Preparation method for novel low-density, low-cost and high-strength shaving board

A low-cost, high-strength technology, which is applied in the jointing of wooden veneers, chemical instruments and methods, pretreatment of molding materials, etc., can solve the problems of veneer veneer, large shavings on the board surface, poor nail holding force, etc. Achieve the effect of high bonding strength, good nail holding force and strong nail holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

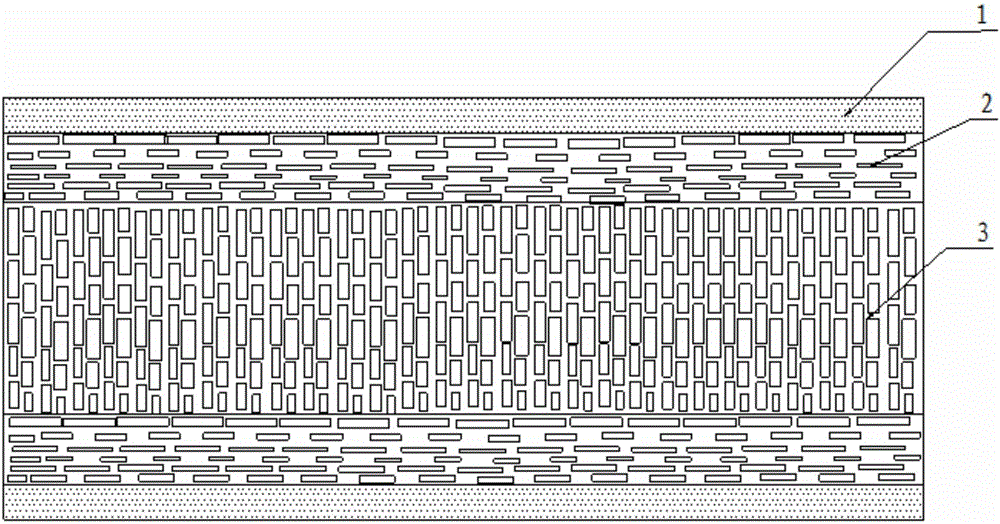

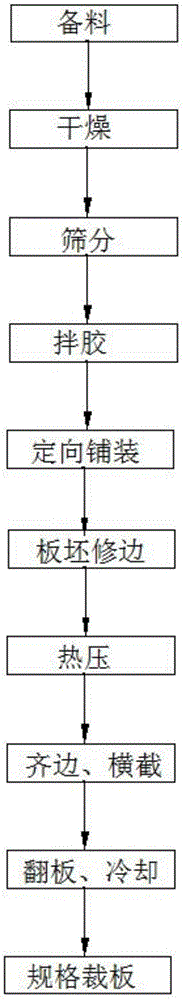

[0046] A kind of preparation method of the novel particle board of low density, low cost and high strength, such as figure 2 As shown, including surface layer 1, particle layer 2 and core layer 3, the number of described particle layer 2 is two, and is respectively arranged on the upper and lower sides of described core layer 3, and the number of described surface layer 1 is two , and are respectively arranged on the outside of the two shaving layers 2, such as figure 1 As shown, the specific steps include:

[0047] (1) Material preparation: obtain long, narrow and thin shavings with a length of 90-130mm, a width of 5-30mm, and a thickness of 0.5mm-2mm through a long wood flaking machine, and send them to the wet shaving silo for storage;

[0048] (2) Drying: The wet shavings obtained in step (1) are dried to a moisture content of 2% to 4% by condensing hot water at 95-98°C; the wet shavings are fed quantitatively to the screw driven by a frequency converter, and then sprink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com