Patents

Literature

30results about How to "Loose material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

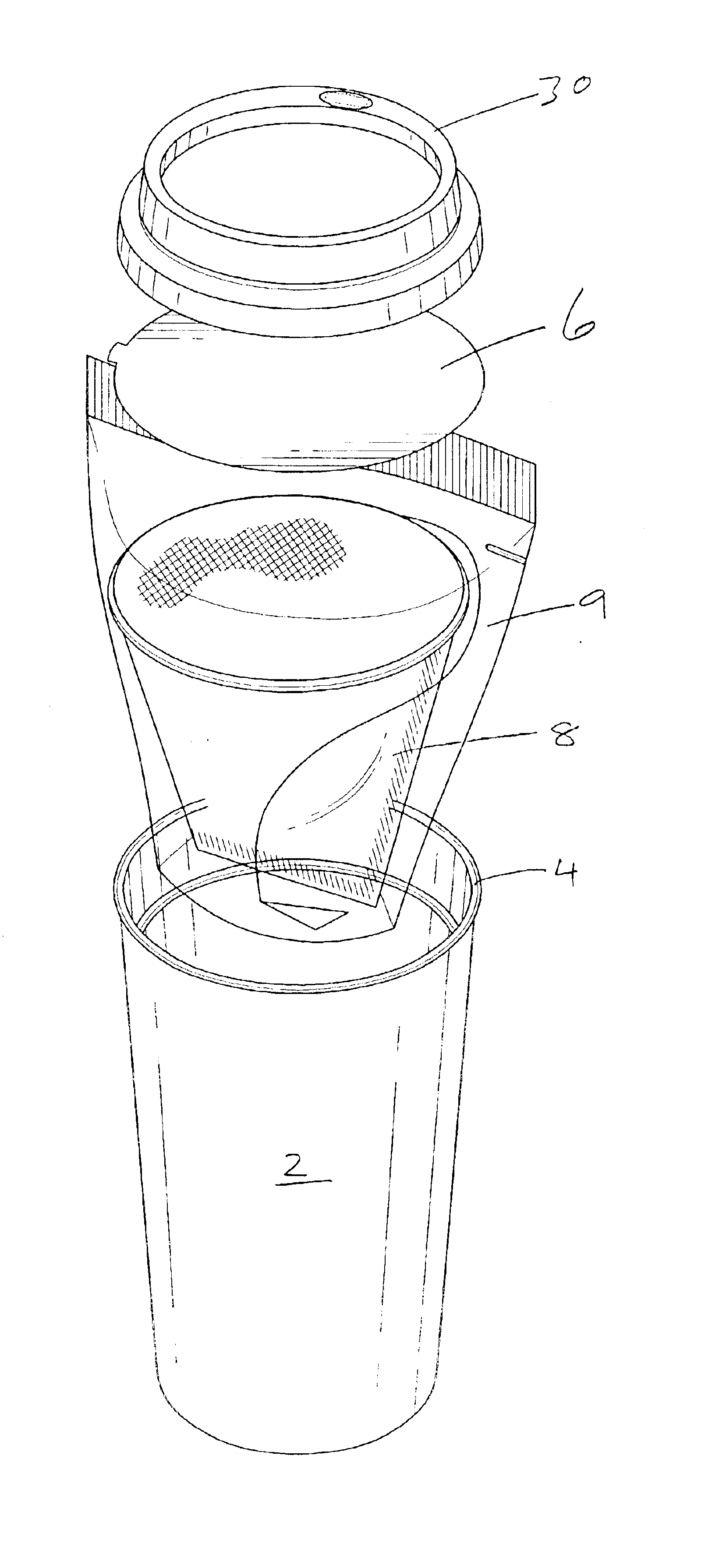

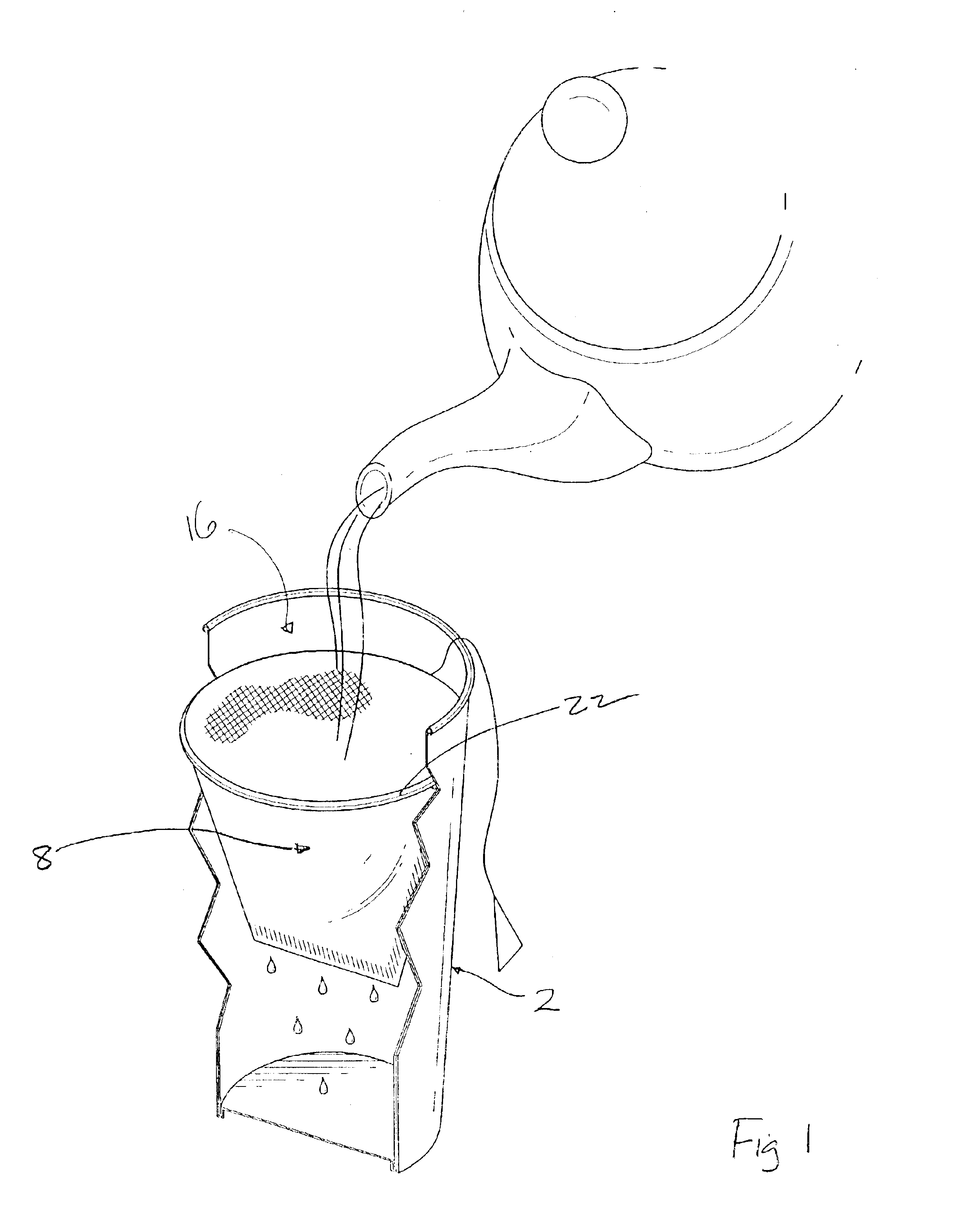

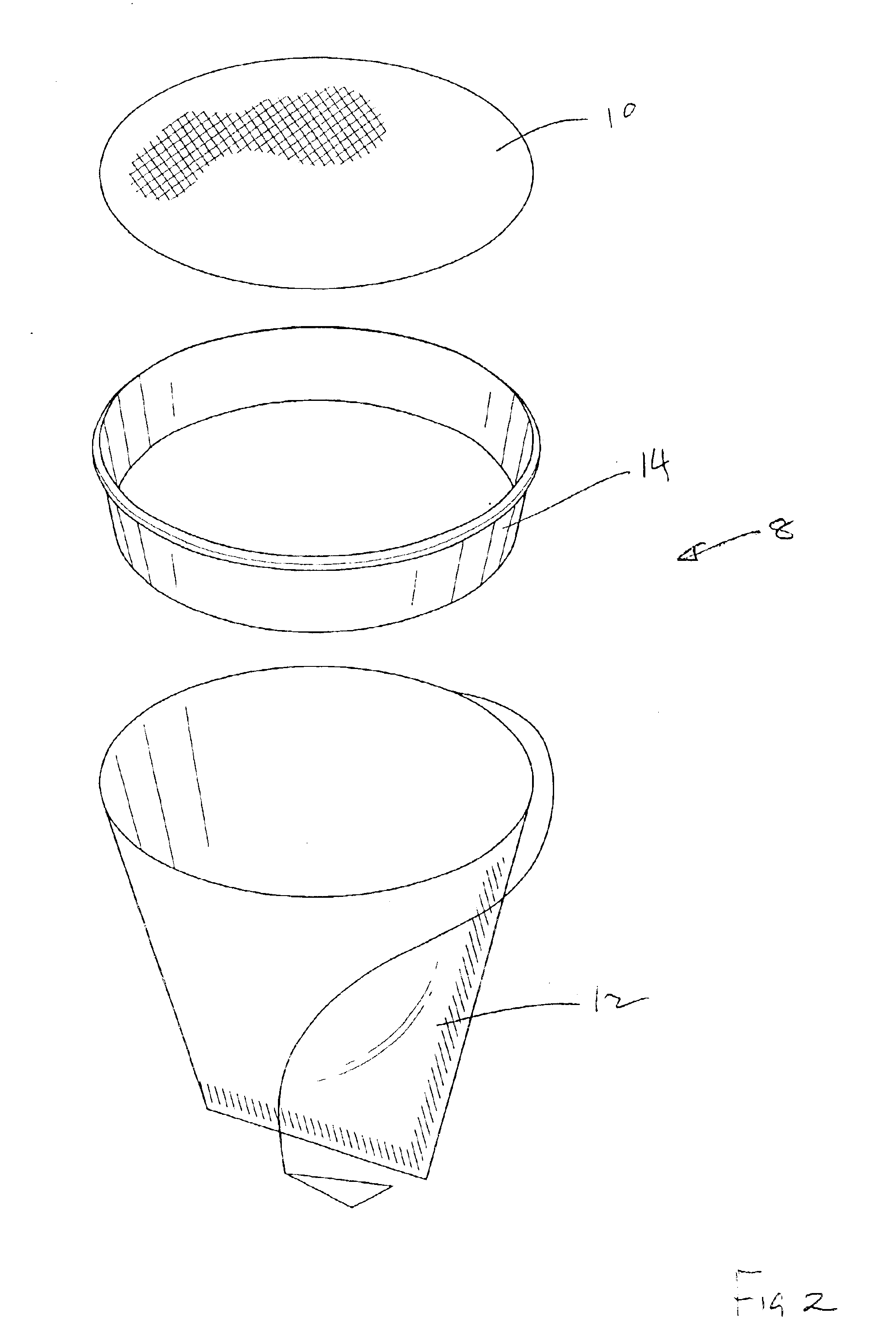

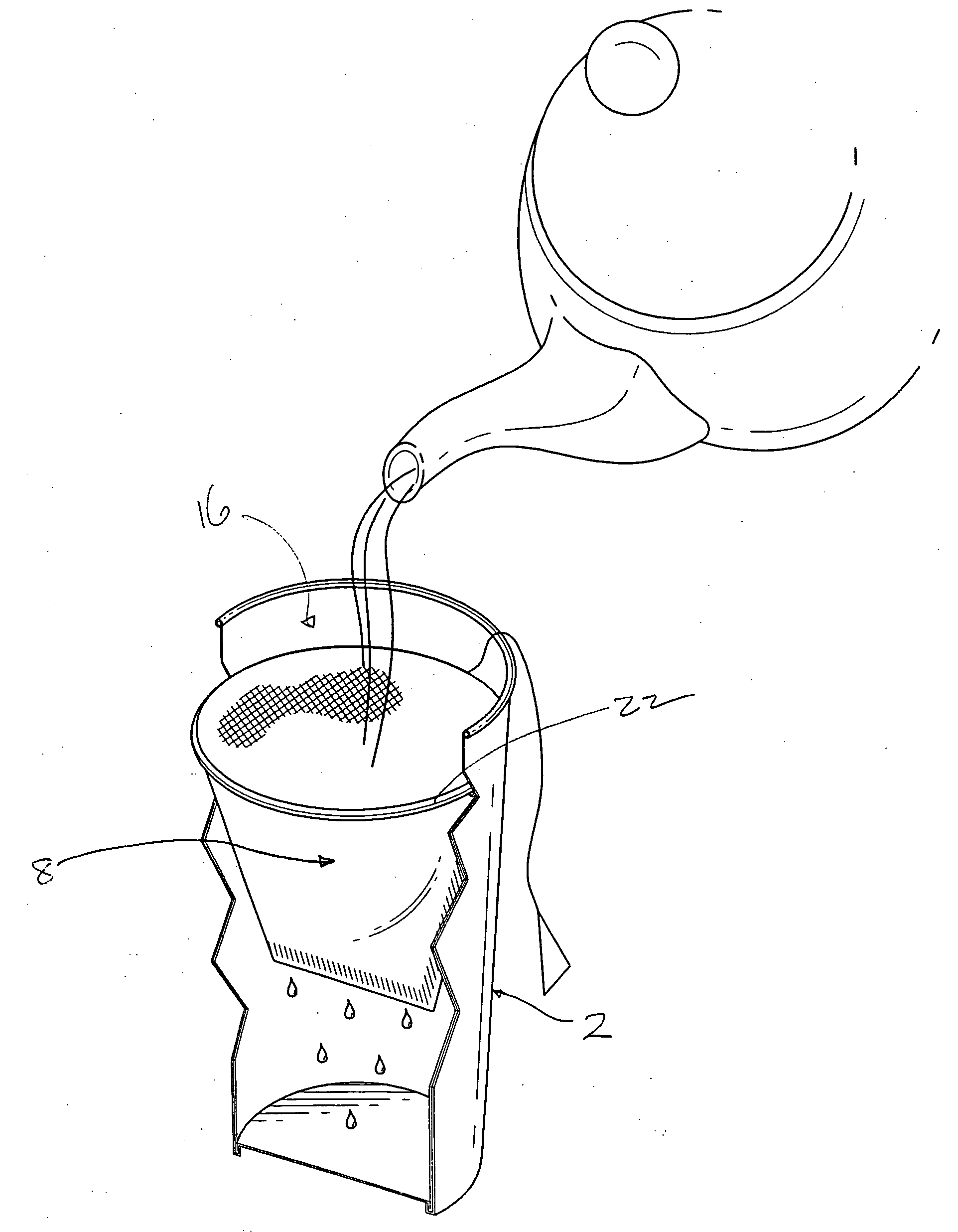

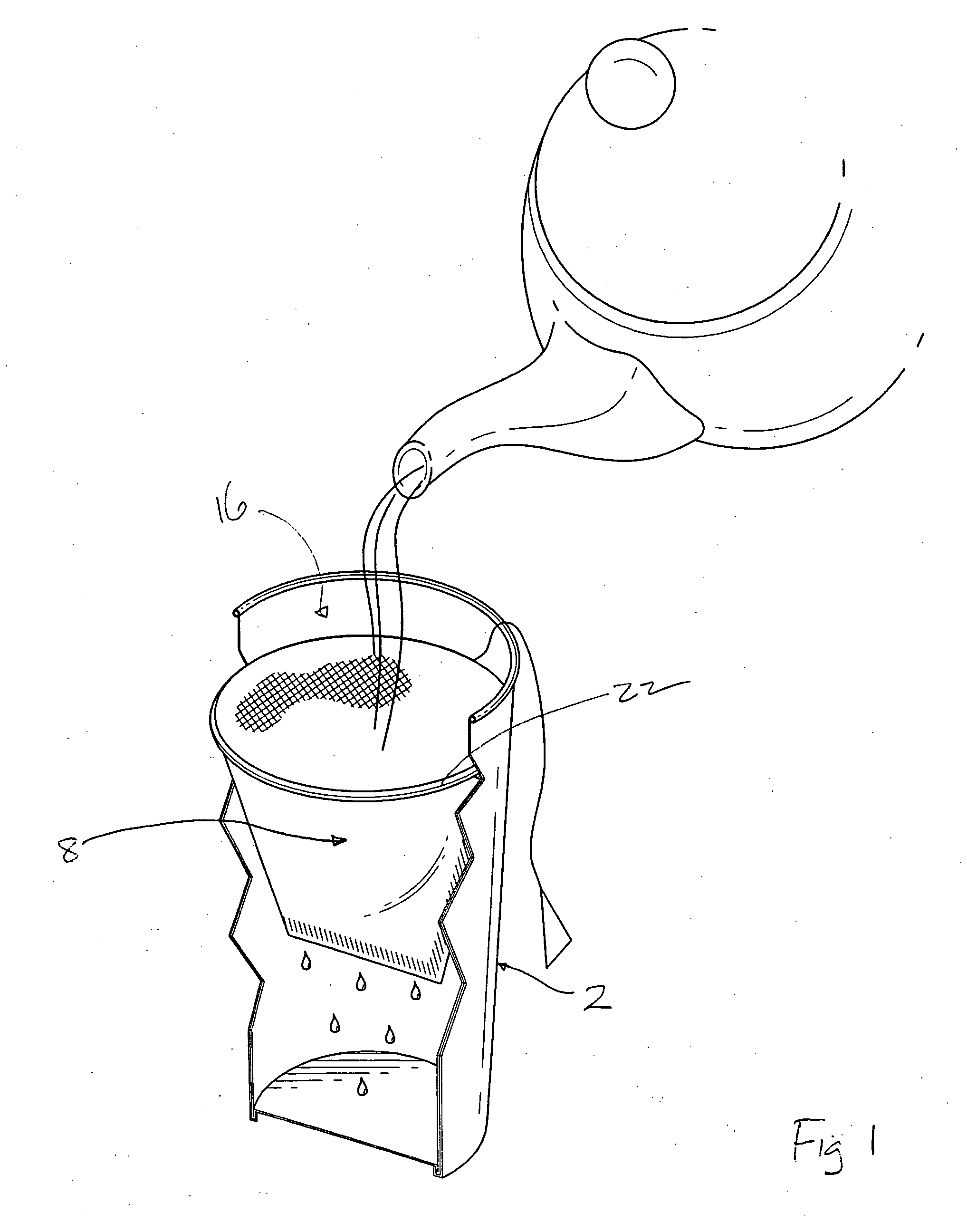

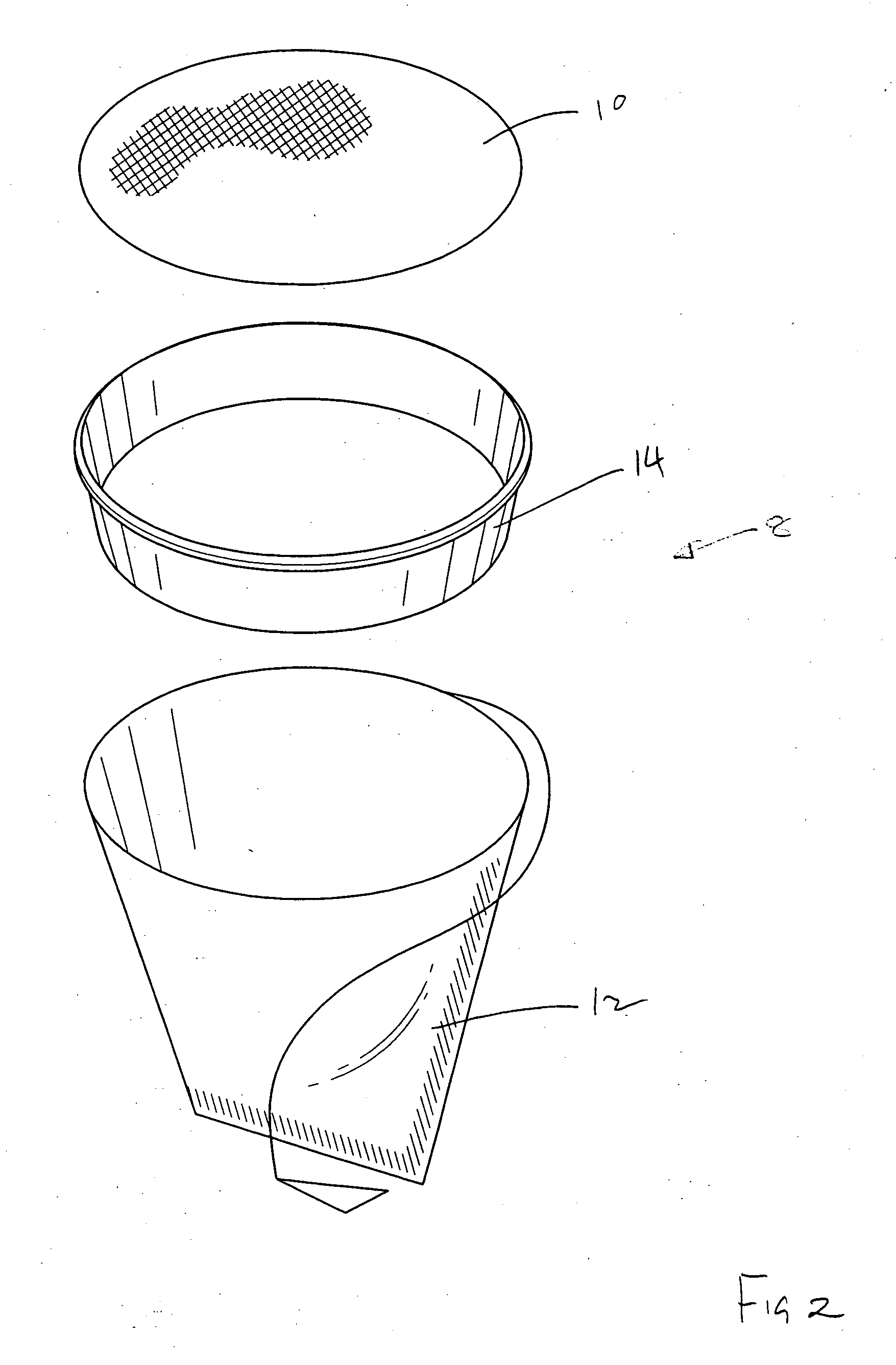

Brew-in-the-cup disposable beverage assembly

A brew-in-the-cup disposable beverage assembly includes a cup and a beverage pouch containing a premeasured charge of beverage material. The pouch is packaged within an airtight bag to preserve the freshness of the beverage material until use. The beverage pouch rests on supporting structure extending inwardly from the cup sidewall supported in an upper region of the cup. An aroma enhancing substance is included in the beverage material. For use, the airtight bag is removed from the beverage pouch which is then placed on the supporting structure and liquid is poured onto the pouch to brew the beverage and drain into the cup.

Owner:YUGUCHI CLIFFORD

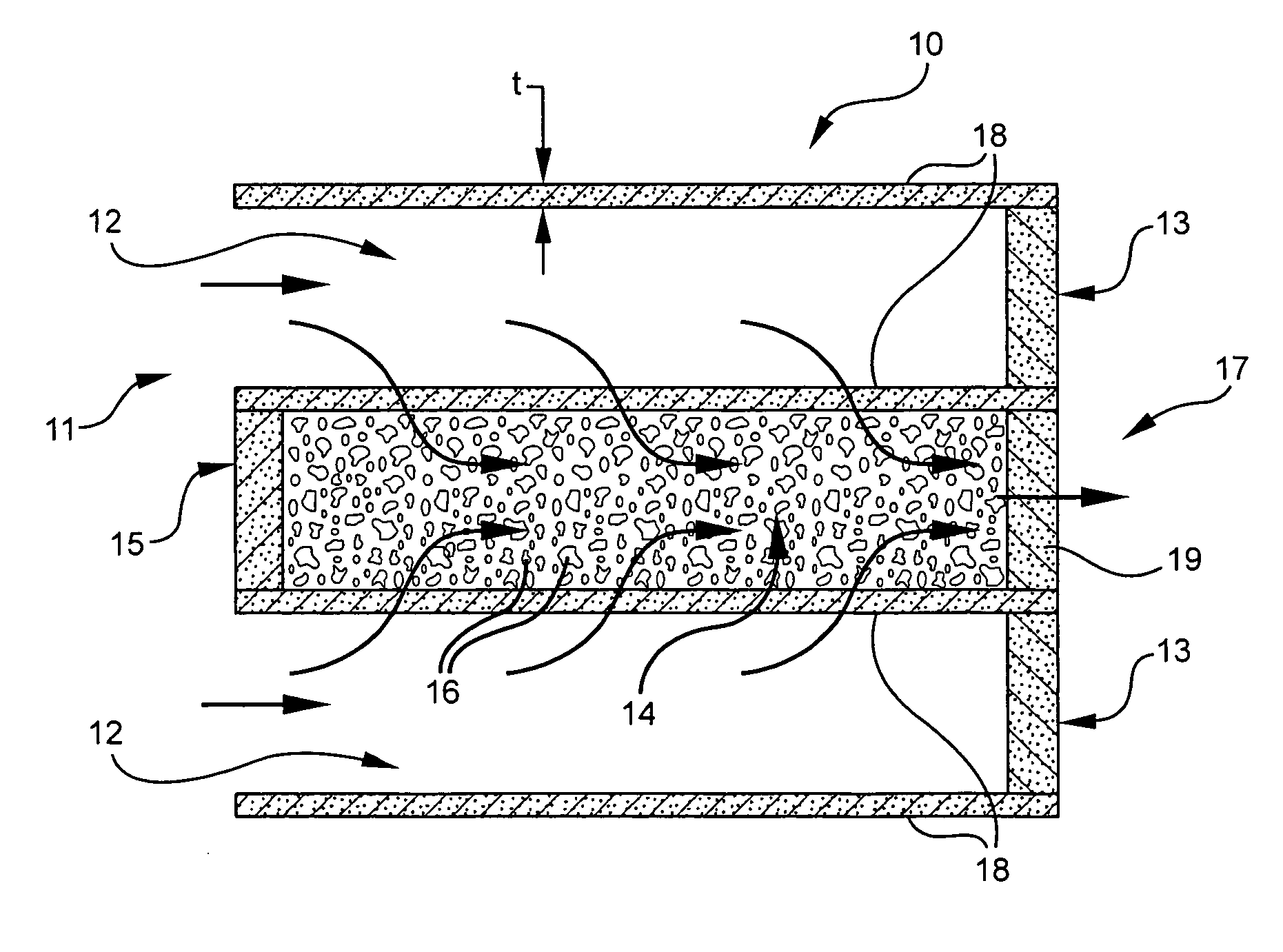

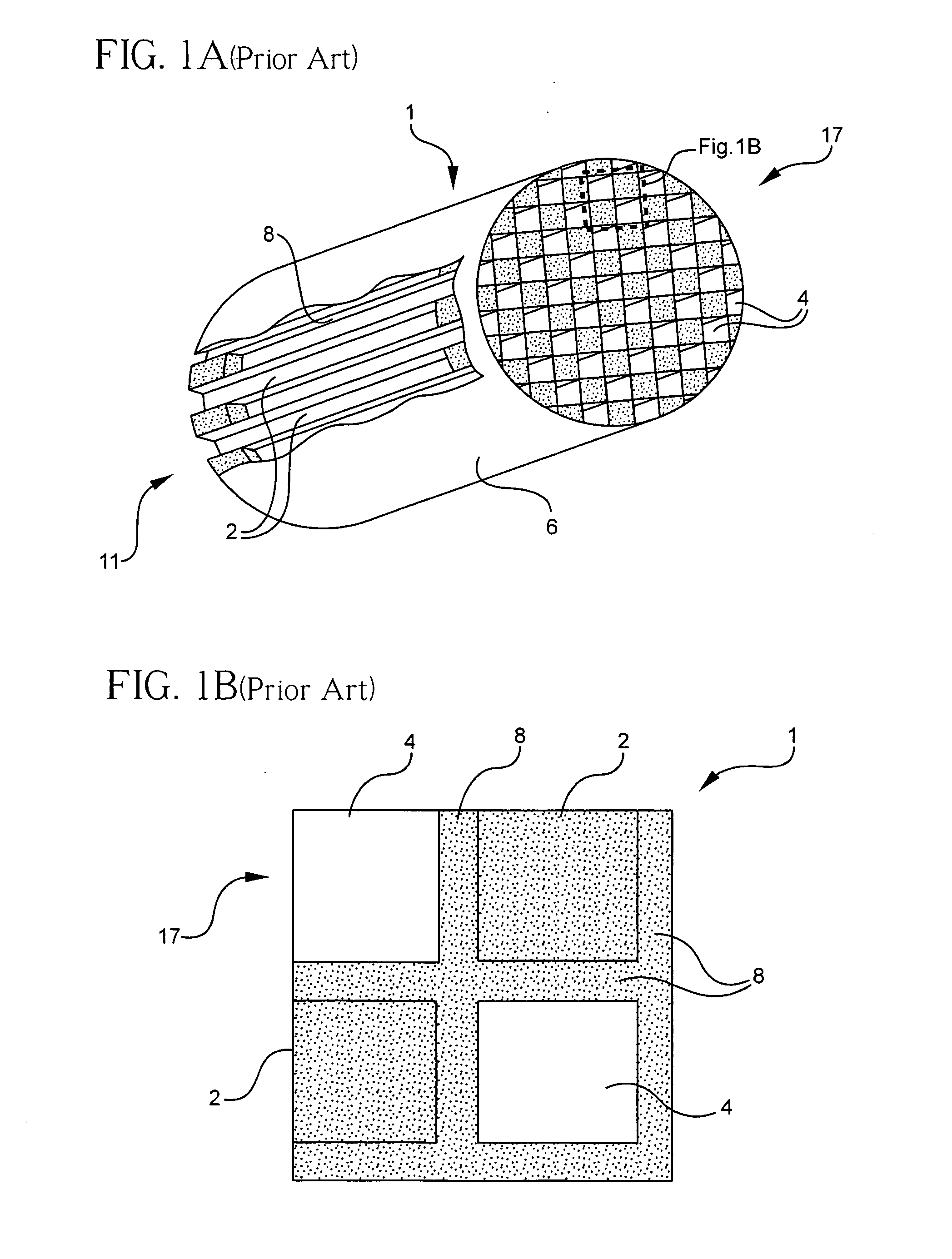

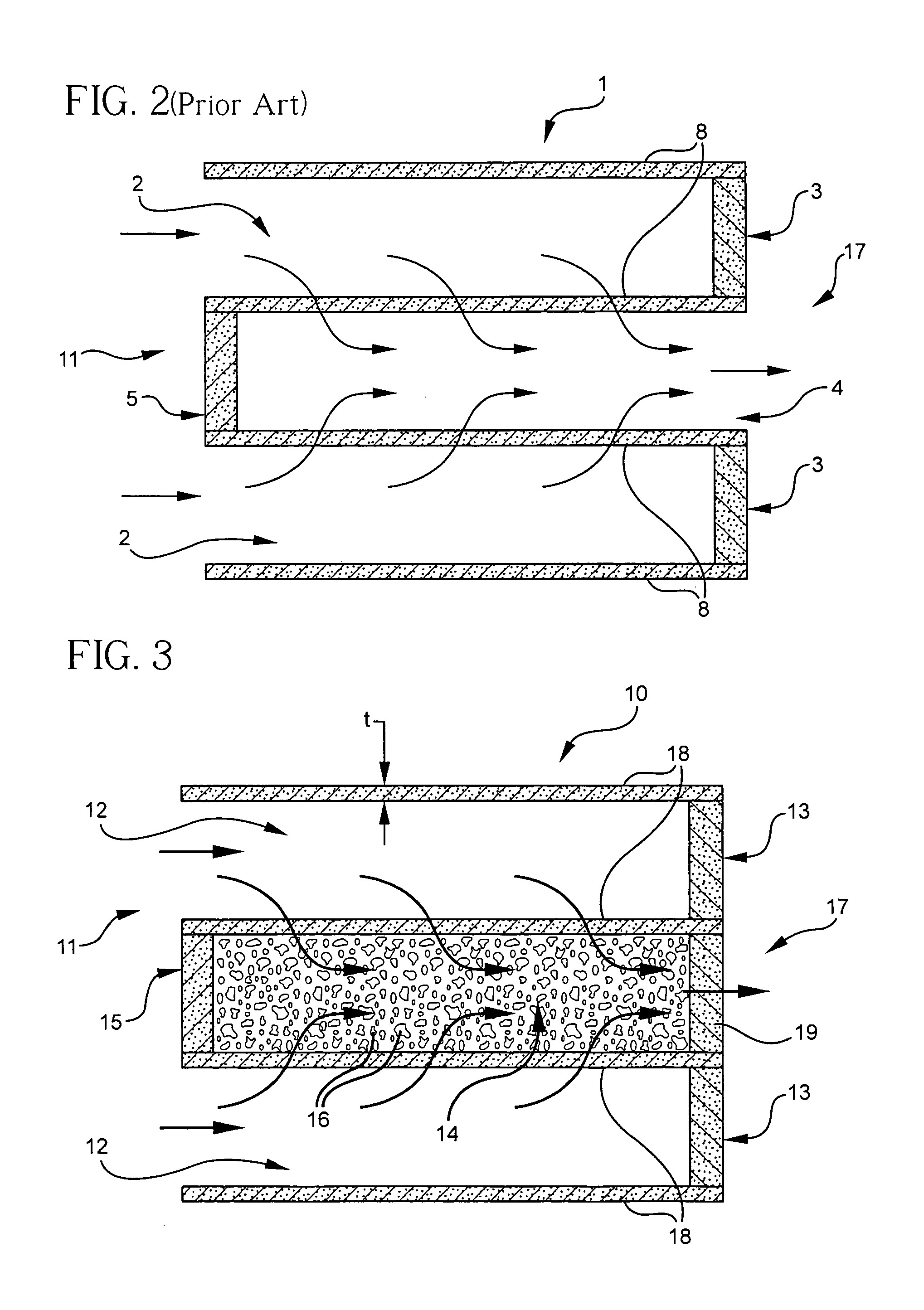

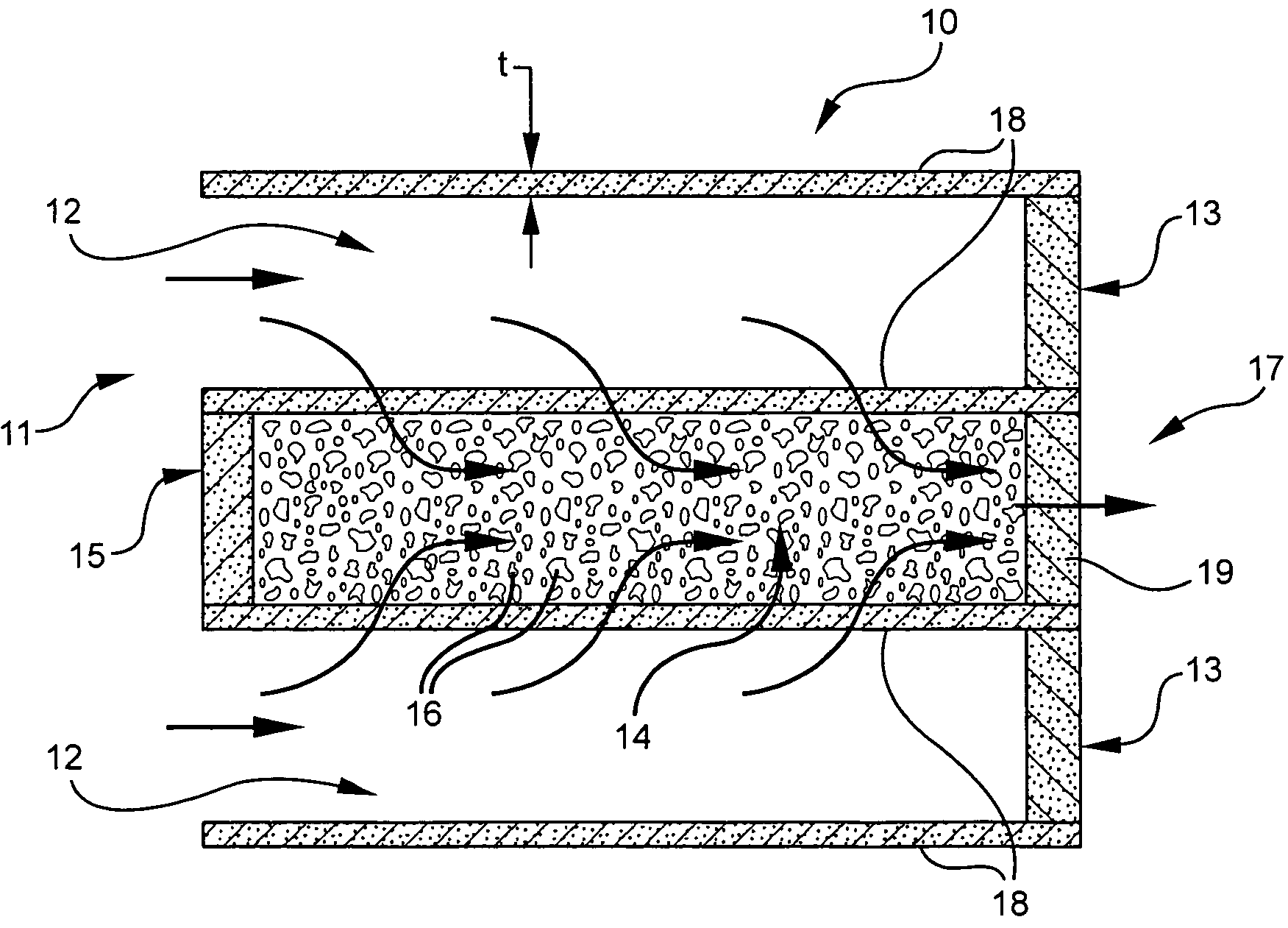

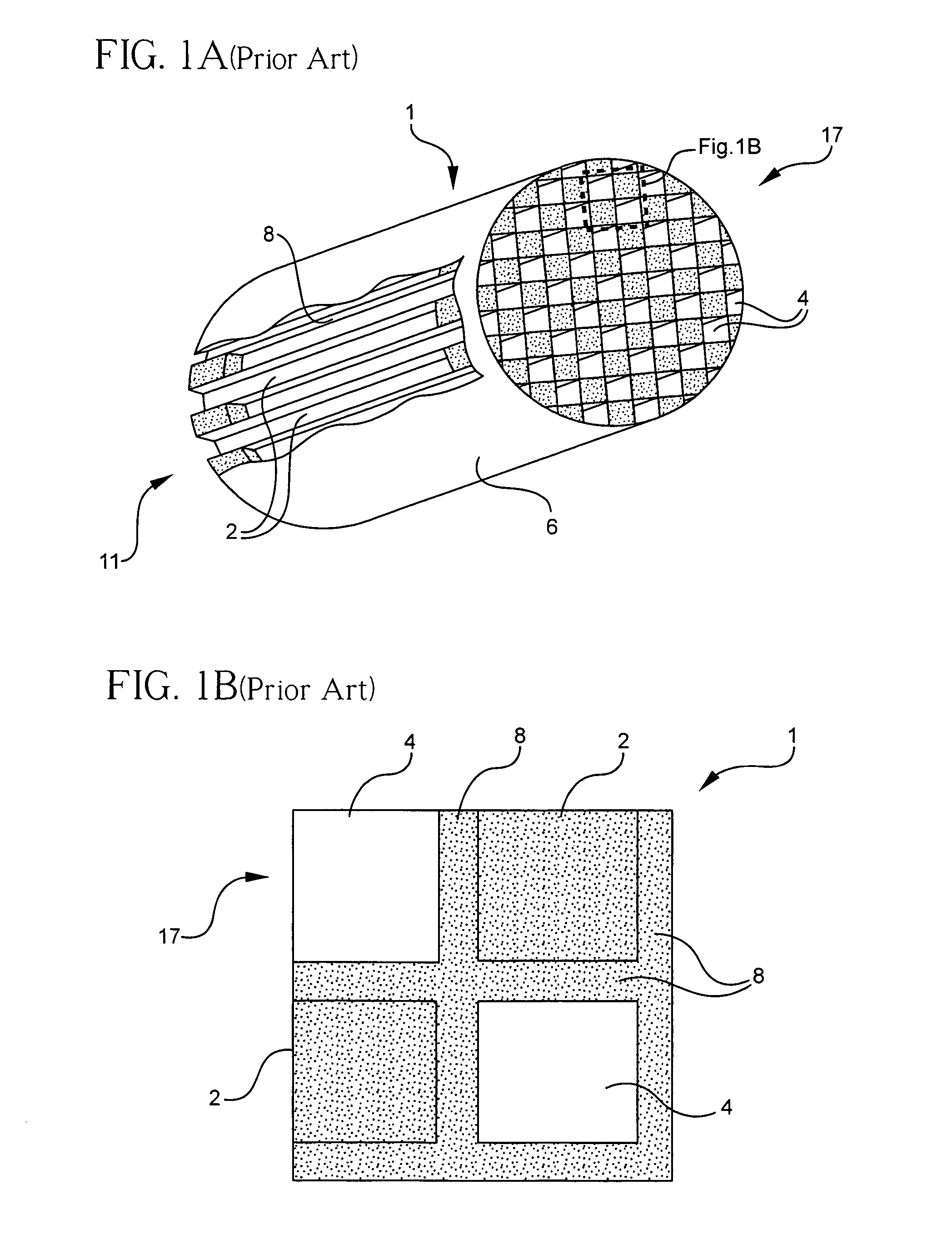

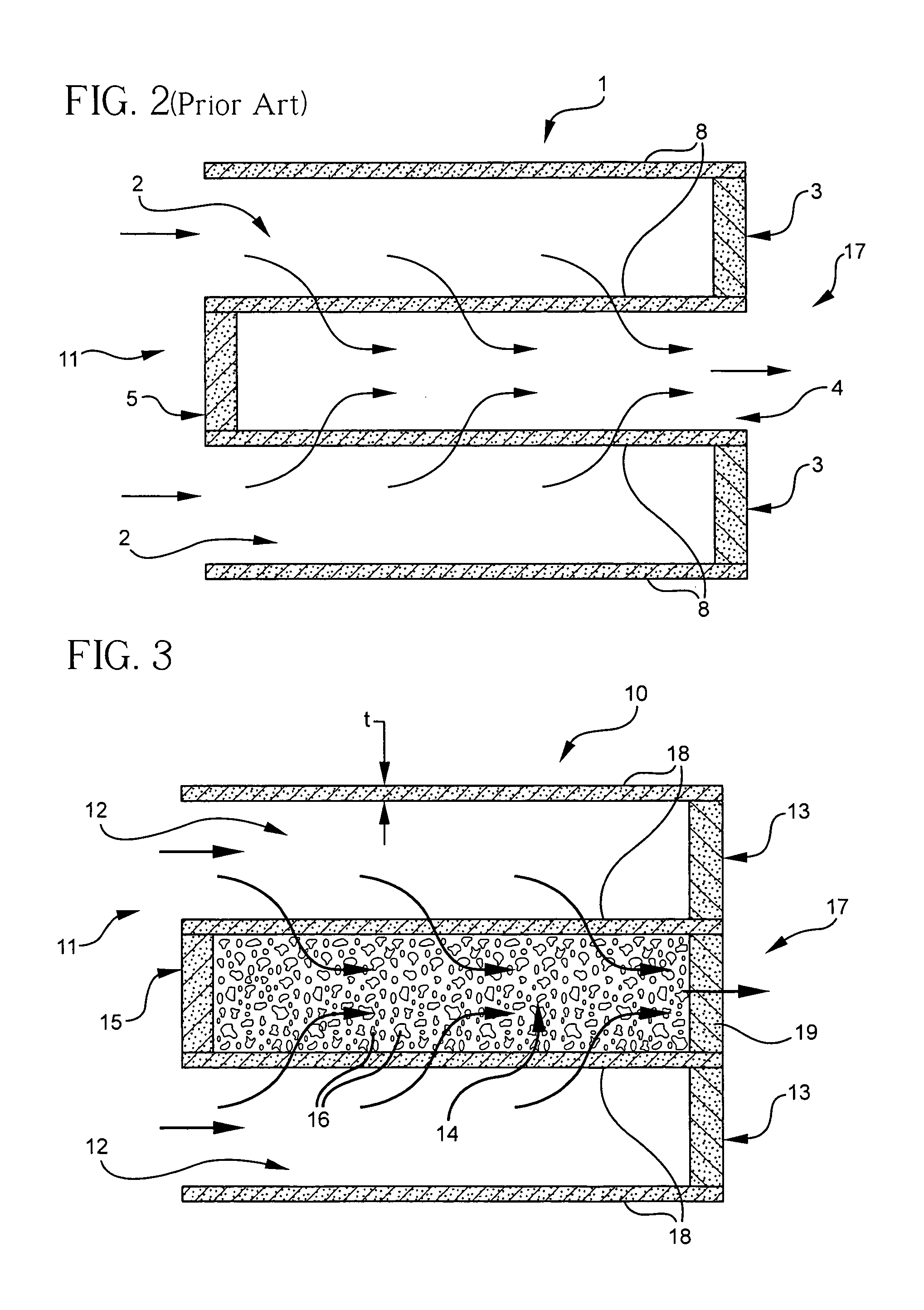

Ceramic wall-flow filter including heat absorbing elements and methods of manufacturing same

ActiveUS20060191248A1Large heat capacitySmall wall thicknessCombination devicesAuxillary pretreatmentParticulatesHeat capacity

A ceramic wall-flow filter for filtering particulate matter from gases and methods for manufacturing such wall-flow filters are disclosed. The filter includes an array of porous ceramic walls defining a pattern of end-plugged inlet and outlet cells, and heat absorbing elements disposed within at least some of the outlet cells such that a bulk heat capacity of the outlet cells is greater than a bulk capacity of the inlet cells. The heat absorbing elements increase a bulk heat capacity of the filter without substantially interfering with a flow of gas through the porous ceramic walls by allowing thinner walls. According to the method, during the step of extruding or thereafter, heat absorbing elements are formed within at least some of the outlet cells such that a heat capacity of the outlet cells is greater than the inlet cells.

Owner:CORNING INC

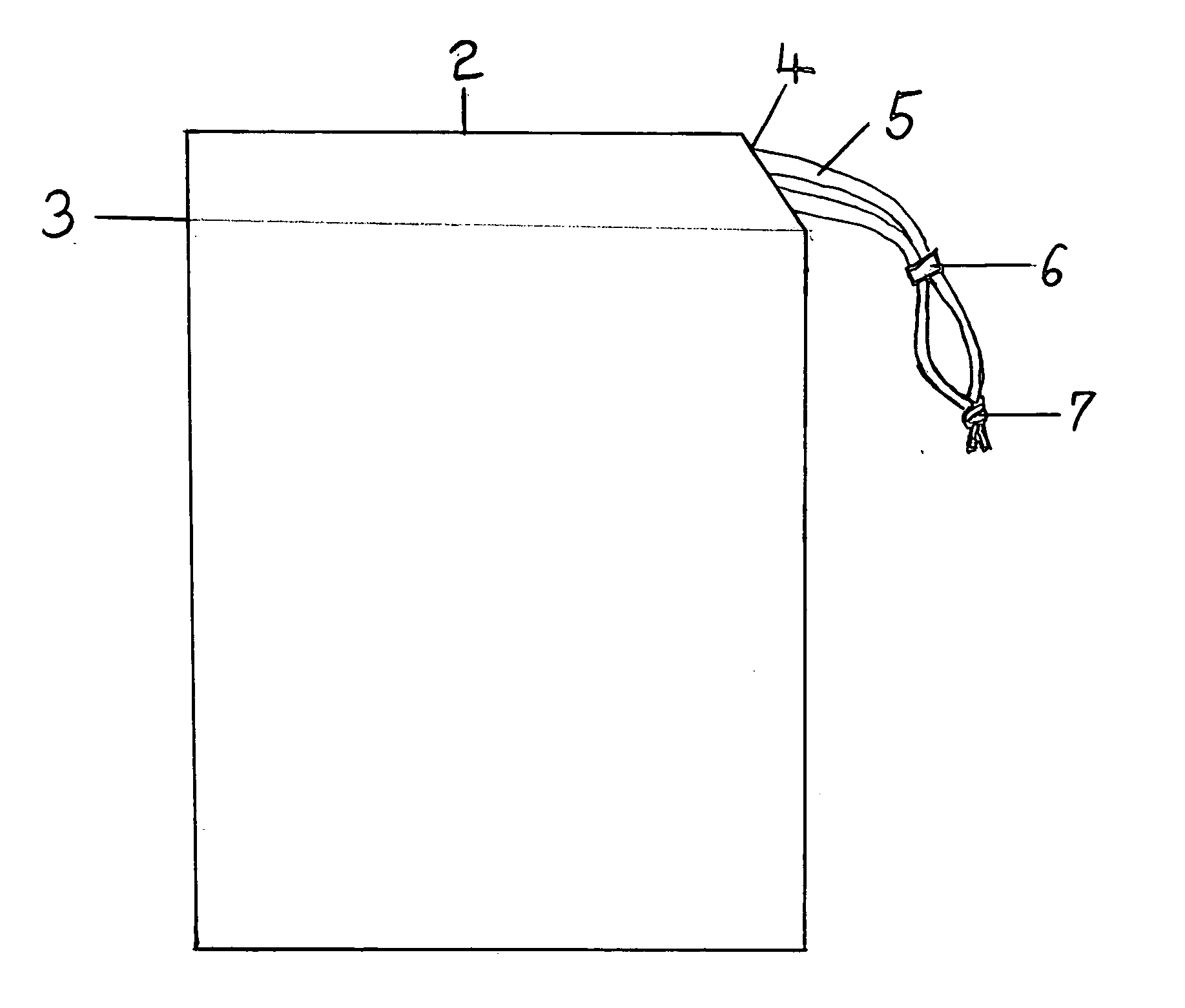

Nuclear fuel assembly end cap arrangement

InactiveUS20060018422A1Restrict movementLoose materialNuclear energy generationFuel element assembliesDry storageNuclear fuel

A method and arrangement to control fuel material debris originating from a fuel assembly for a dry storage system wherein the method includes providing a damaged boiling water reactor nuclear fuel assembly, providing a bottom end cap configured to fit on a bottom of a boiling water reactor nuclear fuel assembly, inserting the bottom end cap into the damaged boiling water reactor nuclear fuel assembly such that the bottom end cap prevents debris from inside the damaged nuclear fuel assembly from leaving the bottom of the fuel assembly, providing a top end cap configured to fit on a top of the boiling water reactor nuclear fuel assembly, and inserting the top end cap into the top of the damaged boiling water reactor nuclear fuel assembly such that the top end cap prevents debris from inside the damaged nuclear fuel assembly from leaving the top of the fuel assembly.

Owner:FRAMATOME ANP RICHLAND

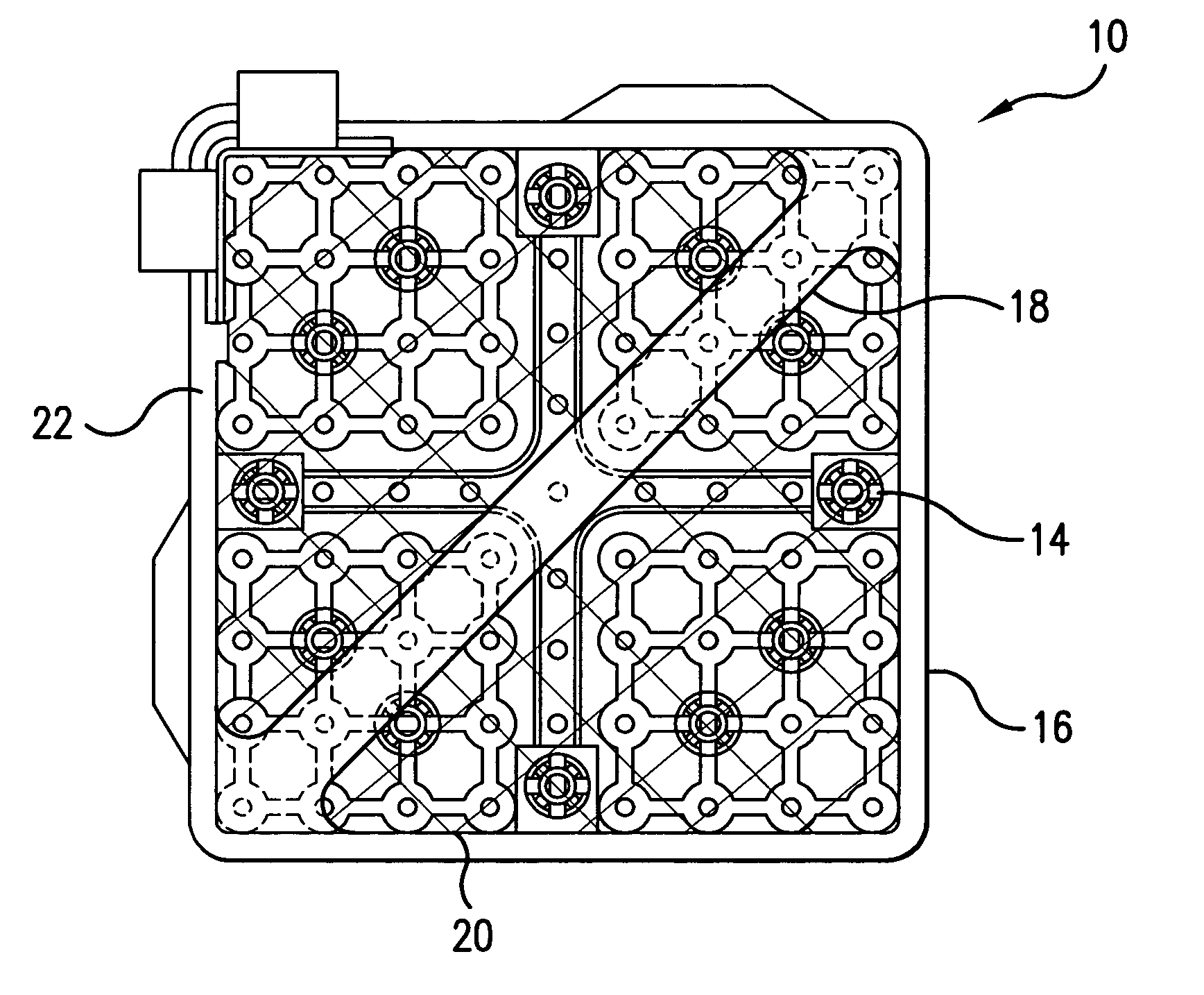

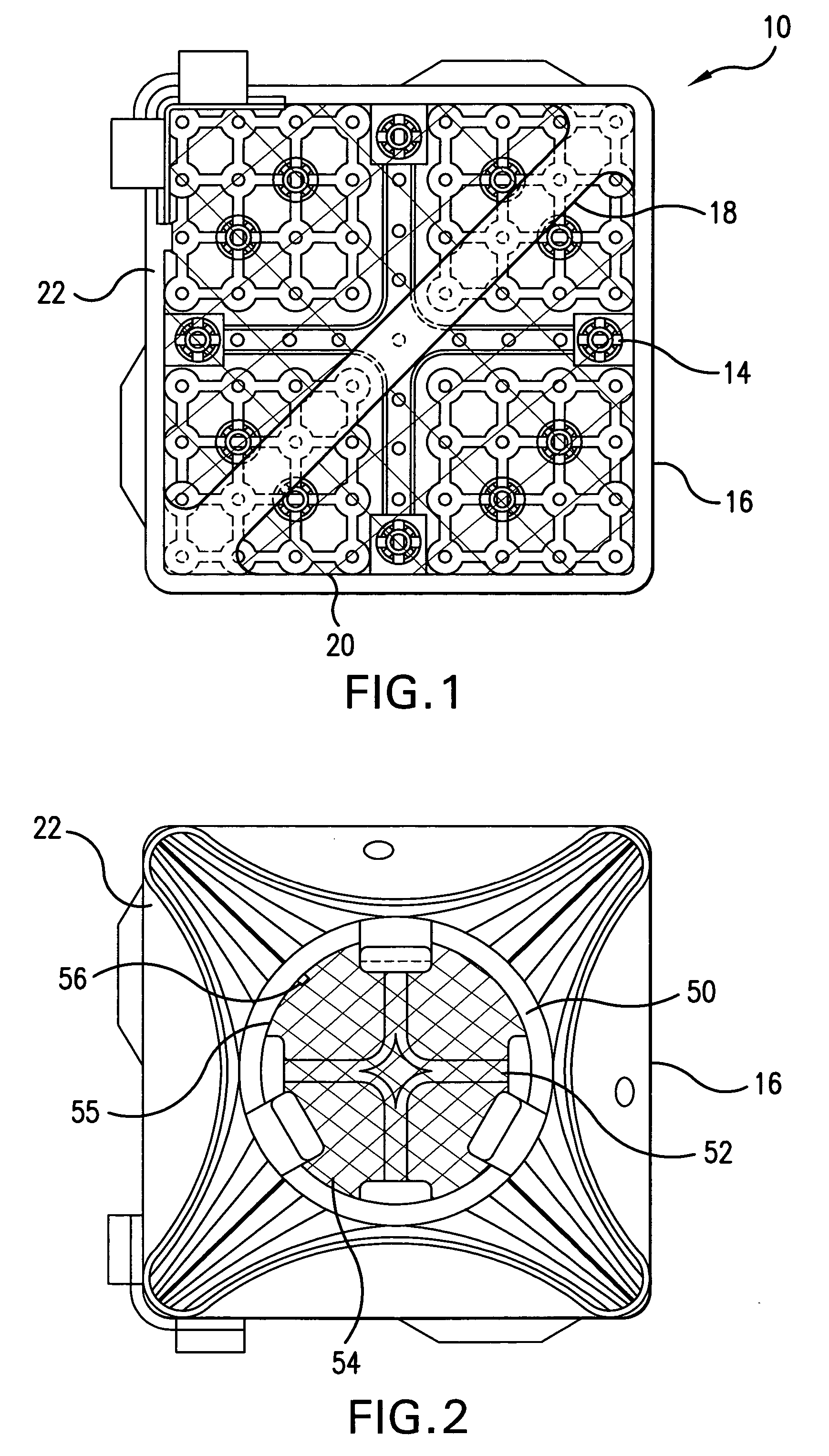

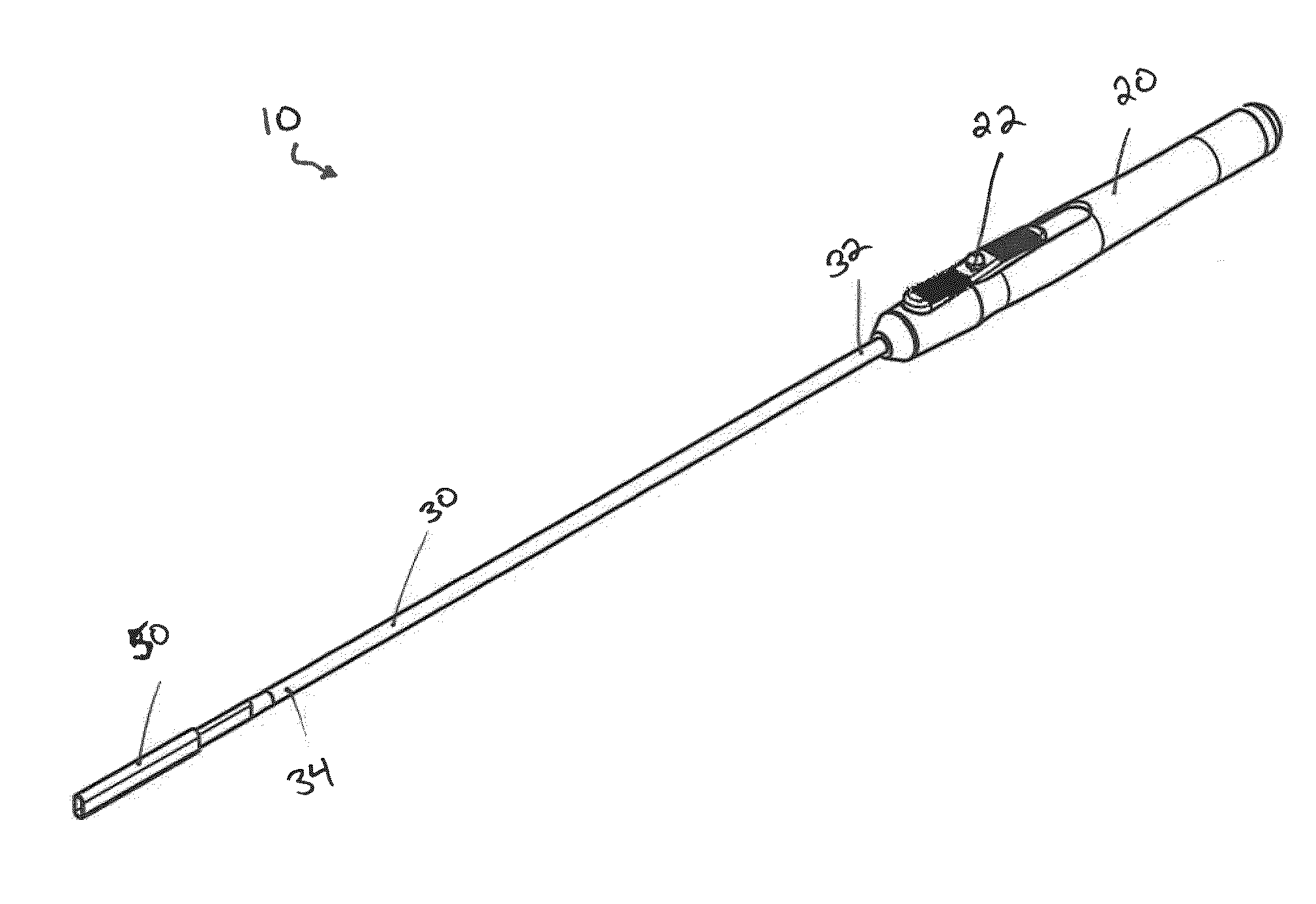

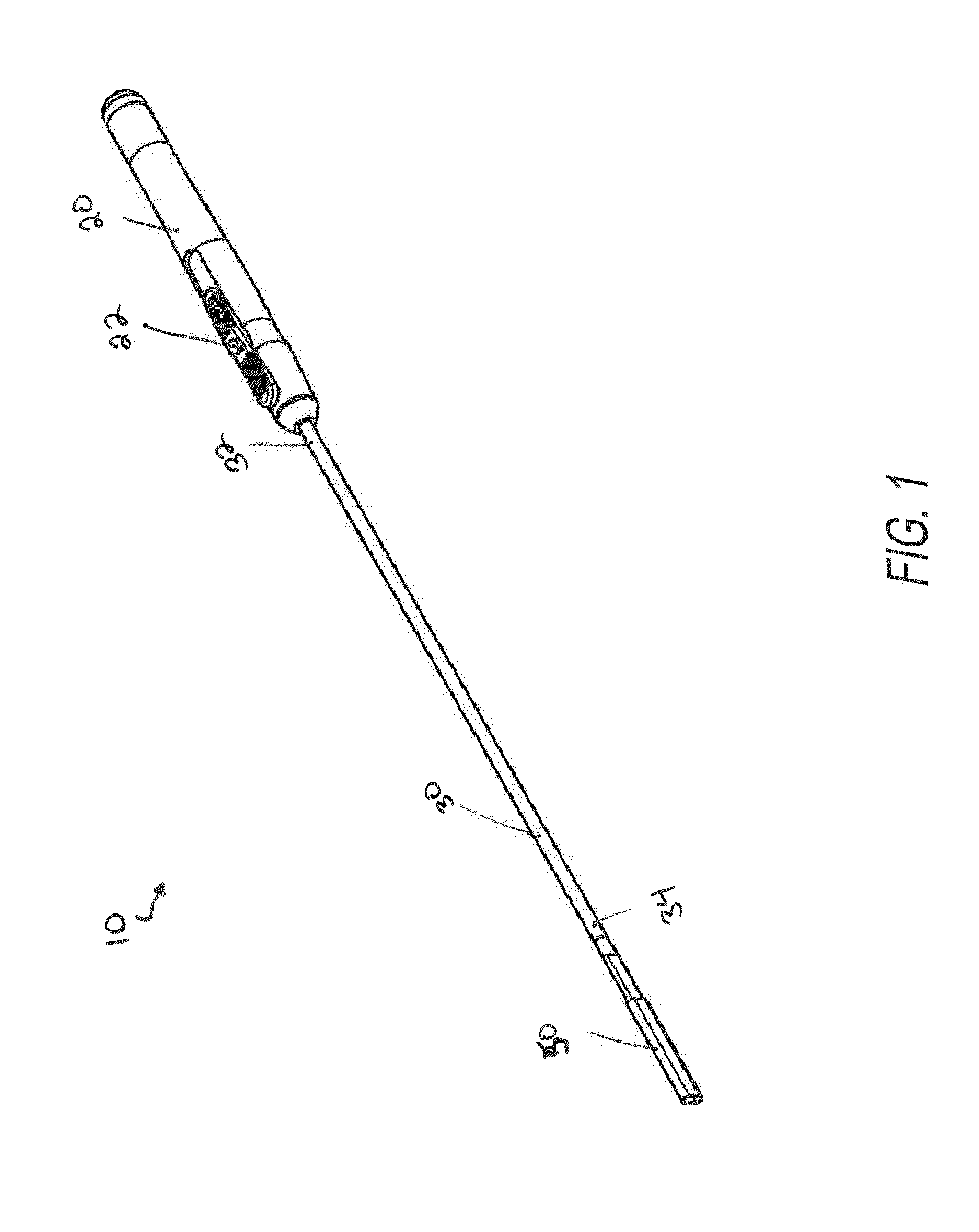

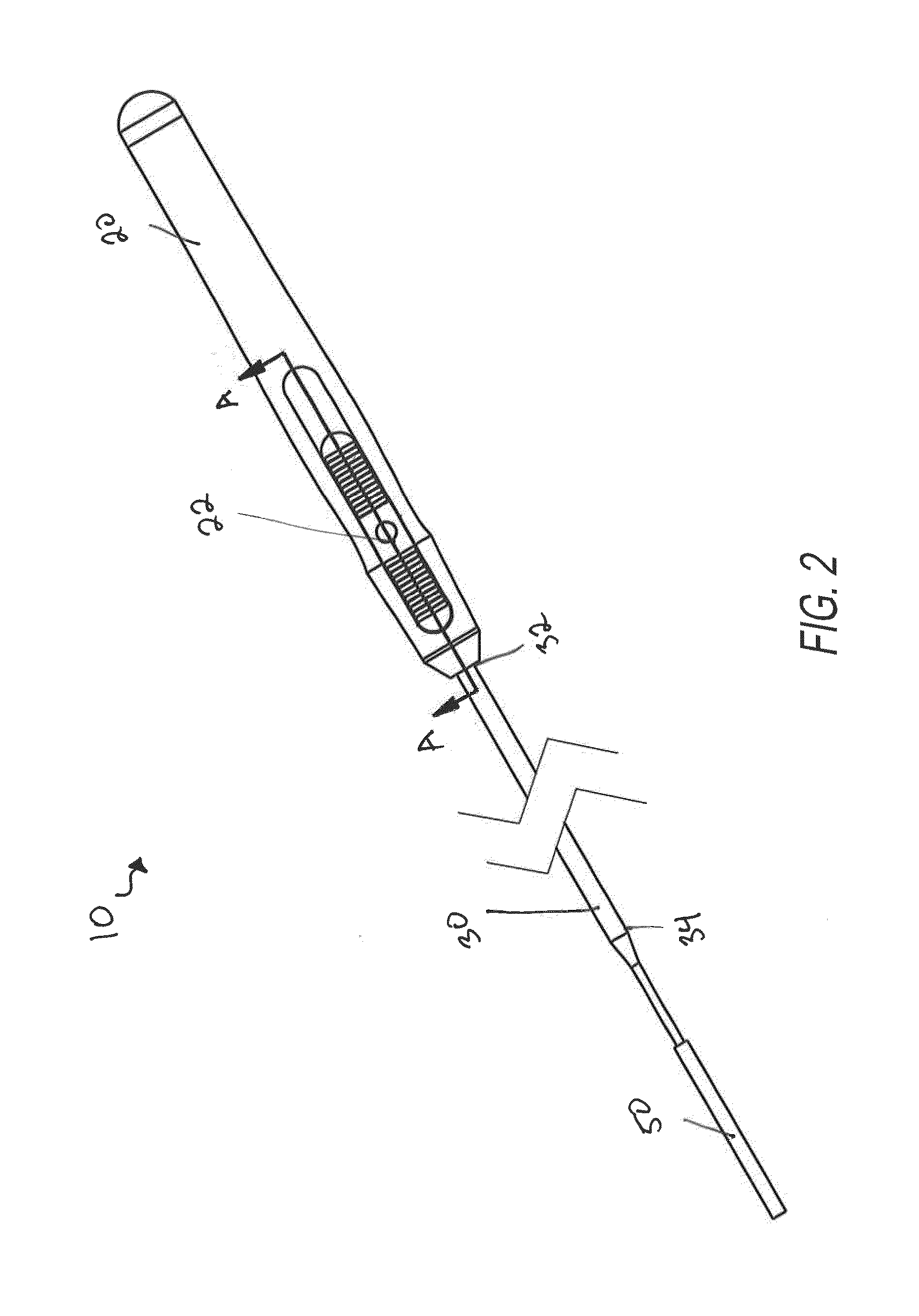

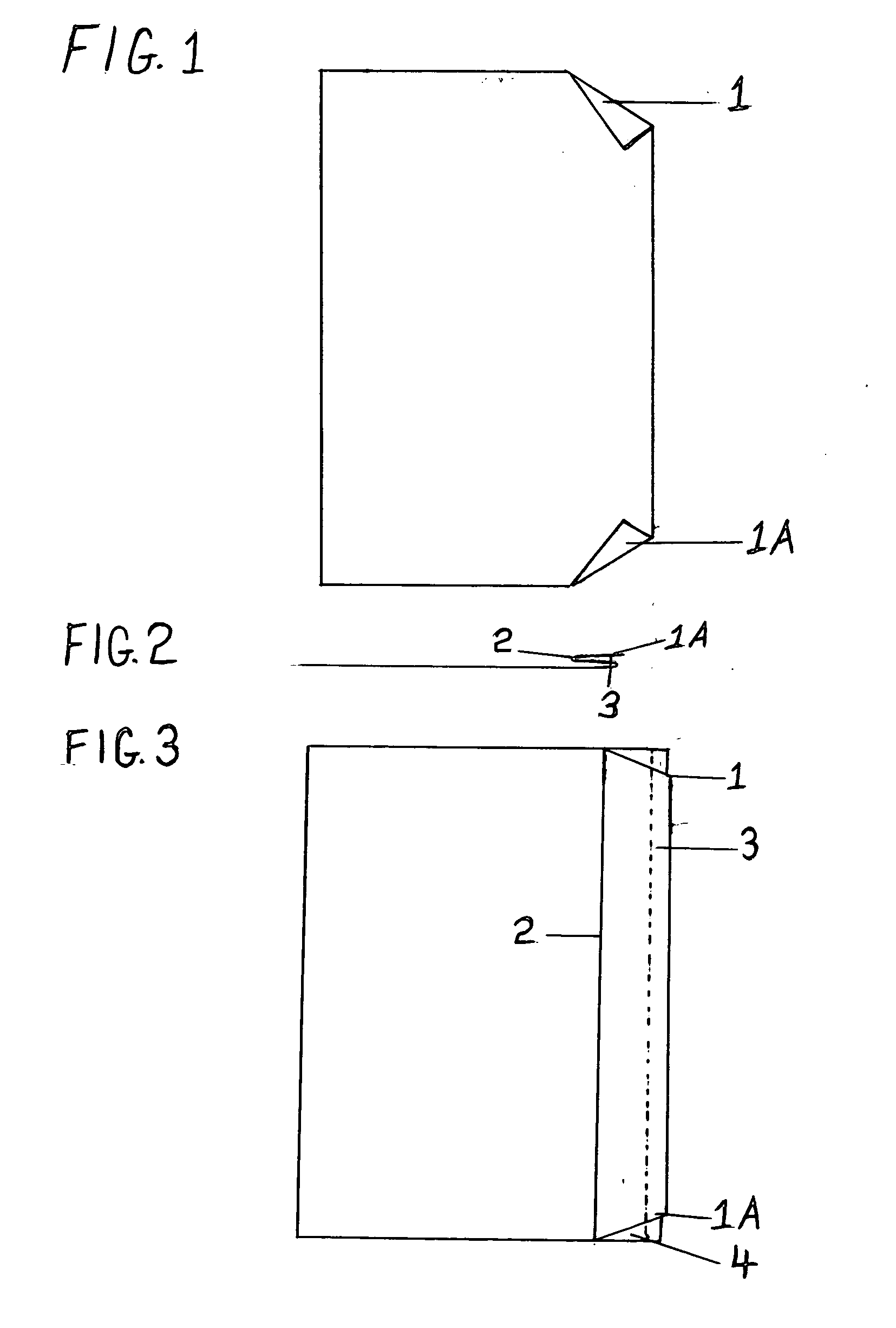

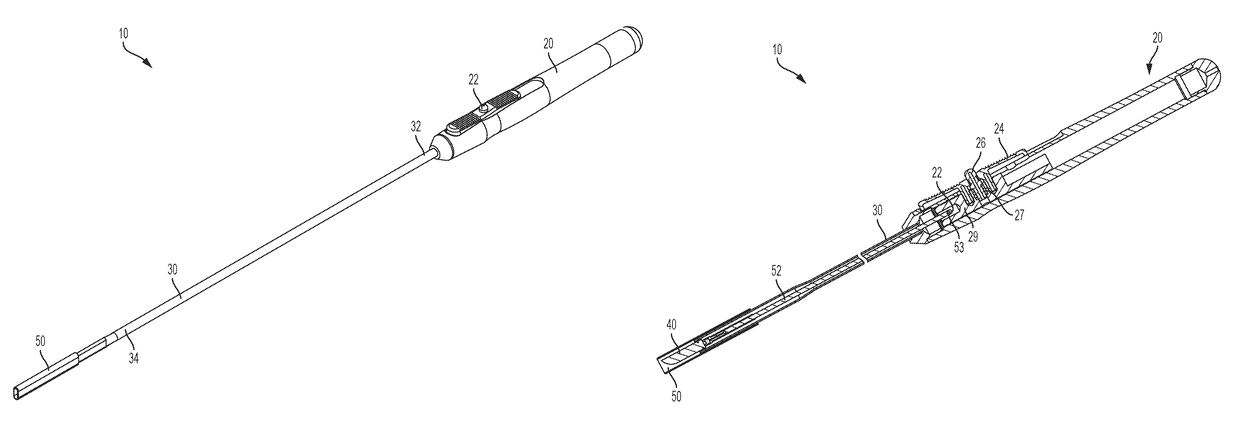

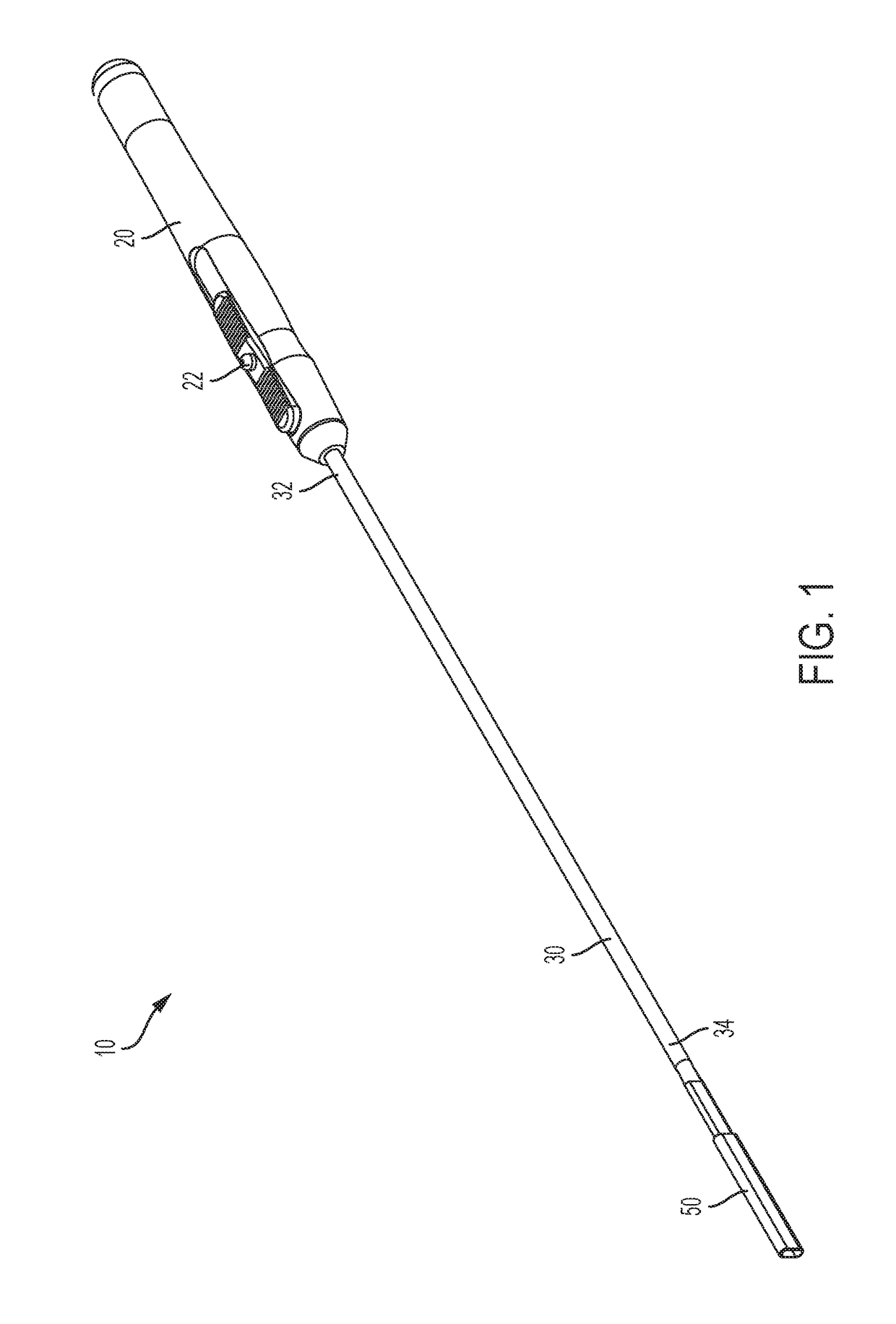

Surgical knife

ActiveUS20160235430A1Precise alignmentAvoids unwanted movementIncision instrumentsEndoscopic cutting instrumentsEngineeringSurgical knife

A surgical knife is provided. The knife has a blade, a handle, an elongated tube connected to the blade and the handle, and a sheath slidable over the tube and blade. The sheath is moveable from a first position that exposes the blade to and second position that conceals the blade. The blade, handle, and tube are in a fixed rigid relationship with each other while the sheath is movable.

Owner:PRECISION ENGINEERED PROD LLC

Ceramic wall-flow filter including heat absorbing elements and methods of manufacturing same

ActiveUS7384442B2Thinner filtration wallMinimized pressure dropCombination devicesAuxillary pretreatmentParticulatesHeat capacity

A ceramic wall-flow filter for filtering particulate matter from gases and methods for manufacturing such wall-flow filters are disclosed. The filter includes an array of porous ceramic walls defining a pattern of end-plugged inlet and outlet cells, and heat absorbing elements disposed within at least some of the outlet cells such that a bulk heat capacity of the outlet cells is greater than a bulk capacity of the inlet cells. The heat absorbing elements increase a bulk heat capacity of the filter without substantially interfering with a flow of gas through the porous ceramic walls by allowing thinner walls. According to the method, during the step of extruding or thereafter, heat absorbing elements are formed within at least some of the outlet cells such that a heat capacity of the outlet cells is greater than the inlet cells.

Owner:CORNING INC

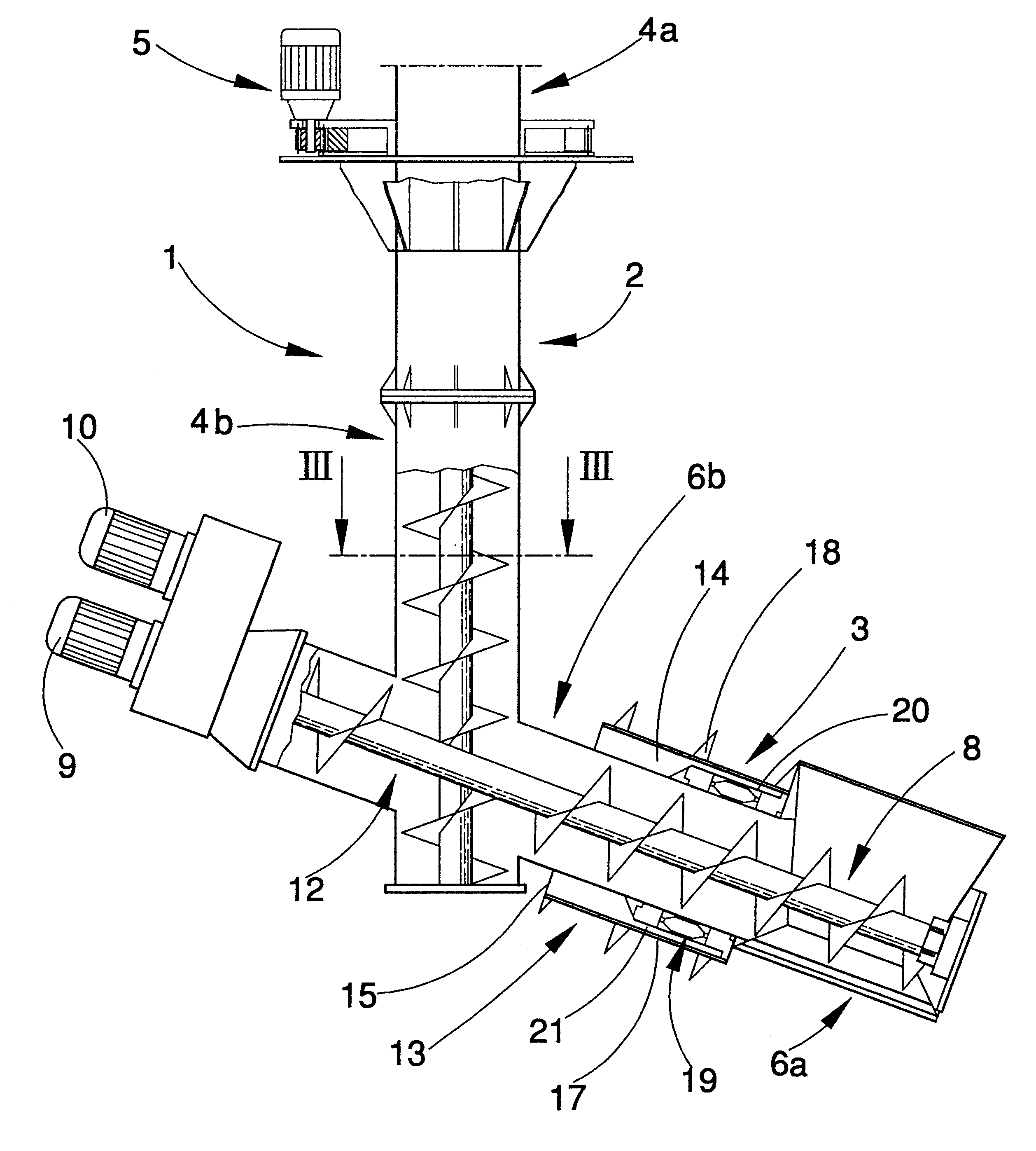

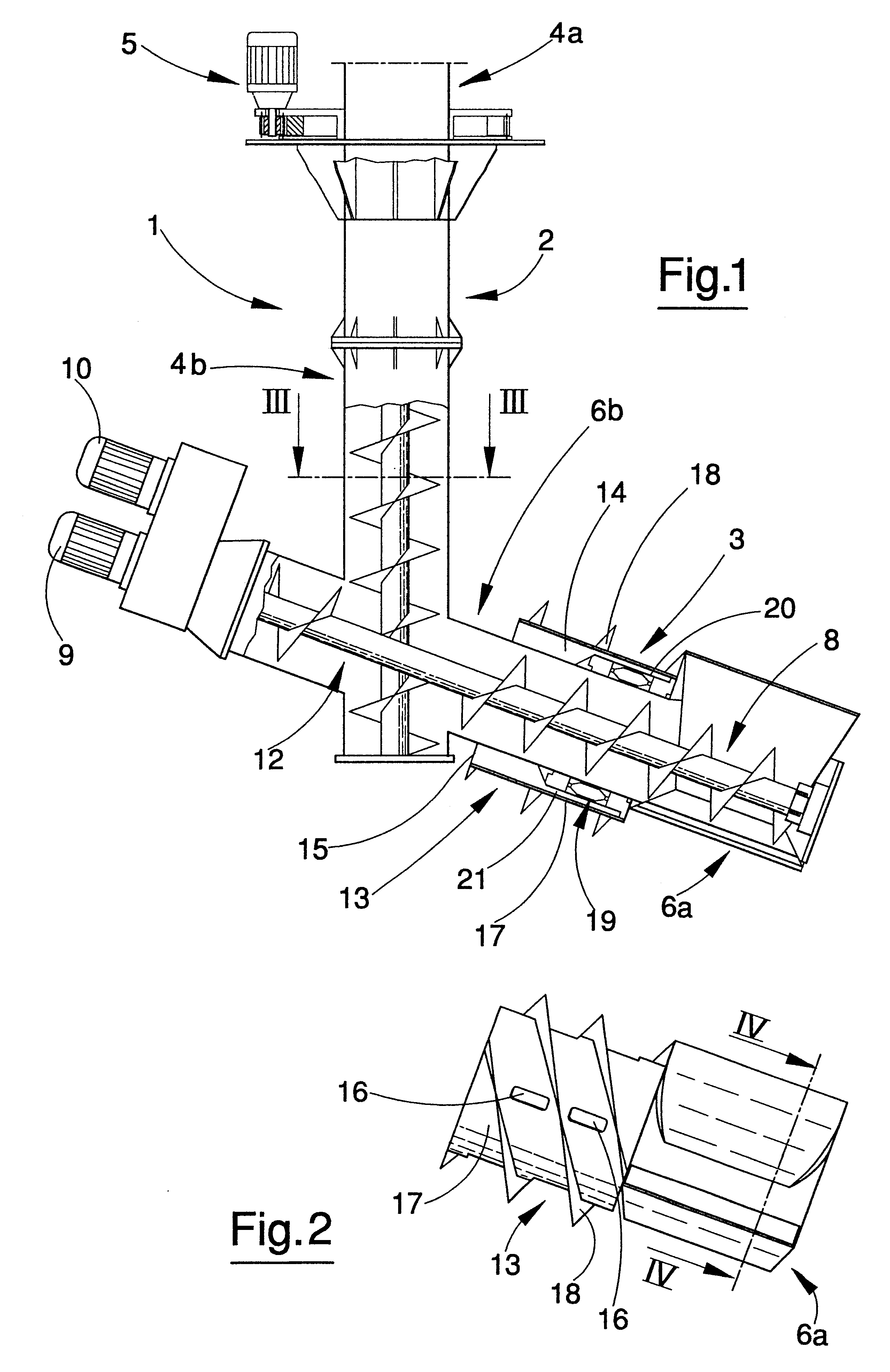

Screw conveyor for loose materials

InactiveUS6296106B1Loose materialHigh level of productivityPackagingLoading/unloadingEngineeringScrew conveyor

A screw conveyor for loose material comprises a tubular casing having a first part which is axially rotatable on command with respect to a second part. The first part is provided with openings through which the material can be introduced into the casing. A screw, internal of and coaxial to the casing, can rotate on command about its own axis and thus convey the material. A helical conveyor device which is solid in rotation with said first part of the casing, conveys the material towards the openings in first part of the casing. There is a hollow jacket between the conveyor device and the second part of the casing, through which the material passes. The invention provides greater efficiency in collecting and removing loose material from a pile.

Owner:WAM SPA

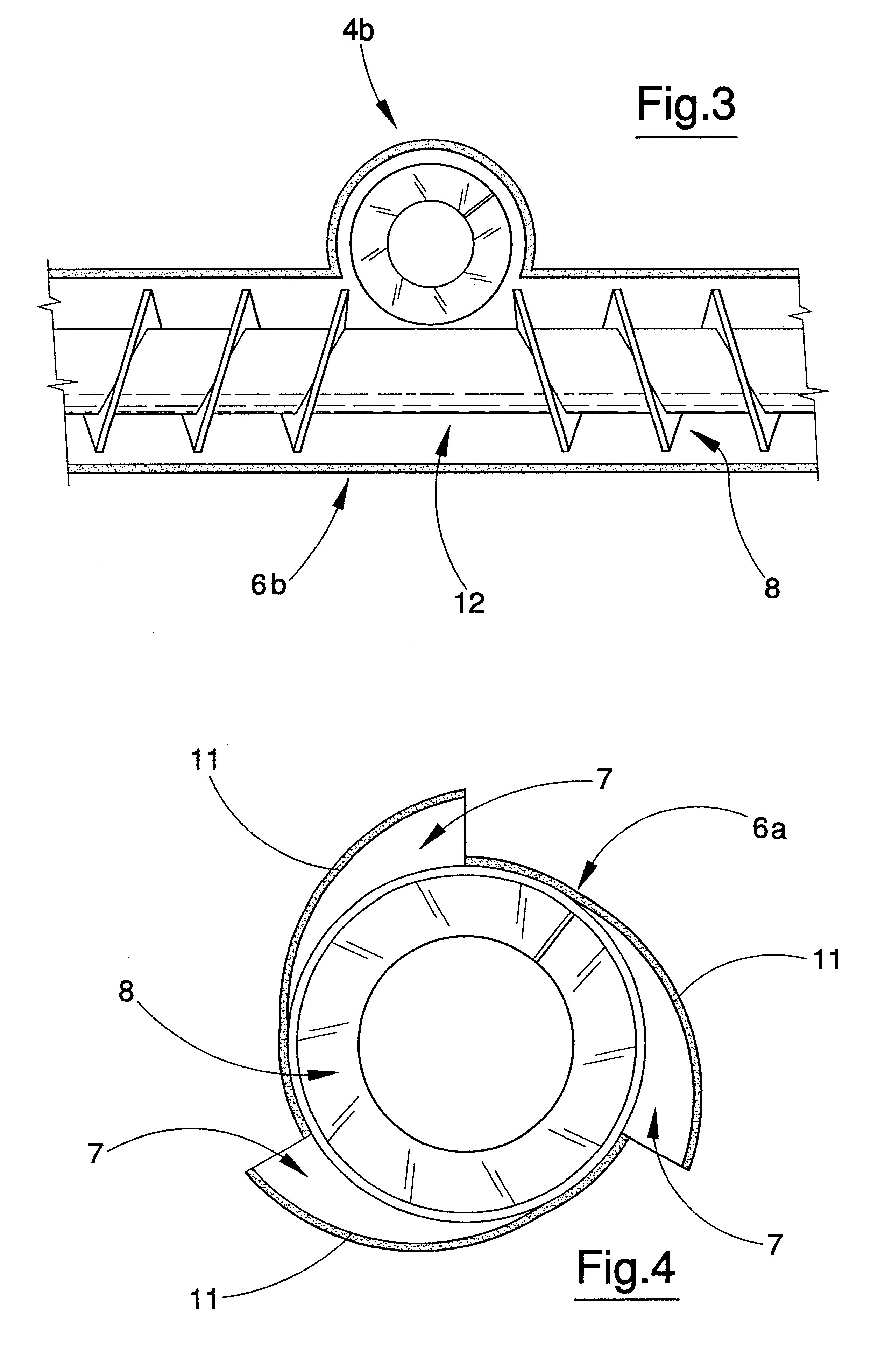

Scrub 'N' bag

InactiveUS20050095056A1Eliminate the problemLoose materialBathroom accessoriesOther pensPolyesterEngineering

The SCRUB'N'BAG is a personal bathing accessory which is composed of polyester mesh material. There is a cord channel around the top opening of the bag through which a nylon cord is threaded. Once the soap bar is placed in the bag, the cord is drawn to close the top of the bag. The excess nylon cord can be placed around the wrist and the vinyl slide is used to comfortably secure the bag to the wrist, eliminating the need to ever have to retrieve a dropped bar of soap again. The material at the top half of the bag can be used instead of a washcloth, or the bather may hold the lower half of the bag, which contains the bar of soap, and wash the body. The mesh polyester material allows the soap suds to pass through while also providing gentle exfoliation of skin.

Owner:KING ELAINE

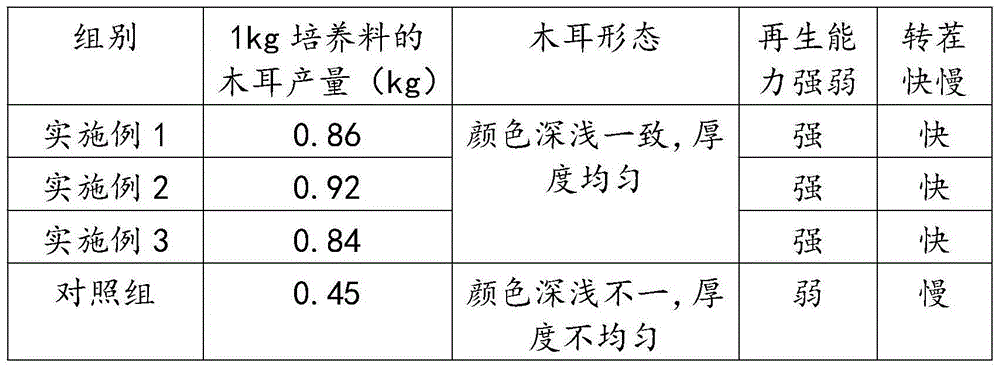

Black fungus culture medium and preparation method thereof

InactiveCN104909894AGood air permeabilityControl growth and pestsFertilizer mixturesHorticultureWater content

The invention discloses a black fungus culture medium and a preparation method thereof, and belongs to the technical field of the cultivation of edible mushrooms. The black fungus culture medium is prepared by adopting the following raw materials by weight percent: 30 to 48 percent of corncob powder, 15 to 36 percent of peanut shell powder, 18 to 25 percent of cottonseed hull powder, 10 to 15 percent of mallee bark chippings, 6 to 17 percent of wheat bran, 3 to 8 percent of bitter buckwheat husk, 1.5 to 3.2 percent of traditional Chinese herbal extraction liquid, 1 to 1.5 percent of gypsum powder, 0.6 to 1.4 percent of brown sugar and water added under stirring until the water content is 48 to 60 percent. By adopting the black fungus culture medium, the problems that the existing culture medium is unreasonable in nutritional structure, susceptible to the infection of bacteria, low in yield and poor in quality can be effectively solved, and the growth of bacteria and insect pest can be effectively controlled; moreover, the black fungus is good in quality and taste, the yield of the black fungus is increased, and the economic benefit of the planters can be increased.

Owner:GUANGXI UNIV

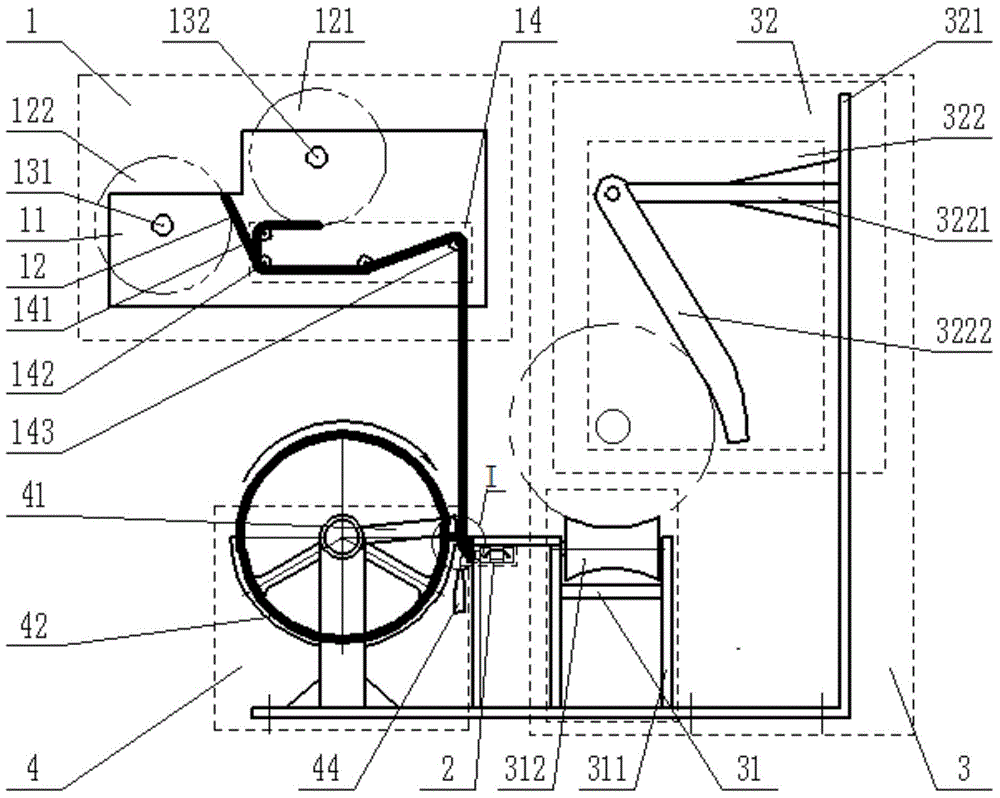

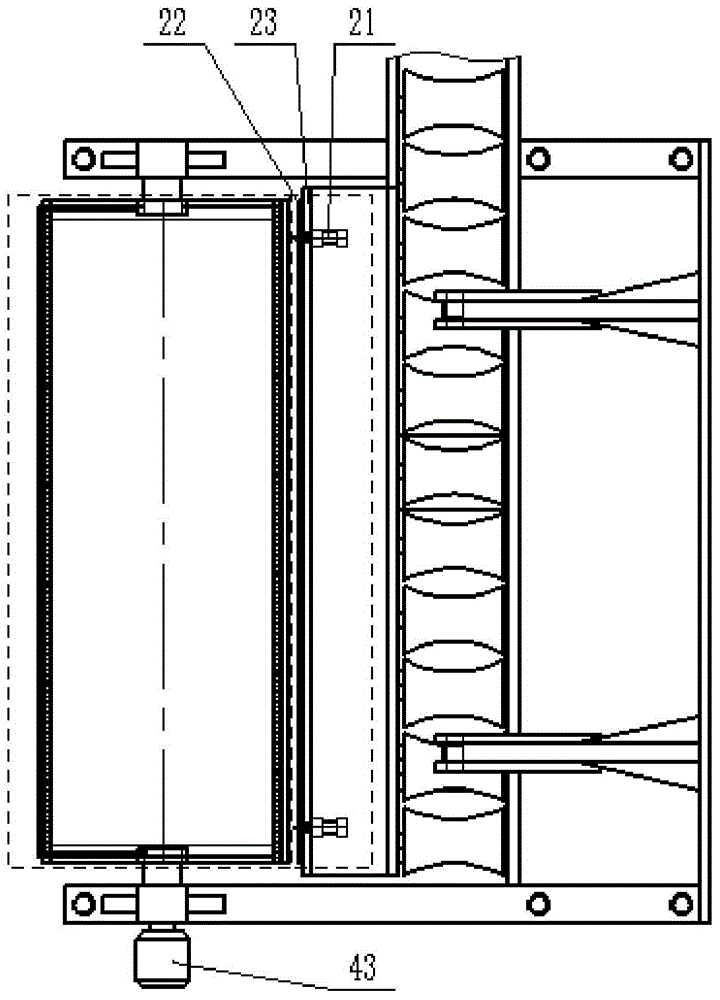

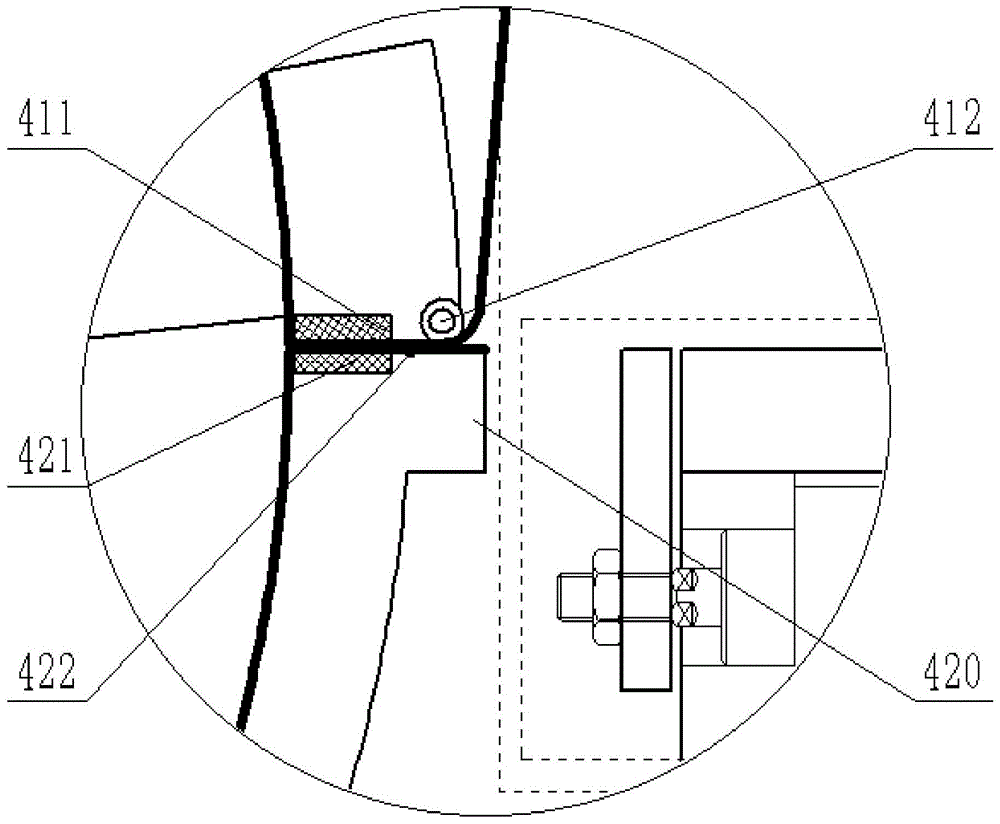

Automatic large coil material packaging equipment

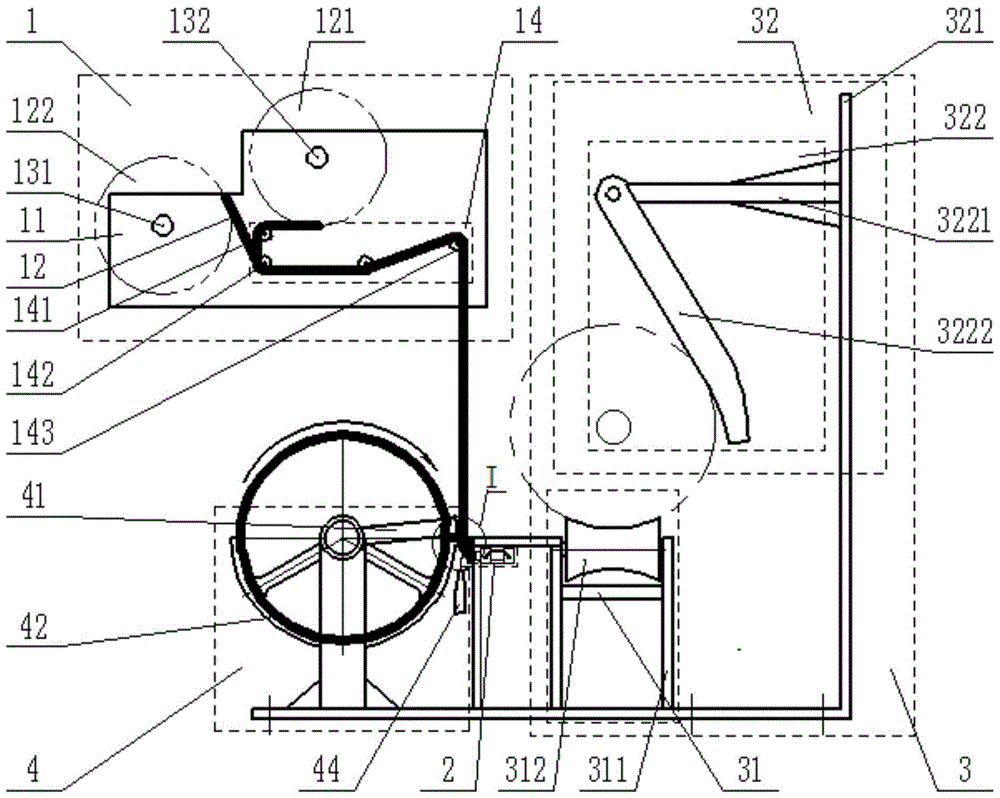

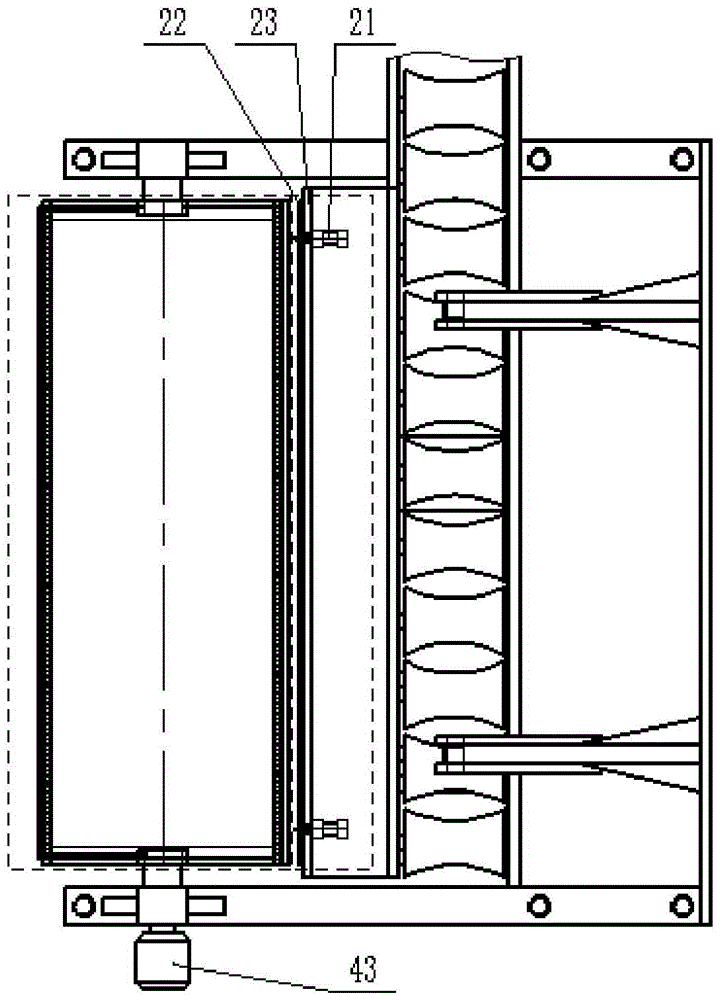

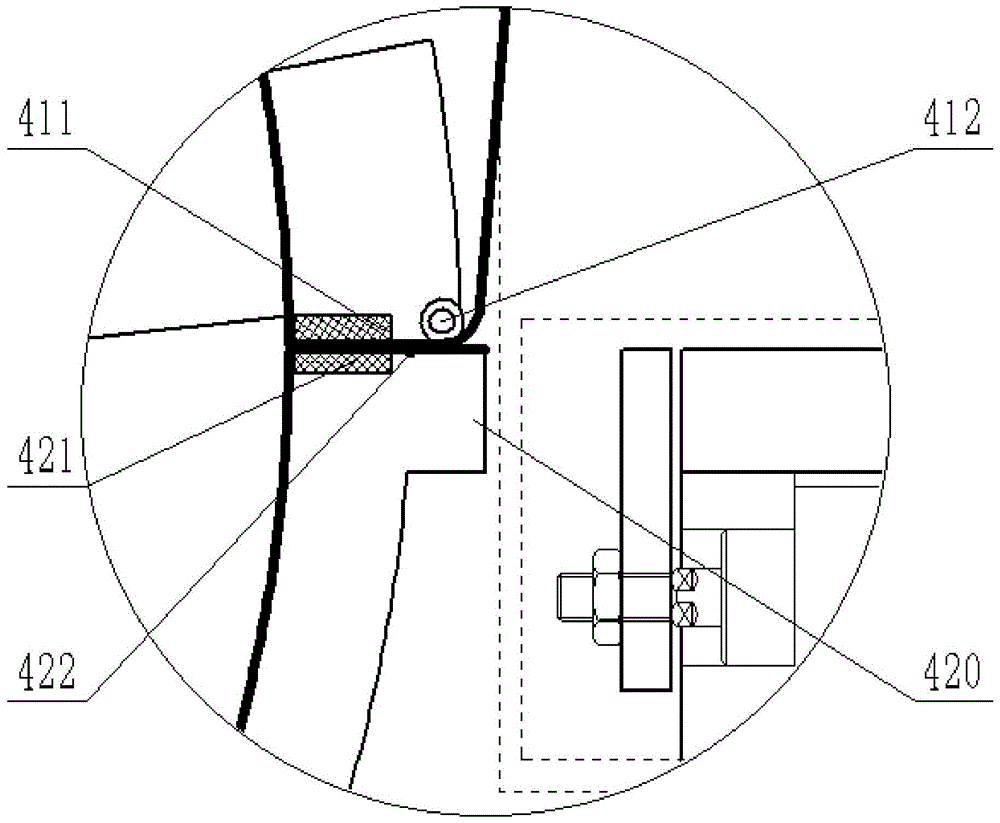

InactiveCN104803023ASimple and fast operationSimple structurePaper article packagingWrapping material feeding apparatusEngineeringMechanical engineering

The invention discloses automatic large coil material packaging equipment. The automatic large coil material packaging equipment is characterized by comprising a film feeding device, a compressing device, a feeding device and a coating device, wherein the feeding device comprises a feeding conveying machine and a coil stirring module; the feeding conveying machine is a supporting roller type feeding conveying machine; the feeding conveying machine comprises a conveying frame body and a coil supporting roller; the coil stirring module is positioned on one side of the feeding conveying machine, and comprises a coil stirring arm frame, a coil stirring arm and a coil stirring driving device; the compressing device comprises a transverse cylinder, a film pressing plate and a transition frame; the film feeding device comprises a packaging film bracket, a low-position mechanical expansion shaft and a driving device thereof, a high-position mechanical expansion shaft and a driving device thereof, and a guide wheel mechanism; the coating device comprises a rotary coating arm and a rotary material supporting bed, wherein the rotary material supporting bed is of a hollow fan-shaped cylindrical structure of which the side plane is opened, and the opening is upward.

Owner:HEBEI UNIV OF TECH

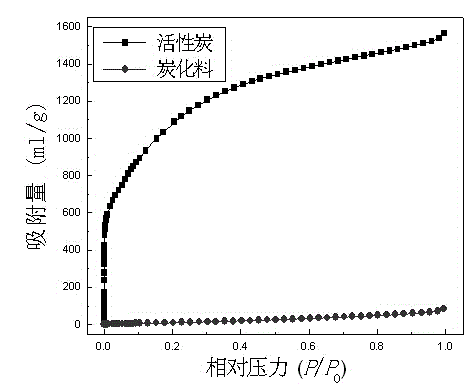

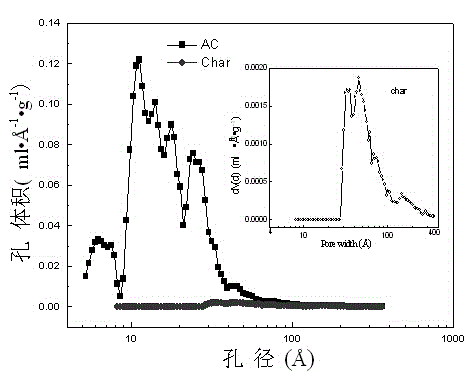

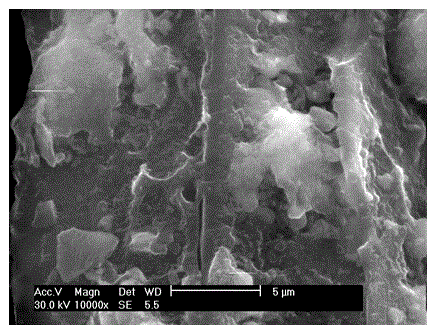

Preparation method of Ageratina-adenophora-base high-specific-area activated carbon

The invention relates to a preparation method of Ageratina-adenophora-base high-specific-area activated carbon, belonging to the field of environmental protection. The method comprises the following steps: uniformly mixing KOH and an Ageratina adenophora carbonization material in a solid-phase state, filling into a ceramic crucible, and putting into a microwave high-temperature reactor; introducing nitrogen to evacuate air in the furnace, heating under microwaves to the last fewer minutes, quickly blowing CO2 into a guide tube communicated with the bottom of the ceramic crucible, and meanwhile, starting an ultrasonic generator; after finishing heating, washing the activated material with water, and recovering the residual KOH activator; and sequentially carrying out acid washing, water washing and drying to obtain the high-specific-area activated carbon. By using the Ageratina adenophora as the raw material, the method uses the CO2 bottom blowing mode to enhance the activation effect of the carbonization material, thereby lowering the production cost of the activated carbon, relieving the environmental pollution, changing harmful substances and waste into valuable substances and implementing comprehensive utilization of natural resources. The high-specific-area activated carbon can be effectively used in the fields of adsorptive collection of gasoline and other organic substances in automobile exhaust emissions and fuel system volatile substances, solvent recovery and the like.

Owner:KUNMING UNIV OF SCI & TECH

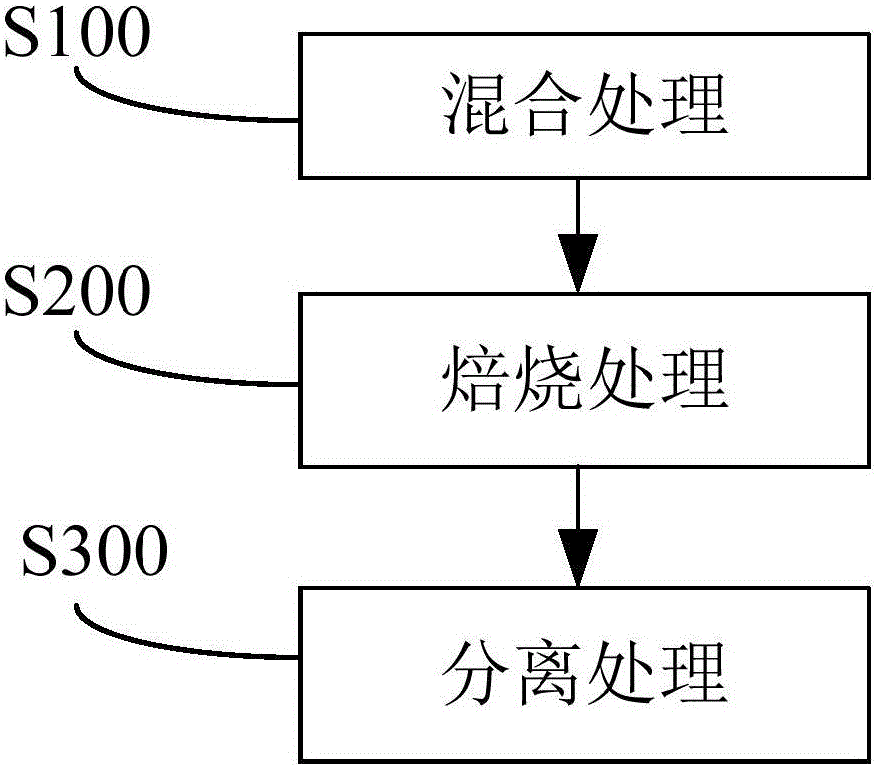

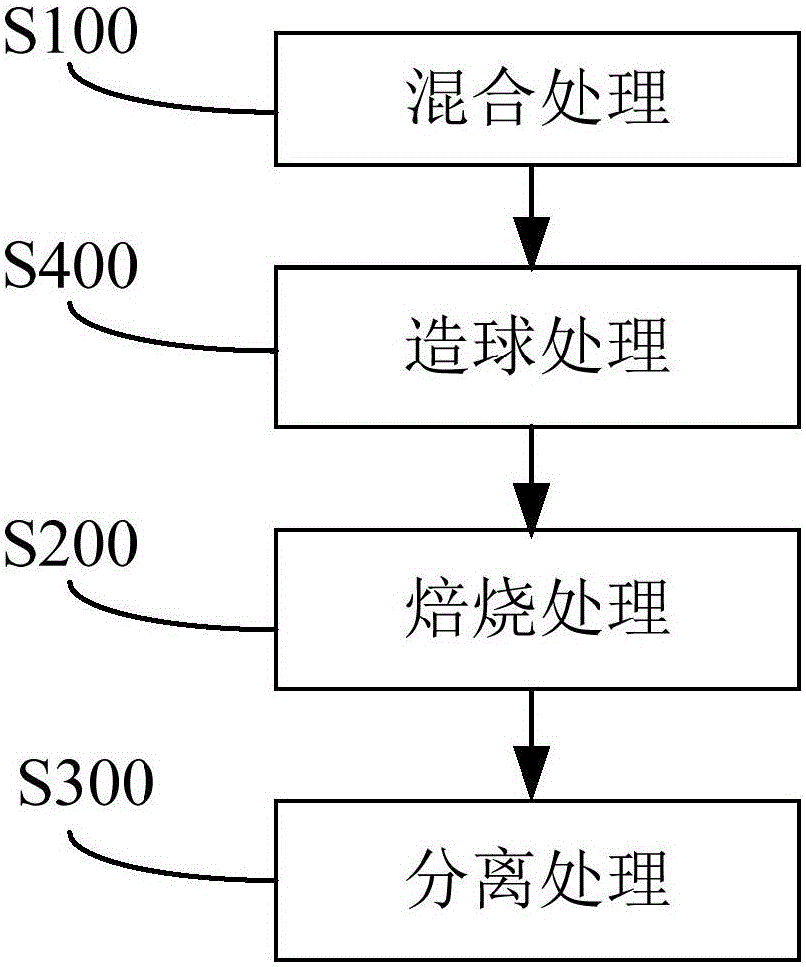

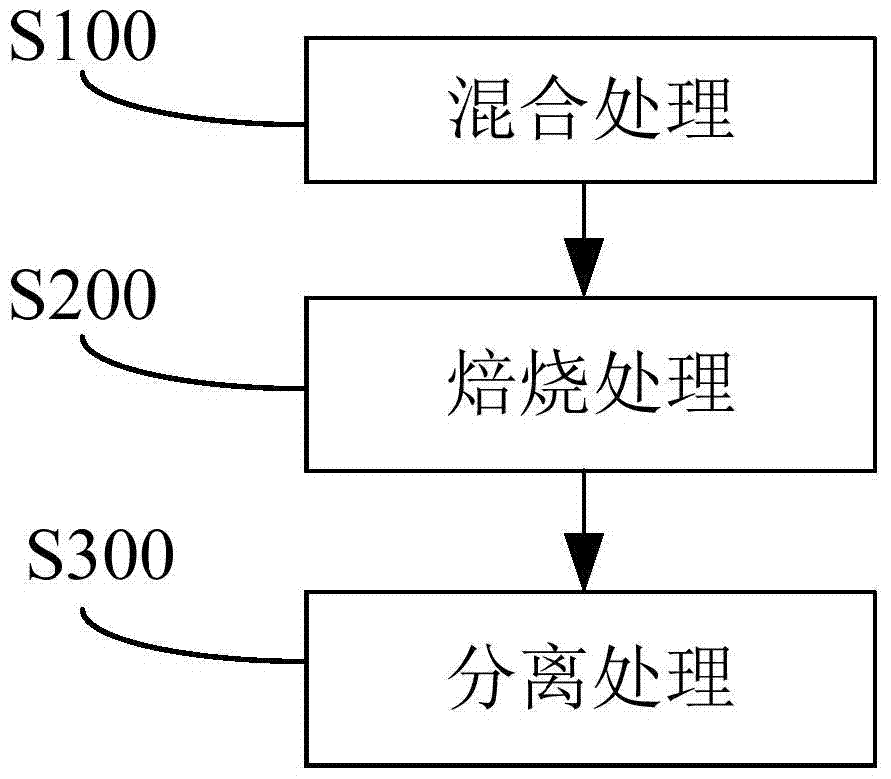

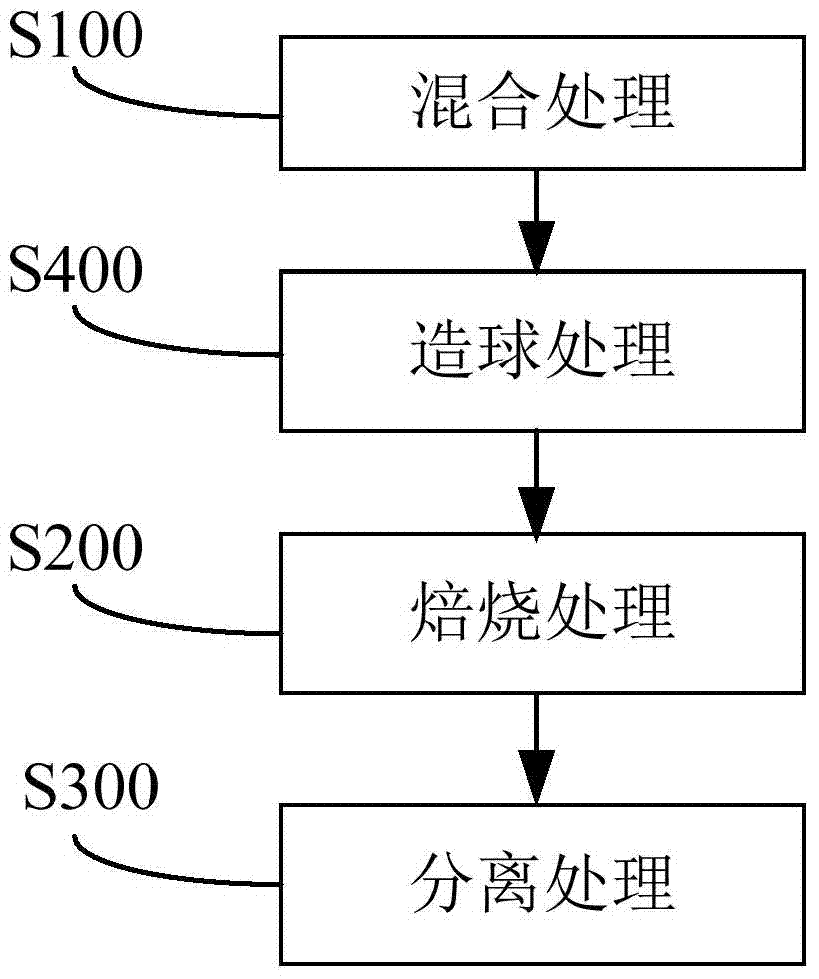

Method for utilizing sulfate slag and red mud comprehensively

The invention discloses a method for utilizing sulfate slag and red mud comprehensively. The method comprises the steps that the sulfate slag and the red mud are mixed with a reducing agent so as to obtain a mixed material; roasting is carried out on the mixed material so as to obtain a reduced iron product; the reduced iron product is separated so as to obtain iron powder. By the utilization of the method, the two metallurgical solid waste resources, namely the red mud and the sulfate slag are utilized comprehensively, so that the iron product with good indexes is obtained.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Brew-in-the-cup disposable beverage assembly

A brew-in-the-cup disposable beverage assembly includes a cup and a beverage pouch containing a premeasured charge of beverage material. The pouch is packaged within an airtight bag to preserve the freshness of the beverage material until use. The beverage pouch rests on supporting structure extending inwardly from the cup sidewall supported in an upper region of the cup. An aroma enhancing substance is included in the beverage material. For use, the airtight bag is removed from the beverage pouch which is then placed on the supporting structure and liquid is poured onto the pouch to brew the beverage and drain into the cup.

Owner:YUGUCHI CLIFFORD

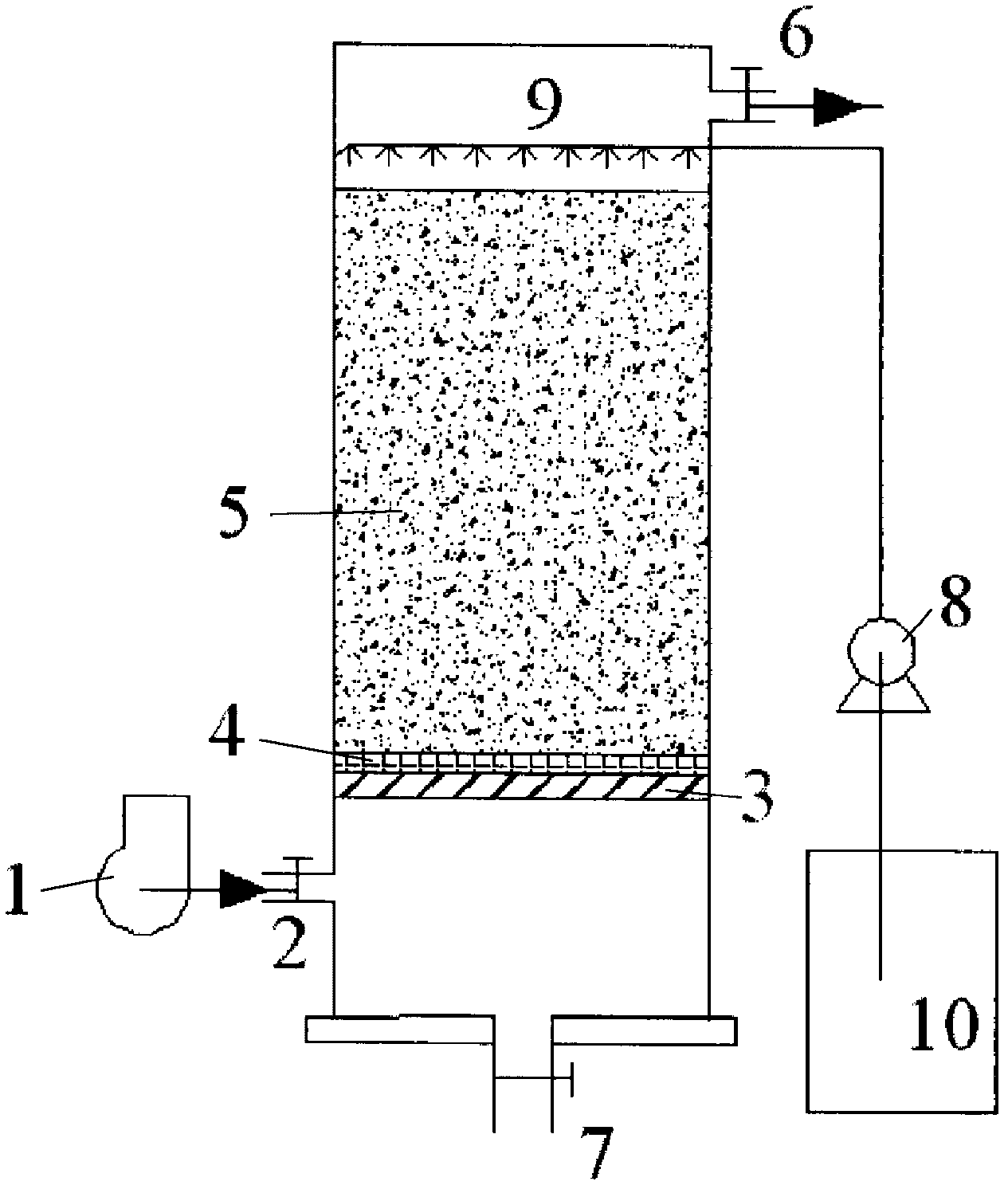

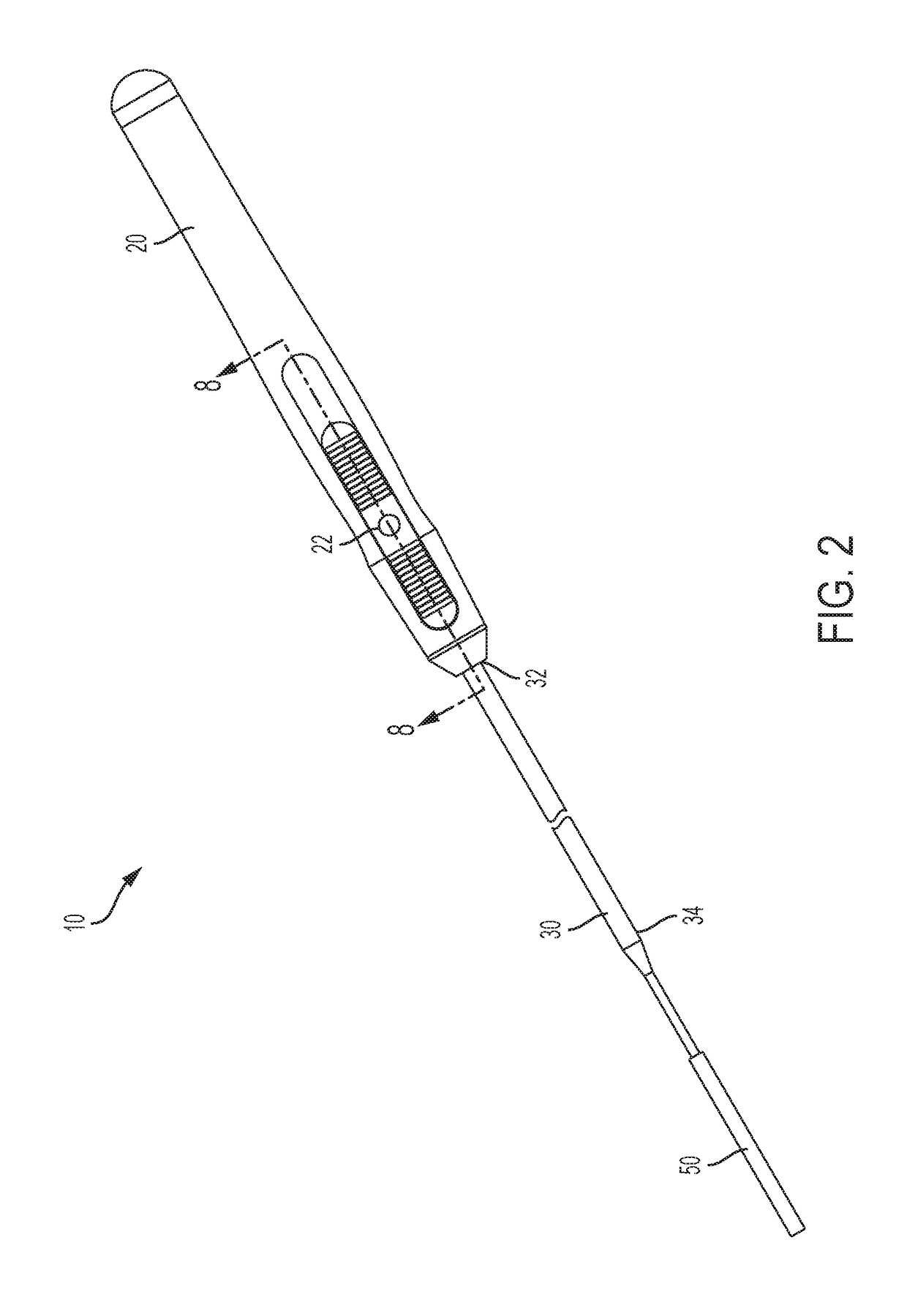

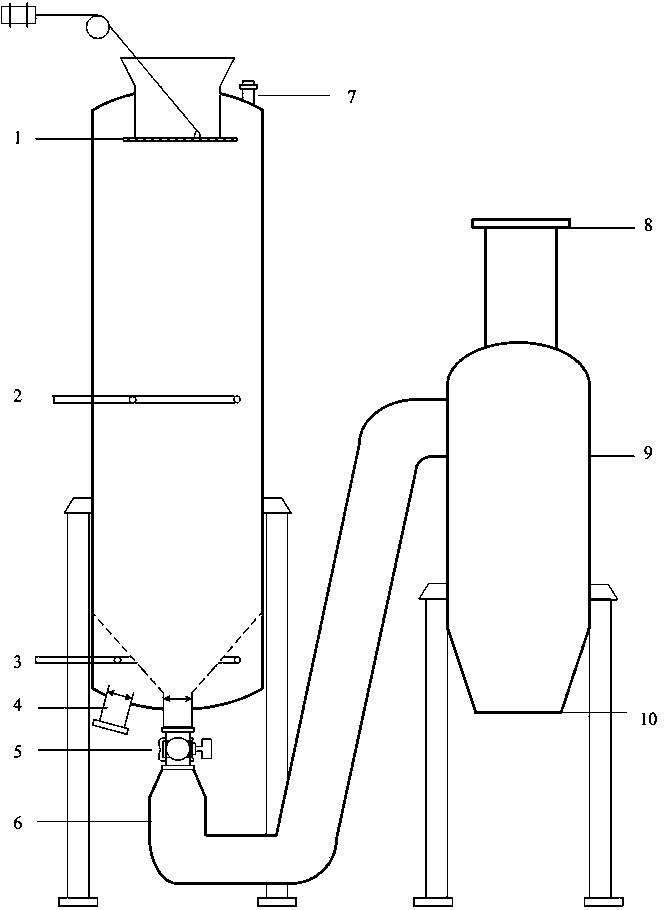

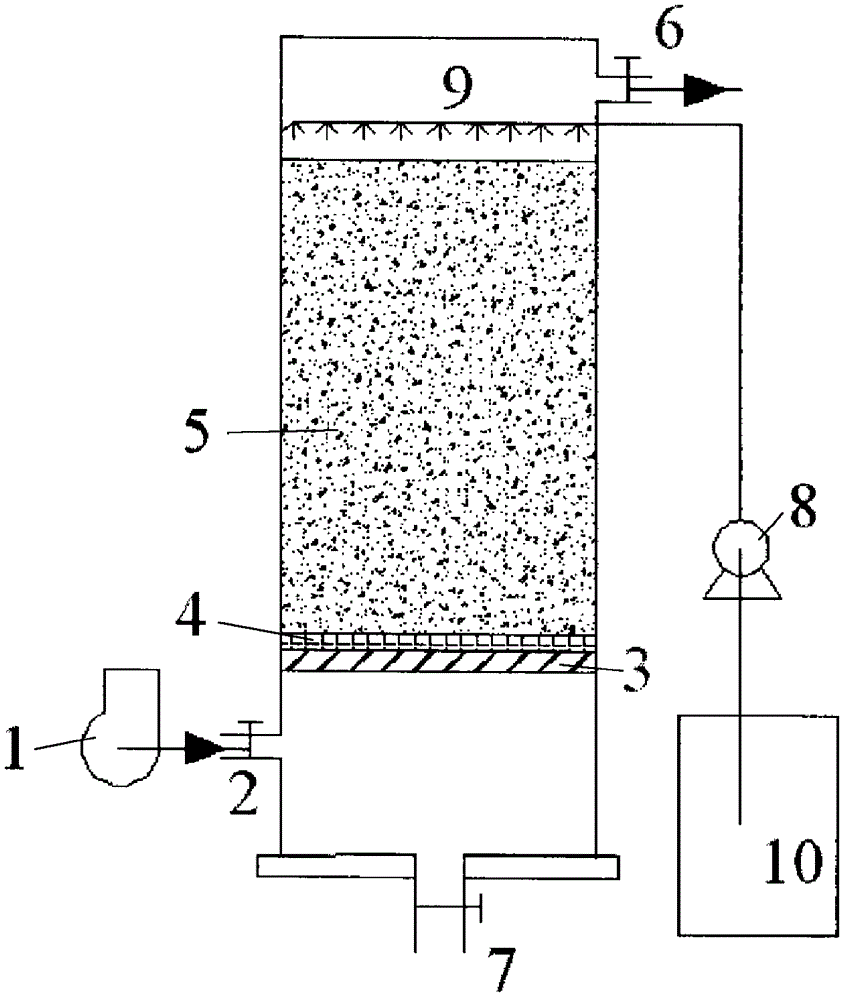

Mushroom bran packing biological deodorizing tower

InactiveCN102580522ALoose materialNot easy to compactDispersed particle separationAir quality improvementLitterEngineering

The invention provides a mushroom bran packing biological deodorizing tower, which mainly comprises: a multi-pore plate mounted inside, wherein the mushroom bran packing is filled above the multi-pore hole, and a spraying device is arranged above the mushroom bran packing; a gas inlet arranged at the position at the side of the deodorizing tower and placed below the multi-pore plate; a gas outlet arranged at the position at the side of the deodorizing tower and placed above the spraying device; and a draining port provided at the bottom of the deodorizing tower. Compared with existing deodorizing packing, the mushroom bran packing used in the deodorizing tower provided by the invention has a wide and cheap resource, and is simple to process, as well as reducing the cost; the mushroom bran packing used in the invention has the characteristics of loose texture, and difficulty in compacting. By using the deodorizing tower, more than 85% H2S and 90%NH3 can be removed within 12 hours, thus, the deodorizing tower can be widely applied to process waste gas in composting plants and refuse processing plants.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Surgical knife

ActiveUS10123815B2Precise alignmentAvoids unwanted movementIncision instrumentsEndoscopic cutting instrumentsEngineeringSurgical knife

A surgical knife is provided. The knife has a blade, a handle, an elongated tube connected to the blade and the handle, and a sheath slidable over the tube and blade. The sheath is moveable from a first position that exposes the blade to and second position that conceals the blade. The blade, handle, and tube are in a fixed rigid relationship with each other while the sheath is movable.

Owner:PRECISION ENGINEERED PROD LLC

Method and device for high temperature sterilization by using steam explosion

InactiveCN103721274AShorten the sterilization cycleShorten the high temperature maintenance timeHeatNutrientProcess engineering

The invention provides a method and device for high temperature sterilization by using steam explosion, which are short in sterilization cycle, low in destruction rate of nutrient substances, loose in materials, easy to amplify, and high in production efficiency aiming at the defects that conventional high-pressure steam sterilization is long in cycle, serious in damage to nutrient substances, easy in caking and the like. According to the method and device provided by the invention, the sterilization time is shortened by improving the sterilization temperature, so as to possibly reduce the damage to the nutrient substances. Meanwhile, the materials and the steam are ejected in a burst state in a rapid emptying manner, so as to loosen a culture medium and simultaneously shorten the cooling time. Thus, the overall sterilization cycle is shortened. The method and the device can facilitate industrial production of solid state fermentation by improving the production efficiency and the fermentation effect of the culture medium.

Owner:北京中科百瑞能工程技术有限责任公司

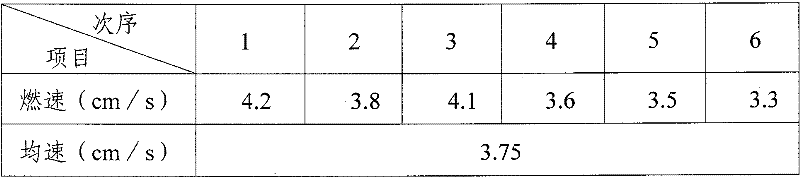

Novel potassium perchlorate paper firing line for firecrackers

InactiveCN101973828BImprove performanceIncrease burn rateInorganic oxygen-halogen salt explosive compositionsFusesFirecrackerPulp and paper industry

Owner:陕西省蒲城县新型花炮技术推广中心

Pleurotuseryngii pollution-free cultivation method

InactiveCN104938213AMeet the temperatureMeet the humidityBioloigcal waste fertilisersCultivating equipmentsMaterials preparationNutrition

The invention discloses a pleurotuseryngii pollution-free cultivation method and belongs to the technical field of edible mushroom cultivation. The pleurotuseryngii pollution-free cultivation method comprises the following steps of cultivation material preparation, bottling and sterilization, inoculation, spawn running, primordia hastening, fruiting management and harvest. Pleurotuseryngii produced by the cultivation method is rich in nutrition, big in size, good in quality, good in taste and high in production volume, and the economic benefit of farmer households is increased.

Owner:GUANGXI UNIV

Edible mushroom waste culture medium and landscaping waste and sludge mixed solid fuel and processing technology thereof

The invention discloses edible mushroom waste culture medium and landscaping waste and sludge mixed solid fuel which is prepared by the following steps: mixing and pressing the following components: 30-40 percent of an edible mushroom waste culture medium, 20-30 percent of sludge, 25-35 percent of landscaping wastes, 8-16 percent of waste oil and 4-12 percent of starch glue, thereby obtaining the solid fuel. According to the solid fuel disclosed by the invention, the treatment problem of the edible mushroom waste culture medium, landscaping wastes and organic matter sludge is solved, and the edible mushroom waste culture medium and landscaping waste and sludge mixed solid fuel pressed by the method has the characteristics of high heating value and good molding effect.

Owner:XIAMEN UNIV OF TECH

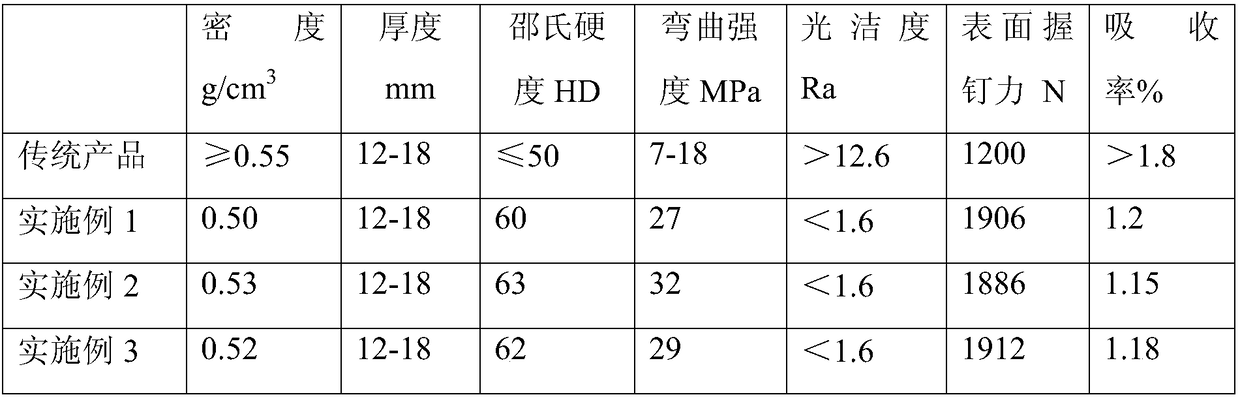

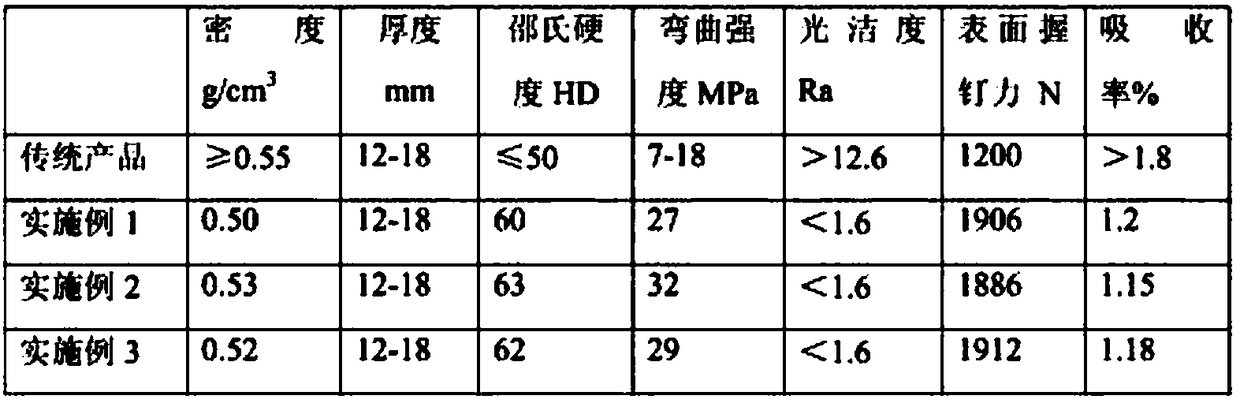

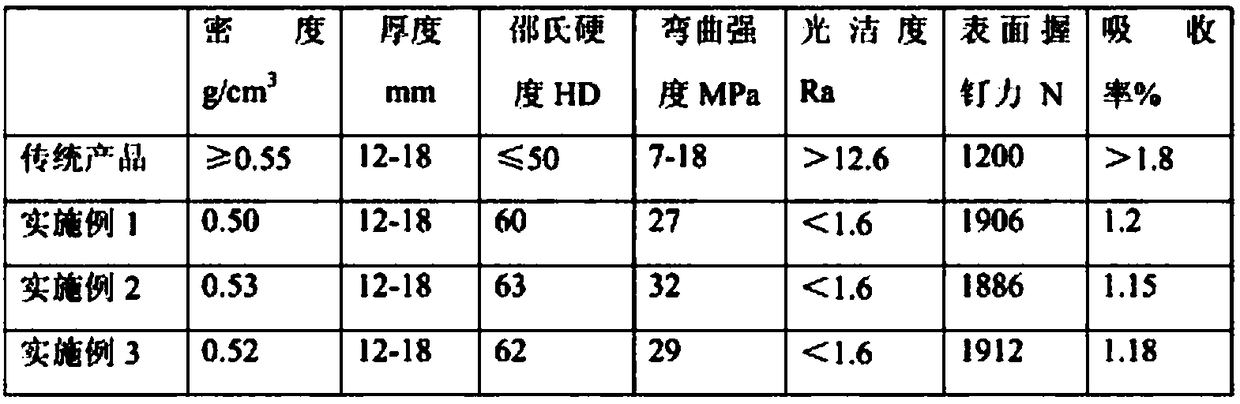

Polyvinyl chloride kitchen and bathroom board and preparation method thereof

The invention discloses a polyvinyl chloride kitchen and bathroom board and a preparation method thereof, belonging to the technical field of polyvinyl chloride plates. The invention solves the problems that hydroscopicity of an existing product is poor, density is low and hardness is poor. The polyvinyl chloride kitchen and bathroom board is prepared from 60-80 parts of polyvinyl chloride SG8 resin, 40-60 parts of ground calcium carbonate, 20-40 parts of reclaimed materials, 7-9 parts of a foaming regulator, 2.7-2.9 parts of a lead salt stabilizer, 0.5-0.6 part of an internal lubricant SP-60,0.2-0.3 part of polyethylene wax, 0.2-0.25 part of micronized polyethylene wax N-14P, 0.1-0.15 part of a plasticizer OA6, 0.5-0.6 part of a heat release type AC foaming agent, 1.2-1.4 parts of a heatabsorption type foaming agent and pigments. The preparation method thereof comprises the following steps: sequentially putting materials into a hot mixing pot, heating and then cooling, and then conveying the cooled materials to an extruding machine, so that the finished product is obtained. The invention is mainly applied to preparation of the polyvinyl chloride kitchen and bathroom board.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

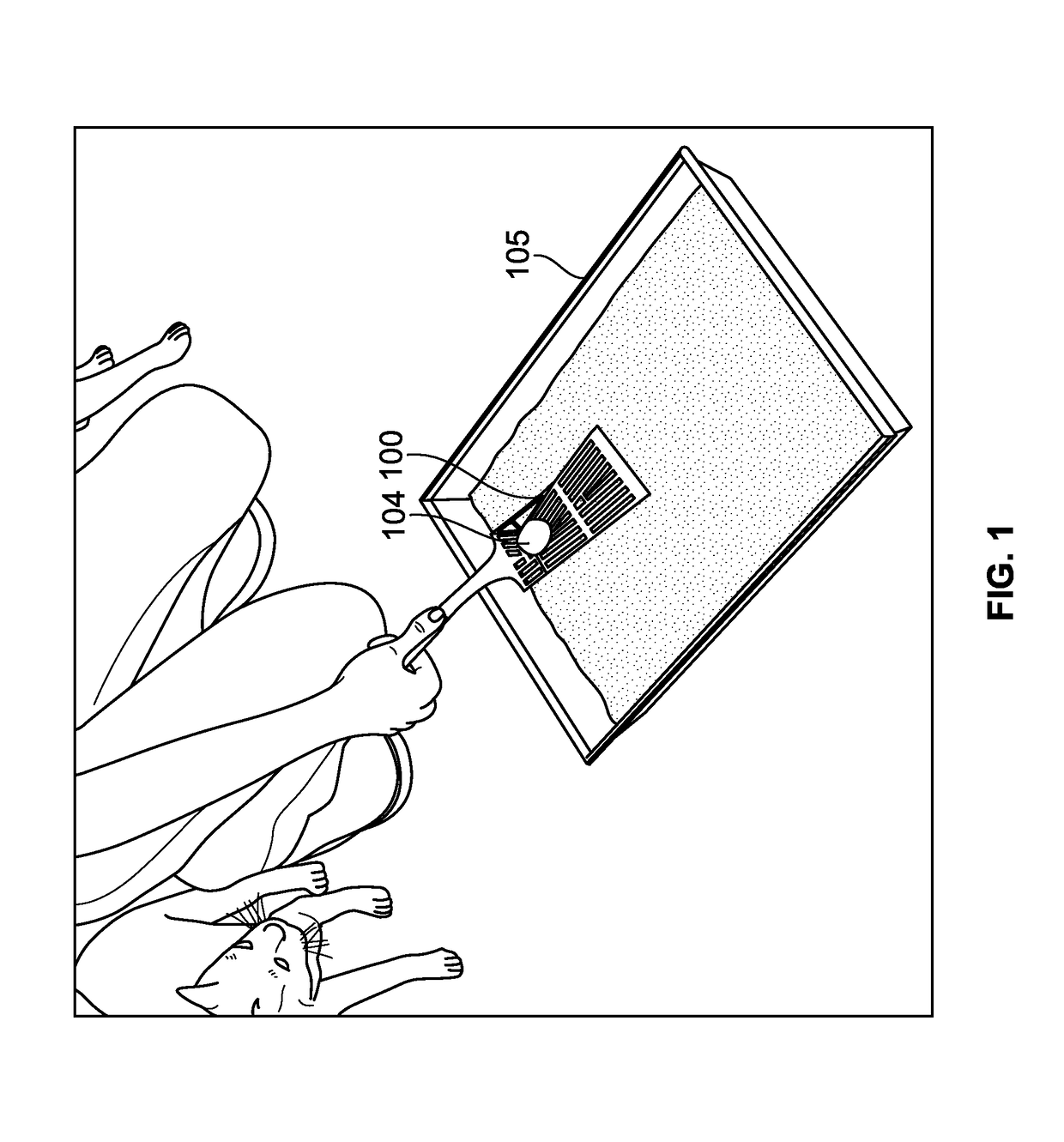

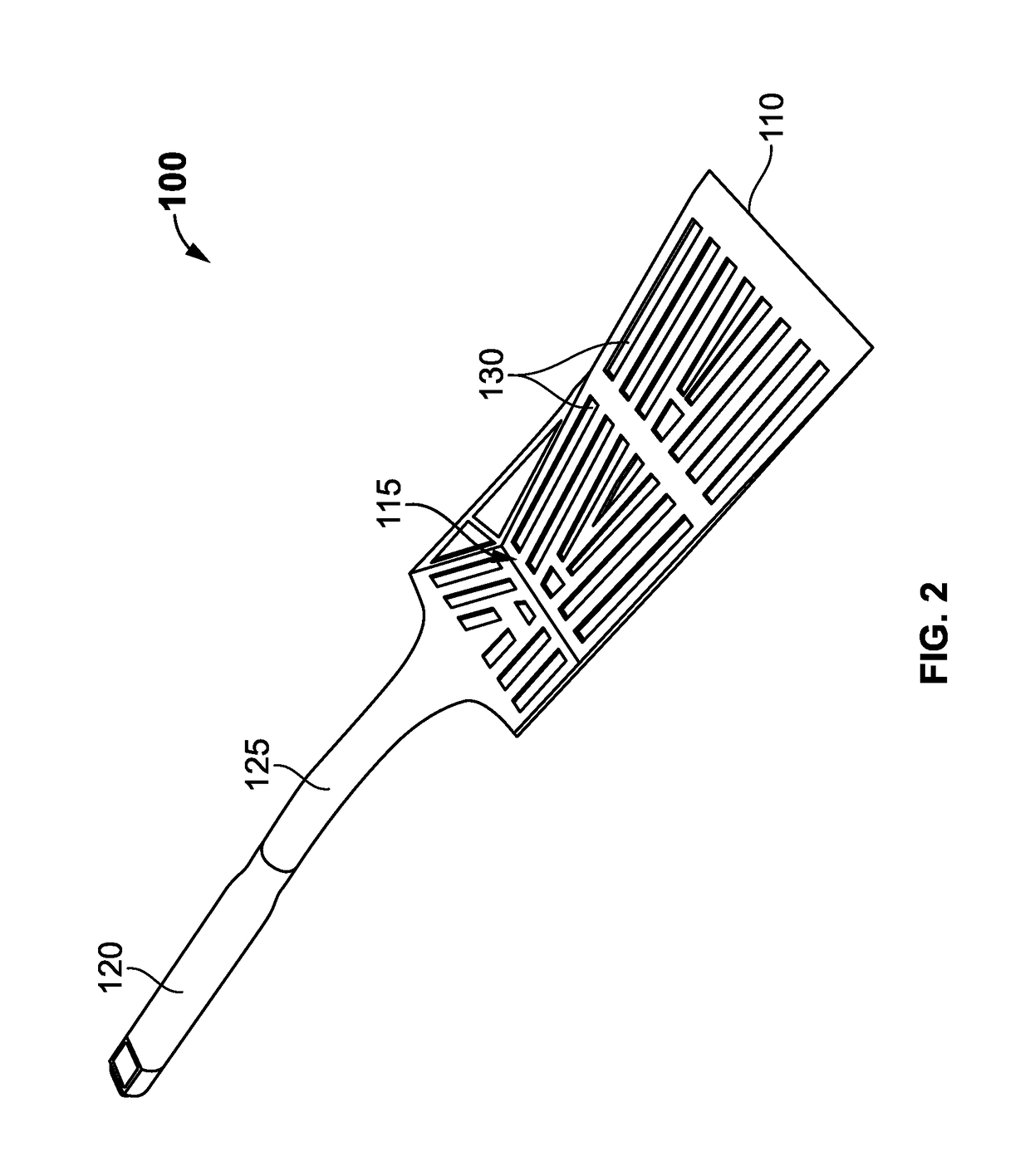

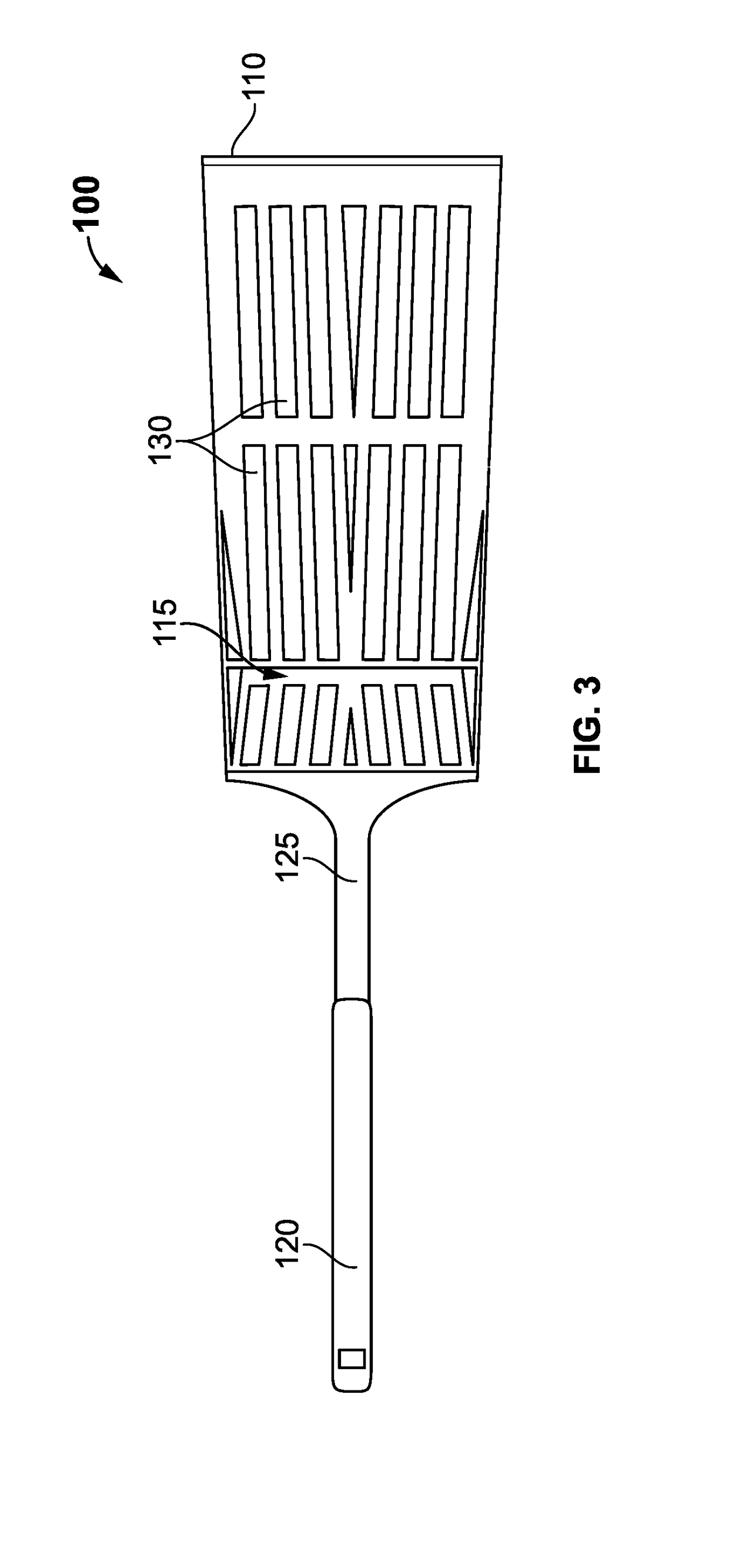

Litter box Scooper

A poop scoop device designed to allow the user to easily segregate urine clump or balls and feces, lift, discard, and wash the device for further use, is disclosed. The scoop device comprises a filter basket, a beveled scraper, and a handle. The filter basket and beveled scraper, are coated by a non-stick material. The filter basket is a spatula shaped end, positioned between the handle and the beveled scraper end in the scoop device. The filter basket is further extended towards to form the flat beveled scraper configuration in the scoop device. The filter basket and the beveled scraper comprises one or more openings that prevent the scoop device from capturing loose litter material. Further, the scraper of the scoop device is beveled and sharpened to allow loosening of the material such as urine clump or feces, inadvertently adhering to the sides of the litter box.

Owner:ECKSTEIN SR JOAN

High-efficiency and low-cost pleurotus eryngii culture compost

The invention discloses high-efficiency and low-cost pleurotus eryngii culture compost, and belongs to the technical field of culturing of edible fungi. The high-efficiency and low-cost pleurotus eryngii culture compost is prepared by, by weight percentage, 40-60% of mulberry branch powder, 20-35% of bean stalk, 5-15% of silkworm excrement, 2-5% of soybean meal, 2-5% of sweet potato powder, 0.6-1.5% of shaddock peel powder, 0.6-1.5% of watermelon peel powder, 0.2-0.6% of monopotassium phosphate, 0.5-1.0% of gypsum powder, 0.5-1.0% of lime and 0.5-1.0% of white granulated sugar. According to the high-efficiency and low-cost pleurotus eryngii culture compost, various waste resources are fully utilized, proportioning is scientific, the nutritional requirements of mycelial growth and sporocarp growth and development of pleurotus eryngii are met, the utilization value is high, and the produced pleurotus eryngii is big in size, good in quality, good in taste, high in yield, rich in nutrition, low in cost, green and environmentally friendly and great in market value.

Owner:GUANGXI UNIV

Mushroom bran packing biological deodorizing tower

InactiveCN102580522BLoose materialNot easy to compactDispersed particle separationAir quality improvementLitterEngineering

The invention provides a mushroom bran packing biological deodorizing tower, which mainly comprises: a multi-pore plate mounted inside, wherein the mushroom bran packing is filled above the multi-pore hole, and a spraying device is arranged above the mushroom bran packing; a gas inlet arranged at the position at the side of the deodorizing tower and placed below the multi-pore plate; a gas outlet arranged at the position at the side of the deodorizing tower and placed above the spraying device; and a draining port provided at the bottom of the deodorizing tower. Compared with existing deodorizing packing, the mushroom bran packing used in the deodorizing tower provided by the invention has a wide and cheap resource, and is simple to process, as well as reducing the cost; the mushroom bran packing used in the invention has the characteristics of loose texture, and difficulty in compacting. By using the deodorizing tower, more than 85% H2S and 90%NH3 can be removed within 12 hours, thus, the deodorizing tower can be widely applied to process waste gas in composting plants and refuse processing plants.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Preparation method of polyvinyl chloride kitchen/bath board

The invention provides a preparation method of a polyvinyl chloride kitchen / bath board. The preparation method of the polyvinyl chloride kitchen / bath board comprises the following steps of sequentially feeding materials, i.e. a reclaimed material, a plasticizer, polyvinyl chloride resin, triple superphosphate, a modifier, polyvinyl chloride resin, triple superphosphate and a reclaimed material into a heat mixing pot, stirring and heating for 30 to 40min until the temperature is 100 DEG C, then adding the residual materials, stirring and heating for 10 to 12min until the temperature is 120 DEGC, then cooling for 3 to 5min until the temperature is 60 to 70 DEG C, cooling for 10 to 20min until the temperature is 40 to 50 DEG C, then conveying a cooled material to an extruder, heating througha charging barrel screw rod so as to plastify favorably, conveying to a mold, controlling the temperature and the pressure in the mold, extruding, cooling, laminating and shaping through a shaping table, and dragging through a dragger so as to obtain a finished product. The polyvinyl chloride kitchen / bath board has the advantages of low density, high hardness, high nail-holding ability and low water absorption rate.

Owner:汪条英

A large roll material automatic packaging equipment

InactiveCN104803023BSimple and fast operationSimple structurePaper article packagingWrapping material feeding apparatusEngineeringMechanical engineering

Owner:HEBEI UNIV OF TECH

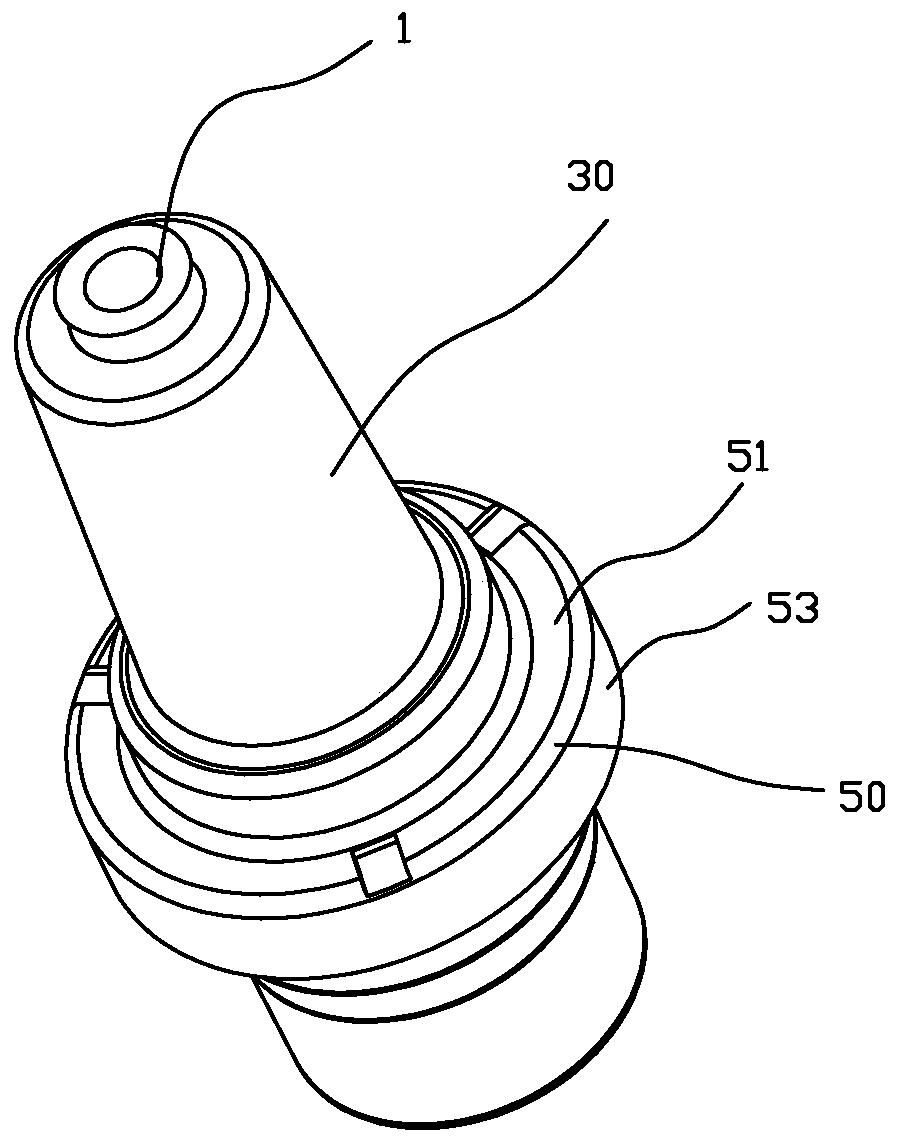

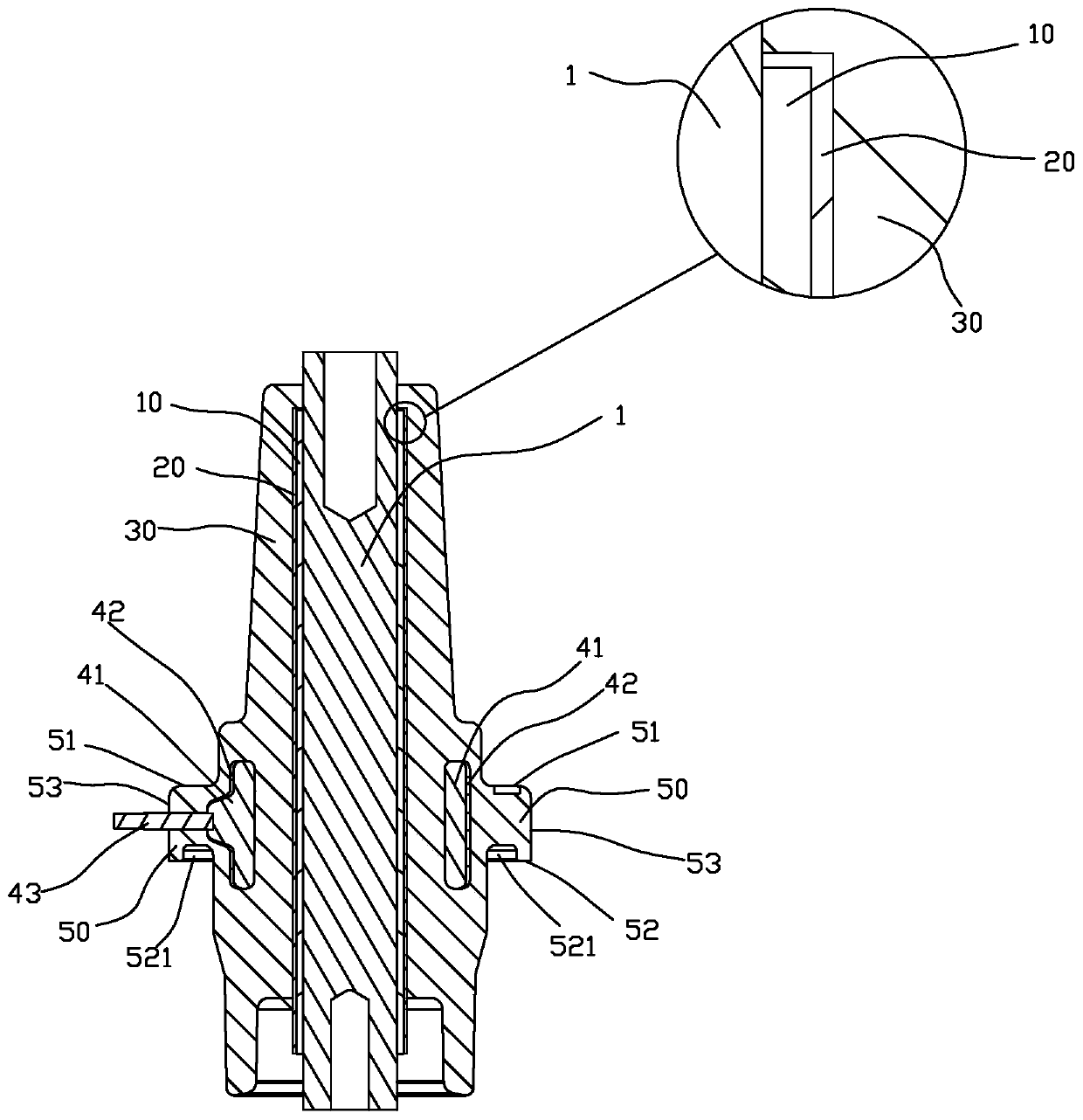

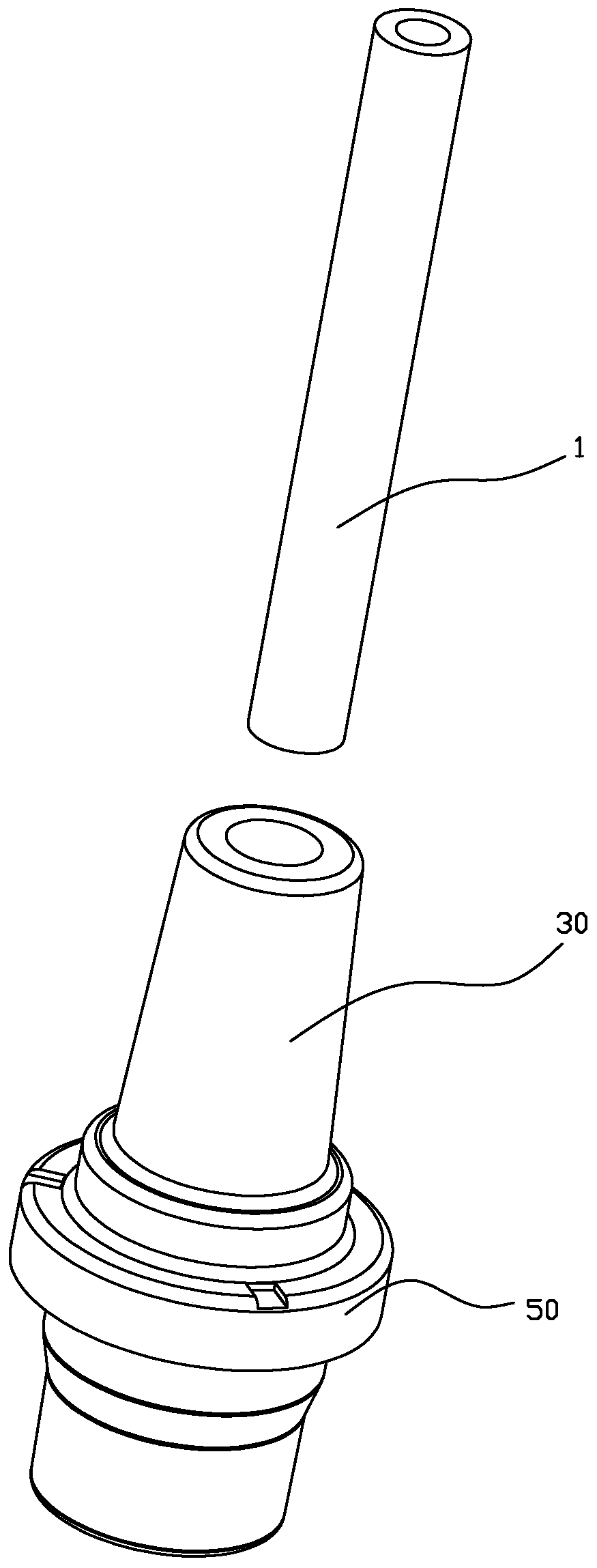

Bushing

PendingCN110010315ALoose materialEliminate partial dischargeInsulating bodiesPartial dischargeEngineering

The invention provides a bushing which comprises a conducting rod and a first insulating layer, a first graphite conducting layer and an insulating casing formed in the outer periphery of the conducting rod successively. The first graphite conducting layer makes electric contact with the conducting rod, an annular outer shielding structure is embedded into the insulating casing, and comprises a second insulating layer and a second graphite conducting layer coating the external surface of the second insulating layer, and a metal lead making electric contact with the second graphite conducting layer is fixed to the insulating casing. Thus, partial discharge caused by influence of temperature change factors is eliminated to largest extent, the bushing can be suitable for equipment of higher voltage, and the structure is simple.

Owner:XIAMEN NAIDE ELECTRIC

Edible fungus waste culture substrate mixed with landscaping waste and sludge as solid fuel and its processing technology

The invention discloses edible mushroom waste culture medium and landscaping waste and sludge mixed solid fuel which is prepared by the following steps: mixing and pressing the following components: 30-40 percent of an edible mushroom waste culture medium, 20-30 percent of sludge, 25-35 percent of landscaping wastes, 8-16 percent of waste oil and 4-12 percent of starch glue, thereby obtaining the solid fuel. According to the solid fuel disclosed by the invention, the treatment problem of the edible mushroom waste culture medium, landscaping wastes and organic matter sludge is solved, and the edible mushroom waste culture medium and landscaping waste and sludge mixed solid fuel pressed by the method has the characteristics of high heating value and good molding effect.

Owner:XIAMEN UNIV OF TECH

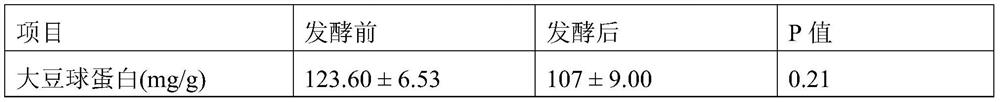

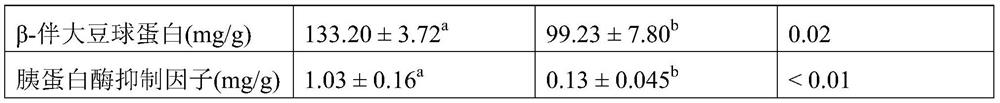

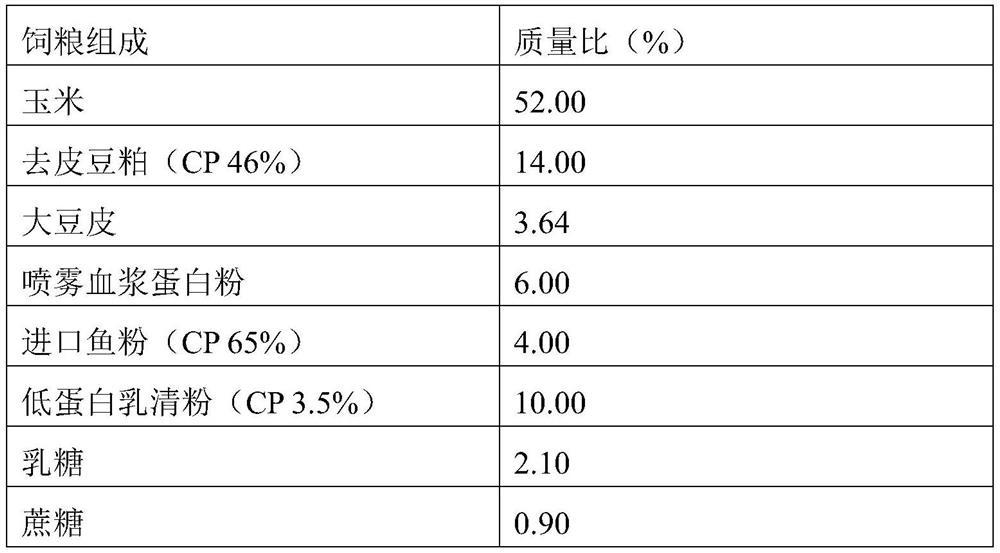

A solid-state fermented feed for improving intestinal health and growth performance of weaned piglets and its preparation method and application

ActiveCN110506862BEasy to operateLow environmental requirementsFood processingAnimal feeding stuffBiotechnologyBacillus licheniformis

The invention provides a solid-state fermented feed for improving intestinal health and growth performance of weaned piglets, a preparation method and application thereof, and belongs to the field of feed. The solid-state fermented feed is formed by fermenting a fermented base material with compound probiotics, the compound probiotics including Bacillus subtilis, Bacillus licheniformis, yeast, Lactobacillus plantarum and Lactobacillus reuteri; the fermented base material includes corn , Peeled soybean meal, soybean hulls, soybean oil, sucrose. The fermented feed provided by the invention has natural fermented flavor, low content of anti-nutritional factors, improves feed intake desire of piglets, and improves growth performance. The preparation method of the solid-state fermented feed is simple in operation, easy to control the fermentation process, low in energy consumption, relatively low in environmental requirements, and reduces production costs. The solid-state fermented feed is especially suitable for feeding weaned piglets, can significantly improve the growth performance of weaned piglets, alleviate diarrhea, and improve the intestinal mucosal barrier function of piglets, and has broad market prospects.

Owner:ANIMAL SCI RES INST GUANGDONG ACADEMY OF AGRI SCI

Improved polyvinyl chloride panel for kitchens and bathrooms

The invention discloses an improved polyvinyl chloride panel for kitchens and bathrooms and belongs to the technical field of polyvinyl chloride sheet materials. The improved polyvinyl chloride panelis used for solving the problem that the existing products are poor in hygroscopicity, low in density and poor in hardness. The improved polyvinyl chloride panel is prepared from 60-80 parts of polyvinyl chloride SG8 resin, 40-60 parts of heavy calcium carbonate, 20-40 parts of reclaimed materials, 7-9 parts of foaming regulator P90, 2.7-2.9 parts of lead salt stabilizer, 0.2-0.3 part of polyethylene wax, 0.2-0.25 part of micronized polyethylene wax N-14P, 0.1-0.15 part of plasticizer OA6, 0.5-0.6 part of heat release type AC foamer, 1.2-1.4 parts of heat-absorbing foamer NS-603 and a pigment.A method for preparing the improved polyvinyl chloride panel comprises the steps of putting the materials into a hot mixing pot sequentially, carrying out heating-up prior to cooling, and then, conveying the cooled material to an extruder, thereby obtaining a finished product. The invention is mainly applied to the preparation of the polyvinyl chloride panel for the kitchens and bathrooms.

Owner:唐安纯

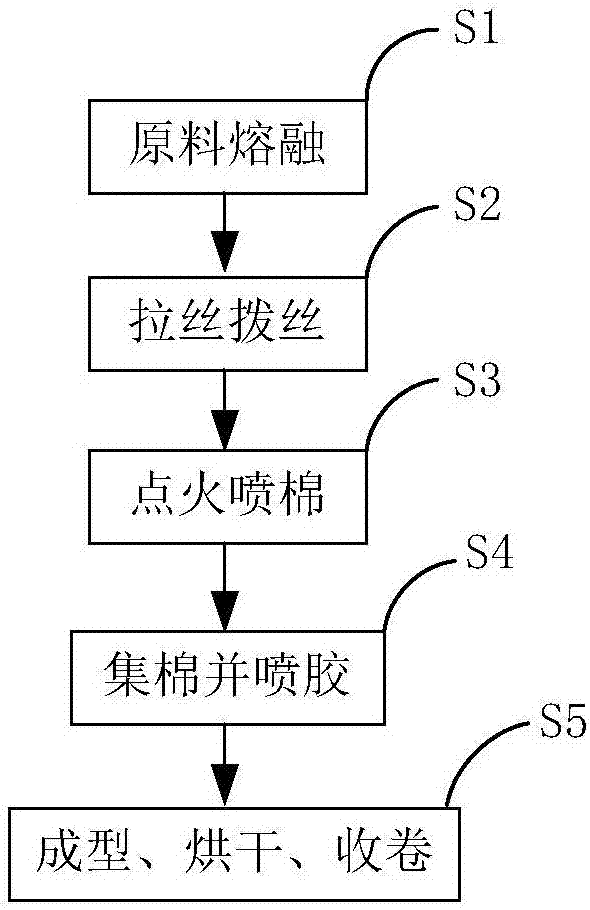

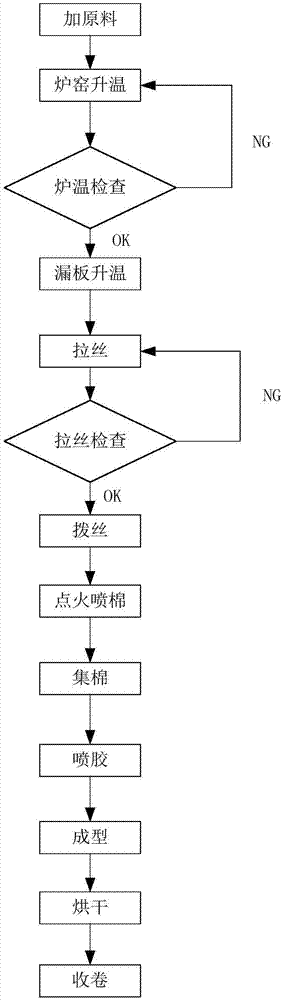

Preparation technology of multi-layer glass wool and production equipment for implementing preparation technology

InactiveCN107503223AIncreasing the thicknessNovel processSynthetic cellulose/non-cellulose material pulp/paperPaper-making machinesThermal insulationLaboratory oven

The invention relates to the technical field of cryogenic thermal insulation, in particular to a preparation technology of multi-layer glass wool and production equipment for implementing the preparation technology. The preparation technology of the multi-layer glass wool comprises the steps of raw material melting, drawing and distributing, ignition and wool spraying, wool collection and glue spraying, forming, drying and rolling up, specifically, raw materials are melted in a kiln, wool collection and glue spraying are performed in a wool collection machine after drawing and distributing as well as ignition and wool spraying, forming and drying are performed in a drying oven, rolling up is performed finally, and the ultrathin multi-layer glass wool with high thickness is obtained. For the ultrathin multi-layer glass wool with high thickness, the thickness is 20-30 mm, the water content is lower than 0.5%, the gram weight is 360-440 g / m<2>, and the applicable temperature ranges from subzero 268 DEG C to 232 DEG C. Therefore, the preparation technology of the multi-layer glass wool is reasonable in process and novel, and the produced ultrathin multi-layer glass wool with high thickness is loose in texture and can be applied to the field of cryogenic thermal insulation and play an important role.

Owner:SUZHOU LONG RANGE CRYOGENIC & INSULATION MATERIALS

Method for Comprehensive Utilization of Sulfuric Acid Slag and Red Mud

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com