A blockboard produced by soybean protein glue and its process method

A technology of soybean protein glue and blockboard, which is applied in the field of wood board production, can solve problems such as human hazards, and achieve the effects of high flexural and compressive strength, beautiful appearance, and tight core structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

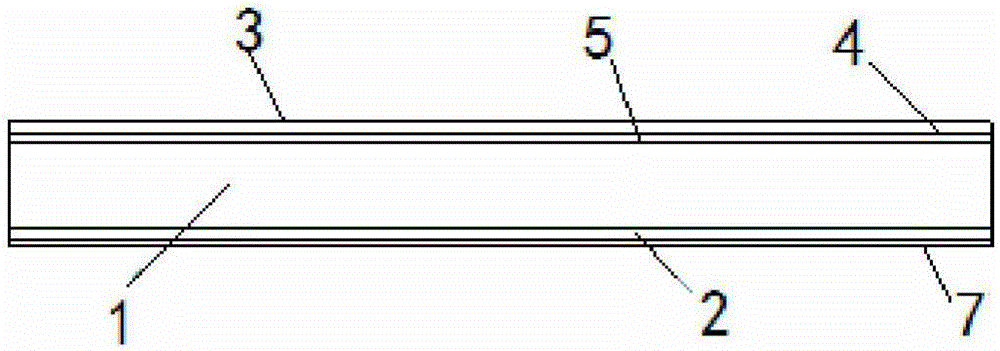

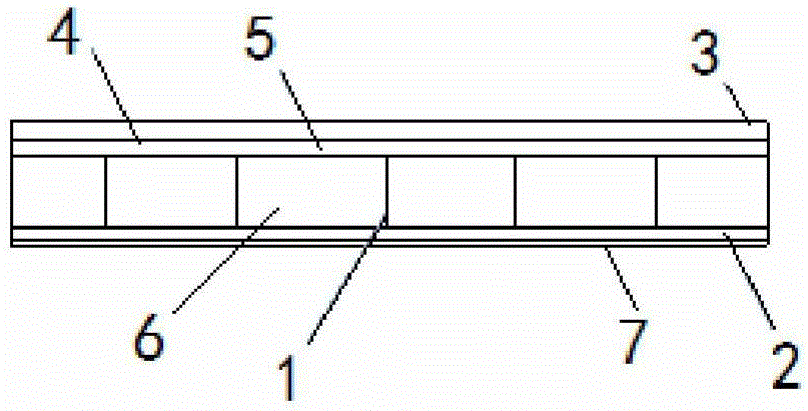

[0036] Embodiment 1: as figure 1 , figure 2 As shown, a blockboard produced by utilizing soybean protein glue, there is a first soybean protein glue layer 1 between the core boards 6, and the core board 6 and the first soybean protein glue layer 1 are combined to form the core board 6 and the first soybean protein glue layer. The combined center board of the protein glue layer 1, the second soybean protein glue layer 5 is arranged between the top surface of the combined center board and the white base layer 4, and the other side of the white base layer 4 is connected with the first veneer layer 3; The third soybean protein glue layer 2 is arranged between the bottom surface and the second veneer layer 7 .

[0037] The blockboard produced by soybean protein glue has completely changed the history of only chemical glue but no real vegetable glue in the world, and created a new era of green and environmental protection for wood boards. It has laid a solid technical foundation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com