Patents

Literature

55results about How to "Strong nail grip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

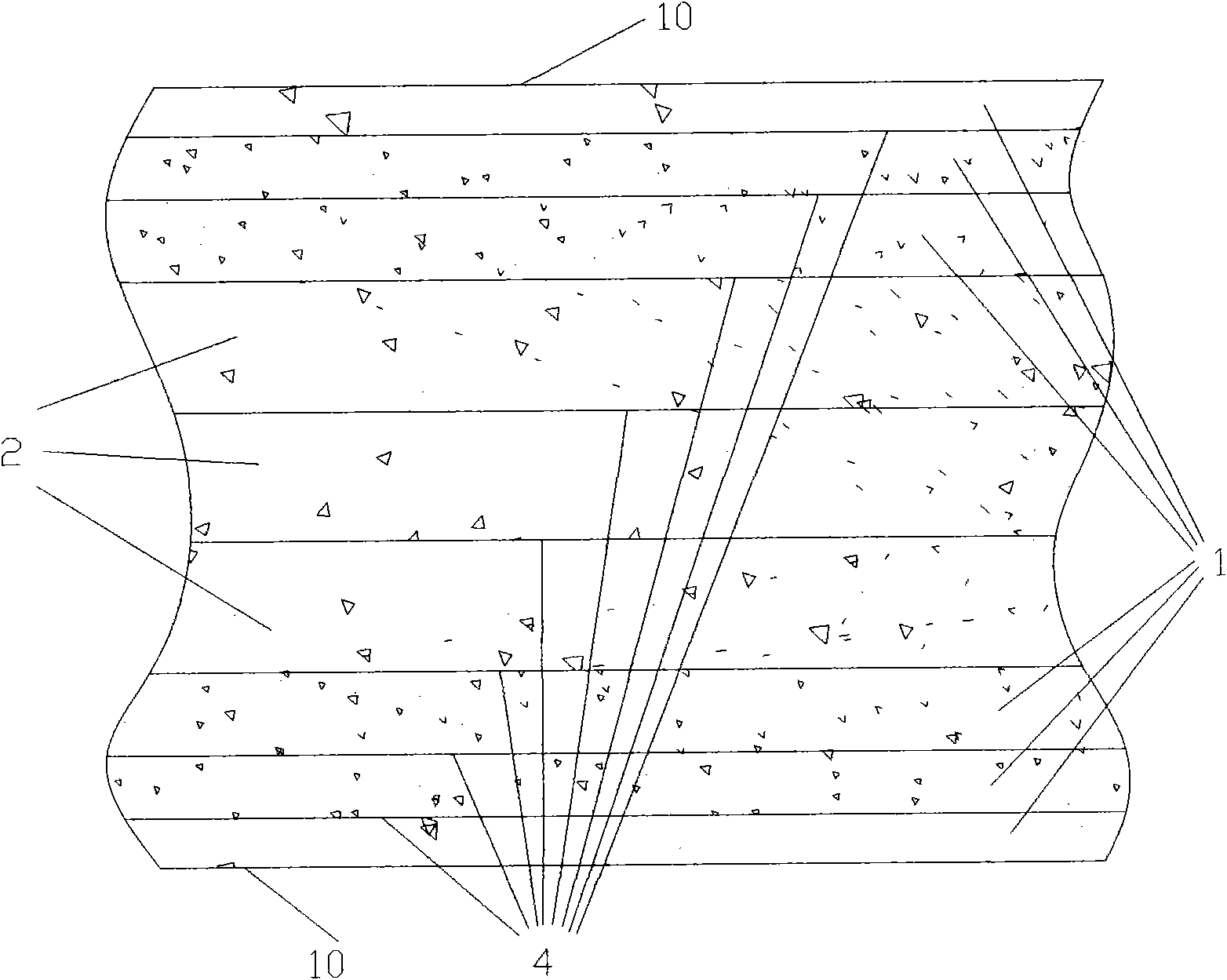

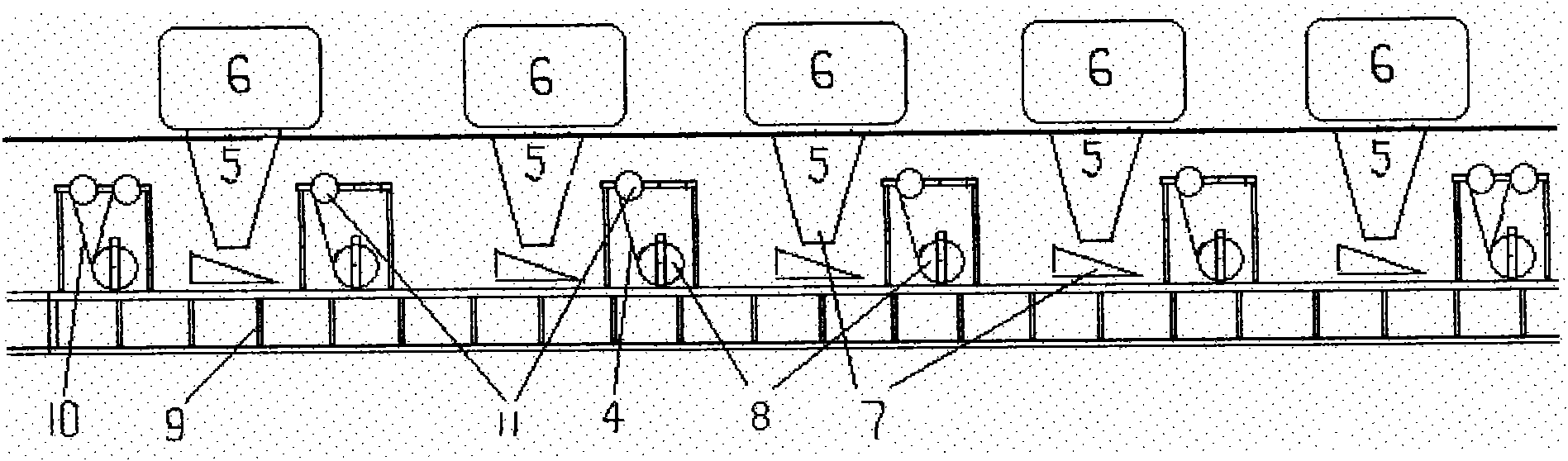

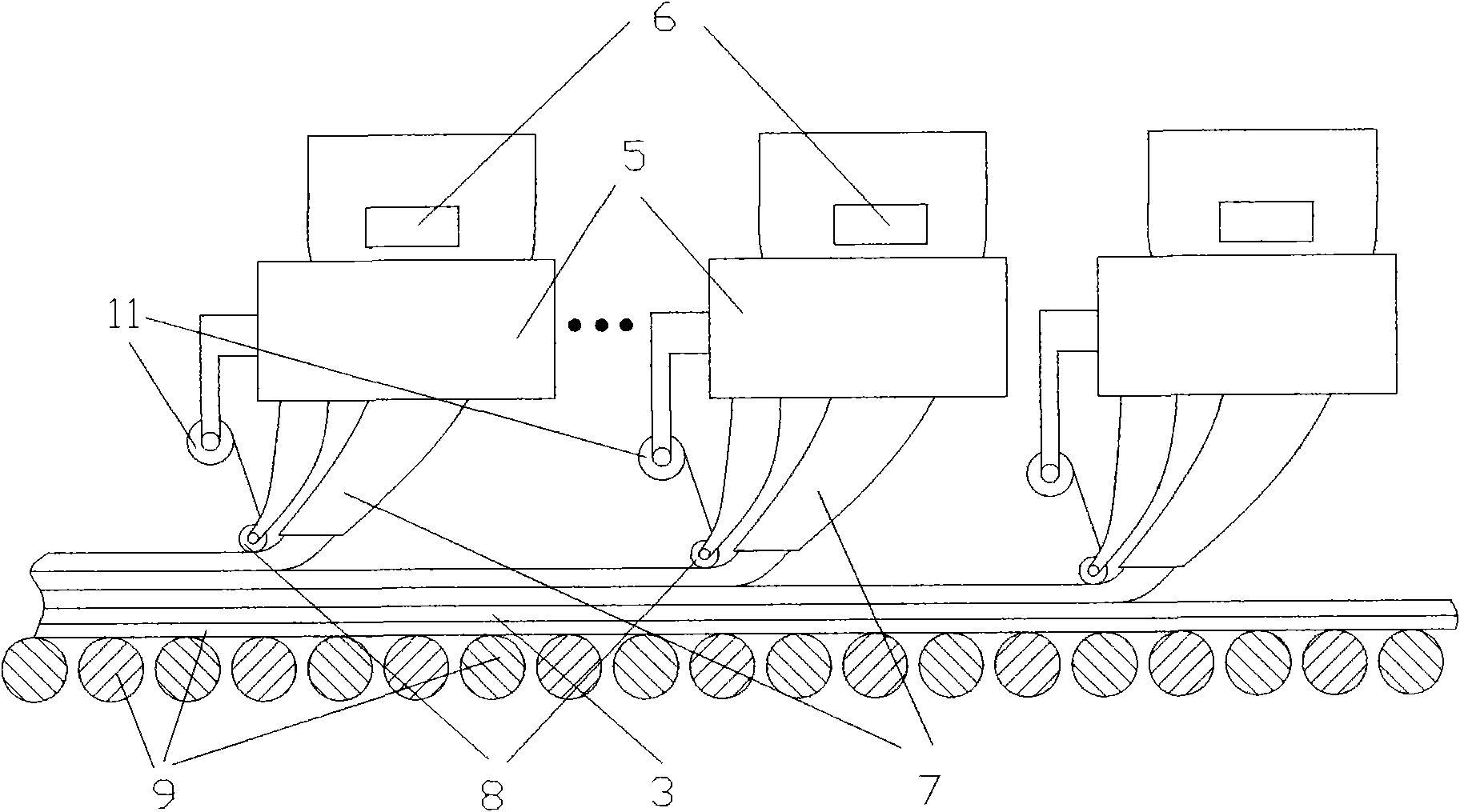

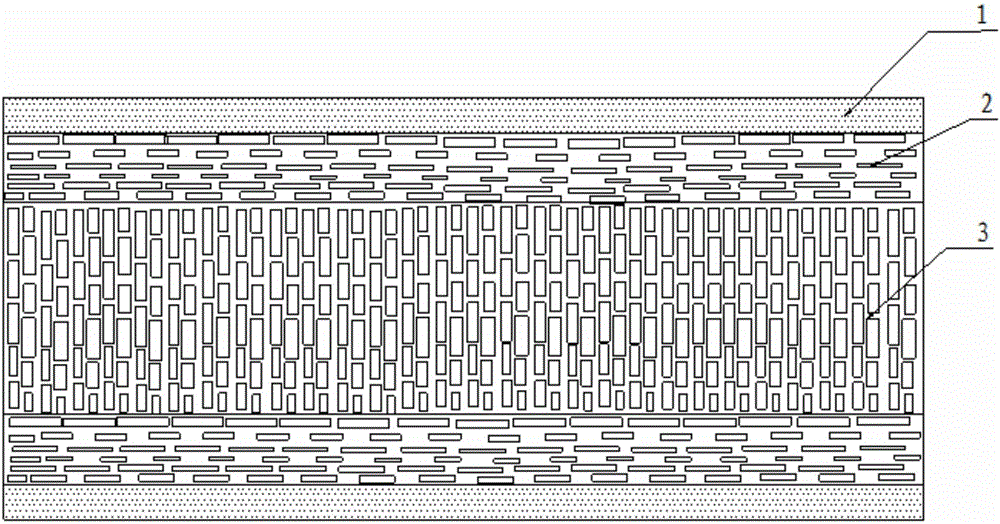

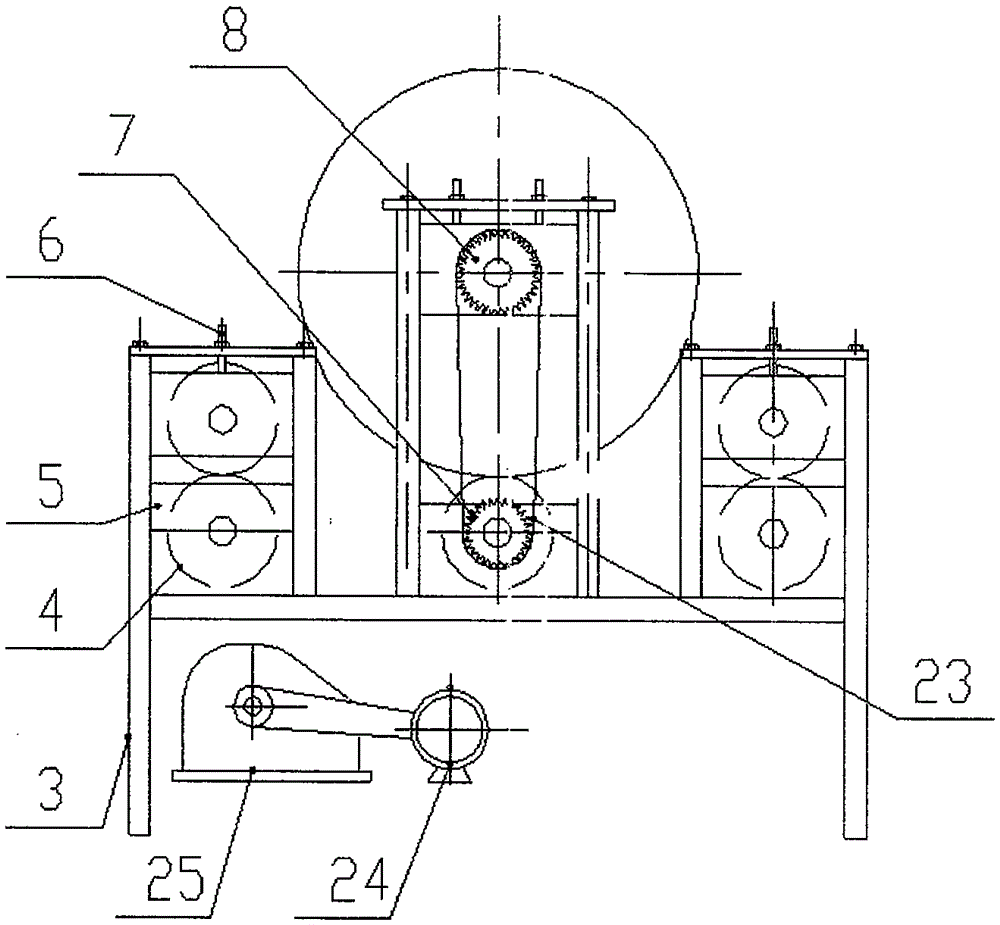

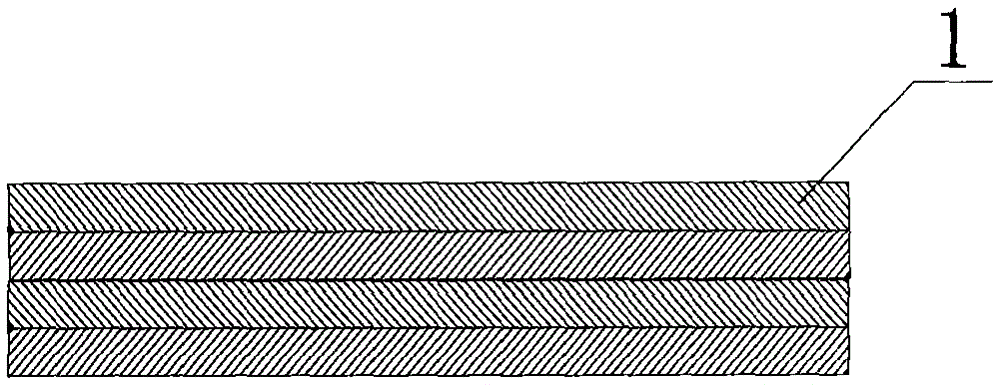

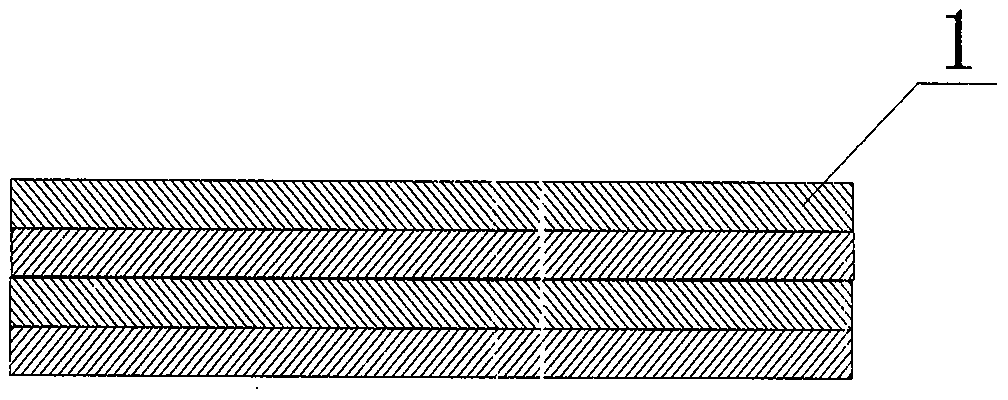

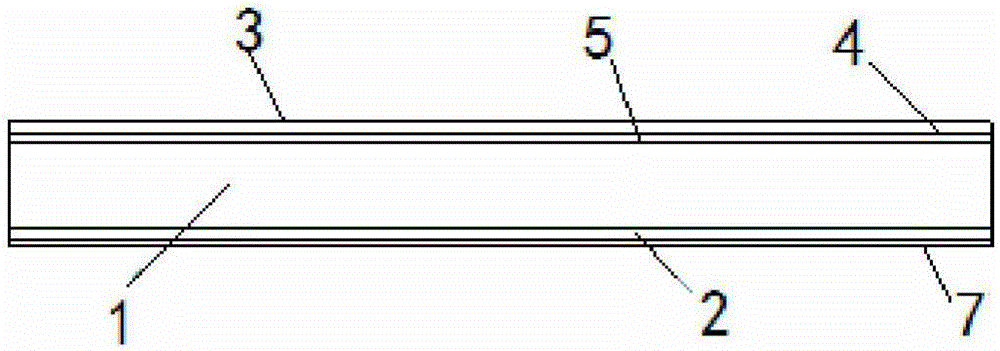

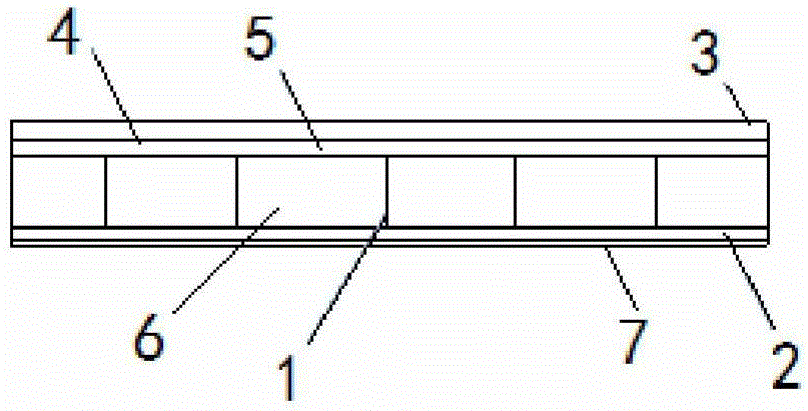

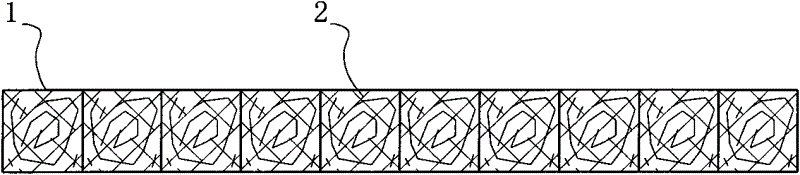

Multilayer composite plate for building templates and brick pallets and preparation process thereof

InactiveCN101633254AWith glazed effectEasy to demouldMouldsMixing operation control apparatusBrickSurface layer

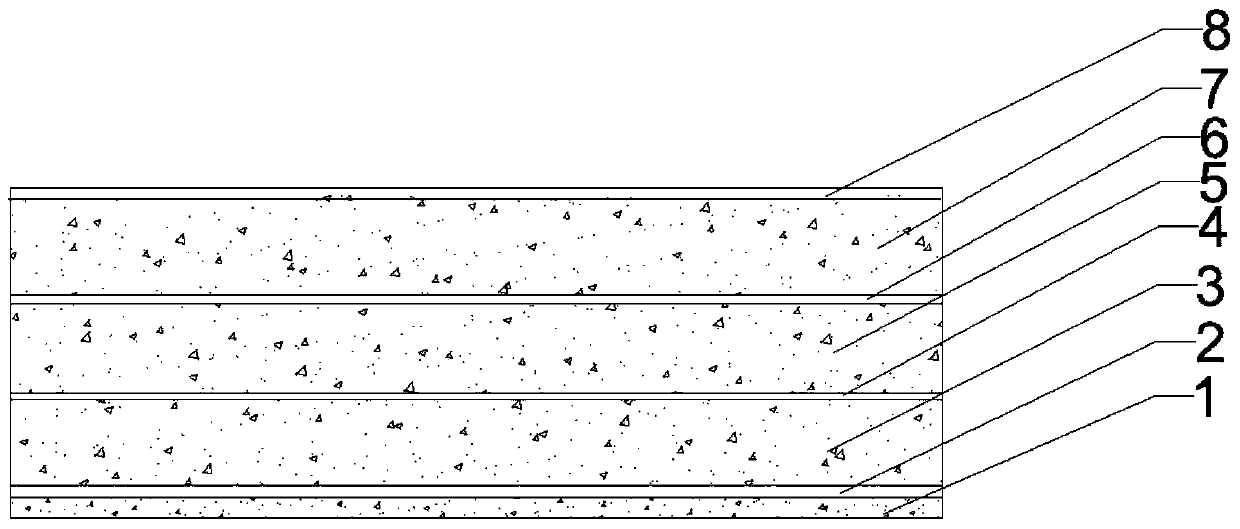

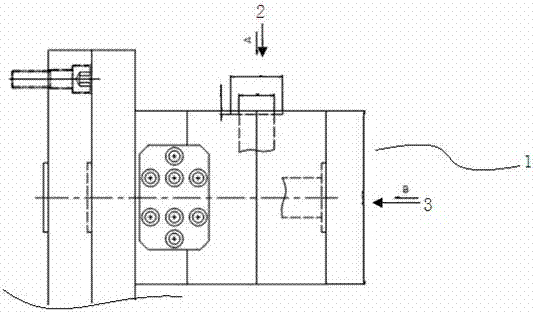

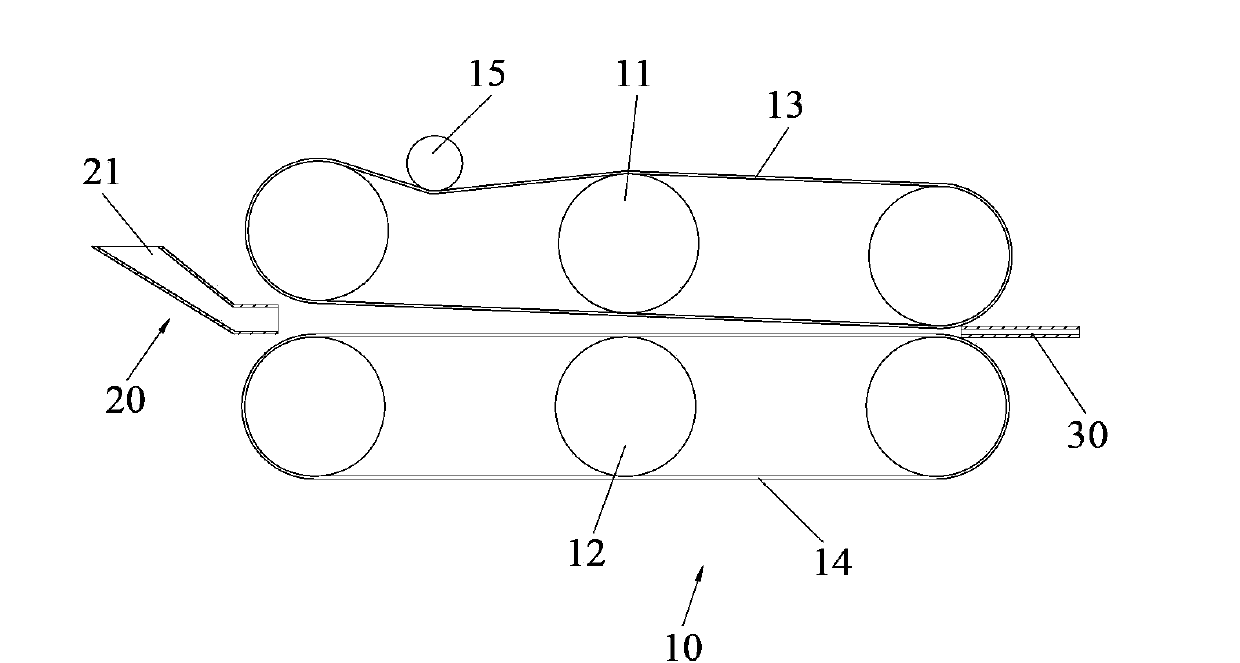

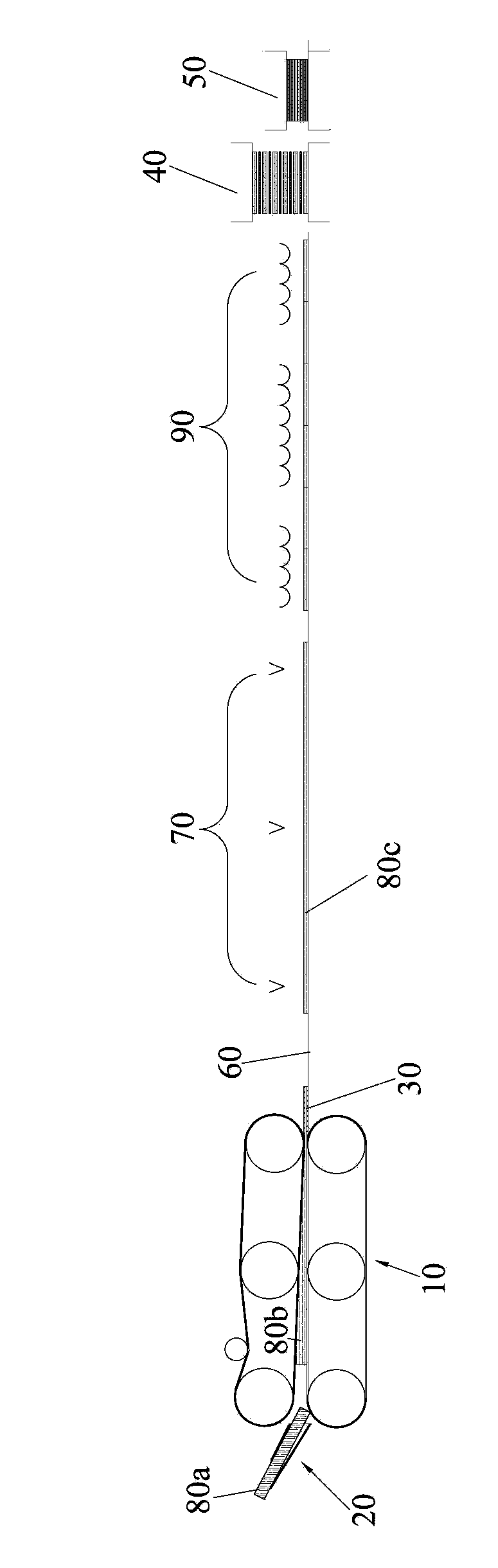

The invention discloses a multilayer composite plate for building templates and brick pallets, which is prepared from magnesium cement gel added with a reinforcing material and a filler, and comprises surface layers (1) and sandwich layers (2); the surface layers (1) or / and the sandwich layers (2) comprise the filler or / and the reinforcing material with even content or gradient change; the number of the sandwich layers (2) is totally between 1 and 5; and the reinforcing material is arranged between adjacent sandwich layers (2). The invention also comprises a preparation process for the multilayer composite plate, which comprises that: production equipment with the capacity of stirring and preparing materials at multiple positions and rolling at multiple positions orderly rolls the surface layers (1) or / and the sandwich layers (2) on a subplate (3); and the reinforcing material is used as a reinforced structure between adjacent surface layers (1) or / and sandwich layers (2). The products corresponding to the invention have the characteristics of strong applicability, good technical effect and suitability for mechanical continuous production, and have predictable great economic and social values.

Owner:LIAONING FENGCHENG INDAL TECH

Method for producing wood plastic composite material using plant straw and waste plastic and material thereof

InactiveCN101417459ASimple processing technologyDo not reproduceFlat articlesDomestic articlesFiberPolyester

The invention relates to a method for manufacturing wood plastic composite material by using plant straw and waste plastics and materials thereof. Polyester and plant wood fiber materials such as sawdust, bamboo powder, rice hull, straw, and the like, are mixed according to certain ratios, a tailor-made additive is added, and after the processes of high temperature, extrusion, molding, and the like, the composite building profile is manufactured. The wood plastic material can replace wood, plastics, and the like, and is mainly used in the industries of packaging, building materials, furniture, logistics, and the like. The invention has simple processing technology, and the product has good processing properties and strength property, good water proof and corrosion resistant property and adjustability, the materials have wide sources and applications, especially the plant straw and waste plastics which contain waste mulch film and are recovered under the northern planting pattern of mulch film can be used for production, thus using the waste and restraining the current pollution of the mulch film planting to the lands effectively.

Owner:石河子市森力新材料科技有限公司

Flame-retardant fiber board and manufacturing method thereof

InactiveCN101602224ALow priceMaterials are readily availableDomestic articlesFlat articlesFiberPolymer science

The invention relates to a flame-retardant fiber board and a manufacturing method thereof. The flame-retardant fiber board is prepared from the following raw materials in portion by weight: 80 to 120 portions of fiber, 80 to 120 portions of magnesia, 80 to 200 portions of water solution of magnesium sulfate, 5 to 30 portions of active silica, 0.5 to 2 portions of organosilicon waterproof agent, and 0.5 to 1.5 portions of plasticizer. The manufacturing method comprises the steps: 1) preparing the fiber, namely cleaning and drying crop straws, wood branches or wood processing residual materials, and then obtaining the fiber through the crushing by a crushing machine; 2) preparing an inorganic adhesive, namely mixing the magnesia, the water solution of the magnesium sulfate, the active silica, the organosilicon waterproof agent and the plasticizer, and stirring the mixture to obtain the inorganic adhesive; 3) mixing the fiber and the inorganic adhesive prepared through the step 1 and the step 2, stirring the mixture, and paving the mixture after the screening by a screening machine; 4) paving a reinforcing network on the upper and lower surfaces of a paved slab; and 5) finally performing hot pressing on the board paved with the reinforcing network for 10 to 25 minutes at a temperature of between 100 and 110 DEG C at a pressure of between 12 and 30MPa to obtain the flame-retardant fiber board. The flame-retardant fiber board has broad application field.

Owner:湖南迪普环保建材有限公司

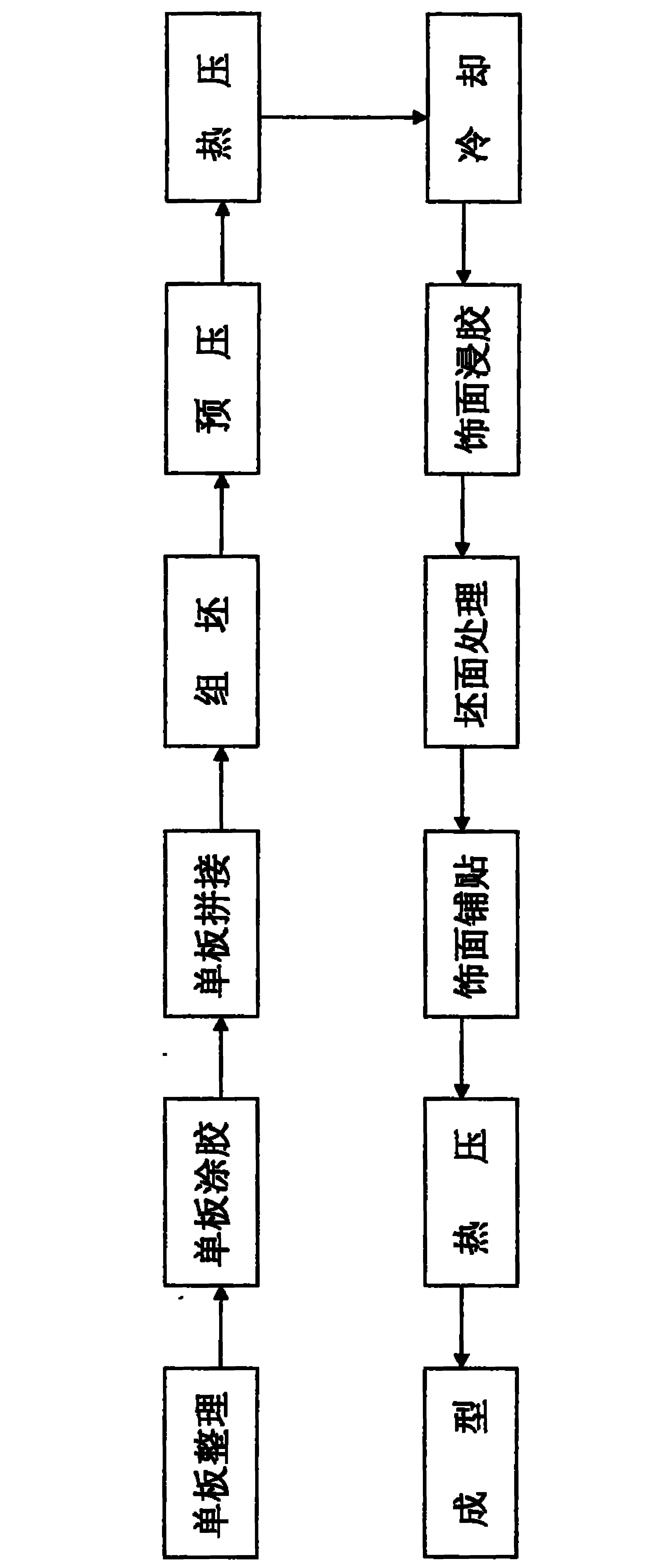

Production method and manufacturing process for environmentally-friendly decorative board

InactiveCN102528861AWaterproofStrong nail gripWood veneer joiningWood layered productsEngineeringMechanical property

The invention relates to a method and a manufacturing process (attached drawing) for producing an environmentally-friendly decorative board by using a fast-growing poplar rotary cut veneer, which mainly solve the problems of low bonding strength, high probability of cracking and warping, uncompacted corner, high formaldehyde release, low nail holding power, high probability of falling, poor water proofing, moisture proofing and fire proofing performance existing in the conventional decorative board. The production method and the manufacturing process are mainly characterized in that: the density of a finished board is determined by using the apparent density (actually measured) of the fast-growing poplar rotary cut veneer in comparison with the density of red pine; a compression ratio is determined according to the two densities; and the thickness of an assembly is determined by using the compression ratio. Modified urea-formaldehyde resin and melamine resin are mixed as an adhesive; and parameters for a hot pressing process of a board blank are determined according to the compression ratio, and curing temperature, time and pressure of an adhesive. Decorative paper which is soaked in the adhesive solution is adhered to the surface and the back surface of the board blank formed after hot pressing, and then secondary hot pressing is performed to finish the final environmentally-friendly decorative board. The production method and the manufacturing process have the advantages of mechanical property of the finished product beyond that of timber, no formaldehyde release, water proofing, moisture proofing, fire proofing and cracking prevention effects, high nail holding power, repeatedly detachable hardware and small variability.

Owner:LIAONING JIUJIU WOOD

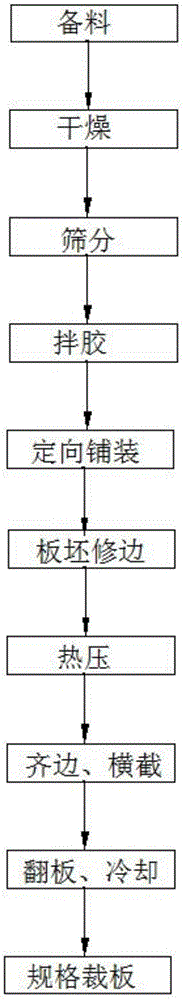

Preparation method for novel low-density, low-cost and high-strength shaving board

The invention relates to a preparation method for a novel low-density, low-cost and high-strength shaving board which comprises a surface layer, a shaving layer and a core layer. The preparation method comprises the following specific steps: (1) carrying out material preparation; (2) carrying out drying, specifically, drying wet shavings obtained in the step (1) until the water content of the shavings reaches 2-4% through condensed hot water at 95-98 DEG C; (3) carrying out sieving, specifically, sieving the shavings dried in the step (2) into surface shavings, core shavings and fine shavings; (4) carrying out glue mixing; (5) carrying out directional pavement; and (6) sequentially carrying out plate blank trimming, hot-pressing, edging and cross cutting, plate turning and cooling, and on-specification plate cutting to obtain the shaving board meeting requirements. According to the preparation method disclosed by the invention, Tongda electric power generating condensed water (at about 95 DEG C) is directly used as drying heat energy, a boiler has no need to be used, the utilization rate of the heat energy is increased by 30%, the drying heat energy cost of the plate is greatly lowered, a fire risk during the drying process is prevented, an industrial model of circular economy is achieved, low-carbon and environment-friendly production is realized, and the economic mode can adapt to the new normal of economic development actively.

Owner:聊城德晟木业有限公司

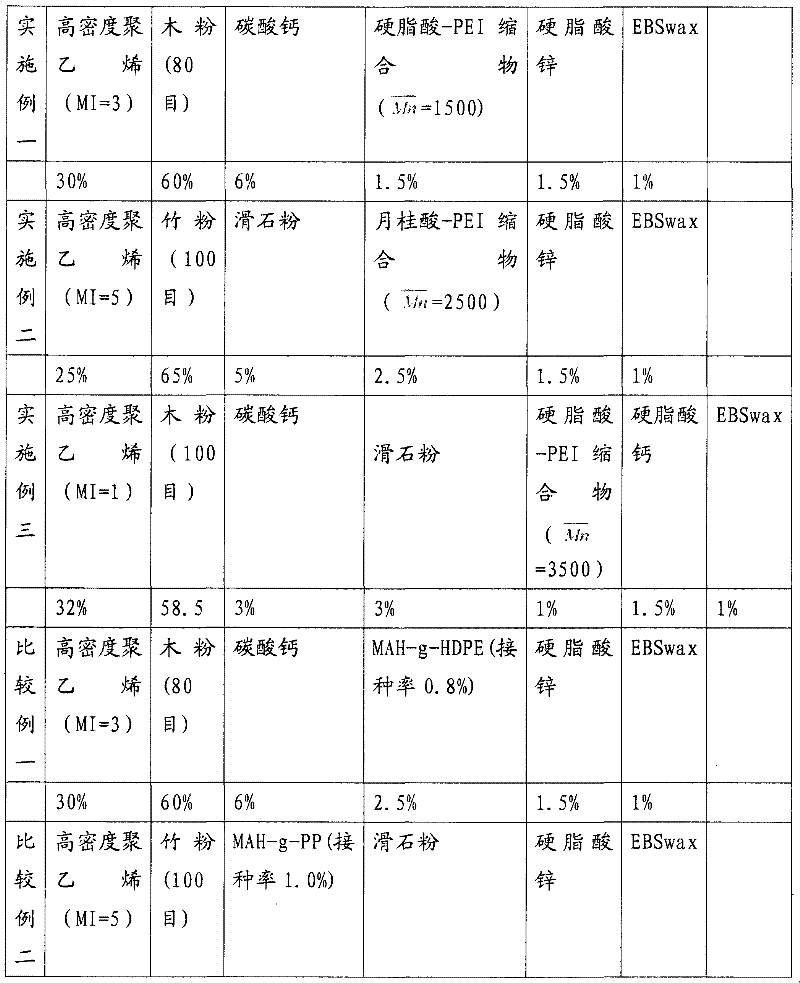

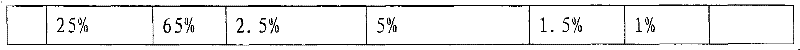

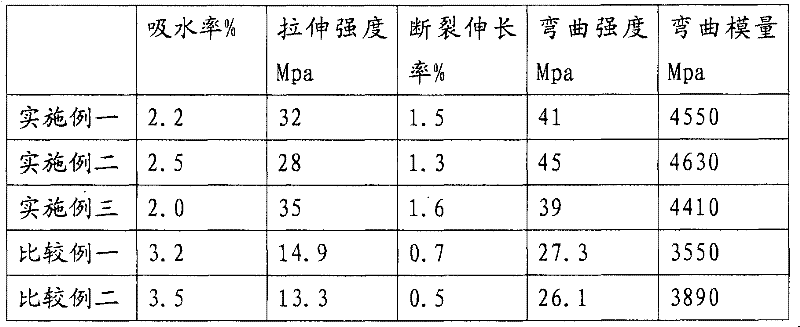

Natural fiber filled polyethylene composite material and preparation method thereof

InactiveCN102532661AGood processing performanceGood mechanical propertiesRevolutions per minuteEthylene imine

The invention provides a natural fiber filled polyethylene composite material and a preparation method thereof. The natural fiber filled polyethylene composite material comprises the following components by weight percent: 20-50% of high density polyethylene, 40-70% of natural fiber powder, 1-6% of fatty acid polyethylenimine condensation product, 1-15% of inorganic mineral filler and 1-6% of lubricating agent. The preparation method comprises the following steps: adding weighed natural fiber powder particles into a high-speed mixer, and stirring for 20-30 minutes at the speed of 2000r / min (revolutions per minute); adding other components in proportion, mutually mixing and stirring for 10-20 minutes, and then adding the mixture into a homodromous and parallel two-screw extruder; and pelleting to obtain the particles of the natural fiber filled polyethylene composite material. By using the preparation method, the defects that a common WPC (wood plastic composite) material is poor in mechanical property and poor in humidity resistance are solved.

Owner:广东省石油化工研究院

Method of preparing plastic-wood material by using abelmoschus manihot straws

The invention discloses a method of preparing a plastic-wood material by using abelmoschus manihot straws. The method comprises the steps of preparing abelmoschus manihot powder, heating in an electrically auxiliary manner, mixing at a high speed, dehumidifying, pelletizing, extruding, processing and forming. According to the method of preparing the plastic-wood material by using the abelmoschus manihot straws, a process design is reasonable, the operability is strong, a preparation process is preferably selected according to fiber characteristics and physical and chemical properties of the abelmoschus manihot, and the prepared plastic-wood is high in strength, strong in nail-holding power, high in wood fiber content, high in impact resistance, high in environment friendliness, and is an excellent plastic-wood material. Moreover, the materials in the method are traditional Chinese medicine wastes, so that the production cost is low; in the materials, plant fibers are long and high in content, waste resources can be recycled, physical performances such as product impact strength can be improved, the service life is prolonged, and economical benefits and social benefits are important.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

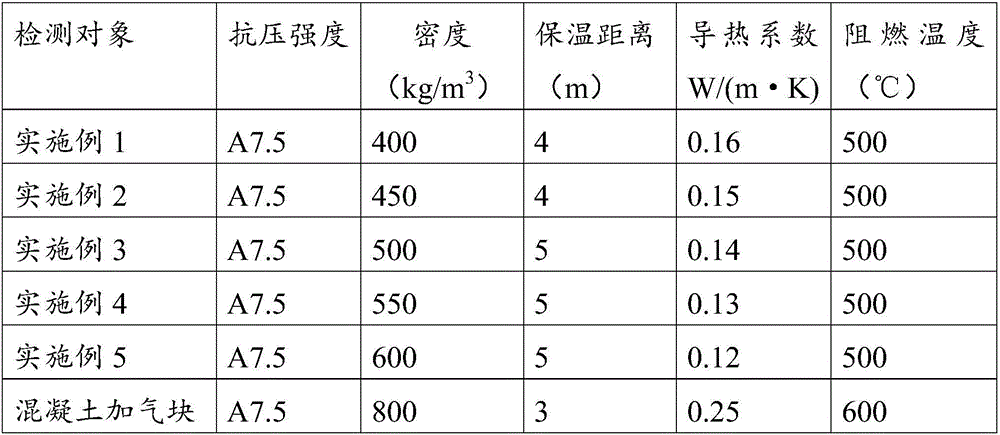

Biological environment-friendly walling material and preparation method thereof

The invention relates to a biological environment-friendly walling material and a preparation method thereof. The walling material comprises the following raw materials in parts by weight: 80-120 parts of main material, 16-24 parts of adhesive and 24-36 parts of water, wherein the main material comprises cement, fine sand, straws and / or couch grass in a mass ratio of (16-24):(8-12):(56-84).The preparation method comprises the following steps: crushing couch grass and / or straws, cutting, and baking to obtain a fiber material; proportionally mixing and blending cement, fine sand, adhesive and water to obtain slurry; uniformly stirring the fiber material and the slurry, and then performing compression molding to obtain a wall blank; and performing natural curing or steam curing on the wall blank until the wall blank is finally set, and cutting to obtain the finished product. The biological environment-friendly walling material provided by the invention is light in weight, has favorable warm keeping / heat insulation / sound insulation properties, achieves a flame retardant effect, and can reduce the weight of a building; and meanwhile, by using the biological environment-friendly walling material, the forest fire hidden danger caused by burning of couch grass and / or straws and resulting air pollution is reduced, and the damage to environmental resources due to massive use of yellow sand is decreased.

Owner:武汉市木兰之春环保科技有限公司

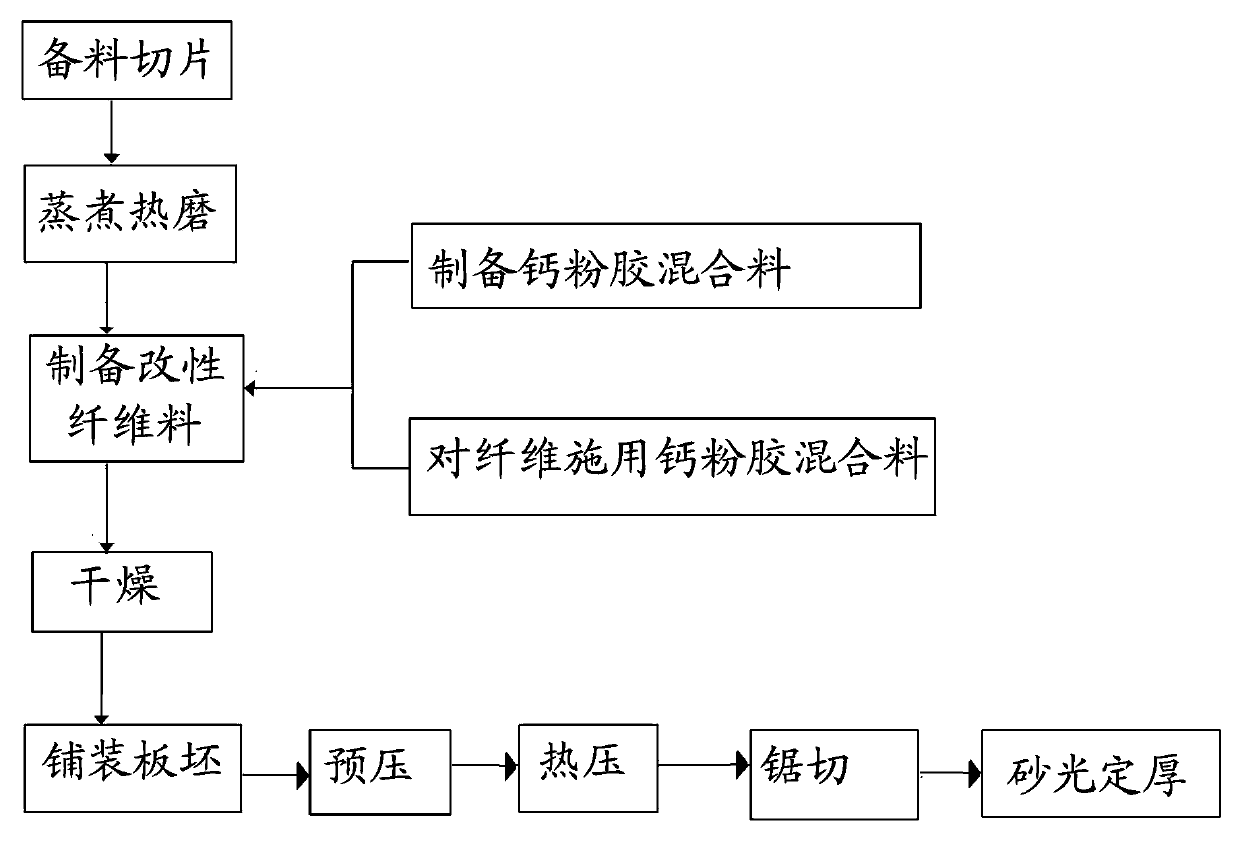

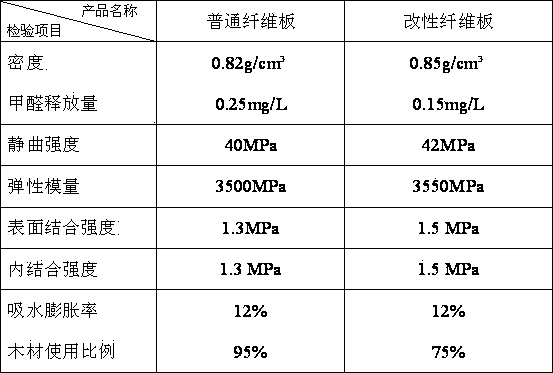

Modified fiber board production process

The invention relates to a modified fiber board production process. The modified fiber board production process includes steps of chipping, digesting, hot grinding, preparation of modified fibers, drying, preparation of blank materials, cold pressing, hot pressing, saw cutting, sanding, thickness determination and the like. In the step of preparation of modified fibers, calcium powder is added into fibers and used for replacing part of wood fibers, the calcium powder is mixed with glue prior to being mixed with the fibers during filling so as to enable clearances of the fibers to be filled by mixture of the calcium powder and the glue, and accordingly physical and chemical performances of fiber boards are improved, and improvement of board density, reduction of wood consumption and improvement of elasticity modulus indexes and static bending strength of the boards are achieved while reduction of fiber board production cost and effective saving of wood resources are realized. Wood consumption is reduced by about 20% as compared with that of common fiber boards, and the modified fiber boards produced according to the process have the advantages of high strength, high nail holding ability, excellent bending resistance and high stability and flame retardance.

Owner:湖北益嘉林业发展有限公司

Production technology of polypropylene building template

InactiveCN103012958AExcellent impact resistanceExcellent deformation resistanceForming/stuttering elementsConstruction engineeringProcess engineering

The invention provides a production technology of a polypropylene building template, which is the technology for producing the building template by adopting waste plastics as the raw materials. The production technology comprises the steps of pretreating the raw materials, mixing the materials, and carrying out extrusion molding. The raw materials are treated based on a certain ratio and prepared into the product building template under a certain condition. The product building template has the characteristics that the construction quality is high, the building template can be recycled for a plurality of times, the cost is reduced, the benefit is increased, the energy conservation and environment protection are realized, and the residues can be recycled; and the product building template has a large market demand and wide prospect, and is an excellent substitute for steel templates, bamboo plywood and wood plywood.

Owner:HUNAN FENGSHUO TECH

Self-insulating composite wallboard and production method

PendingCN105672561AEasy to installStrong nail gripClimate change adaptationBuilding componentsTwo layerTextile

The invention discloses a self-insulating composite wallboard which comprises an outer board and an inner board.In the outer board, two layers of outer grid cloth clamp a middle board in the middle and are sewn and connected together through inorganic alkali-resisting sewing threads and arranged in cement-based mortar.In the inner board, inner grid cloth is arranged on the inner side of steel wire meshes, and the steel wire meshes and the inner grid cloth are evenly arranged in the cement-based mortar.One side of the outer board is fixedly connected with the outer side of the inner board together.The invention further discloses a production method of the self-insulating composite wallboard.The outer board is firstly produced, then the inner board is manufactured, the outer board is arranged on the inner board when inner board mortar is not dried, and the composite wallboard is obtained after drying.The self-insulating composite wallboard adopts the structure that the inner board and the outer board are compounded and meanwhile has the advantages of self insulation, heat insulation, water proofing, fire proofing, cracking prevention, seismic resistance, fracture resistance, light weight, convenient installation, any cutting, strong nail-holding power and convenient slotting and pipe laying.

Owner:罗寅

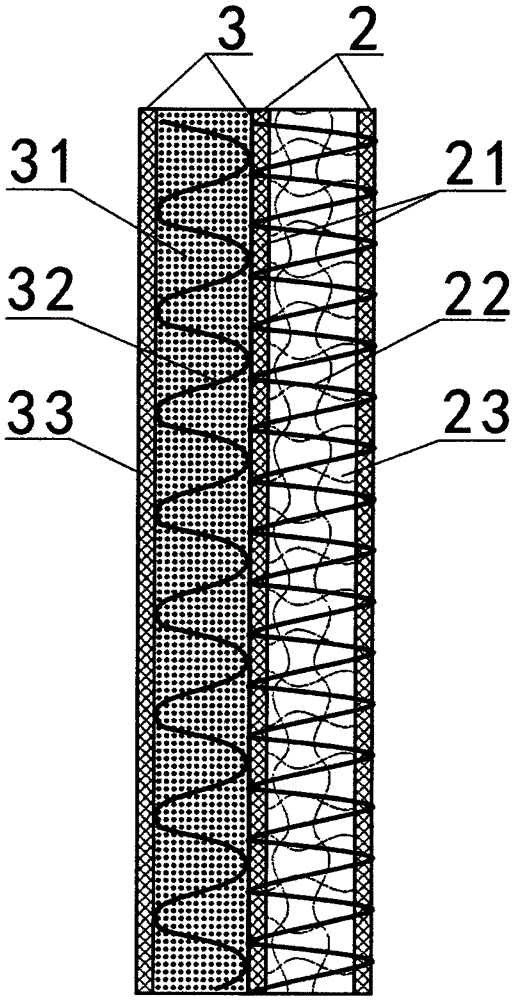

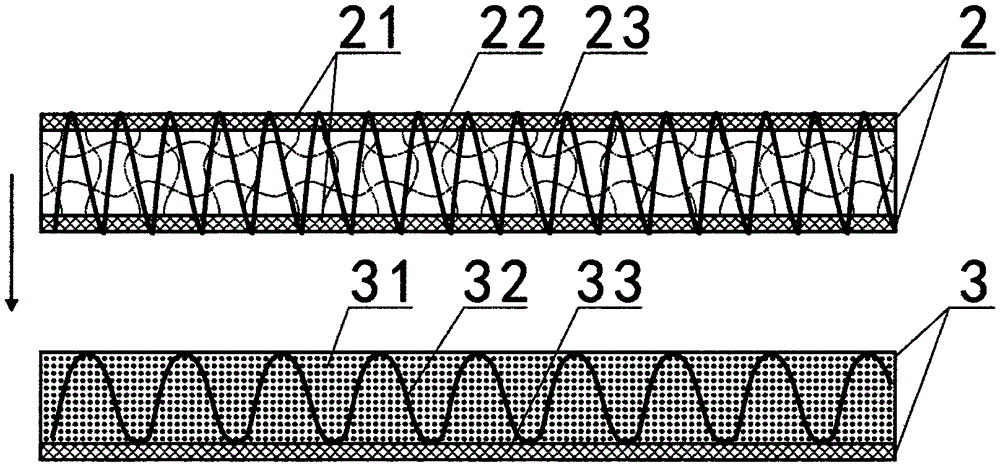

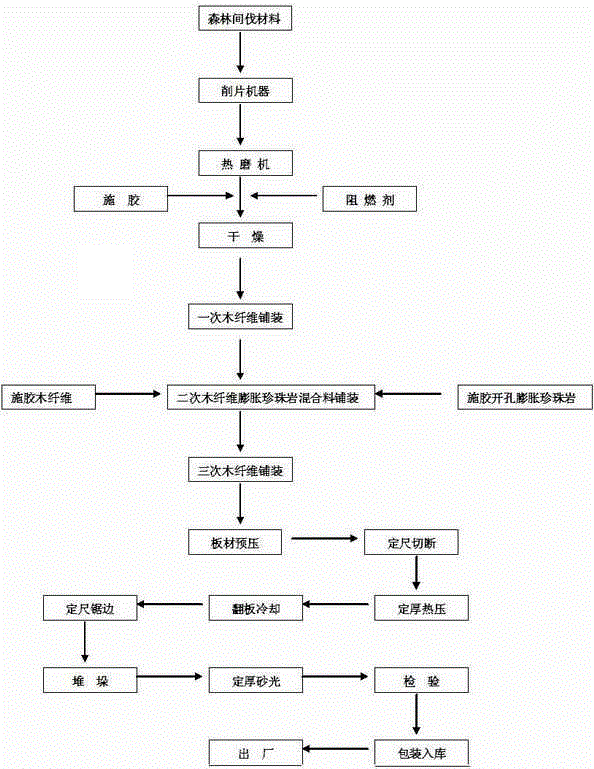

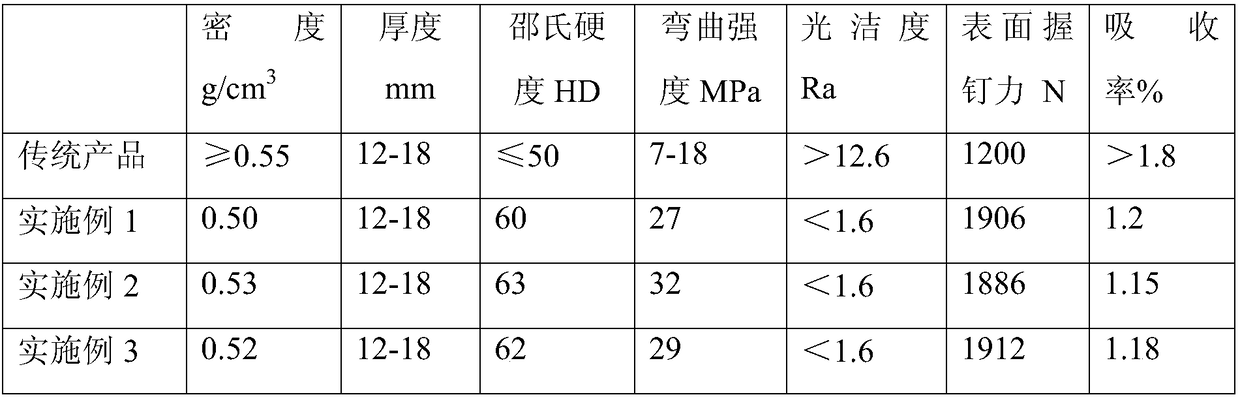

Ultra-light-weight composite environment-friendly fiber board and preparing method of ultra-light-weight composite environment-friendly fiber board

The invention discloses an ultra-light-weight composite environment-friendly fiber board and a preparing method of the ultra-light-weight composite environment-friendly fiber board, and belongs to the technical field of an ultra-light-weight fiber board. The ultra-light-weight composite environment-friendly fiber board is characterized by comprising an upper flame-retardant wood fiber layer, a lower flame-retardant wood fiber layer and a wood fiber and expanded perlite mixing layer arranged between the upper and lower flame-retardant wood fiber layers. The invention also discloses the preparing method of the ultra-light-weight composite environment-friendly fiber board. The ultra-light-weight composite environment-friendly fiber board has a series of advantages that the supporting capacity of a high-rise building partition wall is effectively reduced; the strength of the wall surface is enhanced; the properties such as the impact-resistant property, the folding-resistant property and the nail holding force are good; the heat insulation function, the fireproof function, the sound isolation function, the anti-seismic function and the aging-resistant effect are achieved; the secondary wall surface decoration is convenient; and the attaching force of a decoration surface is strong, and the like.

Owner:河南鑫饰板业有限公司

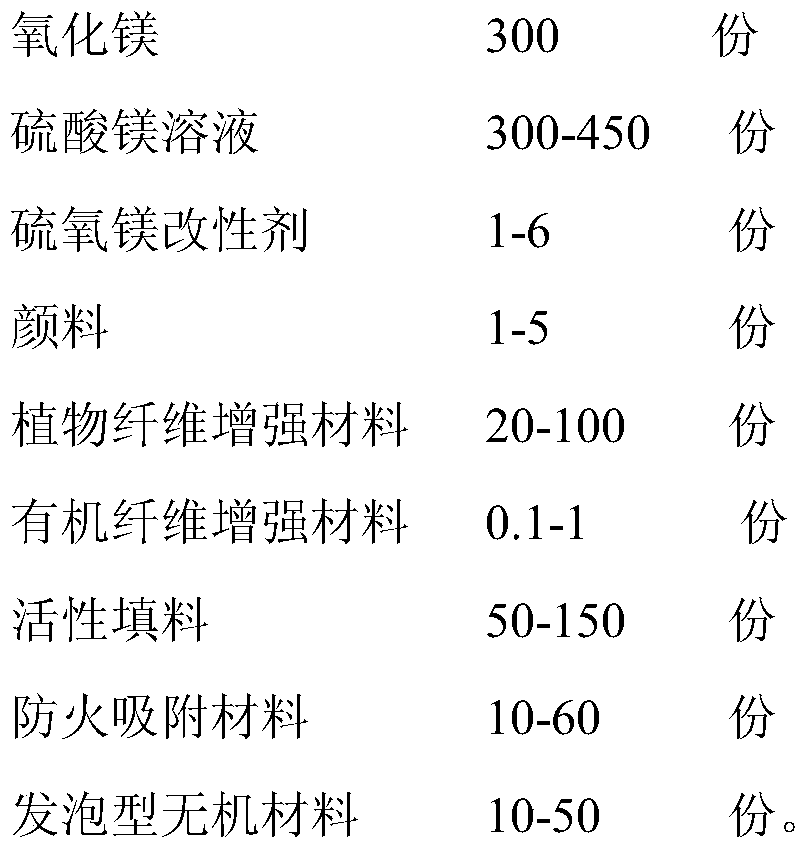

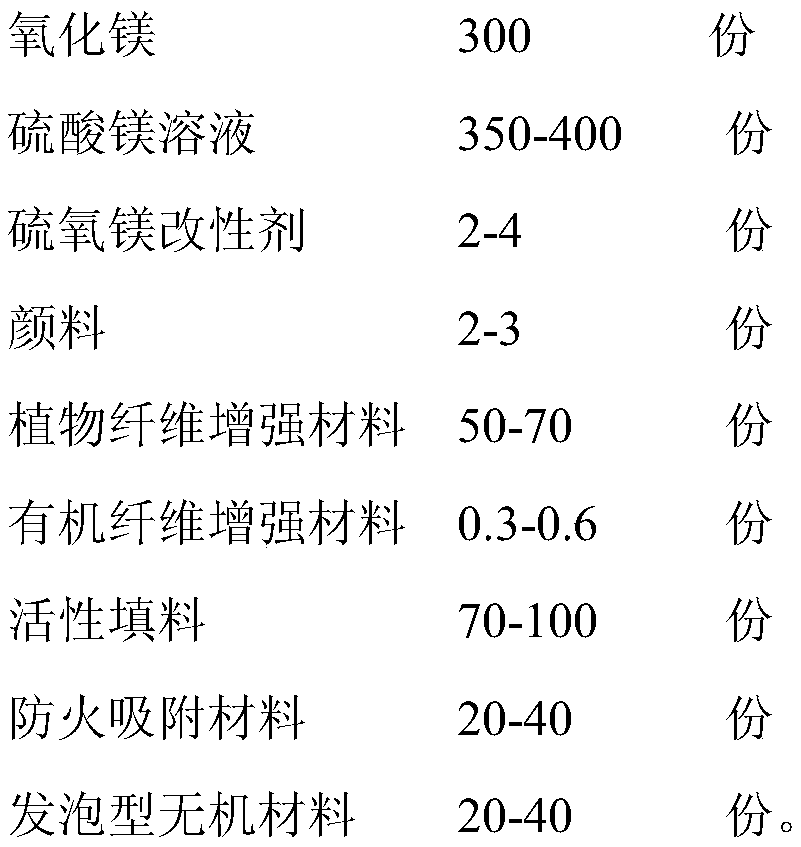

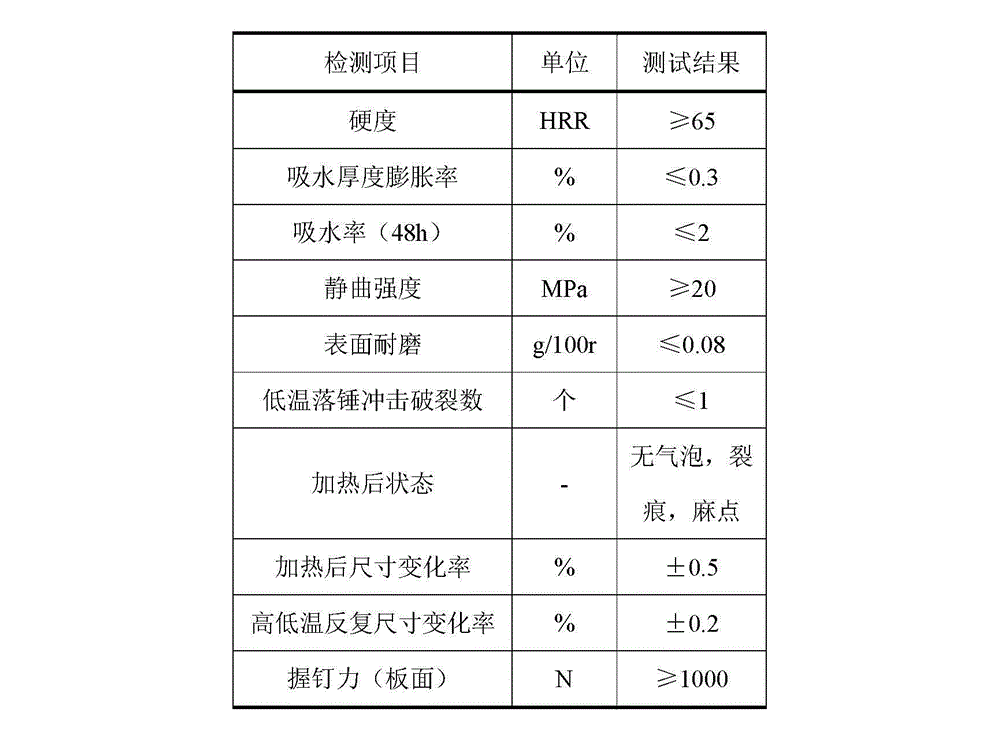

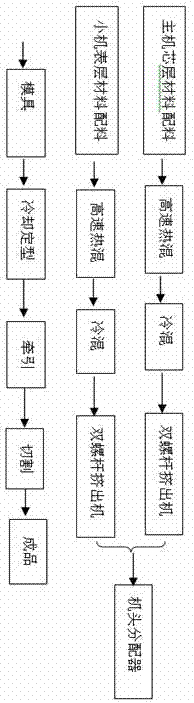

Fireproof and soundproof floor board based on sulfur-oxygen-magnesium materials and preparation method thereof

A fireproof and soundproof floor board based on sulfur-oxygen-magnesium materials and a preparation method thereof disclosed by the invention relate to the field of building materials. The floor board of the invention is prepared by the following materials, by weight: 300 parts of magnesium oxide, 300-450 parts of a magnesium sulfate solution, 1-6 parts of a sulfur-oxygen-magnesium modifier, 1-5 parts of a pigment, 20-100 parts of a plant fiber reinforced material, 0.1-1 part of an organic fiber reinforced material, 50-150 parts of an active filler, 10-60 parts of a fireproof adsorption material, and a foaming type inorganic material. The floor board of the invention retains the fireproof performance and impermeability of the sulfur-oxygen-magnesium materials to provide fireproof and moisture-proof functions for a sound absorbing substrate, is increased in the toughness and machinability and endowed with the characteristics of sawing, planing, slotting, easy splicing and no deformation by adding the plant fiber reinforced material, is further improved in strength by adding the organic fiber reinforced material and the active filler, and reduces the density of a fireproof board, achieves the effect of lightweight and is increased in the soundproof effect by adding the foaming type inorganic material.

Owner:布鲁科技(常州)股份有限公司

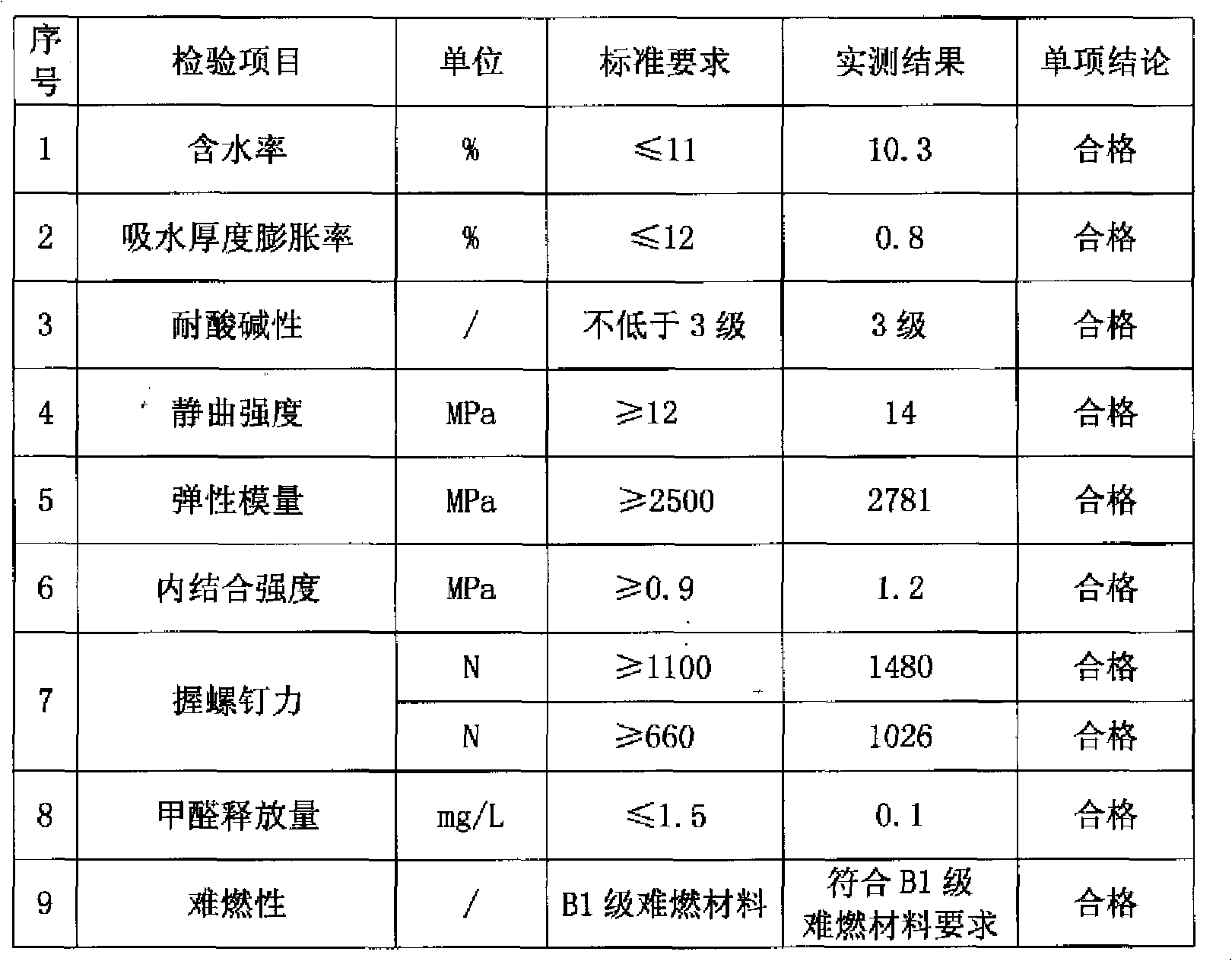

Fiber decoration board with strong nail-holding ability and producing method thereof

The invention relates to a fiber decorative board with high nail-holding ability and a production method thereof, and belongs to the technology field of glass / magnesium fiber decorative boards and production method thereof. The invention is characterized in that the fiber decorative board is made from the following materials according to mass percentage: (1) 1 part of magnesium oxide, 0.8-1.2 parts of aqueous solution of magnesium chloride and 0.2-0.4 parts of talc powder, which are mixed until pasty and serve as coating; (2) 1 part of magnesium oxide, 3-5 parts of aqueous solution of magnesium chloride, 0.3-0.5 parts of talc powder, 0.4-0.6 parts of crop fiber, 1.8-2.2 parts of wood fiber and 0.5-1.5 parts of at least one selected from palm fiber, bamboo fiber, cotton fiber, nylon fiber, polyacrylonitrile fiber, bast fiber, fabric fiber overleft from clothing factory, and waste fabric fiber, which are mixed and serve as major ingredient. The production method comprises the following steps: coating a demoulding agent on a template of work table top, paving neutral-alkaline glass fiber fabric on the template, spreading the coating paste on the glass fiber fabric, spreading the major ingredient on the coating and leveling, paving glass fiber fabric on the flat major ingredient, coating with the coating paste, curing to allow molding, demoulding, ageing, cutting and trimming, packaging and storing. The inventive fiber decorative board has high nail-holding ability and good resistance to fire and water.

Owner:李学进

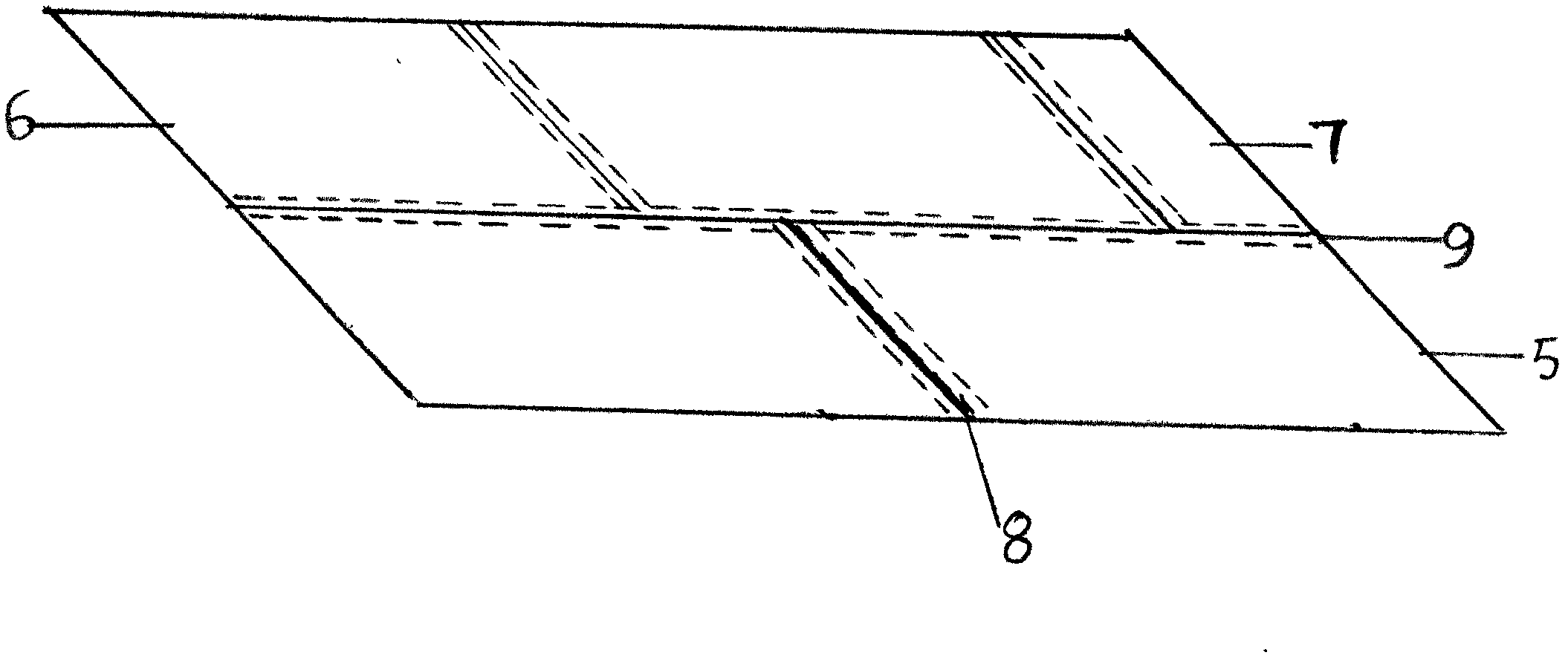

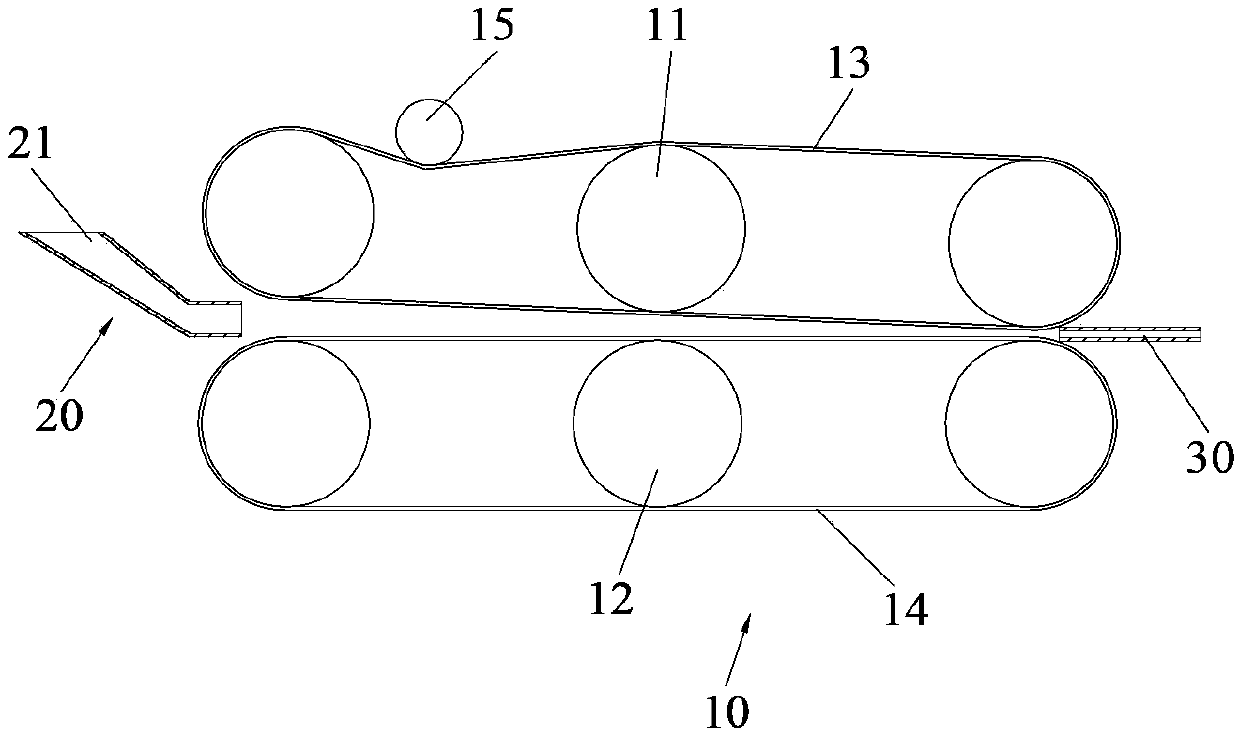

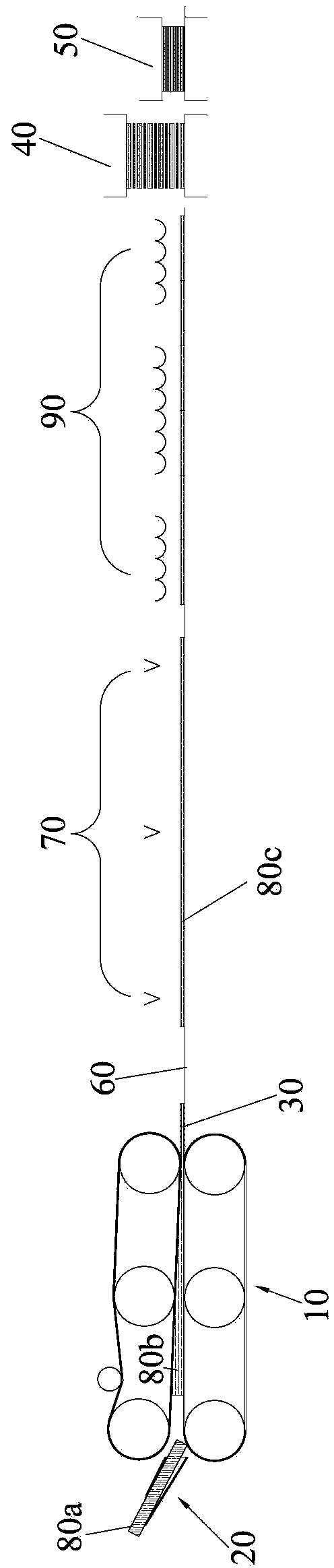

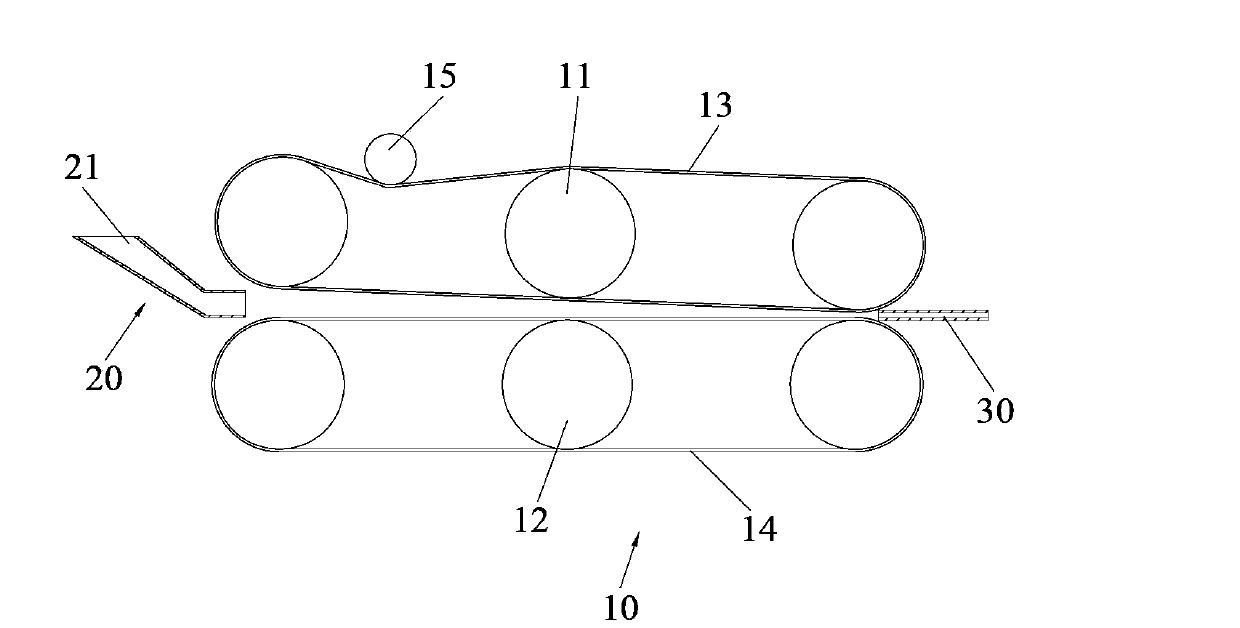

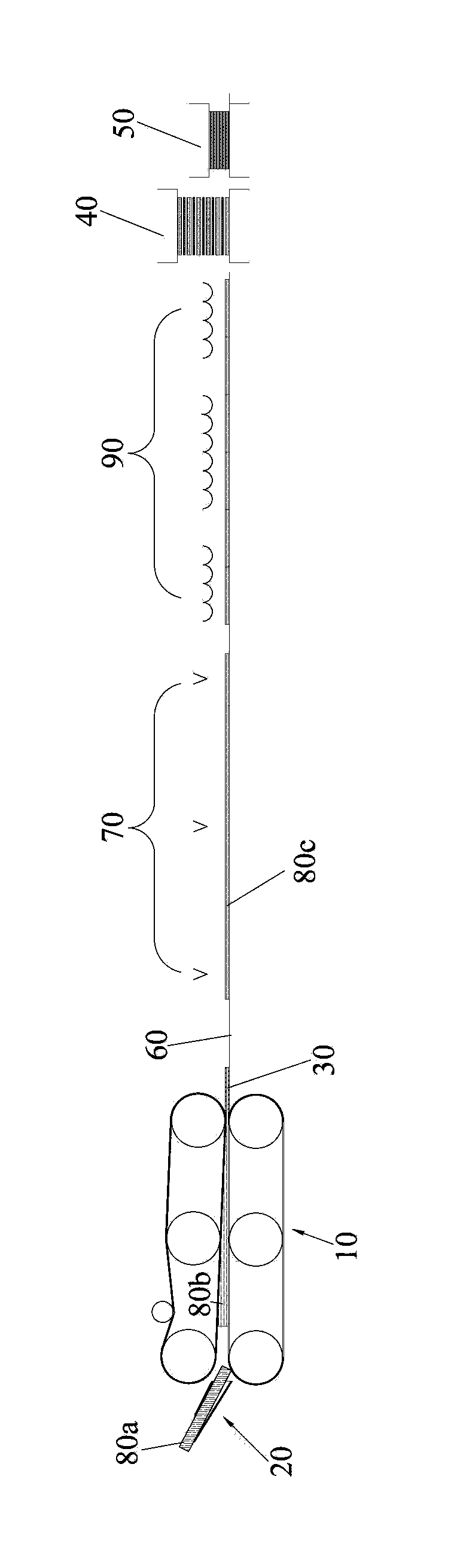

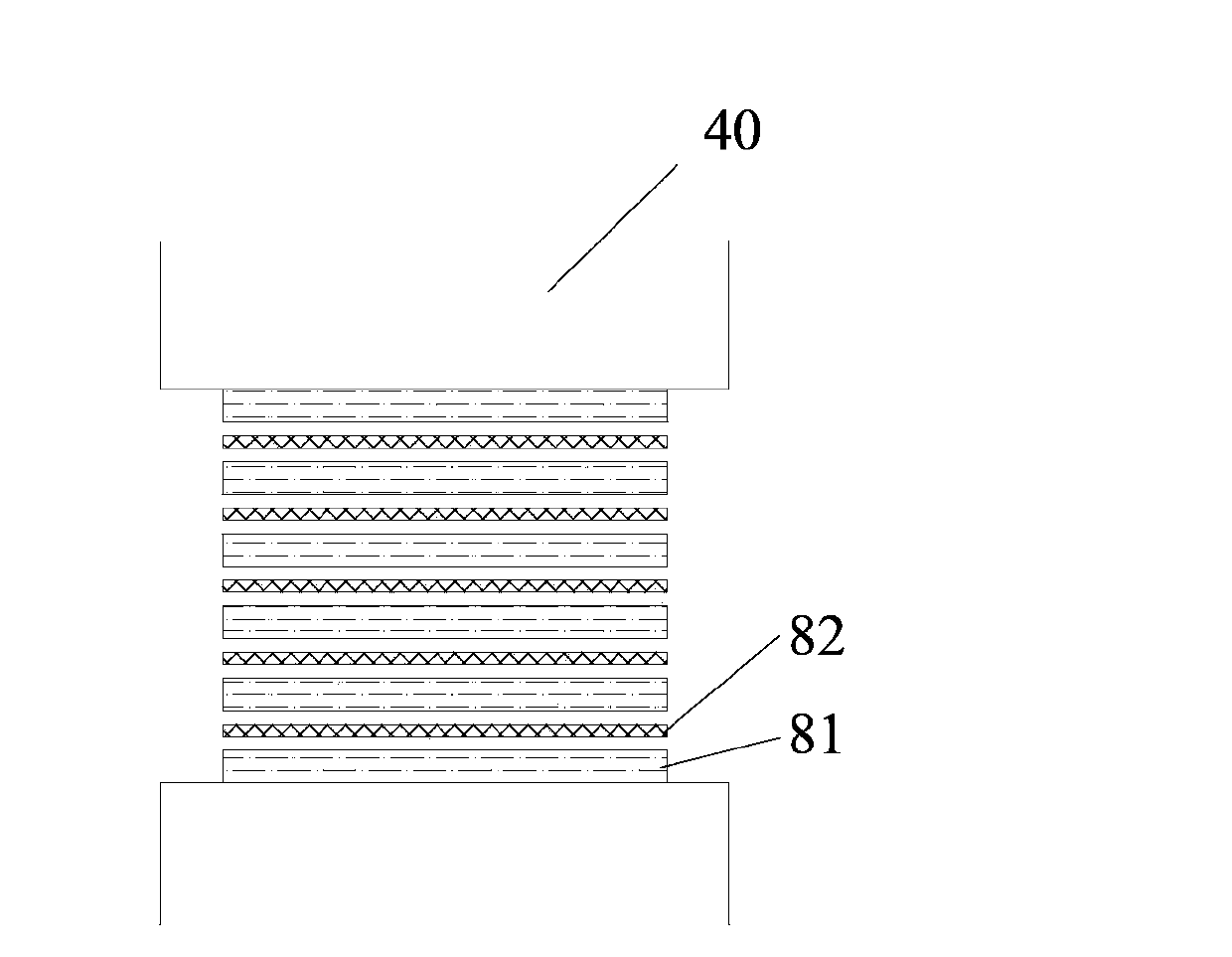

Multilayer board, producing method for multilayer board and lancing device for veneer of multilayer board

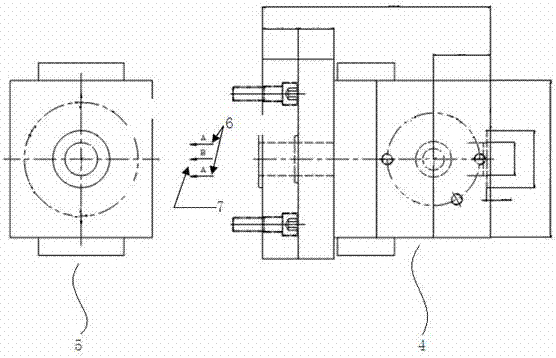

ActiveCN105252606AAvoid deformationStrong nail gripOther plywood/veneer working apparatusWood veneer joiningStructural relationMonoboard

The invention provides a multilayer board, a producing method for the multilayer board and a lancing device for a veneer of the multilayer board. According to the anti-deformation multilayer board and the producing method, a lance is formed in the veneer; the structural relation of the lance can provide a deformation space for the veneer when the veneer is deformed, so that overall deformation of the veneer is prevented; at the same time, the lancing device for the veneer of the multilayer board can process the lance with an anti-deformation structure on the veneer quickly, and the overall deformation of the veneer is prevented. According to the provided multilayer board, the technical effects of being free from deformation, layering, bubbling and seaming and high in nail-holding power can be achieved.

Owner:SHIJIAZHUANG HUAJIE WOOD IND CO LTD

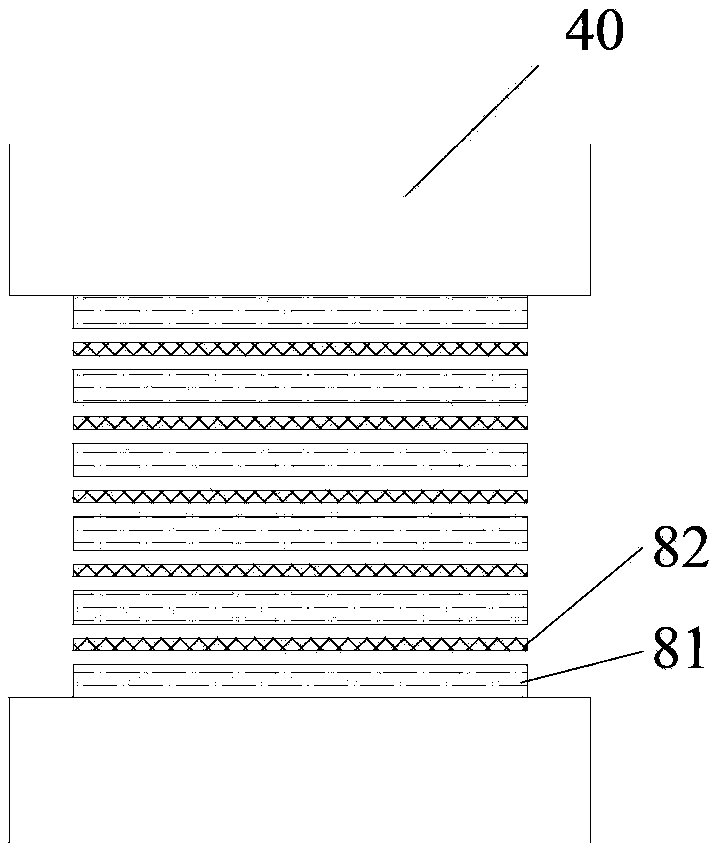

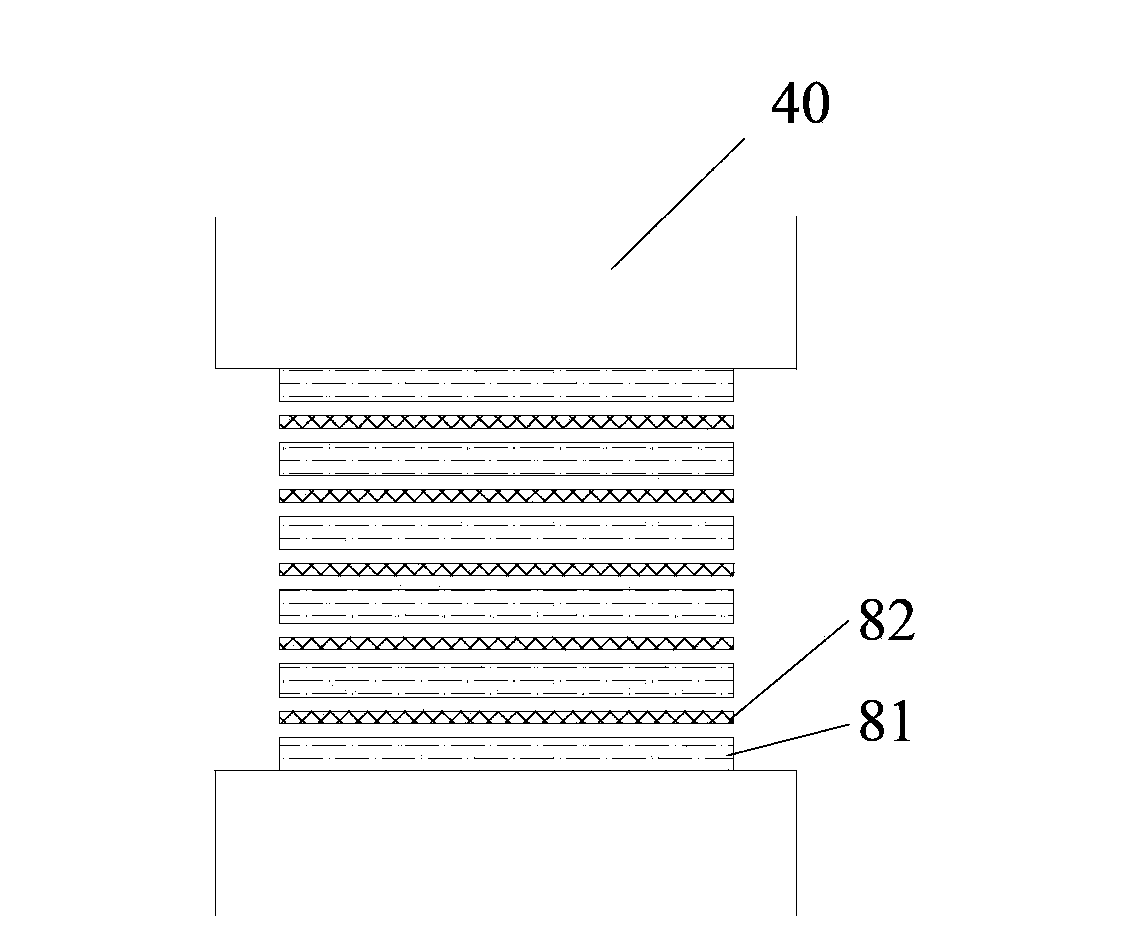

Magnesium cemented pressure plate and manufacturing method thereof

InactiveCN107129258AHigh fire ratingImprove fire performanceCeramic shaping apparatusEpoxyPolyvinyl chloride

The invention discloses a magnesium cemented pressure plate. The magnesium cemented pressure plate comprises the following raw materials in parts by weight: 42-56 parts of domestic waste, 8-16 parts of light-burned magnesium oxide, 5-12 parts of magnesium sulfate, 3-8 parts of magnesium chloride, 2-6 parts of magnesium hydroxide, 6-12 parts of aluminum hydroxide, 8-22 parts of nano silicon dioxide, 10-16 parts of sericite powder, 8-18 parts of glass fiber, 10-18 parts of epoxy resin, 12-32 parts of polyvinyl chloride resin, 1-3 parts of crosslinking agent and 0.3-0.8 part of stabilizer. A manufacturing method of the magnesium cemented pressure plate comprises the following steps: preparing the pressure plate materials; feeding the pressure plate materials into a mold; and performing pressurization, demolding, drying and edging to obtain the finished product. The pressure plate provided by the invention is environment-friendly and nontoxic, the fire-protection rating reaches Level A, and the pressure plate is favorable in wear resistance, heat resistance, water resistance and anti-freezing property and high in nail-holding power; and the manufacturing method is simple and low in production and use cost.

Owner:贵州阳光兴业绿色建材有限公司

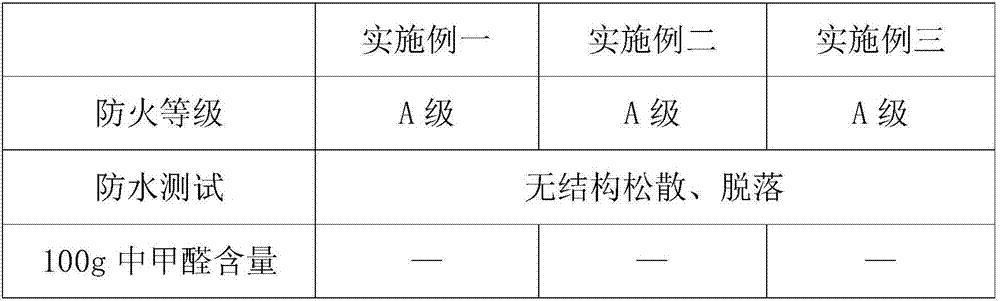

Formaldehyde-free fiber material and formation method thereof, as well as fiber decorative material and manufacturing method thereof

InactiveCN103963134AStrong nail gripStrong resistance to deformationFlat articlesDomestic articlesFiberHigh resistance

The invention provides a formaldehyde-free fiber material and a formation method thereof. The method comprises the following steps: the fiber material is ground into filaments to enable the filaments of the fiber raw material to be loose and basically keep sticky, the filaments and an adhesive are arranged in an alternative manner to form layers, an upper surface layer and a lower surface layer are layers formed by the filaments of the fiber material, and finally hot pressing and cold pressing are sequentially performed, wherein the adhesive comprises LDPE and HDPE. The invention further provides a fiber decorative material and a manufacturing method thereof. According to the fiber decorative material manufacturing method, salix psammophila and a branch material with small diameter are utilized to manufacture the fiber decorative material, and the manufactured fiber decorative material has the advantages of strong nail-holding power, high non-deformability, high resistance to bending and high resistance to tension so as to change salix psammophila and the branch material into valuable things, and the fiber decorative material has great commercial value; in addition, the formaldehyde-free fiber material formation method and the fiber decorative material manufacturing method are simple and have no special requirements for equipment, and the formaldehyde-free fiber material and the fiber decorative material are suitable for large-scale industrial production.

Owner:深圳伟伦嘉禾环保装饰材料有限公司

Formaldehyde-free fiber material and formation method thereof, as well as fiber decorative material and manufacturing method thereof

InactiveCN103963133AStrong nail gripStrong resistance to deformationLaminationWood working apparatusHigh resistanceLinear low-density polyethylene

The invention provides a formaldehyde-free fiber material and a formation method thereof. The method comprises the following steps: the fiber material is ground into filaments to enable the filaments of the fiber raw material to be loose and basically keep sticky, the filaments and an adhesive are arranged in an alternative manner to form layers, an upper surface layer and a lower surface layer are layers formed by the filaments of the fiber material, and finally hot pressing and cold pressing are sequentially performed, wherein the adhesive comprises LDPE and HDPE. The invention further provides a fiber decorative material and a manufacturing method thereof. According to the fiber decorative material manufacturing method, salix psammophila and a branch material with small diameter are utilized to manufacture the fiber decorative material, and the manufactured fiber decorative material has the advantages of strong nail-holding power, high non-deformability, high resistance to bending and high resistance to tension so as to change salix psammophila and the branch material into valuable things, and the fiber decorative material has great commercial value; in addition, the formaldehyde-free fiber material formation method and the fiber decorative material manufacturing method are simple and have no special requirements for equipment, and the formaldehyde-free fiber material and the fiber decorative material are suitable for large-scale industrial production.

Owner:戴武兵

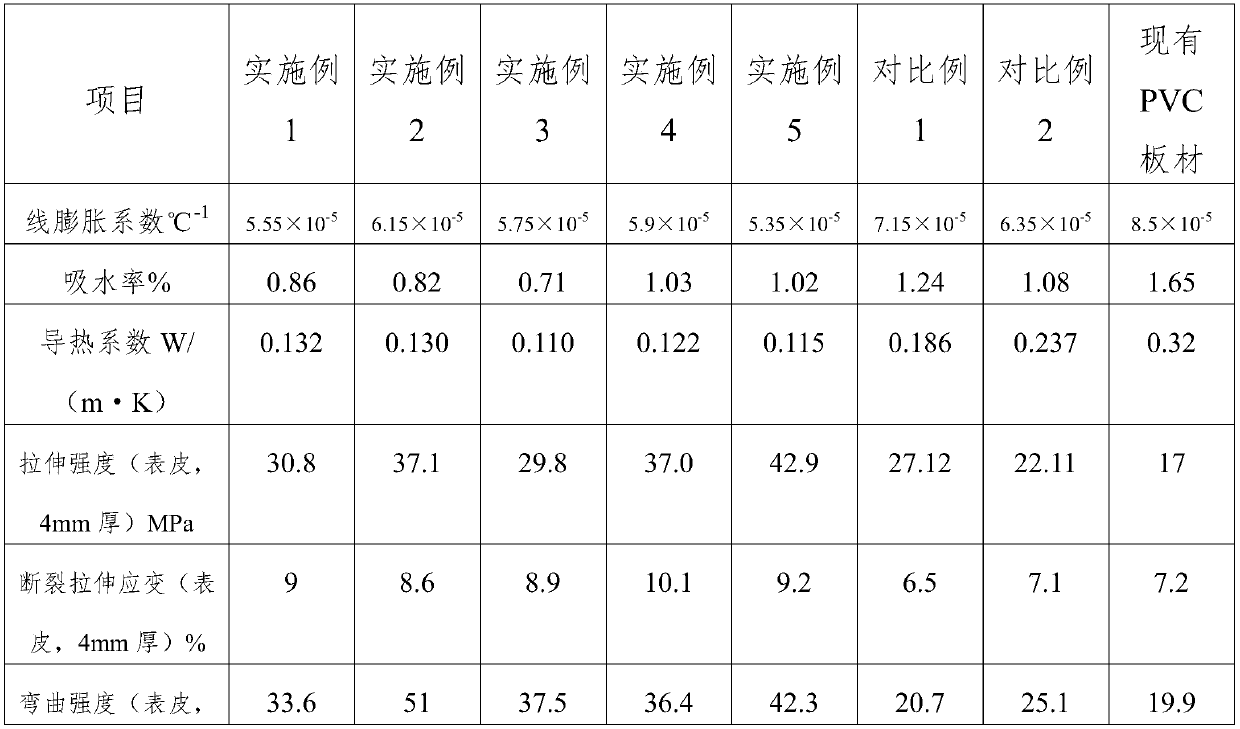

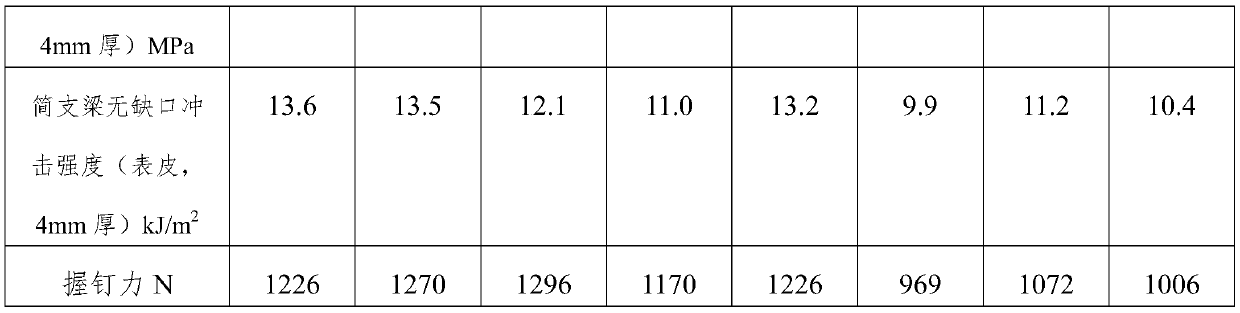

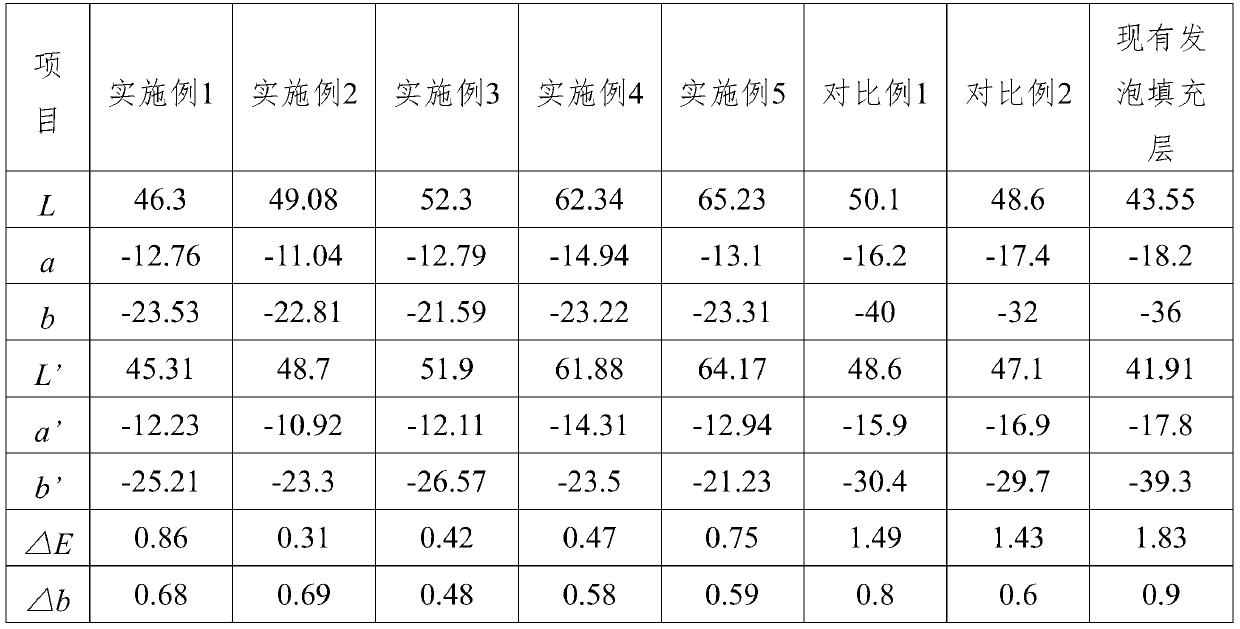

PVC (Polyvinyl Chloride) co-extruded sheet and production method thereof

ActiveCN109910413AHigh strengthGood weather resistanceSynthetic resin layered productsFiberAntioxidant

The invention embodiment discloses a PVC (Polyvinyl Chloride) co-extruded sheet and a production method thereof, and belongs to the technical field of composite materials. The PVC co-extruded sheet comprises a PVC surface layer and a PVC foamed filling layer, wherein the PVC surface layer is prepared from PVC resin, CPVC powder, PBO fibers, a stabilizer, a fire retardant and ground calcium carbonate powder; the PVC foamed filling layer is prepared from the PVC resin, the CPVC powder, the PBO fibers, the stabilizer, the fire retardant, the ground calcium carbonate powder, an impact modifier, talcum powder, an internal lubricant, oxidized polyethlene wax, magnesium oxide, a silane coupling agent, a foam regulator, an ultraviolet light absorber, an antioxidant and an antistatic agent. The PVCco-extruded sheet in the embodiment of the invention has good mechanical property, weather resistance and good promotion value, so that the limitations of an existing PVC foaming material used outdoors are overcome, the cost of outdoor landscape engineering is greatly reduced and further the use field of products is widened.

Owner:北京百草居生物科技集团有限公司

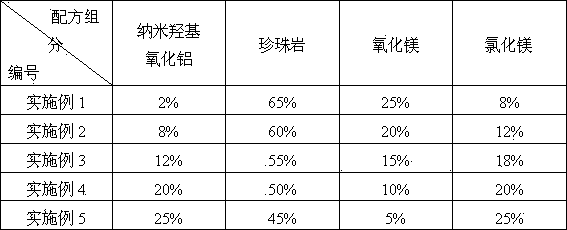

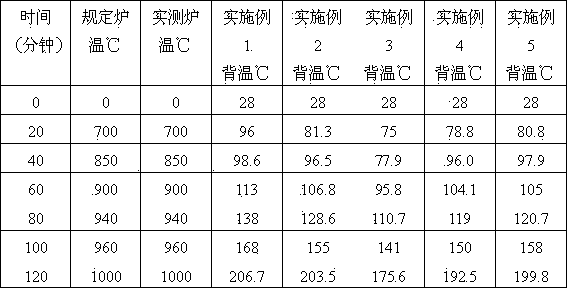

Composite nano-hydroxyl alumina flame-retardant insulation board and manufacturing method and application thereof

The invention discloses a composite nano-hydroxyl alumina flame-retardant insulation board and a manufacturing method and application thereof. The composite nano-hydroxyl alumina flame-retardant insulation board comprises the following components in percentage by weight: 12-18 percent of nano-hydroxyl alumina flame retardant, 50-55 percent of perlite, 15-18 percent of magnesium oxide binder, 16-18 percent of magnesium chloride binder and 30-45 percent of water. The composite flame-retardant insulation board is an inorganic nano-hydroxyl alumina flame-retardant insulation board with low water content, and can be used for making a fireproof door core board and the like. The fireproof door core board has the characteristics of high fire resistance, long fire resistance time, high compressive strength, stable performance, insulation of sound and heat, low heat conductivity coefficient, no toxicity, freeness from nuisance and pollution, excellent environmental protection performance and high machinability.

Owner:安徽顺和消防设备有限公司

Polyvinyl chloride kitchen and bathroom board and preparation method thereof

The invention discloses a polyvinyl chloride kitchen and bathroom board and a preparation method thereof, belonging to the technical field of polyvinyl chloride plates. The invention solves the problems that hydroscopicity of an existing product is poor, density is low and hardness is poor. The polyvinyl chloride kitchen and bathroom board is prepared from 60-80 parts of polyvinyl chloride SG8 resin, 40-60 parts of ground calcium carbonate, 20-40 parts of reclaimed materials, 7-9 parts of a foaming regulator, 2.7-2.9 parts of a lead salt stabilizer, 0.5-0.6 part of an internal lubricant SP-60,0.2-0.3 part of polyethylene wax, 0.2-0.25 part of micronized polyethylene wax N-14P, 0.1-0.15 part of a plasticizer OA6, 0.5-0.6 part of a heat release type AC foaming agent, 1.2-1.4 parts of a heatabsorption type foaming agent and pigments. The preparation method thereof comprises the following steps: sequentially putting materials into a hot mixing pot, heating and then cooling, and then conveying the cooled materials to an extruding machine, so that the finished product is obtained. The invention is mainly applied to preparation of the polyvinyl chloride kitchen and bathroom board.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

Preparation method for wood-plastic board capable of absorbing ultraviolet rays and emitting fluorescence

InactiveCN109720040AImprove the decorative effectStrong nail gripLamination ancillary operationsSynthetic resin layered productsSurface layerFluorescence

The invention relates to the technical field of preparation of fixed luminescent materials, specifically to a preparation method for a wood-plastic board capable of absorbing ultraviolet rays and emitting fluorescence. The wood-plastic board comprises the following materials: 15 to 18% of a core-layer material, 13 to 16% of a surface-layer material located on the surface of the core-layer material, 55 to 60% of wood powder, 1 to 4% of a fluorescent agent, 1 to 4% of a coupling agent and 0.2 to 0.5% of an antioxidant, with the balance being an auxiliary agent. The wood-plastic board prepared byusing the preparation method provided by the invention improves the decorative properties of a material, is broadened in application fields through the function of self-illumination, has long luminescence time, can be used for facilities like indoor decorations and outdoor floors, has more significant utilization value especially in the field of traffic roads, and can exert the effects of illumination, warning, etc.; and the surface of a finished wood-plastic board product has the strength and smoothness of co-extruded polyethylene, and has strong nail-holding force.

Owner:ANHUI RED FOREST NEW MATERIAL TECH

A multi-layer board, a method for producing a multi-layer board, and a slitting device for a multi-layer board veneer

ActiveCN105252606BAvoid deformationStrong nail gripOther plywood/veneer working apparatusWood veneer joiningStructural relationEngineering

The invention provides a multilayer board, a producing method for the multilayer board and a lancing device for a veneer of the multilayer board. According to the anti-deformation multilayer board and the producing method, a lance is formed in the veneer; the structural relation of the lance can provide a deformation space for the veneer when the veneer is deformed, so that overall deformation of the veneer is prevented; at the same time, the lancing device for the veneer of the multilayer board can process the lance with an anti-deformation structure on the veneer quickly, and the overall deformation of the veneer is prevented. According to the provided multilayer board, the technical effects of being free from deformation, layering, bubbling and seaming and high in nail-holding power can be achieved.

Owner:华杰图略科技有限公司

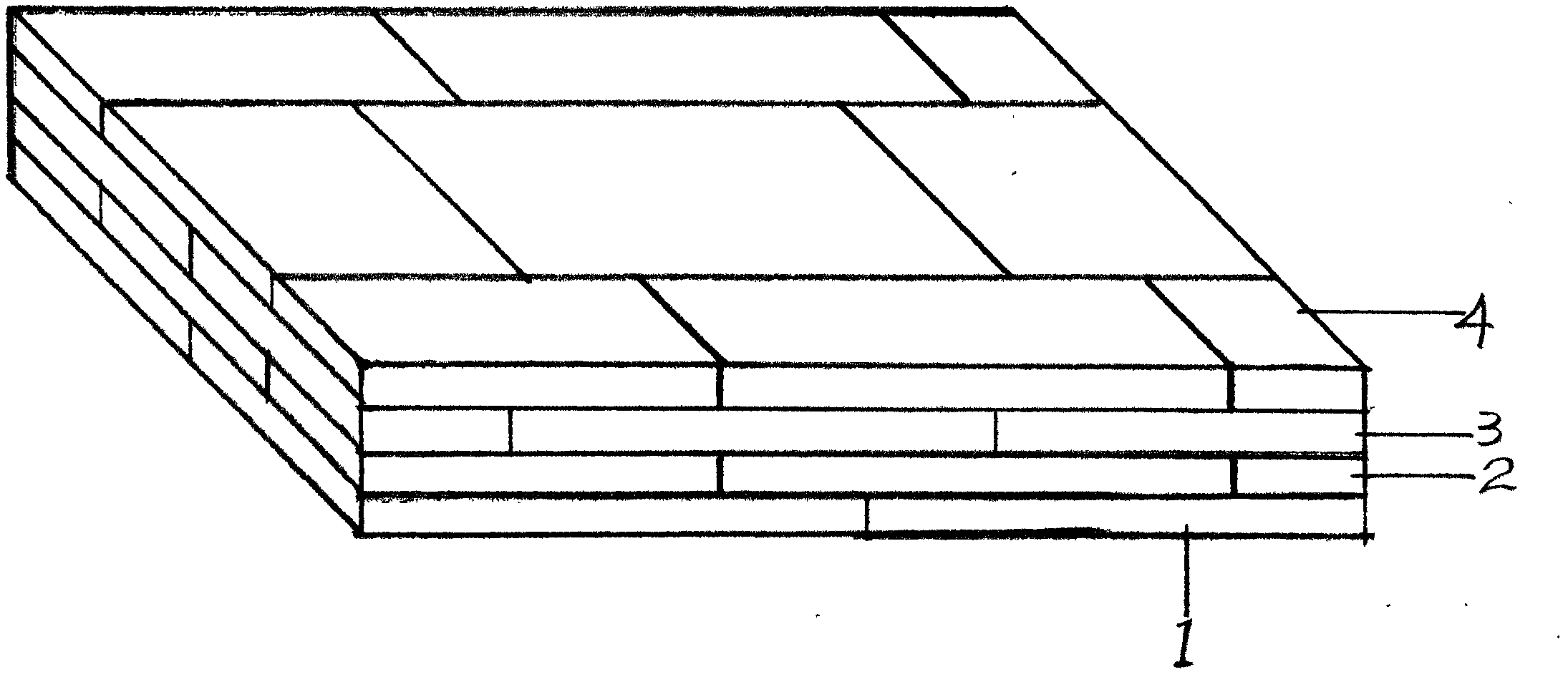

A blockboard produced by soybean protein glue and its process method

ActiveCN103737677BImprove plasticityIncrease elasticityProtein adhesivesWood veneer joiningSolid woodGrip force

The invention relates to a core board produced with soy protein glue and a technique of production, and belongs to the technical field of wood board production. A first soy protein glue layer is arranged between board cores; the board cores and the first soy protein glue layer are combined into a combined center board of board cores and first soy protein glue layer; a second soy protein glue layer is arranged between the top of the combined center board and a white blank layer; the other side of the white blank layer is connected with a first veneer layer; a third soy protein glue layer is arranged between the bottom of the combined center board and the second veneer layer. Compared to solid wood, the core board and the technique of production have the advantages that resources are saved, the appearance is more attractive and elegant, compression ratio is higher than that of a common multi-ply board, the core structure is more compact, compactness is higher, nail gripping force is larger, and the core board has high bending resistance and compressive strength; the core board has low water content and is free of expansion, shrinking and deformation; the soy protein glue used as binder has low volatility and never fails; the core board produced has good hot water tolerance and completely meets the requirements of national standard for type-II plywood.

Owner:SHANDONG BAIER BUILDING MATERIAL CO LTD

Method for producing wood plastic composite material using plant straw and waste plastic and material thereof

InactiveCN101417459BSimple processing technologyEasy to processFlat articlesDomestic articlesFiberPolyester

The invention relates to a method for manufacturing wood plastic composite material by using plant straw and waste plastics and materials thereof. Polyester and plant wood fiber materials such as sawdust, bamboo powder, rice hull, straw, and the like, are mixed according to certain ratios, a tailor-made additive is added, and after the processes of high temperature, extrusion, molding, and the like, the composite building profile is manufactured. The wood plastic material can replace wood, plastics, and the like, and is mainly used in the industries of packaging, building materials, furniture, logistics, and the like. The invention has simple processing technology, and the product has good processing properties and strength property, good water proof and corrosion resistant property and adjustability, the materials have wide sources and applications, especially the plant straw and waste plastics which contain waste mulch film and are recovered under the northern planting pattern of mulch film can be used for production, thus using the waste and restraining the current pollution of the mulch film planting to the lands effectively.

Owner:石河子市森力新材料科技有限公司

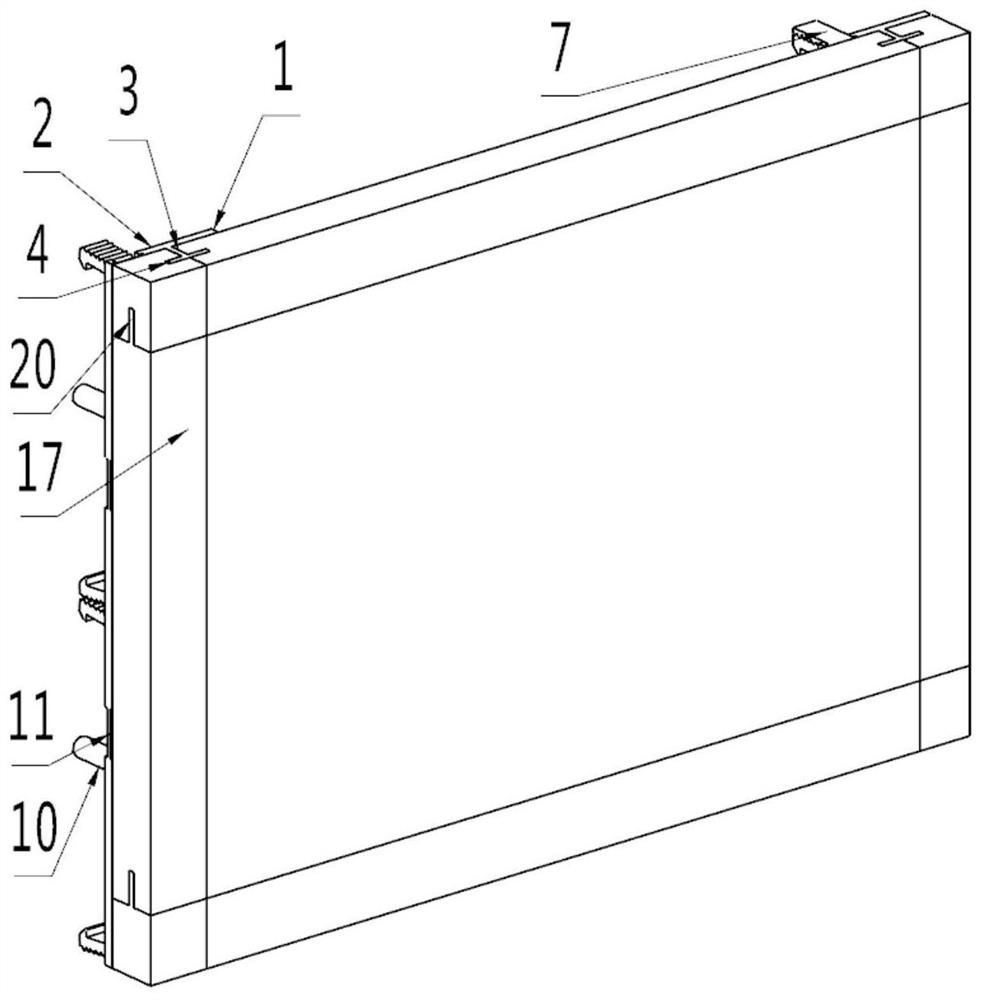

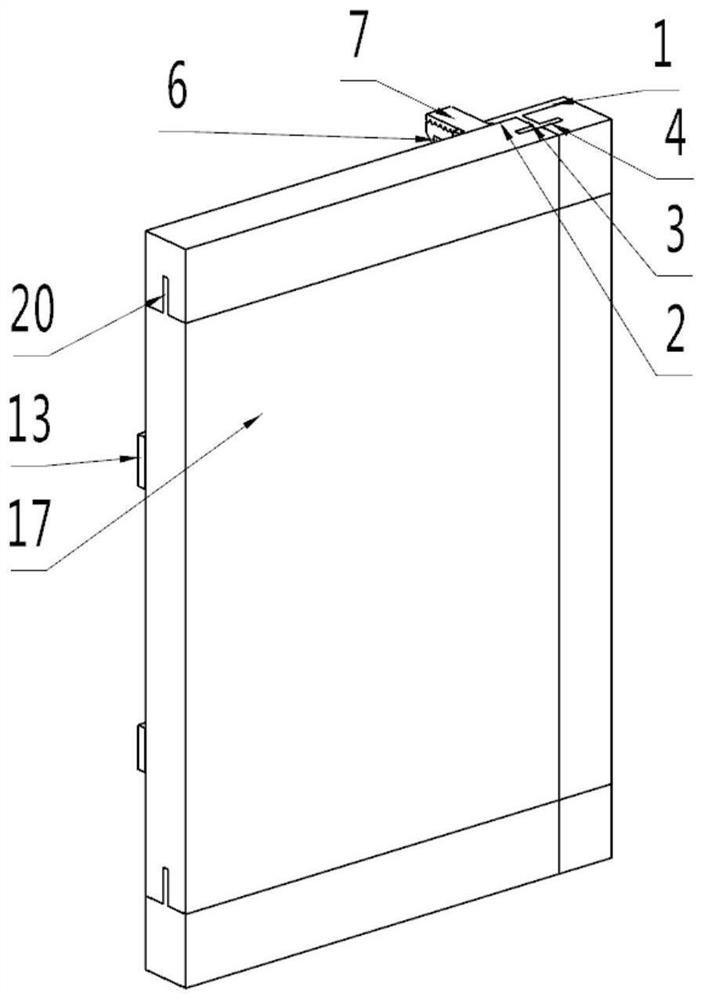

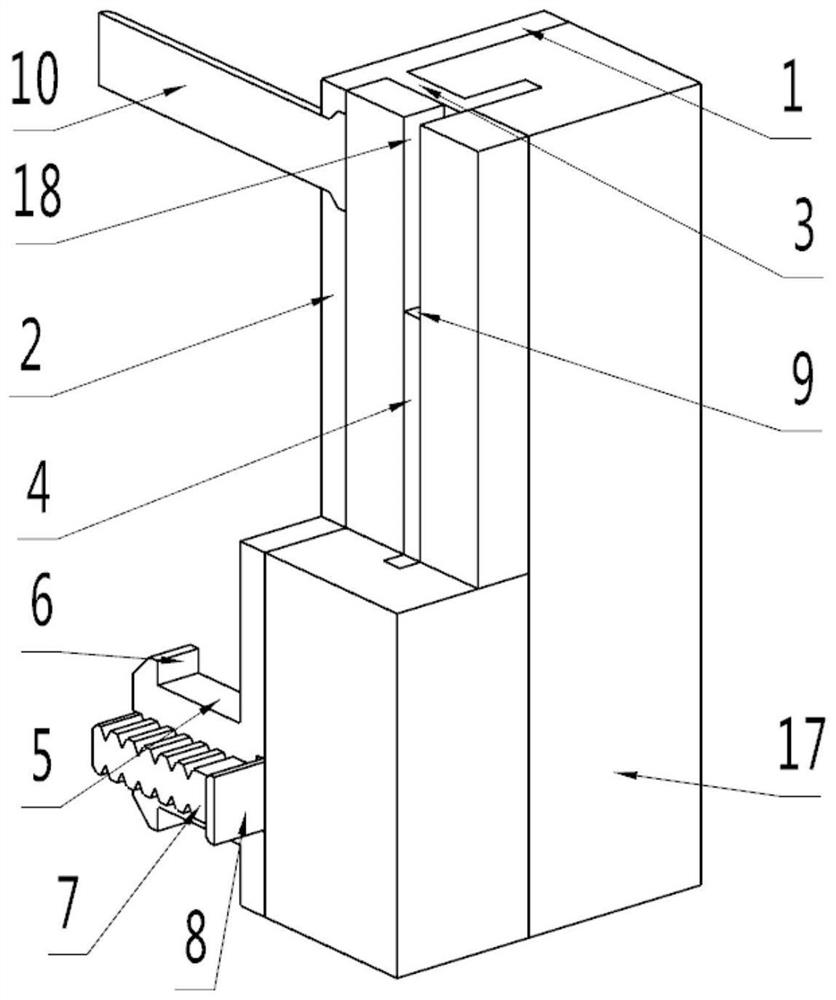

Quick-mounting dry wall brick

PendingCN114232930AImprove stabilityInhibit sheddingCovering/liningsFlooringBrickStructural engineering

The invention discloses a fast-assembly dry-type wall brick which comprises a first bottom plate connected with a wall surface, and the first bottom plate and a second bottom plate are assembled to form a planar integrated structure; the supporting plate is mounted at the front end of the outer surface of the second bottom plate, a limiting plate for limiting is mounted at the front end of the outer surface of the supporting plate, and clamping plates for equidistant elastic clamping are mounted at the rear end of the outer surface of the second bottom plate. According to the fast-assembly dry-type wall brick, the supporting plate which is stably used is arranged, the limiting plate is assembled to assemble the dry-type wall brick body, the length of the second bottom plate is larger than that of the first bottom plate, the second bottom plate, the supporting plate and the limiting plate are integrated, and a clamping plate and a clamping block which have the positioning and nesting functions are arranged at the rear end of the outer surface of the second bottom plate; and the clamping blocks with the sawtooth-shaped structures and the easy-to-disassemble blocks with the inclined structures are stably clamped in the clamping plates, so that falling is prevented, and the use stability of the overall structure of the first bottom plate is improved.

Owner:广西宇邦建筑科技有限公司

Method for manufacturing high-density glue permeated plate in mould pressing solid wood

InactiveCN102615689AGuaranteed infiltrationHave no crackingPressure impregnationFlat articlesSolid woodFiber

The invention discloses a method for manufacturing a high-density glue permeated plate in mould pressing solid wood, which belongs to the technical field of processing of artificial plates and relevant equipment. The method is characterized in that a low-density wood plate or wood strip is placed in a high-pressure container to realize supercharging glue permeation via pressure higher than atmosphere pressure, glue permeation time can be shortened, further, glue can assuredly permeate into seams among fiber tissues of the wood effectively, the wood plate or wood strip dried at low temperature is placed in a hot pressing machine to be compressed into a medium and high-density plate in a mould pressing manner according to a proper compression ratio, and accordingly a finally manufactured medium and high-density glue permeated plate in the solid wood really has performances of no crack, waterproofness and fire protection which do not belong to the solid wood, is high in woodiness feeling and nail-holding ability, has excellent stability, and can be used for replacing increasingly deficient hard wood.

Owner:李启山

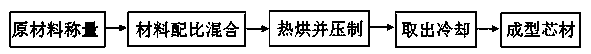

Three-layer coextruded PVC (polyvinylchloride) wood-plastic composite foam board and preparation method thereof

ActiveCN102922838BHigh surface hardnessWith processing performanceSynthetic resin layered productsFiberFoaming agent

The invention relates to a three-layer coextruded PVC (polyvinylchloride) wood-plastic composite foam board and a preparation method of the three-layer coextruded PVC wood-plastic composite foam board. The wood-plastic composite foam board is of an ABA structure; an outer layer, namely an A layer, adopts polyvinyl chloride, a filler, an impact modifier, a lubricating agent, a composite stabilizer, a coupling agent, a processing agent and a polyvinyl chloride recycled material as raw materials, and an inner layer, namely a B layer, adopts the polyvinyl chloride, wood fiber powder, the filler, a foaming agent, an enhancer, a foaming regulator, the impact modifier, the lubricating agent, the composite stabilizer and a plate recycled material as raw materials. The three-layer coextruded wood-plastic composite foam board is formed by a main machine and an auxiliary machine in a coextrusion molding manner after mixing at high temperature and cooling. The three-layer coextruded PVC wood-plastic composite foam board has the processing property similar with that of wood, is anti-flaming and does not release formaldehyde, so that the three-layer coextruded PVC wood-plastic composite foam board becomes an ideal material for replacing the wood, can be used as building templates, cabinet boards and the like.

Owner:JIANGSU RUNJU ENVIRONMENTAL TECH CO LTD +1

A kind of polyvinyl chloride co-extruded wood-plastic board and preparation method thereof

ActiveCN105415839BStrong nail gripSynthetic resin layered productsLaminationSurface layerFoaming agent

The invention discloses a polyvinyl chloride co-extrusion wood-plastic plate and a preparation method thereof. The co-extrusion wood-plastic plate comprises a core layer and surface layers located on the upper surface and the lower surface of the core layer. The core layer is prepared from PVC resin, a foaming agent, a wood-plastic material and auxiliaries. The surface layers are prepared from PVC resin. Due to the fact that the wood-plastic material is used in the core layer, the use amount and the raw material cost of PVC materials can be reduced, recycling can be achieved after the service life is reached, and the polyvinyl chloride co-extrusion wood-plastic plate is very environmentally friendly. The polyvinyl chloride co-extrusion wood-plastic plate has the strength and the finish degree of the surface of a co-extrusion foam plate and can be directly applied to the advertising industry, and printing can be directly conducted on the surface of the polyvinyl chloride co-extrusion wood-plastic plate. The polyvinyl chloride co-extrusion wood-plastic plate has the characteristics of a wood-plastic plate, nail holding power is better than that of the co-extrusion plate, and the polyvinyl chloride co-extrusion wood-plastic plate is widely used in the furniture industry, the decoration industry and the bathroom industry.

Owner:FOSHAN GAOMING AIBO ADVERTISING & DECORATION MATERIAL CO LTD

Formaldehyde-free fiber material and formation method thereof, as well as fiber decorative material and manufacturing method thereof

InactiveCN103963135AStrong nail gripStrong resistance to deformationFlat articlesDomestic articlesFormaldehyde freeHigh-density polyethylene

The invention provides a formaldehyde-free fiber material and a formation method thereof. The method comprises the following steps: the fiber material is ground into filaments to enable the filaments of the fiber raw material to be loose and basically keep sticky, the filaments and an adhesive are arranged in an alternative manner to form layers, an upper surface layer and a lower surface layer are layers formed by the filaments of the fiber material, and finally hot pressing and cold pressing are sequentially performed, wherein the adhesive comprises LDPE and HDPE. The invention further provides a fiber decorative material and a manufacturing method thereof. According to the fiber decorative material manufacturing method, salix psammophila and a branch material with small diameter are utilized to manufacture the fiber decorative material, and the manufactured fiber decorative material has the advantages of strong nail-holding power, high non-deformability, high resistance to bending and high resistance to tension so as to change salix psammophila and the branch material into valuable things, and the fiber decorative material has great commercial value; in addition, the formaldehyde-free fiber material formation method and the fiber decorative material manufacturing method are simple and have no special requirements for equipment, and the formaldehyde-free fiber material and the fiber decorative material are suitable for large-scale industrial production.

Owner:戴武兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com