Composite nano-hydroxyl alumina flame-retardant insulation board and manufacturing method and application thereof

A technology of aluminum oxyhydroxide, flame retardant and heat preservation, which is applied in the direction of fire doors, etc., can solve the problems of poor flame retardancy of fire door core boards, restrictions on the improvement of fire door performance levels, and potential safety hazards, so as to achieve strong processing performance and reduce negative Influence and improve the effect of flame retardant time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

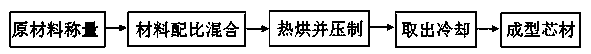

Method used

Image

Examples

Embodiment 1

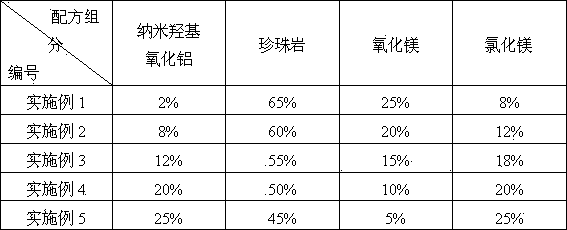

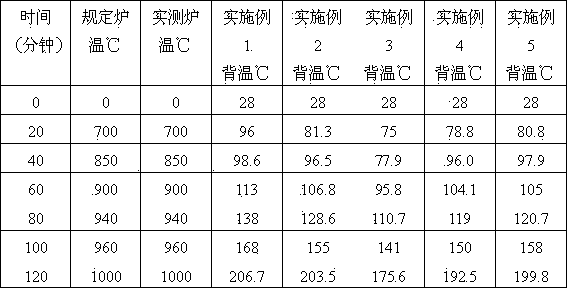

[0038] The fire door core boards of Embodiment 1, Embodiment 2, Embodiment 3, Embodiment 4, and Embodiment 5 are made according to the different component formulas in Table 1, and the heat insulation performance of the door core board is reflected in the fire door firing experiment. The above is, after subtracting the ambient temperature, the time when the average temperature of each point on the unfired surface does not exceed 140°C and the time when the maximum temperature does not exceed 180°C is called the fire resistance limit time, and the longer the value, the better.

[0039] Table 1 Proportion of nano-alumina oxyhydroxide composites

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com