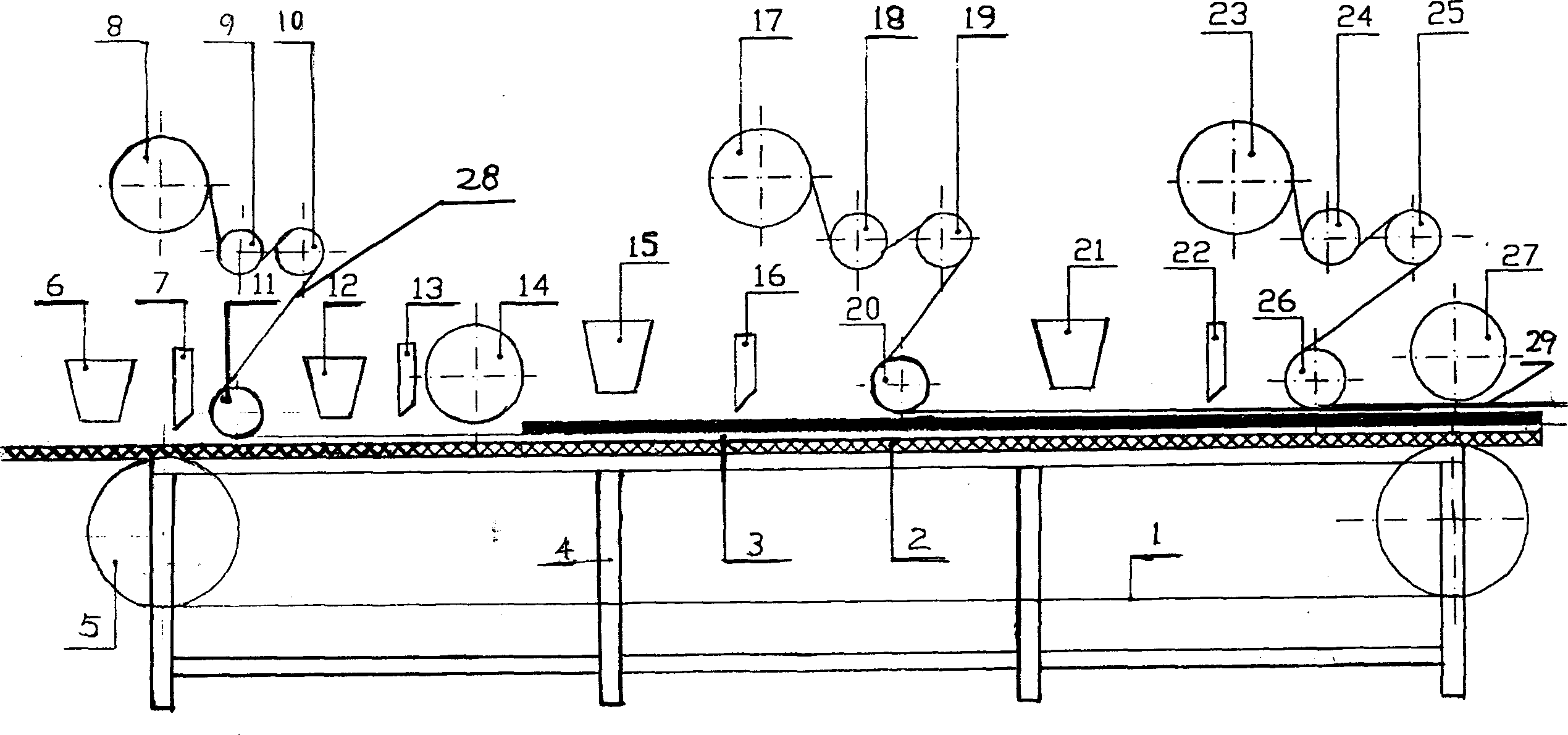

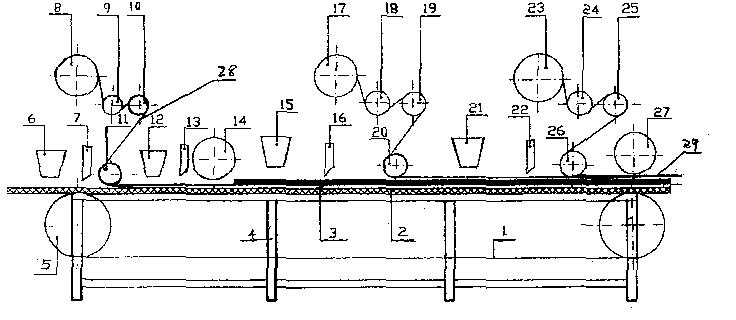

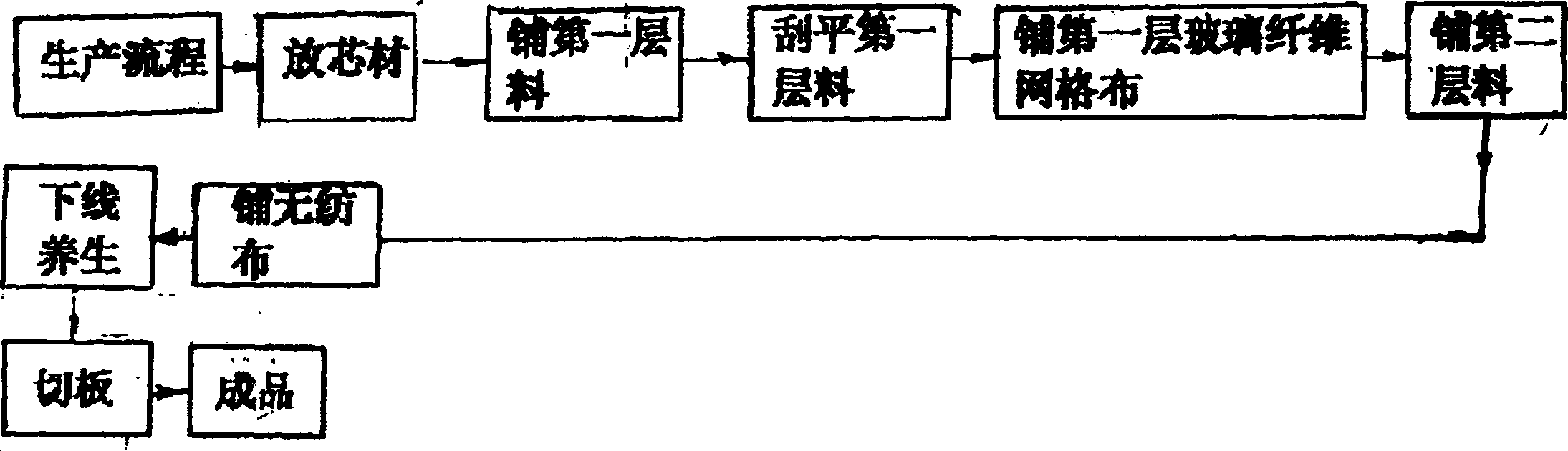

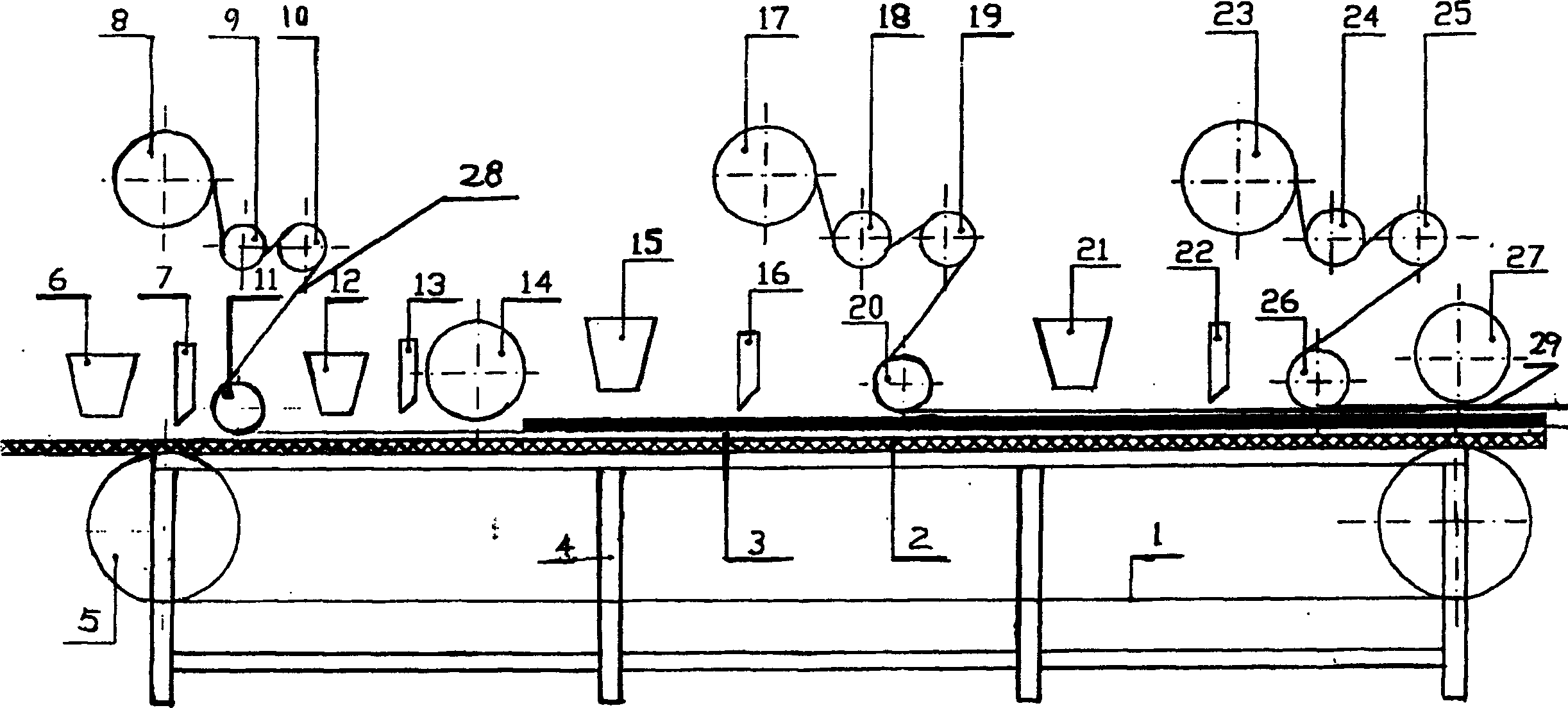

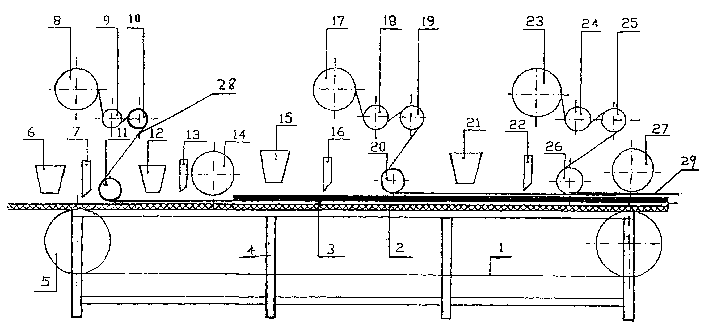

Process and equipment for producing external adhesive type composite plate

InactiveCN1425543AShape stableGeometrically stableShaping conveyorsHeat proofingFiberglass meshGlass fiber

The present invention is suitable for production of external adhesion type composite plate. The production process includes the successive step of setting light organic heat-insulating material as core material, spreading GRC cement mortar layer, leveling the cement mortar layer with vibrating scraper to required thickness, spreading glass fiber cloth, spreading the second GRC cement, mortar layer, leveling, spreading non-woven cloth, off-line curing for 24 hr and cutting in required size. The production equipment consists of belt conveyer, driving wheel, scraper, vibrating bin, support wheel shaft and leveling unit combined together. The product of the present invention is suitable for fast in-situ installation.

Owner:沈阳建宝丽新型建材有限公司 +2

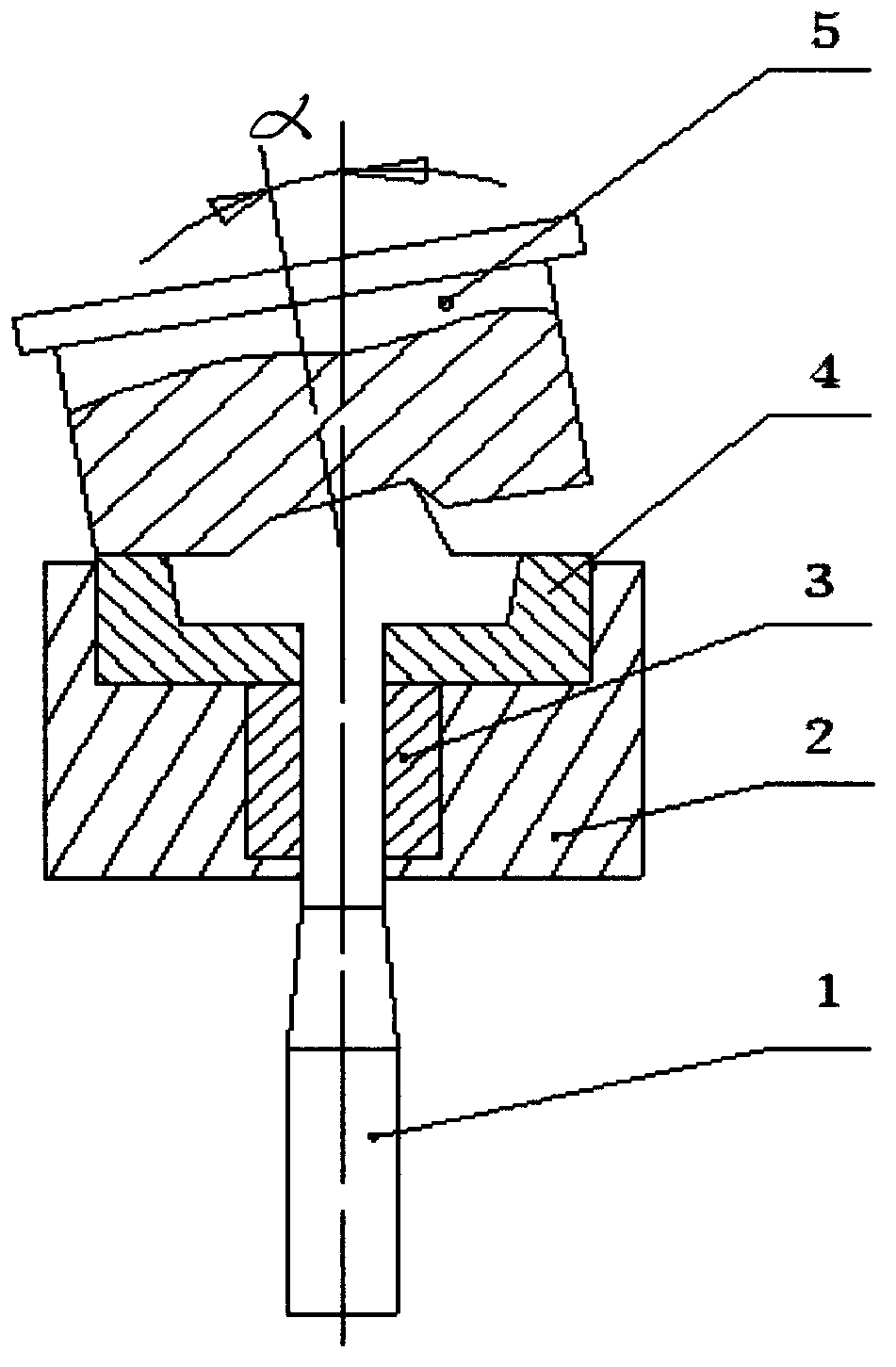

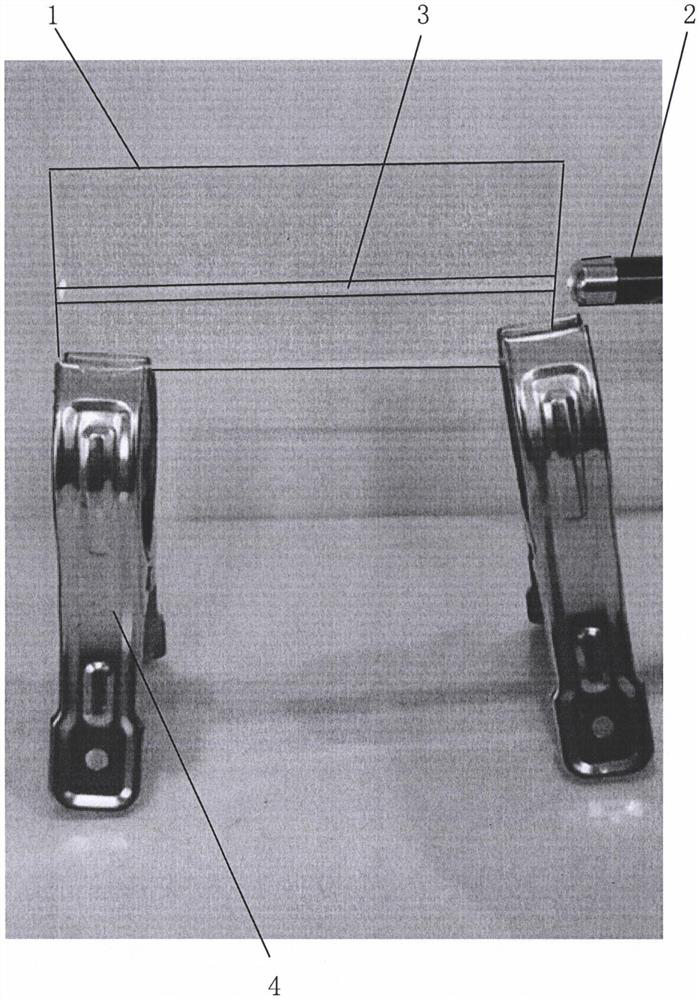

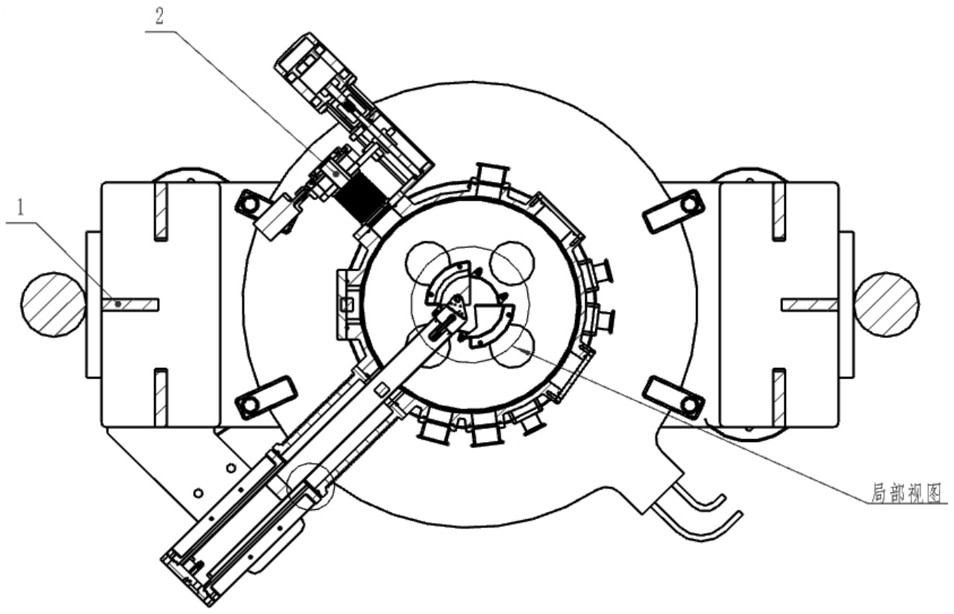

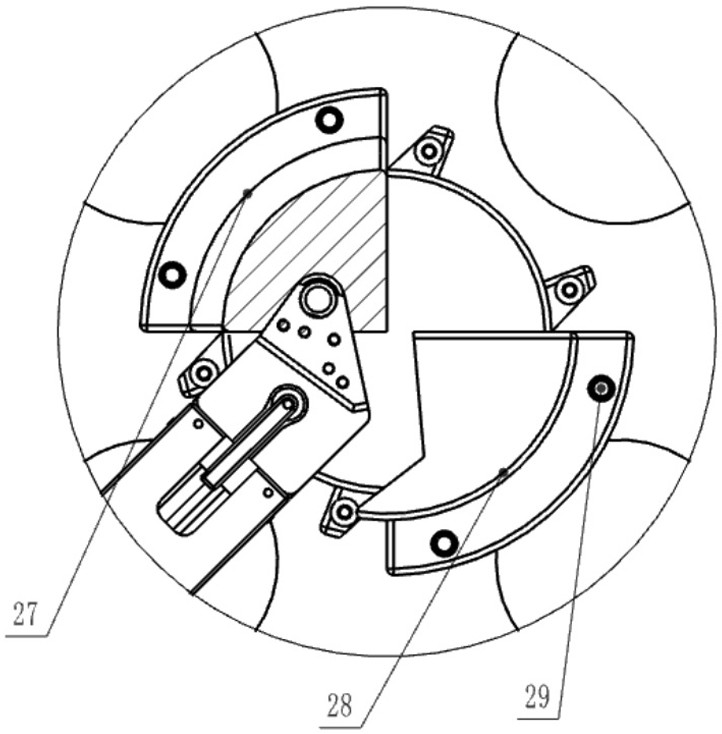

Automobile half-axle pendulum rolling formation technology mould

InactiveCN103567344AImprove pass rateHalf shaft quality improvedForging/hammering/pressing machinesForgePendulum

The invention discloses an automobile half-axle pendulum rolling formation technology mould which is characterized by comprising a half-axle blank (1), a fixture body (2), a mold core (3), a lower mould (4) and an upper mould (5), wherein the mold core (3) and the upper mould (5) are arranged in the fixture body (2); when the upper mould (5) is installed, a 10-degree incline angle is formed by the center line of the upper mould (5) and the center line of the lower mould (4); the lower part of the half-axle blank (1) is fixed and does not jump; the half-axle blank (1) is rotated, and press formation is gradually realized. The automobile half-axle pendulum rolling formation technology mould has the beneficial effects of obviously improving the half-axle quality, being stable in geometric dimension and smooth in surface, saving the material, lowering the cost, being convenient in technological operation, safe and reliable, and improving the yield of forge pieces.

Owner:CAR HALF AXLE MFG HONGZE COUNTY

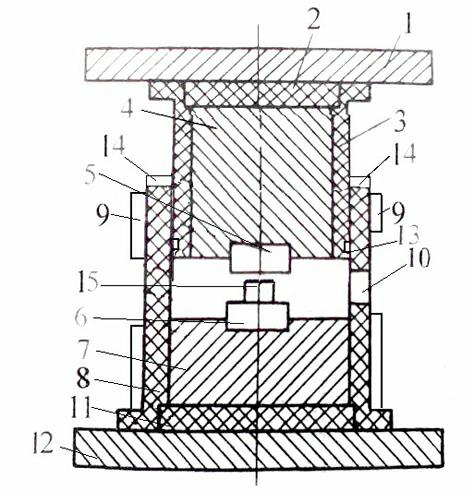

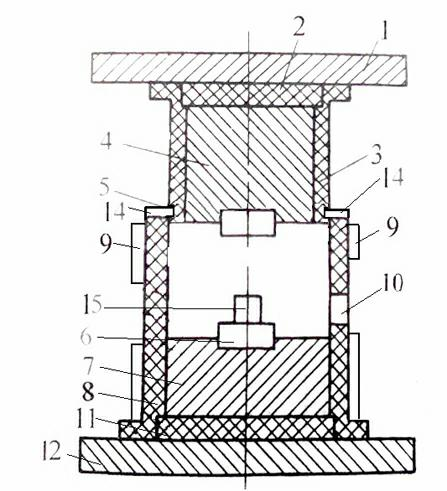

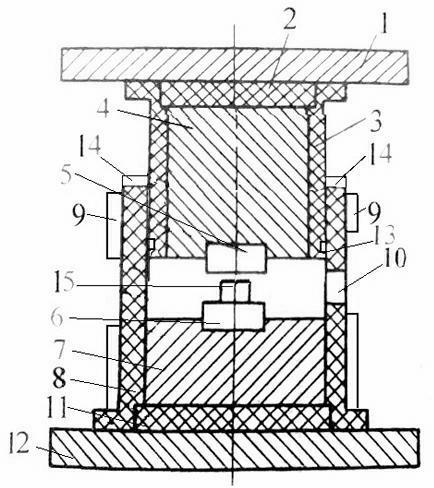

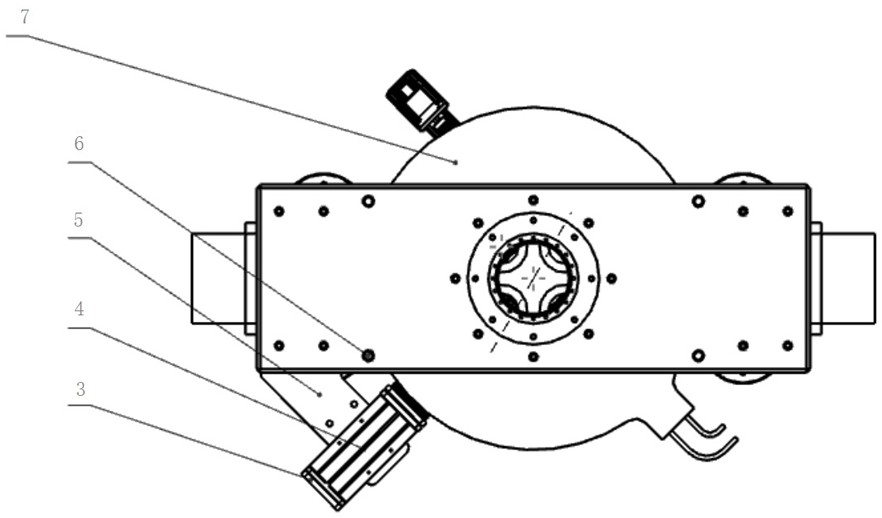

Efficient isothermal forging mould base

InactiveCN102672091AHigh dimensional accuracyMaintain a constant temperatureForging/hammering/pressing machinesIsothermal forgingMachining

The invention discloses an efficient isothermal forging mould base. The efficient isothermal forging mould base comprises an upper supporting plate, an upper heat-insulating plate, an upper sleeve, an upper mould rack, an upper mould, a lower mould, a lower mould rack, a lower sleeve, a sensor, a hole, a lower heat-insulating plate and a lower supporting plate, wherein the upper mould and the lower mould are fixed on the upper mould rack and the lower mould rack respectively; the upper sleeve and the lower sleeve are arranged on the outer sides of the upper mould rack and the lower mould rack respectively; the upper mould rack is connected with the upper supporting plate through the upper heat-insulating plate; the lower mould rack is connected with the lower supporting plate through the lower heat-insulating plate; a clamping block is arranged on an axial end surface of the lower sleeve; the sensor is arranged on the outer side of the lower sleeve; and the hole is formed on the lower sleeve. The efficient isothermal forging mould base is heated through the sensor and a mould is fed therein and taken out through the special hole, so that after isothermal forging, the mould is high in size precision, stable in geometric size, small in machining allowance and small in residual stress; and the mold can be heated to a deformation temperature at a very high heating efficiency, so that the production cost is reduced and resources are saved.

Owner:太仓奥科机械设备有限公司

Synthetic beta-spodumene solid solution, microcrystalline glass prepared from synthetic beta-spodumene solid solution and preparation method of microcrystalline glass

ActiveCN112552032AHeat resistantGeometrically stableGlass productionChemical compositionPhysical chemistry

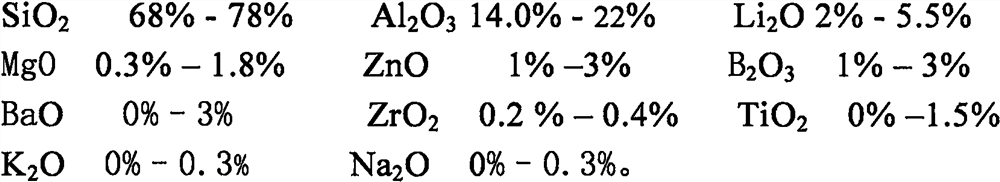

The invention belongs to the technical field of inorganic materials, and relates to a synthetic beta-spodumene solid solution, microcrystalline glass prepared from the synthetic beta-spodumene solid solution and a preparation method of the microcrystalline glass In the synthetic beta-spodumene solid solution, according to the theoretical mass ratio of Li2O to Al2O3 to nSiO2 in the chemical formulaLi2OAl2O3nSiO2 of the beta-spodumene solid solution, n is larger than 4 and smaller than or equal to 8, corresponding raw materials containing Li2O, Al2O3 and SiO2 are prepared according to the ratiorequired by synthesis and sintered at the sintering temperature, and the synthesized Li2OAl2O3nSiO2 is obtained, wherein the part of SiO2 of which n is greater than 4 is excessive free SiO2 absorbedin beta spodumene crystal lattices or added SiO2 to form the beta-spodumene solid solution. The microcrystalline glass is prepared from the synthesized beta spodumene solid solution and matrix glass.The microcrystalline glass comprises the following chemical components in percentage by weight: 68%-78% of SiO2, 14.0%-22.0% of Al2O3, 2%-5.5% of Li2O, 0.3%-1.8% of MgO, 1%-3% of ZnO, 1%-3% of B2O3, 0%-3% of BaO, 0.2%-0.4% of ZrO2, 0-1.5% of TiO2, 0%-0.3% of K2O and 0%-0.3% of Na2O.

Owner:胡勇波

Method for realizing tight serial and parallel connection on cylindrical battery cells in battery pack

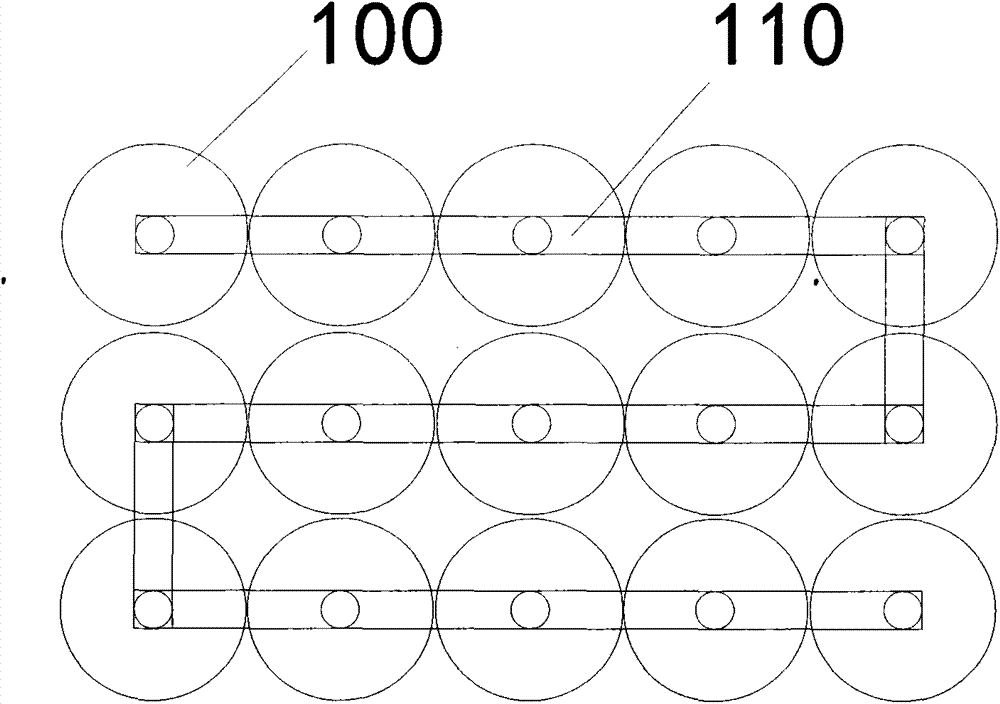

InactiveCN103682229AGeometrically stableAvoid deformationCell component detailsAcute angleEngineering

The invention discloses a method for realizing tight serial and parallel connection on cylindrical battery cells in a battery pack. According to the method, firstly, a plurality of battery cells which have the same appearances and are in cylindrical shapes are mutually parallelly gathered for forming several rows, then, bridge connection fixation is carried out at the round cross section part of each battery cell through welding connecting sheets for forming the battery pack consisting of a plurality of battery cells, and the single battery cell is connected with the adjacent electric cells in the current row through the welding connecting sheets and is also welded with one battery cell in the adjacent row, so the welding connecting sheets of the battery cell and other two connected battery cells form obtuse angle or acute angle fixed connection structures, and the two obtuse angle or acute angle fixed connection structures are connected into a Z shape. The method has the advantages that through a plurality of piled and gathered battery cells in the battery pack, the battery cells are adopted and are directly provided with Z-shaped or square-shaped welding connecting sheets, so the battery cells realize the serial and parallel connection conduction on the circuit structure, and in addition, the piled and gathered battery cells cannot easily become loose like solid gum or fixing support frames.

Owner:SUZHOU BROADLINE POWER SUPPLY TECH

Manufacture method of rigidity seal ball valve

The invention discloses a manufacture method of a rigidity seal ball valve. The manufacture method of the rigidity seal ball valve comprises the following steps: 1) casting thermal treatment; 2) ball body and valve seat surface hardening treatment; 3) ball body and valve seat cleaning treatment. In the step of casting thermal treatment, a casting is heated to temperature which is 30-50DEG C above a critical point during cooling, and the casting is taken out to naturally cool in the air after the casting is kept warm for 2-5 hours; then, the casting is reheated to the temperature which is 20-30DEG C below critical temperature, and the casting is naturally cooled in the air after the casting is kept warm for 4-8 hours. Thermal spraying technology is adopted for the ball body and valve seat surface hardening treatment. The ball body and valve seat cleaning treatment comprises ungrease treatment and shot blasting. According to the manufacture method of the rigidity seal ball valve, which is provided by the invention, valve body tissue stability is further improved, the internal stress of the valve body is eliminated, ball body and sealing surface hardness can be furthest improved, and the service life of the sealing surface under the states of high temperature, high pressure, corrosion and granularity medium is guaranteed.

Owner:WUHU JINMAO FLUID TECH CO LTD

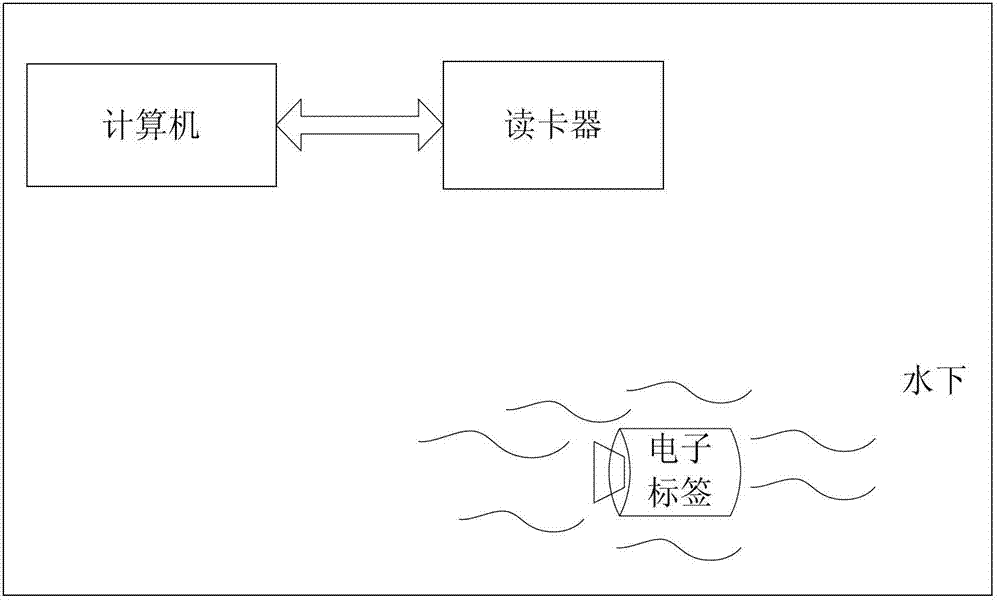

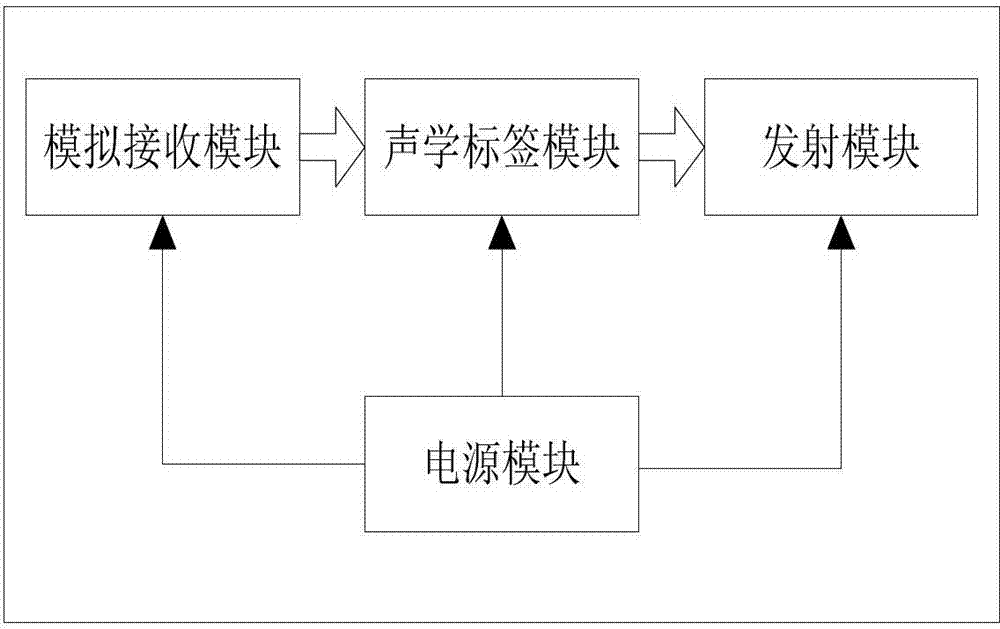

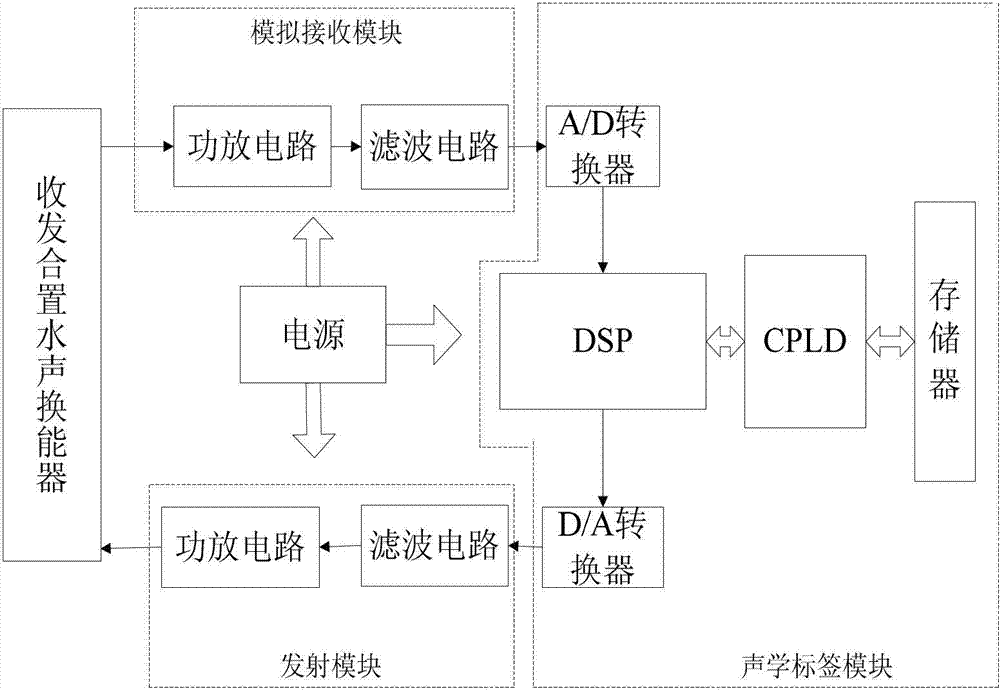

Underwater acoustic electronic tag for identity authentication and control method thereof

InactiveCN103020699AGeometrically stableSave powerCo-operative working arrangementsRecord carriers used with machinesAcoustic tagElectricity

The invention discloses an underwater acoustic electronic tag for identity authentication. The underwater acoustic electronic tag comprises a stimulation receiving module, an acoustic tag module, a transmitting module and a power supply module, wherein the power supply module is used for supplying electricity to the stimulation receiving module, the acoustic tag module and the transmitting module; the stimulation receiving module establishes communication connection with a receiving-sending-integrated underwater acoustic transducer and is connected with the acoustic tag module to send a command signal received from the receiving-sending-integrated underwater acoustic transducer into the acoustic tag module; the output end of the acoustic tag module is connected with the transmitting module; and the acoustic tag module acquires relevant information of underwater devices after processing the signal and sends the information from the transmitting module back to a card reader. According to the underwater acoustic electronic tag for the identity authentication, the electronic tag can be used for realizing underwater identity authentication and can contain the relevant information of the underwater devices, a plurality of tags can be simultaneously identified, and great conveniences are provided to the acquiring of the device information of each port. The invention further discloses a control method of the underwater acoustic electronic tag for the identity authentication.

Owner:JIANGSU UNIV OF SCI & TECH

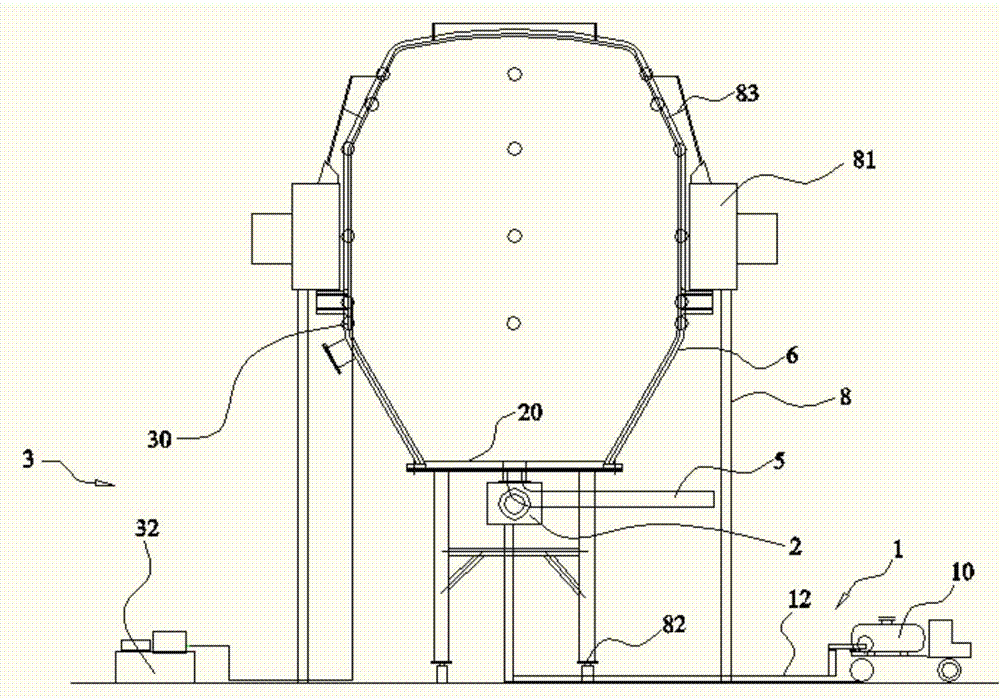

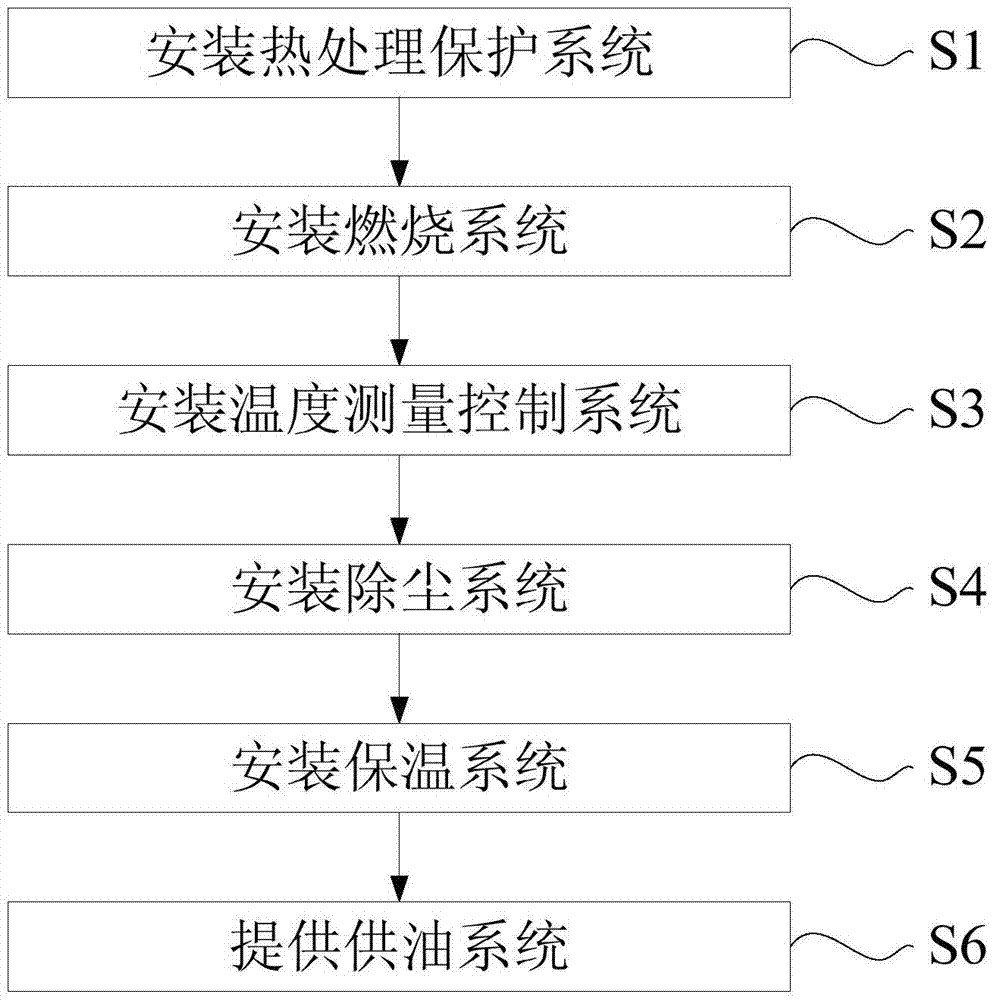

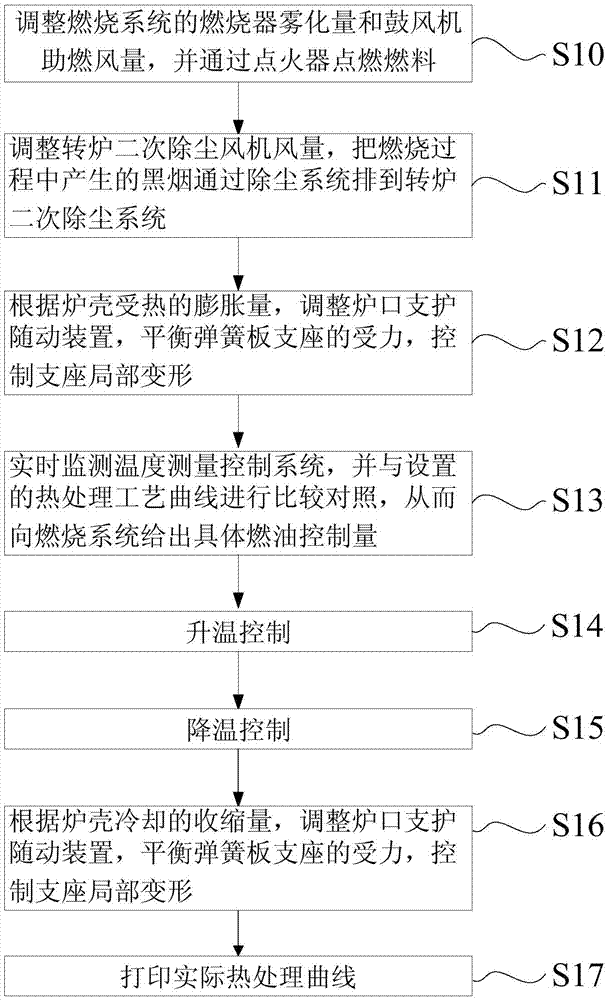

Heat treatment device and method for large steel plate converter shell

ActiveCN105441646AEnsure safe use requirementsGeometrically stableFurnace typesHeat treatment furnacesCombustion systemSheet steel

The invention discloses a heat treatment device for a large steel plate converter shell. The heat treatment device for the large steel plate converter shell comprises an oil supply system, a combustion system, a temperature measurement control system, a dedusting system, a heat preservation system and a heat treatment protection system. The heat treatment protection system comprises heat insulation materials, a backing ring supporting device and a converter supporting follow-up device. The heat insulation materials are arranged between a converter body and a backing ring. The backing ring supporting device tightly abuts against the backing ring. The converter supporting follow-up device is arranged at a converter mouth. The invention further provides a heat treatment method for the large steel plate converter shell. By the adoption of the heat treatment device and method for the large steel plate converter shell, the assembly precision of the converter shell can be guaranteed, the safety using requirement for a converter can be met, and the cost is relatively low.

Owner:BEIJING SHOUGANG CO LTD

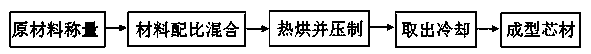

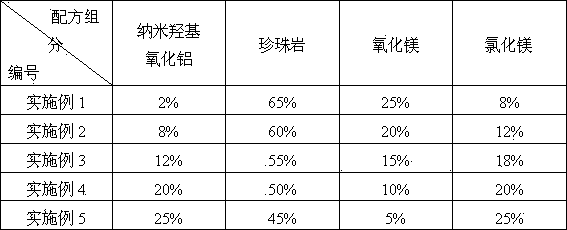

Composite nano-hydroxyl alumina flame-retardant insulation board and manufacturing method and application thereof

The invention discloses a composite nano-hydroxyl alumina flame-retardant insulation board and a manufacturing method and application thereof. The composite nano-hydroxyl alumina flame-retardant insulation board comprises the following components in percentage by weight: 12-18 percent of nano-hydroxyl alumina flame retardant, 50-55 percent of perlite, 15-18 percent of magnesium oxide binder, 16-18 percent of magnesium chloride binder and 30-45 percent of water. The composite flame-retardant insulation board is an inorganic nano-hydroxyl alumina flame-retardant insulation board with low water content, and can be used for making a fireproof door core board and the like. The fireproof door core board has the characteristics of high fire resistance, long fire resistance time, high compressive strength, stable performance, insulation of sound and heat, low heat conductivity coefficient, no toxicity, freeness from nuisance and pollution, excellent environmental protection performance and high machinability.

Owner:安徽顺和消防设备有限公司

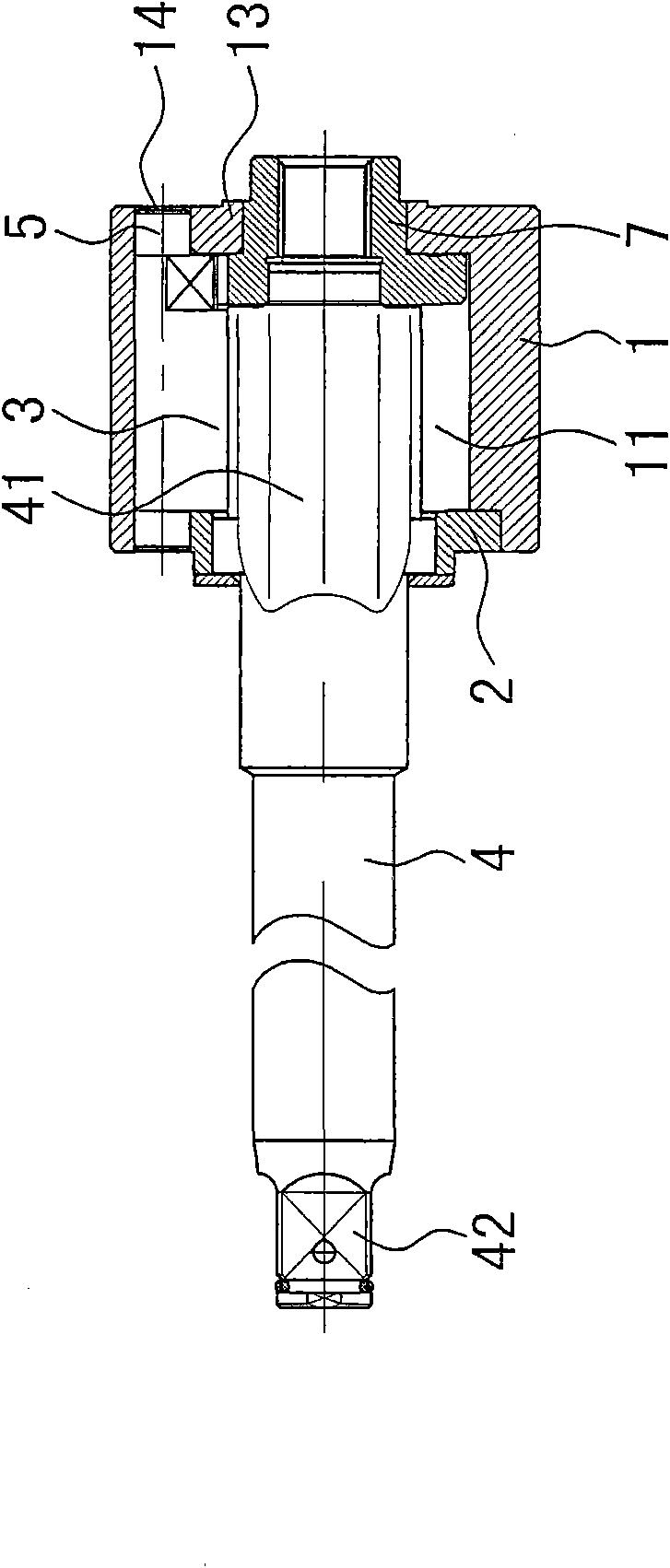

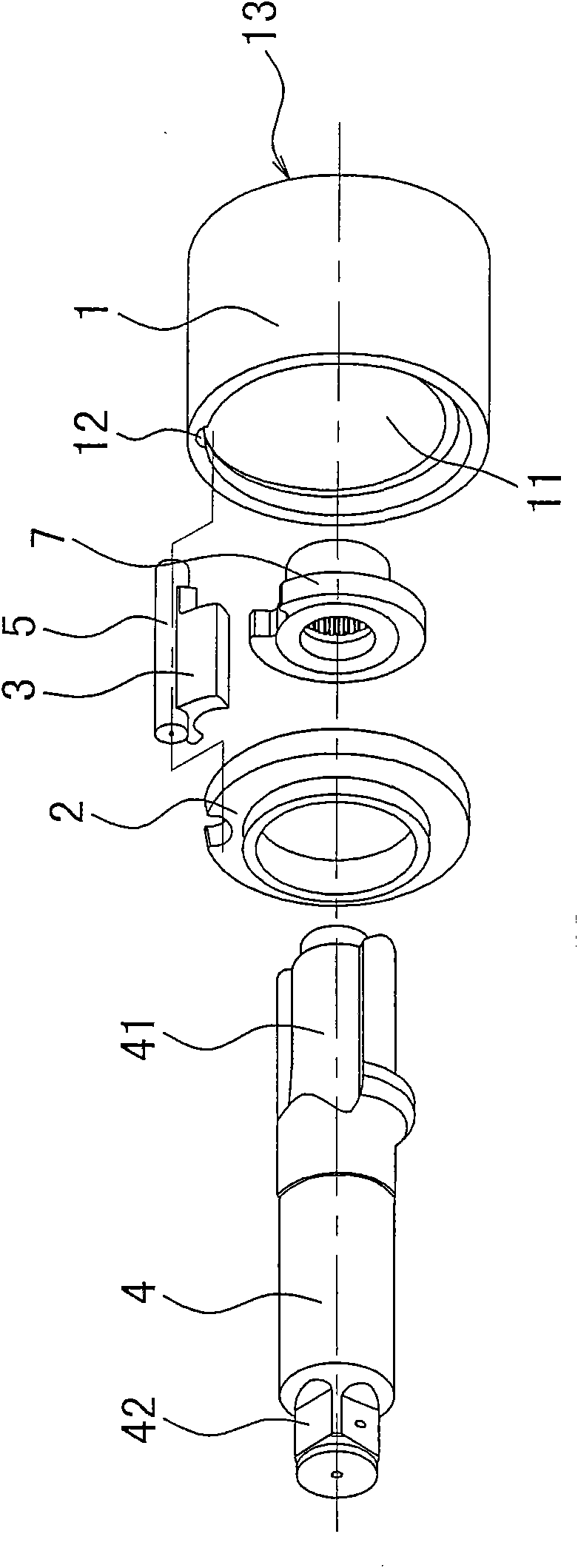

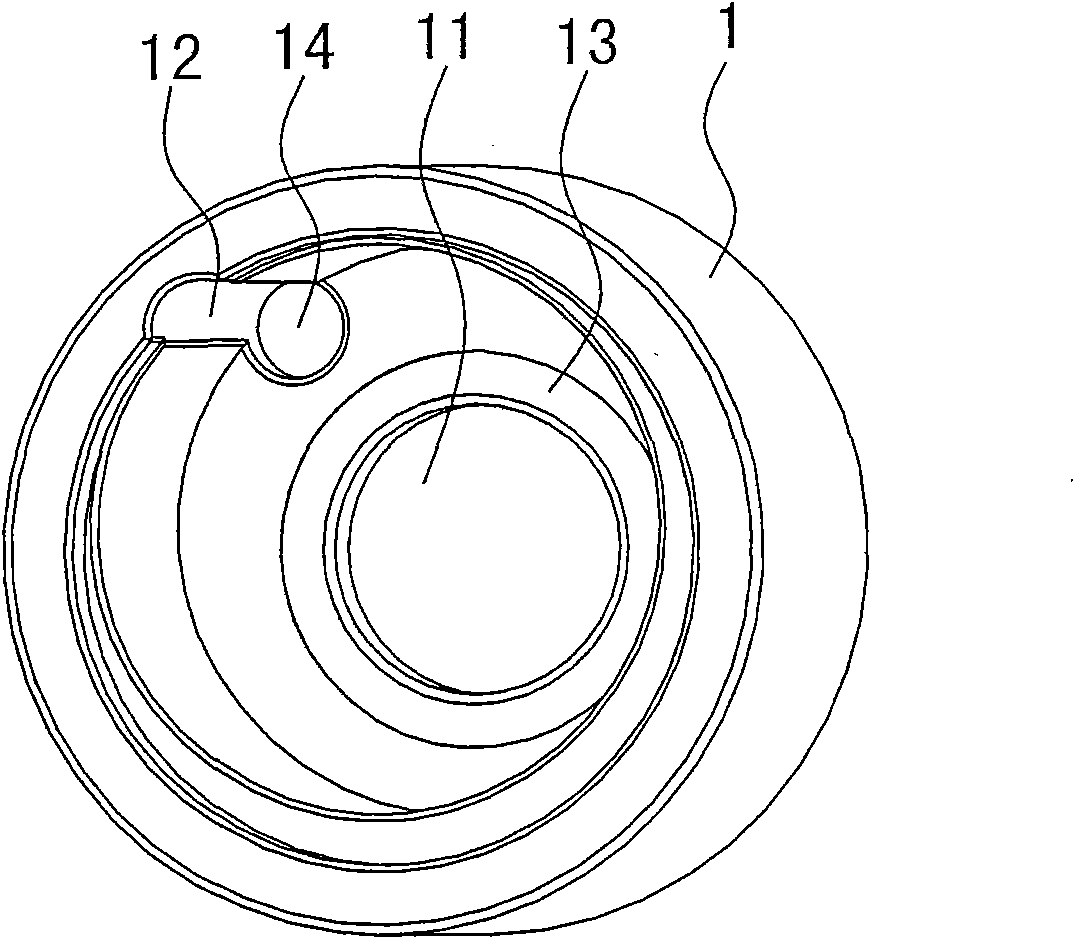

Method for processing impact cylinder of pneumatic tool

InactiveCN101637861AStable jobExtended service lifeFurnace typesHeat treatment furnacesPneumatic toolEngineering

The invention relates to a method for processing an impact cylinder of a pneumatic tool. The pneumatic tool consists of a power source and an impact mechanism, wherein the power source is supplied by an air motor which consists of blades, a rotor and a cylinder; the impact mechanism comprises a striking shaft; one end of the striking shaft is provided with a striking surface which is matched witha striking block; the striking block is provided with a striking pin; two ends of the striking pin are fixed in the impact cylinder through a liner and a drive sleeve respectively; the drive sleeve is meshed with the rotor; and the other end of the striking shaft is made into a rectangular head which is connected with a sleeve. The method is characterized by comprising the following steps for processing the impact cylinder: taking metal blanks, and forging the metal blanks into a solid cylinder; performing normalizing heat treatment on the forged and molded solid cylinder; forming a center hole in the center of the solid cylinder through rough machining, and reserving an end face as an end cover; performing quenching heat treatment; performing fine machining; processing a semicircle orifice straight-through end cover at one end of the inner wall of the cylinder center hole through linear cutting, and forming a round orifice on the end cover; performing destressing tempering; and performing sandblasting on the surface of the cylinder and the hole wall to obtain the finished product.

Owner:ZHEJIANG FENGLI INTELLIGENT TECH CO LTD

Rich mineral paper tableware, and preparation method thereof

The invention discloses rich mineral paper tableware, and a production method thereof. The rich mineral paper tableware comprises calcium carbonate, polyethylene, polypropylene, an anti-oxidant, a resin, ACR adhesive, a composite stabilizing modifier, and wood fiber powder. The production method comprises following steps: (1) the raw materials are delivered into a mixer for high speed mixing at a certain ratio; (2) modification is carried out, wherein a mixture obtained via high speed mixing is subjected to full dispersing and kneading so as to obtain a strip material or a plate material; (3) pelleting is carried out, wherein a pelletizer is used for preparing material particles from the obtained strip material or the plate material, so that it is convenient for transporting, raw materials can be provided for a plurality of parallel production lines, and production efficiency is increased; and (4) production is carried out, wherein the material particles are subjected to extrusion and blow moulding so as to obtain needed products.

Owner:杨金龙

Ionization ray shielding protection plate and manufacture method thereof

The invention discloses an ionization ray shielding protection plate. The protection plate includes the following components by weight: 30%-40% of lead sulfide, 10%-20% of mica, 10%-20% of wollastonite, 5%-10% of blanc fixe, 5%-10% of expanded perlite, 15%-30% of binding material, 1%-8% of phosphoric acid and 2%-8% of ferrous sulfate. A manufacture method of the ionization ray shielding protection plate is further disclosed. The ionization ray shielding protection plate is light in plate material weight, high in strength, stable in geometrical size, not easy to deform, strong in shielding performance of ionization ray and capable of being widely used in ionization ray protection and can replace a lead plate in use.

Owner:曾小荣

Protective plate material for X ray

A method for preparing X ray protection slab includes mixing magnesium sulfate with water as per certain ratio uniformly, adding a match amount of lead oxide or iron oxide in mixed material, agitating said material uniformly to be a semi-fluid adhesion matter with shielding function and then using template to form said semi-fluid adhesion matter for obtaining protection slab.

Owner:赵仲强 +1

High-rigidity synchronously spreading folded space extension arm

InactiveCN1232738CGeometrically stableImprove structural rigidityElongated constructional elementsRod connectionsSolar sailDrive shaft

Owner:SHANGHAI JIAOTONG UNIV

Wear-resistant alloy and application thereof in millstone tile

ActiveCN103255347AReduce labor intensityImprove performanceCocoaGrain treatmentsRare-earth elementChemical composition

The invention relates to the field of a wear-resistant material and an application thereof, and in particular relates to a wear-resistant alloy and an application thereof in a millstone tile of a coal mill, which are used for solving the problems that the wear-resistant material in the prior art has lower comprehensive performance in strength, hardness, toughness, service life and the like. The wear-resistant alloy comprises the following chemical components in percentage by weight: 0.32-0.35% of C, 0.9-1.1% of Si, 0.8-1.0% of Mn, less than or equal to 0.04% of P, less than or equal to 0.04% of S, 22-24% of Cr, 1.1-1.2% of Cu, 1-3% of Mo, 0.1-0.2% of Al, 0.4-0.6% of V, 0.02-0.004% of B, 0.3-0.5% of rare earth element and the balance of Fe. The millstone tile is subjected to sand casting and casting molding by use of the wear-resistant alloy. By adopting the specific alloy components and the heat treatment technology, the service life of the produced millstone tile is not shorter than twice the average service life of the like products; the millstone tile still can be used normally after 19,859 hours of test use, thereby indicating good performance of the product; and moreover, the labor intensity of workers can be reduced, and the efficiency can be improved.

Owner:SHENYANG WEIYUELI ELECTRICAL EQUIP

Thermal spraying process for tungsten carbide grinding roller for grain and oil mechanical grinding machine

The invention discloses a thermal spraying process for a tungsten carbide grinding roller for a grain and oil mechanical grinding machine. The thermal spraying process comprises the following steps ofperforming base material detection before thermal spraying, and determining a base material to be chromium-molybdenum alloy; performing geometric size detection to ensure the surface of a tungsten carbide grinding roller to be free of processing defects and the hardness HRC to be 55-58 degrees; preheating the tungsten carbide grinding roller to be 55-65 DEG C before spraying; starting a powder feeding device to convey prepared tungsten alloy powder to a combustion chamber, performing heating to 1800 DEG C to enable the tungsten alloy powder to be in a molten state; starting a high-pressure fan to spray a tungsten alloy liquid flow in the molten state onto the surface of the tungsten carbide grinding roller at a speed of 840 meters per second; axially moving a spray gun along the self-rotating tungsten carbide grinding roller to form a tungsten alloy coating layer; detecting that the thickness of the coating layer is 0. 02-0.04 mm, the hardness is HV1300 -1500, the surface roughness ofa tooth roller is Ra0.2-0.8, and the roughness of a smooth roller is larger than Ra3.2; and performing marking and boxing on a finished product. The thermal spraying process has the advantages that the tungsten carbide grinding roller is good in chromium-molybdenum base material and free of block falling and stripping and tooth breakage; and a thermal spraying coating layer is high in hardness and resists wear, high temperature and corrosion.

Owner:史继明

Colored profiled polyester multifilament fiber with stable dimension and preparation method thereof

ActiveCN101525786BHigh strengthLow shrinkageMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterYarn

The invention relates to a colored profiled polyester multifilament fiber with stable dimension and a preparation method thereof. The preparation method comprises the following steps: adjusting contents of polyester, pigment masterbatch and an additive in a fusant according to a certain proportion, drying and dehydrating, forming after melting, extrusion, spinning and cooling, and obtaining finished filament after oiling, coiling, heating, tensioning, heat setting, inspection and grading. The fiber can be prepared with conventional spinning equipment, has even multifilament bundle yarn and even color distribution, can be widely applied to fields of clothing, decoration and industry. Fabric is smooth, is characterized by soft luster, high breaking strength and low breaking elongation, can ensure stable geometric dimension of the fabric without easy deformation; and the fiber has the advantages of good fabric elastic resilience, less creep and relaxation and low boiling water shrinkage,and can improve the stability due to hard deformation at high temperature.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD

Process and equipment for producing external adhesive type composite plate

InactiveCN1172062CShape stableGeometrically stableShaping conveyorsHeat proofingFiberglass meshGlass fiber

Owner:沈阳建宝丽新型建材有限公司 +2

Ion source experiment platform

PendingCN113411942AImprove functional scalabilityEasy to operatePlasma techniqueNuclear energy generationMagnetic polesCyclotron

The invention discloses an ion source experiment platform which comprises a coil module, a magnet structure module, an ion source module, a leading-out module, a vacuum module, a hydraulic module and an ion source platform supporting module. The coil module comprises a coil and a coil barrier strip, and the coil barrier strip is installed on the outer side of the coil; the magnet structure module comprises an upper cover plate, a lower cover plate, a first lower magnet yoke, a first upper magnet yoke, a second upper magnet yoke, a second lower magnet yoke, an upper magnetic pole, a boss and a lower magnetic pole, wherein the upper cover plate and the lower cover plate are located on the upper side and the lower side of the coil respectively. The ion source experiment platform ensures that the distribution of magnetic lines generated in the ion source experiment area is basically consistent with the distribution of magnetic lines in the central area of a compact cyclotron; the vacuum condition provided by the vacuum box can reach the magnitude of 10^-5Pa, the operation is easy, and the problem that the vacuum degree of a traditional ion source platform cannot be reached due to the structural design that the wall of a vacuum cavity is thin is solved.

Owner:四川玖谊源粒子科技有限公司

Metallocene polyethene (PE) rich mineral paper and making method thereof

The invention relates to metallocene polyethene (PE) rich mineral paper and a making method thereof. The metallocene polyethene (PE) rich mineral paper consists of an upper surface layer, a middle layer and a lower surface layer; the master batch of the upper surface layer comprises the following components in percentage by weight: 40 to 60 percent of titanium dioxide, 35 to 55 percent of metallocene PE, 0.5 to 1 percent of coupling agent, 0.5 to 1 percent of dispersing agent, 0.5 to 1 percent of flame retardant, 0.5 to 1 percent of compatilizer and 0.5 to 1 percent of slipping agent; the master batch of the middle layer comprises the following components: 40 to 60 percent of calcium carbonate powder, 35 to 55 percent of metallocene PE, 0.5 to 1 percent of titanate coupling agent, 0.5 to 1 percent of dispersing agent, 0.5 to 1 percent of flame retardant, 0.5 to 1 percent of compatilizer and 0.5 to 1 percent of slipping agent; and three-layer composited rich mineral paper is made by a three-layer calendering process. The metallocene PE rich mineral paper has the advantages of high tensile strength, moisture resistance, waterproofness, high dimensional stability, tearing and foldingresistance, stable physical dimension, high printing definition and the like.

Owner:深圳市石头记环保科技有限公司

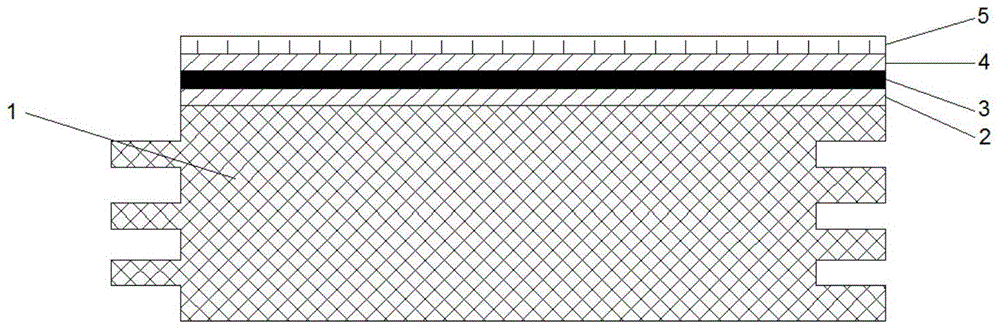

A fabric elastic floor and its processing method

ActiveCN104612376BControl thermal expansion and contractionGeometrically stableSynthetic resin layered productsLaminationThermal expansionMachining

The invention discloses a cloth elastic floor and a machining method of the cloth elastic floor, and belongs to the field of building floor materials. The cloth elastic floor has no pollution, and is environmentally friendly, durable, abrasion-resistant, elastic, good in foot feeling and diverse in style, and the thermal expansion and cold contraction of the floor can be effectively controlled. The cloth elastic floor comprises a bottom material layer, a lower-layer EVA film layer is arranged above the bottom material layer, a cloth layer is arranged above the lower-layer EVA film layer, an upper-layer EVA film layer is arranged above the cloth layer, an abrasion-resistant layer is arranged above the upper-layer EVA film layer, and the bottom material layer, the cloth layer and the abrasion-resistant layer are compounded through the upper-layer EVA film layer and the lower-layer EVA film layer in a vacuum heat compounding mode. The invention further discloses the machining method of the cloth elastic floor. The machining method resolves the problem of bubbles and avoids the situation that products are not flat. The cloth elastic floor and the machining method of the cloth elastic floor are suitable for installation of building floors.

Owner:埃弗朗格瑞(上海)环保科技有限公司

Assemblied polyvinyl chloride building engineering shuttering

InactiveCN101089329BConstruction and transportation are convenientAccelerated corrosionForming/stuttering elementsSurface finishPolyvinyl chloride

The present invention relates to a kind of combined polyvinyl chloride building engineering form. It includes hollow perforated board, special-shaped outside corner, special-shaped square pien, square wood, beam side and form closing cover basic structure unit made of polyvinyl chloride material. The above-mentioned basic structure unit can be formed into the engineering form meeting the externalform of said designed building component.

Owner:天津市富士特实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com